www.osram-os.com

Produktdatenblatt | Version 1.1

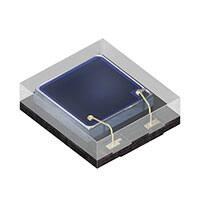

SFH 2704

SFH 2704

CHIPLED ®

Silicon PIN Photodiode

Applications

——Health Monitoring (Heart Rate Monitoring, Pulse

Oximetry)

Features:

——Package: clear epoxy

——ESD: 2 kV acc. to ANSI/ESDA/JEDEC JS-001 (HBM, Class 2)

——Suitable for reflow soldering

——Especially suitable for applications from 400 nm to 1100 nm

——Small package (LxWxH): 2.0 mm x 1.8 mm x 0.6 mm (WxDxH)

Ordering Information

Type

Photocurrent

Ee = 0.1 mW/cm²; λ = 535 nm

IP

≥ 0.35 µA

Preliminary datasheet version

SFH 2704

1 Version 0.0 | 2018-09-12

Photocurrent

typ.

Ee = 0.1 mW/cm²; λ = 535 nm

IP

0.51 µA

Ordering Code

Q65112A7214

�SFH 2704

Maximum Ratings

TA = 25 °C

Parameter

Symbol

Operating Temperature

Top

min.

max.

-40 °C

85 °C

Storage temperature

Tstg

min.

max.

-40 °C

85 °C

Reverse voltage

VR

max.

6V

ESD withstand voltage

acc. to ANSI/ESDA/JEDEC JS-001 (HBM, Class 2)

VESD

max.

2 kV

Preliminary datasheet version

2 Version 0.0 | 2018-09-12

Values

�SFH 2704

Characteristics

Preliminary datasheet version

TA = 25 °C

Parameter

Symbol

Photocurrent

Ee = 0.1 mW/cm²; λ = 535 nm; VR = 5 V

IP

min.

typ.

0.35 µA

0.51 µA

Photocurrent

Ee = 0.1 mW/cm²; λ = 940 nm; VR = 5 V

IP

min.

typ.

0.85 µA

1.22 µA

Wavelength of max sensitivity

λS max

typ.

900 nm

Spectral range of sensitivity

λ10%

typ.

400 ... 1100

nm

Radiant sensitive area

A

typ.

1.51 mm²

Dimensions of active chip area

LxW

typ.

1.23 x 1.23

mm x mm

Half angle

φ

typ.

60 °

Dark current

VR = 5 V

IR

typ.

max.

Spectral sensitivity of the chip

λ = 535 nm

Sλ

typ.

0.34 A / W

Quantum yield of the chip

λ = 535 nm

η

typ.

0.79 Electrons

/ Photon

Open-circuit voltage

Ee = 0.1 mW/cm²; λ = 535 nm; VR = 5 V

VO

min.

typ.

490 mV

510 mV

Rise time

VR = 5 V; RL = 50 Ω; λ = 525 nm; IP = 600 µA

tr

typ.

47 ns

Fall time

VR = 5 V; RL = 50 Ω; λ = 525 nm; IP = 600 µA

tf

typ.

67 ns

Forward voltage

IF = 10 mA; E = 0

VF

typ.

0.95 V

Capacitance

VR = 0 V; f = 1 MHz; E = 0

C0

typ.

13.4 pF

Noise equivalent power

VR = 5 V; λ = 535 nm

NEP

typ.

0.017 pW /

Hz1/2

Detection limit

VR = 5 V; λ = 535 nm

D*

typ.

7.4e12 cm x

Hz1/2 / W

3 Version 0.0 | 2018-09-12

Values

0.1 nA

25 nA

�SFH 2704

Relative Spectral Sensitivity

1), 2)

Srel = f (λ)

[ ]

100

80

60

40

20

0

400

Directional Characteristics

600

800

1000

λ[

]

1), 2)

Srel = f (φ)

Φ[ ]

-20°

-40°

-50°

-60°

-70°

-30°

-10°

0° 10° 20° 30° 40° 50° 60° 70° 80° 90°

1.0

0.9

0.8

0.7

0.6

0.5

0.4

Preliminary datasheet version

0.3

-80°

0.2

0.1

-90°

4 Version 0.0 | 2018-09-12

0.0

�SFH 2704

Dark Current

1), 2)

IR = f (VR); E = 0

[ ]

100

90

80

70

60

50

0

Capacitance

2

4

6

[ ]

1), 2)

C = f (VR); f = 1 MHz; E = 0;

[ ]

14

12

10

8

Preliminary datasheet version

6

4

2

10-3

0.01

0.1

1

[ ]

5 Version 0.0 | 2018-09-12

10

�SFH 2704

Dark Current

1)

IR = f (TA); E = 0; VR = 5 V

[ ] 100

10

1

0.1

0

20

40

Preliminary datasheet version

6 Version 0.0 | 2018-09-12

60

80

[ ]

�SFH 2704

Dimensional Drawing

3)

Approximate Weight:

4.4 mg

Package marking:

Cathode

Preliminary datasheet version

7 Version 0.0 | 2018-09-12

�SFH 2704

Recommended Solder Pad

3)

Reflow Soldering Profile

Product complies to MSL Level 3 acc. to JEDEC J-STD-020E

OHA04525

300

˚C

T 250

Tp 245 ˚C

240 ˚C

tP

217 ˚C

200

150

tL

tS

Preliminary datasheet version

100

50

25 ˚C

0

0

50

100

150

200

250

s 300

t

8 Version 0.0 | 2018-09-12

�SFH 2704

Profile Feature

Symbol

Pb-Free (SnAgCu) Assembly

Minimum

Recommendation Maximum

Ramp-up rate to preheat*)

25 °C to 150 °C

tS

Time tS

TSmin to TSmax

60

Ramp-up rate to peak*)

TSmax to TP

2

3

100

120

2

3

Unit

K/s

s

K/s

Liquidus temperature

TL

217

Time above liquidus temperature

tL

80

100

s

Peak temperature

TP

245

260

°C

Time within 5 °C of the specified peak

temperature TP - 5 K

tP

20

30

3

6

Ramp-down rate*

TP to 100 °C

10

480

Time

25 °C to TP

All temperatures refer to the center of the package, measured on the top of the component

* slope calculation DT/Dt: Dt max. 5 s; fulfillment for the whole T-range

Taping

°C

3)

Preliminary datasheet version

9 Version 0.0 | 2018-09-12

s

K/s

s

�SFH 2704

Tape and Reel

4)

W1

D0

P0

A

N

F

W

E

13.0 ±0.25

P2

Label

P1

Direction of unreeling

Direction of unreeling

W2

Leader: min. 400 mm *

Trailer: min. 160 mm *

*) Dimensions acc. to IEC 60286-3; EIA 481-D

OHAY0324

Reel dimensions [mm]

A

W

Nmin

W1

W2 max

Pieces per PU

180 mm

8 + 0.3 / - 0.1

60

8.4 + 2

14.4

3000

Preliminary datasheet version

10 Version 0.0 | 2018-09-12

�SFH 2704

Barcode-Product-Label (BPL)

Dry Packing Process and Materials

3)

Moisture-sensitive label or print

Barcode label

L

VE

LE

see

lab

e

If

nk,

bla cod

bar

hu

ve

y

el

.

H)

(R

dit

mi

e

ed ag

%

.

RH

/60

˚C

rar ck

rel

30

N s VE RS

inf pa

%

ainITI TO

of

to ak

90

d

ntNSUC

<

ns

(pe

or

TIO

d

,

cte

itio

an bje ing

U g coSEND

˚C

nd

5

˚C su ss

CO

Ais baRE

co

±

ce

y

40 be

TU MI

CThIS

˚C

<

ll pro

tor

SE

ati

_

<

).

urs

urs

Ho

de

urs

Ho

co

72

Ho urs

te

48

e

Ho

24 6

da

e

tim

e

th

tim

or

).

23

tim e

at t wi nt

l wi

or

fac

˚C

Flo

s

tim

at

or

ca

at

re.

Flo

tha ale el

d

or

nth

nti

Flo

du

uiv

if: rea

es

l 4 5

Flo

mo

lab

ce

ide

eq

low

g,

l

ve

vic

5a

is

or

be

24

de

tin en

pro

ve l

6

Le

de ,

e

te

co

g:

,

un wh

Le ve l

ke

r

se

da

ba ed low

ure

Le ve

mo %

ba

e

ba

al

d

ure

Le

ist

en ref e

e 10

for

tim

se

ist ure

ale op se

for >

,

Mo

se

3

ure

is

or .

,

se

is ha

Mo istist

nk

be

g

nk

-03

rd

Mo

in

n Flo

r-p

RH g,

bla

Mo

ba

TD

po If blathi

life s

%

kin Ca

(if

ar

t.

wi

J-S

10 ba tor

thi, va p.

elf

Ye ar ks

_

<

e icat me , C

1

tem ted

Ye ee urs

Sh ter

at

ed

low

uir

>

1

W Ho

un

Af

Ind no uir DE

1.

dy

d

e

4

ref

8

y

is

req

JE

2.

bo

e

Mo ore

tim

req

16

:

C/

e

es dit2b

a)

St

tim

or

is IP

mior

ed

vic

tim e

b)

g e

or

Hu

en

Flo

tim

or

De

2a kin nc

te

Flo

op

a)

or

3.

b) baere

Flo

da

e

l 1 2

Flo

If

al

ref

tim ve

l

4.

se

d

l 2a

ve

Le

3

g

an

ve l

Le

Ba

te

ure

Le ve

ure

ist

Le

Da

ure

ist

Mo

ist ure

Mo

Mo ist

Mo

MO

TO

OP

M

RA

OS

Humidity indicator

Barcode label

Please check the HIC immidiately after

bag opening.

Discard if circles overrun.

Avoid metal contact.

Do not eat.

Comparator

check dot

WET

If wet,

examine units, if necessary

bake units

15%

If wet,

examine units, if necessary

bake units

10%

5%

If wet,

parts still adequately dry.

change desiccant

Humidity Indicator

MIL-I-8835

Desiccant

AM

OSR

Preliminary datasheet version

OHA00539

Moisture-sensitive product is packed in a dry bag containing desiccant and a humidity card according JEDEC-STD-033.

11 Version 0.0 | 2018-09-12

�SFH 2704

Transportation Packing and Materials

3)

DE

R

18

-1

-1

+Q

P

OU

P:

44

01

C:

99

8

D/

20

00

(9

D)

210

021

:

34

O

H

12

(Q

)Q

TY

:

S S

em R

ic AM

o

nd O

uc p

to to

H

rs

NO

TC

BA

3G

5

14

2

(6

P)

NO

: 12

T

11

00

LO

(1

T)

NO

:

OD

M

Y

DE

-1

18

P

-1

+

Q

R

G

RO

UP

:

(G

)

44

01

D/

C:

(9

D)

0

AM

00

TY

:2

)Q

O

SR

34

NO

:

(X

)

PR

O

D

5

14 2

110 0

(Q

A

R

ic

NO

:

O

S

em

S

(1

T)

LO

T

NO

(6

P)

: 12

3G

BA

TC

H

H

12

o M

n O

d

u p

ct to

o

rs

M

Muster

u L

lt S

iT Y

O T6

P 76

L

E Bi

D Bi n1

Bi n2 : P-

n3 : Q 1: -1 20

M

-2

2 L

0

Te

2a

22 m

3

24 0 p ST

Ad 26 0 C R

C

R0 ditio 0 C R

PA 77 na RT

l TE

CK

VA

XT

R:

(X

)

PR

<

8

2199

2100

GR

L

el

at

(G

)

M

u L

lt S

iT Y

O T67

P

L 6

Muster

E

V

LE

see

.

lab

e

H)

nk,

cod

(R

bla

r

If

ty

ba

.

idi

RH

m

hu

0%

e

/6

ive d

˚C

re ag

lat

ra ck

re

30

_

<

inf pa

%

k

s

of

to

90

ea

ur s

d

).

<

ns

(p

or

d

Ho ururs s

,

de

cteg

itio

Ho

an bje

co

˚C

72

sin

nd

Ho ur

5

te

48

˚C su es

e

Ho

co

±

24 6

da

40 be oc

ry

tim e e

˚C

th

r

pr

ll

tim

cto

).

23

oo r

wi nt

tim e

l wi

fa

r

˚C

Fl oo

tim

s

at

at ale

e.

at

ica

Fl

th

oo r

th

ur

el

nt

Fl oo

on es uiv

if: read

ed

l 4 5

Fl

,

lab

m

ide

eq

low

oc

ve l

vic

is

ingen

de

be

24 de or

l 5a6

pr

Le ve

nt wh

e

te

co

, w,

g:

ve l

Le

ke

r

re

ou%

se

da

ed

ba

flo ba

Le ve

tu re

m

ba

e

al

d

Le

r

en re

re

e

re 10

ois tu

tim

se

fo

tu re

ale op se

fo >

,

M ois

r

se

3

is

,

is ha

se

M

ois tu

nk

be

oo .

03

nk

rd

g

M ois

in

r-p

bla

in Fl RH g,

DM

ba

Ca

po If blath

%

kin

life is

(if

.

ar

ST

p.

wi

10 baator et

Jelf r th va

Ye ar ks s

m

_

<

m

ed

1

Ye ee ur

d, C

iredic t

Sh te w, te

at

nt

>

1

W Ho

Af flody

qu In no ire DE

1.

e

ou

4 8

re

ed re ty is

qu JE

2.

bo

M

or

tim e e

16

re C/

:

es idi 2b

r

a)

St

tim

mor

is IP

e

ed

r

oo

vic

tim

b)

g e

r

Hu

Fl oo

en

tim

De

2a kin nc

te

Fl oo r

a)

op

re

3.

b)

Fl oo

da

ba

e

fe

l 1

Fl

If

al

re

tim ve l 2

4.

se

d

l 2a3

Le ve

g

an

ve l

Le

re

Ba

te

Le ve

tu re

Le

Da ois tu

re

tu re

M

ois

M

ois tu

M ois

M

Nns IVEORS

ai IT

ntNS CT

TIO

DU

U g EcoSE

ON

A ba

IC

UR

M

CThisSTSE

OI

M TO

OP

M

Y

Barcode label

E Bi

D n1

Bi

Bi n2 : Pn3 : Q- 1: 1- 20

M

20

2 L

Te

2a

22 m

3

24 0 p ST

Ad 26 0 C R

0 C

R0 dit

ion C R

PA 77 al RT

CK

TE

VA

XT

R:

Barcode label

Packing

Sealing label

Dimensions of transportation box in mm

Width

Length

Height

200 ± 5 mm

195 ± 5 mm

30 ± 5 mm

Preliminary datasheet version

12 Version 0.0 | 2018-09-12

OHA02044

�SFH 2704

Notes

The evaluation of eye safety occurs according to the standard IEC 62471:2006 (photo biological safety of

lamps and lamp systems). Within the risk grouping system of this IEC standard, the device specified in this

data sheet fall into the class exempt group (exposure time 10000 s). Under real circumstances (for exposure time, conditions of the eye pupils, observation distance), it is assumed that no endangerment to the

eye exists from these devices. As a matter of principle, however, it should be mentioned that intense light

sources have a high secondary exposure potential due to their blinding effect. When looking at bright light

sources (e.g. headlights), temporary reduction in visual acuity and afterimages can occur, leading to irritation, annoyance, visual impairment, and even accidents, depending on the situation.

Subcomponents of this device contain, in addition to other substances, metal filled materials including silver.

Metal filled materials can be affected by environments that contain traces of aggressive substances. Therefore, we recommend that customers minimize device exposure to aggressive substances during storage,

production, and use. Devices that showed visible discoloration when tested using the described tests above

did show no performance deviations within failure limits during the stated test duration. Respective failure

limits are described in the IEC60810.

For further application related informations please visit www.osram-os.com/appnotes

Preliminary datasheet version

13 Version 0.0 | 2018-09-12

�SFH 2704

Disclaimer

OSRAM OS assumes no liability whatsoever for any use of this document or its content by recipient including, but not limited to, for any design in activities based on this preliminary draft version. OSRAM OS may

e.g. decide at its sole discretion to stop developing and/or finalising the underlying design at any time.

Disclaimer

Language english will prevail in case of any discrepancies or deviations between the two language wordings.

Attention please!

The information describes the type of component and shall not be considered as assured characteristics.

Terms of delivery and rights to change design reserved. Due to technical requirements components may

contain dangerous substances.

For information on the types in question please contact our Sales Organization.

If printed or downloaded, please find the latest version in the OSRAM OS Webside.

Packing

Please use the recycling operators known to you. We can also help you – get in touch with your nearest

sales office.

By agreement we will take packing material back, if it is sorted. You must bear the costs of transport. For

packing material that is returned to us unsorted or which we are not obliged to accept, we shall have to

invoice you for any costs incurred.

Product safety devices/applications or medical devices/applications

OSRAM OS components are not developed, constructed or tested for the application as safety relevant

component or for the application in medical devices.

In case Buyer – or Customer supplied by Buyer– considers using OSRAM OS components in product safety

devices/applications or medical devices/applications, Buyer and/or Customer has to inform the local sales

partner of OSRAM OS immediately and OSRAM OS and Buyer and /or Customer will analyze and coordinate the customer-specific request between OSRAM OS and Buyer and/or Customer.

Preliminary datasheet version

14 Version 0.0 | 2018-09-12

�SFH 2704

Glossary

1)

Typical Values: Due to the special conditions of the manufacturing processes of semiconductor devices, the typical data or calculated correlations of technical parameters can only reflect statistical figures.

These do not necessarily correspond to the actual parameters of each single product, which could differ from the typical data and calculated correlations or the typical characteristic line. If requested, e.g.

because of technical improvements, these typ. data will be changed without any further notice.

2)

Testing temperature: TA = 25°C

3)

Tolerance of Measure: Unless otherwise noted in drawing, tolerances are specified with ±0.1 and

dimensions are specified in mm.

4)

Tape and Reel: All dimensions and tolerances are specified acc. IEC 60286-3 and specified in mm.

Preliminary datasheet version

15 Version 0.0 | 2018-09-12

�SFH 2704

Preliminary datasheet version

Published by OSRAM Opto Semiconductors GmbH

Leibnizstraße 4, D-93055 Regensburg

www.osram-os.com © All Rights Reserved.

16 Version 0.0 | 2018-09-12

�