Male-Male Sandwich Mounts

P

L

Male-Female Sandwich Mounts

P

P

Female-Blank Sandwich Mounts

L

L

P

D

D

G

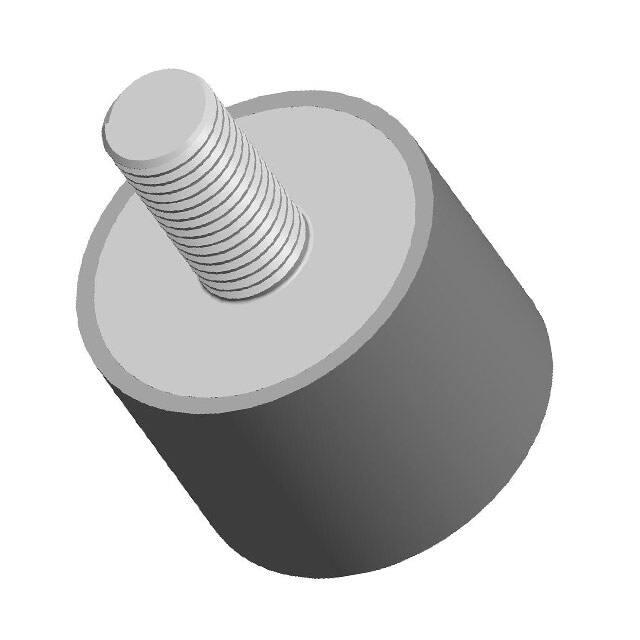

Male-Blank Sandwich Mounts

L

D

G

G

G

TD

Family

Product

D

Load (lbs)

TD

Dimensions

Metal Insert

D

L

P

G

TD

Maximum

Compressive

Maximum

Shear

Diam.

(in)

Length

(in)

Type

Overall

Height

Grip

(in)

Depth

(in)

MM-100-UC04-H

MM-100-UC04-SL20100

MM-100-UC04-SL25200

MM-200-UC06-H

MM-200-UC06-SL20100

MM-200-UC06-SL25200

MM-200-UC08-H

MM-200-UC08-SL20100

MM-200-UC08-SL25200

MM-300-UC25-H

MM-400-UC31-H

4.0

0.5

0.5

8.0

1.0

1.0

8.0

1.0

1.0

20.0

50.0

1.5

0.2

0.2

3.0

0.4

0.4

3.0

0.4

0.4

5.0

13.0

.275

.280

.280

.400

.405

.405

.400

.405

.405

.615

1.00

.320

.320

.320

.500

.500

.500

.500

.500

.500

.625

.750

#4-40

#4-40

#4-40

#6-32

#6-32

#6-32

#8-32

#8-32

#8-32

1/4-20

5/16-18

.200

.200

.200

.375

.375

.375

.375

.375

.375

.500

.625

.060

.060

.060

.060

.060

.060

.060

.060

.060

.100

.100

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

MB-100-UC04-H

MB-100-UC04-SL20100

MB-100-UC04-SL25200

MB-200-UC06-H

MB-200-UC06-SL20100

MB-200-UC06-SL25200

MB-200-UC08-H

MB-200-UC08-SL20100

MB-200-UC08-SL25200

MB-300-UC25-H

MB-400-UC31-H

4.0

0.5

0.5

8.0

1.0

1.0

8.0

1.0

1.0

20.0

50.0

.275

.280

.280

.400

.405

.405

.400

.405

.405

.615

1.00

.320

.320

.320

.500

.500

.500

.500

.500

.500

.625

.750

#4-40

#4-40

#4-40

#6-32

#6-32

#6-32

#8-32

#8-32

#8-32

1/4-20

5/16-18

.200

.200

.200

.375

.375

.375

.375

.375

.375

.500

.625

.060

.060

.060

.060

.060

.060

.060

.060

.060

.100

.100

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

Male-Female

MF-100-UC04-H

MF-100-UC04-SL20100

MF-100-UC04-SL25200

MF-200-UC06-H

MF-200-UC06-SL20100

MF-200-UC06-SL25200

MF-200-UC08-H

MF-200-UC08-SL20100

MF-200-UC08-SL20100

MF-300-UC25-H

MF-400-UC31-H

2.0

0.3

0.3

4.0

0.6

0.6

4.0

0.6

0.6

12.0

45.0

.275

.280

.280

.400

.405

.405

.400

.405

.405

.615

1.00

.320

.320

.320

.500

.500

.500

.500

.500

.500

.625

.750

#4-40

#4-40

#4-40

#6-32

#6-32

#6-32

#8-32

#8-32

#8-32

1/4-20

5/16-18

.200

.200

.200

.375

.375

.375

.375

.375

.375

.500

.625

.060

.060

.060

.060

.060

.060

.060

.060

.060

.100

.100

.110

.110

.110

.160

.160

.160

.160

.160

.160

.260

.290

Female-Blank

FB-100-UC04-H

FB-100-UC04-SL20100

FB-100-UC04-SL25200

FB-200-UC06-H

FB-200-UC06-SL20100

FB-200-UC06-SL25200

FB-200-UC08-H

FB-200-UC08-SL20100

FB-200-UC08-SL25200

FB-300-UC25-H

FB-400-UC31-H

2.0

0.3

0.3

4.0

0.6

0.6

4.0

0.6

0.6

12.0

45.0

.275

.280

.280

.400

.405

.405

.400

.405

.405

.615

1.00

.320

.320

.320

.500

.500

.500

.500

.500

.500

.625

.750

#4-40

#4-40

#4-40

#6-32

#6-32

#6-32

#8-32

#8-32

#8-32

1/4-20

5/16-18

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

.110

.110

.110

.160

.160

.160

.160

.160

.160

.260

.290

ISOLOSS

SPR-00009

HD/SL SANDWICH

MOUNTS

Male-Male

Male-Blank

材質 ISOLOSS HD

數量100, 200

n/a

n/a

n/a

n/a

n/a

n/a

0.8

0.1

0.1

2.0

0.3

0.3

2.0

0.3

0.3

3.5

10.0

n/a

n/a

n/a

n/a

n/a

n/a

“H” after part number indicates ISOLOSS HD material; “SL-XXXXX” after part number indicates ISOLOSS SL material. Dimensions given here are nominal.

Exact specification print available on request.

13

Website: www.earsc.com

E-mail: solutions@earsc.com

7911 Zionsville Road

Indianapolis, IN 46268

Phone (317) 692-1111

Fax (317) 692-3111

650 Dawson Drive

Newark, DE 19713

Phone (302) 738-6800

Fax (302) 738-6811

�M o l d i n g

M a t e r i a l s / C u s t o m

Fo r

c u s t o m - engineered parts to

control noise, vibration or shock,

E-A-R offers numerous moldable

thermoplastic and thermoset

materials to choose from.

VersaDamp 2000 Series TPEs are olefinic

dynamic vulcanizates. They are usually

selected to optimize damping performance or durometer or both. The materials

eliminate the need to make tradeoffs in

damping and operating temperature

range. They feature durometers ranging

from 40 Shore Ato 74 Shore A, and

they have widely varying energy

control capabilities.

Thermoplastics: ISODAMP C-1000

Series Thermoplastics are highly

damped vinyl materials that exhibit

extremely low amplification at resonance and quick return to system

equilibrium after shock input. C-1000

Series materials are soft and pliable, yet

physically strong and wear-resistant.

The three formulations are engineered

to perform in discrete temperature

ranges: ISODAMP C-1002 from 13C to

41C (55F to 105F); C-1105 from 27C to

54C (80F to 130F); and C-1100 from

35C to 63C (95F to 145F).

Description

Typical Process

Method

Peak Transmissibility

at Resonance (dB)

Hardness Nominal

ASTM D2240

15 sec impact at 23C (73F)

Shore A Durometer

Bashore Resilience

1st Rebound (%)

Tensile Strength (psi)

Elongation (%)

Post Compression

Recovery (%)

at 20C (68F)

Resistance to:

Ozone

Water

UV

Kerosene

Thermosets: ISOLOSS HD Elastomers

exhibit excellent load bearing strength,

compression-set resistance and stiffness

stability over a broad temperature

range. With a recommended maximum

continuous operating temperature of

90C (195F), the materials can withstand

intermittent exposure as high as 107C

(225F). Designed specifically for use

in metal-bonded elastomeric mounts,

these elastomers exhibit excellent

environmental-resistance properties.

ISODAMP C-8000 Series Thermoplastics

are highly damped elastomers that

provide the same benefits of the C-1000

series materials in a halogen-free

formulation. They are also formulated

to be environmentally clean; providing

excellent flammability performance

(UL 94 V-0) without halogens, silicones

or metal oxides. This unique family of

elastomers will meet most of the

emerging environmentally “green”

initiatives and specifications. ISODAMP

C-8000 materials have a peak performance temperature range of 17C to 41C

(62F to 105F).

Typical Properties

Property

P a r t s

ISOLOSS SL Thermoset Materials

combine good damping performance

with stable material properties over a

broad temperature range. The molding

stability of ISOLOSS SL materials allows

it to be used in isolator and snubber

designs with very thin sections.

ISODAMP ISODAMP ISODAMP ISODAMP VersaDamp VersaDamp VersaDamp

C-1002

C-1105

C-1100

C-8002

V-2325

V-2590

V-2725

ISOLOSS

HD

Vinyl

Solid

Injection

Mold

Vinyl

Solid

Injection

Mold

Vinyl

Solid

Injection

Mold

TPE

Solid

Injection

Mold

TPE

Solid

Injection

Mold

TPE

Solid

Injection

Mold

TPE

Solid

Injection

Mold

3

3

3

3

13

7

11

4

56

63

70

57

40

57

74

58

4.8

1574

459

5.4

1807

417

5.7

2058

317

4.0

1150

750

40

380

278

12.0

653

344

35

976

381

86

77

76

82

90

85

Good

Good

Good

Fair

Good

Good

Good

Fair

Good

Good

Good

Fair

Good

Good

Fair

Poor

Good

Good

Good

Poor

Good

Good

Good

Poor

ISOLOSS

SL-20100

ISOLOSS

SL-25200

Urethane

Synthetic

Synthetic

Solid

Rubber

Rubber

Transfer/

Transfer/

Transfer/

Compression Compression Compression

Mold

Mold

Mold

7

7

21

27

4.5

1300

424

12

530

625

12

636

600

80

96

97

97

Good

Good

Good

Poor

Good

Good

Good

Fair

Good

Good

Good

Poor

Good

Good

Good

Poor

See material summary sheets for more data and testing method information. The data listed in this guide are typical or average values based on tests conducted by independent laboratories or by the

manufacturer. They are indicative only of the results obtained in such tests and should not be considered as guaranteed maximums or minimums. Materials must be tested under actual service to

determine their suitability for a particular purpose.

Website: www.earsc.com

E-mail: solutions@earsc.com

7911 Zionsville Road

Indianapolis, IN 46268

Phone (317) 692-1111

Fax (317) 692-3111

650 Dawson Drive

Newark, DE 19713

Phone (302) 738-6800

Fax (302) 738-6811

14

�

很抱歉,暂时无法提供与“MB-400-UC31-H”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格 香港价格

- 1+70.057491+8.41215

- 10+60.4478910+7.25828

- 25+57.6365925+6.92071

- 50+55.7834650+6.69820

- 100+54.12729100+6.49933

- 250+52.19727250+6.26758

- 500+50.90486500+6.11240

- 1000+49.736521000+5.97211