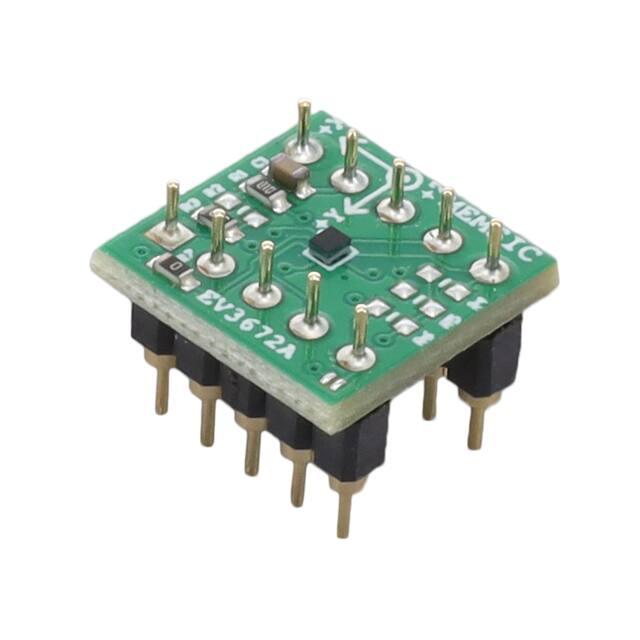

The MC3672 Evaluation Board

Quick Start Guide and Demo

GENERAL DESCRIPTION

MC3672 FEATURES

The MC3672 is an ultra-low power, lownoise, integrated digital output 3-axis

accelerometer with a feature set optimized

for wearables and consumer product

motion sensing. Applications include

wearable consumer products, IoT devices,

user interface control, gaming motion input,

electronic compass tilt compensation for

cell phones, game controllers, remote

controls and portable media products.

Range, Sampling & Power

The EV3672A/B is a prebuilt circuit board

with MC3672 WLCSP 3-axes sensor. The

MC3672 has internal sample rate from 14 to

1300 samples / second and measures

acceleration with a wide usage range, from

+/-2g up to +/-16g, and 6-bit to 14-bit high

precision ADC output, which is easy to fit

on top of the microcontroller, such as an

Arduino. The accelerometer communicates

via I2C/SPI and gives out motion detection

or sample acquisition conditions to trigger

an interrupt toward an MCU.

Simple System Integration

The sensor data is easily readable by

connecting DVDD to 3.3V, GND to ground,

and SCL/SDA pins to your Arduino I2C

clock and data pin respectively. Download

the MC3672 library from MEMSIC onto the

board, run the example sketch, and then

sensor data shortly comes out in raw data

count and SI unit accelerometer

measurements. An easy-to-use

demonstration on EV3672A/B using the

Arduino platform is included in this

document.

MEMSIC EV3672A+B APS-045-0017 v1.6

±2, 4, 8, 12 or 16g ranges

8, 10 or 12-bit resolution with FIFO

o 14-bit single samples

Sample rate 14 - 1300 samples/sec

Sample trigger via internal

oscillator, clock pin or software

command

Sniff and Wake modes

0.4 μA Sniff current @ 6Hz

Separate or combined sniff/wake

Ultra-Low Power with 32 sample

FIFO

o 0.9 μA typical current @ 25Hz

o 1.6 μA typical current @ 50Hz

o 2.8 μA typical current @ 100Hz

o 36 μA typical current @ 1300Hz

Page 1 of 19

I2C interface, up to 1 MHz

SPI Interface, up to 8 MHz

1.29 × 1.09 × 0.742 mm 8-pin

WLCSP package

Single-chip 3D silicon MEMS

Low noise to 2.3mg RMS

Formal release date: 2020/08/12

�TABLE OF CONTENTS

1

General Operation ........................................................................................................... 3

1.1

Pinouts ................................................................................................................................. 3

1.2

Power Pins ........................................................................................................................... 3

1.3

I2C Pins ............................................................................................................................... 4

1.4

SPI Pins ............................................................................................................................... 5

1.5

Interrupt Pins........................................................................................................................ 5

2

Assembly and Test .......................................................................................................... 6

2.1

I2C Interface ........................................................................................................................ 6

2.2

SPI Interface ........................................................................................................................ 7

3

Demo ............................................................................................................................... 8

3.1

GET the Driver from MEMSIC .............................................................................................. 8

3.2

Load the Demo .................................................................................................................... 8

4

Library Reference .......................................................................................................... 11

4.1

Create MEMSIC_MC36XX Object ...................................................................................... 11

4.2

Initialize and Configure Sensor........................................................................................... 11

4.3

Set Range .......................................................................................................................... 11

4.4

Read Range ....................................................................................................................... 11

4.5

Set Resolution .................................................................................................................... 11

4.6

Read Resolution................................................................................................................. 12

4.7

Set CWake Sampling Rate ................................................................................................. 12

4.8

Read CWake Sampling Rate.............................................................................................. 12

4.9

Set Sniff Sampling Rate ..................................................................................................... 12

4.10

Read Sniff Sampling Rate .................................................................................................. 12

4.11

Config Sniff Mode............................................................................................................... 12

4.12

Config Interrupt Mode ........................................................................................................ 13

4.13

Read Raw Count Data ....................................................................................................... 13

5

Schematics .................................................................................................................... 14

6

Bill of Materials .............................................................................................................. 16

7

Fabrication Print............................................................................................................. 17

8

Note ............................................................................................................................... 18

9

Revision History ............................................................................................................. 19

MEMSIC EV3672A+B APS-045-0017 v1.6

Page 2 of 19

Formal release date: 2020/08/12

�1 GENERAL OPERATION

1.1 PINOUTS

1.2 POWER PINS

DVDD – 3.3V Power Supply Input

GND – Ground Pin for Power and Logic

R7: The current drawn the sensor can be measured by putting an ammeter in

place of R7.

In the following demonstration, an Arduino DUE is used to illustrate on how to test

the evaluation board with a microcontroller.

Please be advised that if an Arduino UNO is used instead, hardware modification

on Arduino UNO MUST be made for it to output at 3.3V. (WARNING: attempting to

power the part at 5V is likely to damage it.)

By default, Arduino UNO operates at 5V, which is higher than the maximum

voltage rating for the evaluation board. Please refer to an excellent tutorial on

modifying Arduino UNO to output at 3.3V:

https://learn.adafruit.com/arduino-tips-tricks-and-techniques/3-3v-conversion

MEMSIC EV3672A+B APS-045-0017 v1.6

Page 3 of 19

Formal release date: 2020/08/12

�1.3 I2C PINS

Connect the SCL (I2C clock pin) to your microcontroller’s I2C clock line.

Connect the SDA (I2C data pin) to your microcontroller’s I2C data line.

R4, R5: If using I2C and I2C pull-up resistors are needed for your application then

install~4.7KΩ resistors into R4 (SCL clock pin) and R5 (SDA data pin) which are not

installed by factory default. In addition, besides soldering resisters on R4/R5, you can add

axial lead 4.7K ohm resistors to the SDA and SCL pin respectively. It will work the same

either way.

NOTE: DO NOT install more than one setup pull-up resistors per I2C bus.

MEMSIC EV3672A+B APS-045-0017 v1.6

Page 4 of 19

Formal release date: 2020/08/12

�1.4 SPI PINS

With an SPI connection, there is always one master device (usually a microcontroller)

which controls the peripheral devices. Typically, there are four wires commonly connected

to all the devices:

Connect the SCS (Slave Chip Select) to the pin on the device that the master can use to

enable and disable SPI cycles.

Connect the SCL (Serial Clock) to the pin where the clock pulses synchronize data

transmission generated by the master

Connect SDO to the pin where the Slave sends data to the master (Master Input, Slave

Output).

Connect SDA to the pin where the Master sends data to the peripherals (Master Output,

Slave Input).

1.5 INTERRUPT PINS

INT - HW interrupt signal pin. This pin will be triggered by the device when data is ready

to read, or a motion event is detected by the accelerometer. (Not currently supported in

the library for the interrupt pin, so please check the datasheet for the I2C commands and

related registers).

R6: If using the sensor interrupt signal as open-drain, then install pull-up resistor ~4.7KΩ

into R6 (not installed by default).

MEMSIC EV3672A+B APS-045-0017 v1.6

Page 5 of 19

Formal release date: 2020/08/12

�2 ASSEMBLY AND TEST

Please note that the SPI and I2C interfaces cannot both be active at the same time as

the clock (SCK) and data (SDA) are shared between the two protocols.

2.1 I2C INTERFACE

The EV3672A/B evaluation board can be easily wired to any microcontroller. This example

shows a typical Arduino DUE platform. For other microcontrollers, be sure it has I2C with

repeated-start support, then port the code. Please refer to the illustration below to connect the

related pins.

Connect DVDD to the power supply, 3.3V. (WARNING: attempting to power the part at

a voltage exceeds the maximum rating of 3.6V is likely to damage it.)

Connect GND to common power/data ground.

Connect the SCL pin to the I2C clock SCL pin on your Arduino.

Connect the SDA pin to the I2C data SDA pin on your Arduino.

The MC3672 has a default I2C address of 0x4C and it can be changed to 0x6C by tying

the SDO pin to VDD.

MEMSIC EV3672A+B APS-045-0017 v1.6

Page 6 of 19

Formal release date: 2020/08/12

�2.2 SPI INTERFACE

The EV3672A/B evaluation board can be easily wired to any microcontroller. This example

shows a typical Arduino DUE platform. Please refer to the illustration below for connecting the

related pins and then port the code to get the raw X, Y, Z sensor data.

Connect DVDD to the power supply, 3.3V. (WARNING: attempting to power the part at

a voltage exceeds the maximum rating of 3.6V is likely to damage it.)

Connect GND to common power/data ground.

Connect SCL to ICSP-3 as Serial Clock.

Connect SDO to ICSP-1 as Master Input, Slave Output.

Connect SDA to ICSP-4 as Master Output, Slave Input.

Connect SCS to digital I/O pin 10 as Slave Chip Select.

MEMSIC EV3672A+B APS-045-0017 v1.6

Page 7 of 19

Formal release date: 2020/08/12

�3 DEMO

3.1 GET THE DRIVER FROM MEMSIC

To begin reading sensor data, you will need to get the MC3672 Library from MEMSIC.

Rename the uncompressed folder Accelerometer_MC36XX and check that the

Accelerometer_MC36XX folder consisting of MC36XX.cpp and MC36XX.h

If you need the sensor running on SPI, please configure the bus as SPI in the

MC36XX.h shown as below. Otherwise, the default is I2C bus.

//#define MC36XX_CFG_BUS_I2C

#define MC36XX_CFG_BUS_SPI

SPI could support 8MHz speed if high speed mode is enabled as below.

#define SPI_HS

Place the Accelerometer_MC36XX library folder to your

Arduino_sketch_folder/libraries/ folder.

You may need to create the library subfolder if it is your first library files. Then just restart

the IDE.

An excellent tutorial on Arduino library installation is located at:

http://learn.adafruit.com/adafruit-all-about-arduino-libraries-install-use

3.2 LOAD THE DEMO

Open File->Examples->MC36XX-> MC36XX_demo and upload to your Arduino while it is

wired to the sensor.

MEMSIC EV3672A+B APS-045-0017 v1.6

Page 8 of 19

Formal release date: 2020/08/12

�Now open the serial terminal window at 115,200 baud rate speed to begin the test.

MEMSIC EV3672A+B APS-045-0017 v1.6

Page 9 of 19

Formal release date: 2020/08/12

�You will see the output from the serial terminal showing the current range scale and resolution

of the sensor in the first three lines followed by two lines of output sensor data at some output

data rate which depict “raw count" data for line 1: X: 18 Y: 24 Z: 1015 with 8G range, 14bit

ADC resolution.

Line 2 indicates the SI units for measuring acceleration as X: 0.17 m/s^2 Y: 0.23 m/s^2 Z:

9.72 m/s^2.

This demo also includes the example for FIFO and Sniff interrupt mode. Those could be

enabled by modify the definition below. These two examples must be run separately.

#define ENABLE_FIFO_WAKEUP

1

#define ENABLE_SNIFF_SHAKE_WAKEUP

0

Default input pin for interrupt is pin 8 and default FIFO threshold is 3 samples. FIFO size could

be set to maximum 32 samples or just enable FIFO to FIFO_FULL mode.

#define INTERRUPT_PIN

8

#define FIFO_SIZE

3

MEMSIC EV3672A+B APS-045-0017 v1.6

Page 10 of 19

Formal release date: 2020/08/12

�4 LIBRARY REFERENCE

4.1 CREATE MEMSIC_MC36XX OBJECT

You can create the MEMSIC_MC36XX object with:

MC36XX MC36XX_acc = MC36XX();

4.2 INITIALIZE AND CONFIGURE SENSOR

Initialize and configure the sensor with:

MC36XX_acc.start();

Wake up sensor with your own configuration, it will follow the factory default setting:

MC36XX_acc.wake();

Stop sensor to change setting:

MC36XX_acc.stop();

Set sensor as sniff mode:

MC36XX_acc.sniff ();

4.3 SET RANGE

Set the accelerometer max range to ±2g, ±4g, ±8g or ±16g with:

MC36XX_acc.SetRangeCtrl(MC36XX_RANGE_8G);

4.4 READ RANGE

Read the current range with:

MC36XX_acc.GetRangeCtrl();

It returns: 0 for ±2g, | 1 for ±4g, | 2 for ±8g | 3 for ±16g.

4.5 SET RESOLUTION

Set the accelerometer resolution to 6, 7, 8, 10, 12 or 14 bit.

MC36XX_acc.SetResolutionCtrl(MC36XX_RESOLUTION_14BIT);

When the FIFO is enabled, the output of the FIFO is mapped to registers 0x02 to 0x07,

and the data has a maximum resolution of 12-bits.

MEMSIC EV3672A+B APS-045-0017 v1.6

Page 11 of 19

Formal release date: 2020/08/12

�4.6 READ RESOLUTION

Read the current resolution with:

MC36XX_acc.GetResolutionCtrl();

It returns: 0 for 6-bit | 1 for 7-bit | 2 for 8-bit | 3 for 10-bit | 4 for 12-bit | 5 for 14-bit.

4.7 SET CWAKE SAMPLING RATE

Set the accelerometer CWake mode sampling rate with:

MC36XX_acc.SetCWakeSampleRate (MC36XX_CWAKE_SR_DEFAULT_54Hz);

4.8 READ CWAKE SAMPLING RATE

Read the current CWake sampling rate with:

MC36XX_acc.GetCWakeSampleRate ();

It returns sampling rate from 14 ~ 600 Hz.

4.9 SET SNIFF SAMPLING RATE

Set the accelerometer sniff mode sampling rate with:

MC36XX_acc.SetSniffSampleRate (MC36XX_SNIFF_SR_DEFAULT_7Hz);

4.10 READ SNIFF SAMPLING RATE

Read the current sniff sampling rate with:

MC36XX_acc.GetSniffSampleRate ();

This returns sampling rate from 0.4 ~ 600 Hz.

4.11 CONFIG SNIFF MODE

Set the threshold values used by the SNIFF logic for activity detection:

MC36XX_acc.SetSniffThreshold (MC36XX_AXIS_X,5);

All three axes could be configured separately with different threshold value.

Set the threshold values used by the SNIFF logic for activity detection:

MC36XX_acc.SetSniffDetectCount (MC36XX_AXIS_X,3);

For each axis, a delta count is generated and compared to the threshold. When the delta

count is greater than the threshold, a SNIFF wakeup event occurs. There is a unique

MEMSIC EV3672A+B APS-045-0017 v1.6

Page 12 of 19

Formal release date: 2020/08/12

�sniff threshold for each axis, and an optional “false detection count” which requires

multiple sniff detection events to occur before a wakeup condition is declared.

Configure sniff and/or mode with:

MC36XX_acc.SetSniffAndOrN(MC36XX_ANDORN_OR);

The SNIFF block supports the logical AND or OR of the X/Y/Z SNIFF wakeup flags when

generating a SNIFF wakeup interrupt.

Configure sniff delta mode with:

MC36XX_acc.SetSniffDeltaMode(MC36XX_DELTA_MODE_C2P);

C2P mode: The current sample and the immediate previous sample are subtracted

generate a delta

C2B mode: The current sample and the first sample captured when entering SNIFF

mode are subtracted to generate a delta.

4.12 CONFIG INTERRUPT MODE

Configure the interrupt mode with:

MC36XX_acc.SetINTCtrl(0,0,0,0,1);

MC36XX have 5 interrupt modes – FIFO_THR | FIFO FULL | FIFO EMPTY | ACQ | WAKE.

These modes can only be enabled separately.

4.13 READ RAW COUNT DATA

Read the raw count data and SI unit measurement with:

MC36XX_acc.readRawAccel();

MEMSIC EV3672A+B APS-045-0017 v1.6

Page 13 of 19

Formal release date: 2020/08/12

�5 SCHEMATICS

Above is a schematic on EV3672A/B. This is the factory preset when receiving the part.

For other options, please refer to the following table:

Interface (EV3672A)

R1

R2

R3

SPI (Factory Default)

4.7KΩ

DNI

4.7KΩ

SPI or I2C 0x4C

100KΩ

DNI1

10KΩ

SPI or I2C 0x6C

100KΩ

10KΩ

DNI

R1

R2

R3

SPI or I2C 0x4C (Factory Default)

100KΩ

DNI

10KΩ

SPI or I2C 0x6C

100KΩ

10KΩ

DNI

Interface (EV3672B)

1

DNI: Do Not Install

MEMSIC EV3672A+B APS-045-0017 v1.6

Page 14 of 19

Formal release date: 2020/08/12

�The difference between EV3672A and EV3672B is the resistor values for R1 and R2.

EV3672A could be worked on I2C interface by changing R1 value to 100KΩ and R3 value

to 10KΩ (for 0x4C I2C address).

EV3672B could be worked on I2C interface (with address 0x4C) without any reworking.

Configure the bus in the MC36XX Driver accordingly when changing from SPI to I2C

interface, and vice versa (please refer to Section 3.1).

R4, R5: Install ~4.7KΩ (if no other pull-up installed) as the pull-up for I2C interface.

NOTE: It is recommended not to install more than one pull-up per I2C bus.

R6: Install ~4.7KΩ pull-up resistor if sensor interrupt pin is set to open-drain. (DNI by default)

R7: The driving current of sensor can be measured by putting an ammeter in place of R7.

The physical location of the resistor is in the diagram in Section 1.3.

MEMSIC EV3672A+B APS-045-0017 v1.6

Page 15 of 19

Formal release date: 2020/08/12

�6 BILL OF MATERIALS

MEMSIC EV3672A+B APS-045-0017 v1.6

Page 16 of 19

Formal release date: 2020/08/12

�7 FABRICATION PRINT

NOTE: All dimensions are in millimeters.

MEMSIC EV3672A+B APS-045-0017 v1.6

Page 17 of 19

Formal release date: 2020/08/12

�8 NOTE

All the mCube logo in the document will be replaced later by MEMSIC logo.

MEMSIC EV3672A+B APS-045-0017 v1.6

Page 18 of 19

Formal release date: 2020/08/12

�9 REVISION HISTORY

Date

2016-12

2017-02

2018-05

Revision

APS-045-0017v1.0

APS-045-0017v1.1

APS-045-0017v1.2

2018-11

APS-045-0017v1.3

2020-02

APS-045-0017v1.4

2020-03

2020-08-12

APS-045-0017v1.5

APS-045-0017v1.6

MEMSIC EV3672A+B APS-045-0017 v1.6

Description

First release.

Added SPI mode interface.

Added example codes for high speed SPI mode,

FIFO mode, and Sniff mode.

Added revised schematics with hardware settings

for I2C and SPI interface and BOM list.

Revised schematics and BOM

Added warning in section 1.2.

Changed illustration to Arduino DUE.

Revised section 3 & 4 to illustrate demo program.

Added description for A/B versions in Section 5.

Change to MEMSIC format based on the License

Agreement with mCube

Page 19 of 19

Formal release date: 2020/08/12

�