Approval Sheet

for

Cement Resistors

Power Wirewound & Axial / Vertical

Lead Type

PSP & PSM series

±5% & ±10%

YAGEO CORPORATION

Headquarters: 3F, No.233-1, Pao Chiao Rd., Xindian, Taipei, Taiwan, R.O.C.

Tel: 886-2-6629-9999 Fax: 886-2-6628-8885

URL: www.yageo.com

Page-1

�Rev.

Description

Issue Date

Drawn

Approved

00

issue new spec.

Feb 12, 2008

Lynn Chen

Joyce Chung

01

Series adjustment

Sep 1, 2008

Lynn Chen

Joyce Chung

02

Product marking information is included

Dec 3, 2010

Feng Ye

Ken Hsu

03

Electrical characteristics table and

environmental characteristics are

adjusted

Revise dimension map

Dec 29, 2010

Feng Ye

Ken Hsu

Dec 06, 2012

Feng Ye

Flora Shen

Revise dimensions of PSM700,

PSM7WS and PSM 900 series.

Revise maps of derating curve and

dimensions

PSP11A, PSP17A, PSM11A, PSM17A

are included.

Taped in reel is included, add packing

info.

Dec 12, 2012

Feng Ye

Flora Shen

Feb 21, 2013

Feng Ye

Ken Hsu

Jul. 07, 2016

Feng Ye

Flora Shen

Jul. 19, 2016

Feng Ye

Flora Shen

04

05

06

07

08

Description

Cement Resistors-Power Wirewound & Axial/Vertical Lead Type

Series

PSP&PSM

Rev.

Page-2

08

�1.

PRODUCT:

1. Power Wirewound Resistors. Fiber Glass Core and with Ceramic Case. Wirewound

construction, Insulated and Flameproof

(PSP & PSM SERIES)

2.

PART NUMBER:

Part number of the cement resistor is identified by the name, power, tolerance, packing,

temperature coefficient and resistance value.

Example:

PSP

400

J

B

-

100R

(1)

(2)

(3)

(4)

(5)

(6)

Series Power Resistance Packing Temperature Resistance

Name Rating Tolerance Style

Coefficient

Value

of Resistance

(1) Style: PSP SERIES: Axial Type

PSM SERIES: Vertical Type

(2) Power Rating: 400=4W、500=5W、7WS=7W、700=7W、900=9W、11A=11W、

17A=17W

(3) Tolerance: J = ±5%、K = ±10%

(4) Packaging Type: B = Bulk Packing

R = Taped in reel

(5) Temperature Coefficient : ±400ppm/℃

(6) Resistance Value:E24 Series

Example:0R1, 1R、10R、100R、10K……

Page-3

�3.

ELECTRICAL CHARACTERISTICS

STYLE

Power Rating at 70 ℃

Max. Cont. Work. Voltage

PSP400

4W

Resistance range

Operating Temp. Range

0.1~2.2KΩ

Temperature Coefficient

±400ppm/℃

STYLE

Power Rating at 70 ℃

Max. Cont. Work. Voltage

PSM400

4W

Resistance range

Operating Temp. Range

0.1~2.2KΩ

Temperature Coefficient

±400ppm/℃

PSP500

5W

PSP7WS

7W

PSP700

PSP900

9W

PSP11A

11W

PSP17A

17W

P70 R

0.1~2.5KΩ 0.5~3.9KΩ

1~10KΩ

- 55 ℃ to + 275 ℃

PSM500

5W

PSM7WS

7W

PSM700

PSM900

9W

PSM11A

11W

PSM17W

17W

P70 R

0.1~2.5KΩ 0.5~3K9Ω

1~10KΩ

- 55 ℃ to + 275 ℃

* Below or over this resistance range on request

4.

DERATING CURVE

For resistors operated in ambient temperatures above 70℃, power rating must be derated in accordance with

the curve below.

Rated Load (%)

70℃

275℃

100

80

60

40

20

-55

0

20 40 60 80 100 120 140 160 180 200 220 240 260 280

Ambient Temperature (℃)

Page-4

�5.

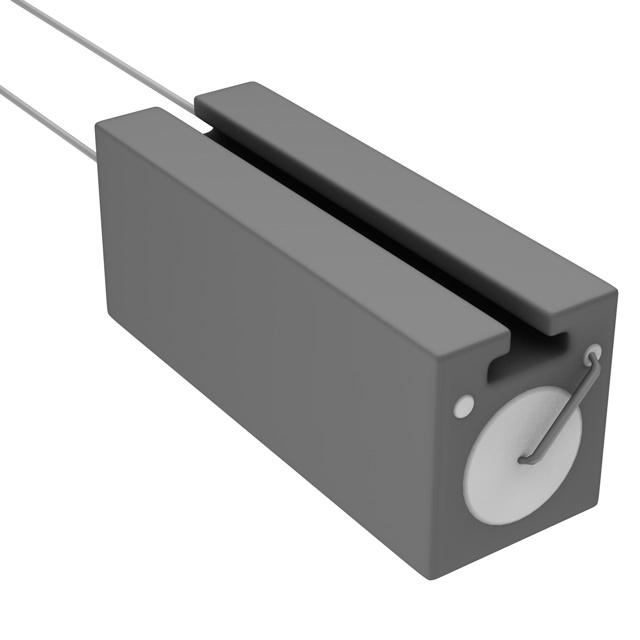

DIMENSIONS

Yageo logo

PSP Series

Produce date

Resistance

Value

Power

Tolerance

PSM Series

PSM400-PSM700

Unit:mm

TYPE

L1

W

H

PSP400

20±1.0

6.4 ± 0.3

6.4 ± 0.3

PSP500

25±1.0

6.4 ± 0.3

6.4 ± 0.3

PSP700

38±1.0

6.4 ± 0.3

6.4 ± 0.3

PSP7WS

25±1.0

9.0 ± 0.3

9.0 ± 0.3

PSP900

38±1.0

9.0 ± 0.3

9.0 ± 0.3

PSP11A

50±1.5

9.0 ± 0.3

9.0 ± 0.3

PSP17A

75±2.0

9.0 ± 0.3

9.0 ± 0.3

TYPE

L1

W

H

PSM400

20±1.0

7.0 ± 0.5

8.0 ± 0.4

PSM500

25±1.0

7.0 ± 0.5

8.0 ± 0.4

PSM700

38±1.0

7.0 ± 0.5

8.0 ± 0.4

PSM7WS

25±1.0

9.0 ± 0.4

10.0 ± 0.4

PSM900

38±1.0

9.0 ± 0.4

10.0 ± 0.4

PSM11A

50±1.5

9.0 ± 0.4

10.0 ± 0.4

PSM17A

75±2.0

9.0 ± 0.4

10.0 ± 0.4

Page-5

PSM7WS-PSM17A

�6.

ENVIRONMENTAL CHARACTERISTICS

(1) Short Time Over Load Test

At 2.5 times of the rated voltage applied for 5 seconds, the resistor should be free from defects after the

resistor is released from load for about 30 minutes

Short Time Overload Voltage =

2.5 * Power Rating Resistance Value

The change of the resistance value should be within ± 2.0 % + 0.05Ω

(2) Voltage Proof

The resistor shall be clamped in the trough of a 90° metal V Block. Apply the insulation voltage of 1000V

between the terminals connected together with the block for about 60 seconds.

The resistor shall be able to withstand without breakdown or flashover.

(3) Temperature Coefficient Test

Test of resistors above room temperature 100°C ± 2°C ( Testing Temperature 115°C to 130°C ) at the

constant temperature silicon plate for over 5 minutes. Then measure the resistance value.

The Temperature Coefficient is calculated by the following equation and its value should be within the

range of requested.

Re sistor Temperature Coefficient

R

R0

t

to

R R0

1

10 6

R0

t t0

= Resistance value under the testing temperature

= Resistance value at the room temperature

= The testing temperature

= Room temperature

(4) Insulation Resistance

Apply "measuring voltage" between protective coating and termination for 1 min.,then measure. The

measuring voltage shall be either 100V±15V d.c. for resistors with an insulation voltage lower than 500V

or 500V±50V d.c. for resistors with an insulatin voltage equal to or greater than 500V.

The test resistance should be high than 1,000M ohm.

(5) Solderability

Immerse the specimen into the solder pot at 235 ± 5 °C for 3 ± 0.5 seconds.

At least 90% solder coverage on the termination.

(6) Solvent Resistance of Marking

The specimen into the appropriate solvent of IPA condition of ultrasonic machine for 5± 0.5 minutes.

The specimen is no deterioration of coatings and color code.

(7) Robustness of Terminations

Direct Load – Resistors shall be held by one terminal and the load shall be gradually applied in the

direction of the longitudinal axis of the resistor unit the applied load reached the requirement.

The load shall be held for 10 seconds. The load of weight shall be ≧ 2.5 kg ( 24.5N ).

Page-6

�(8) Periodic-pulse Overload

Apply 4 times of rated voltage to the specimen at the 1 second on and 25 seconds off cycle, subjected

to voltage application cycles specified in 10,000 time。

The change of the resistance value shall be within ± 2.0% + 0.05 Ω

(9) Damp Heat Steady State

Place the specimen in a test chamber at 40 °C and 93 % relative humidity. Apply the rated voltage to

the specimen at the 1.5 hours on and 0.5 hour off cycle. The total length of test is 1,000 hours

The change of the resistance value shall be within ± 5.0 % + 0.05 Ω

(10) Endurance at 70 °C

Placed in the constant temperature chamber of 70 ± 3 °C the resistor shall be connected to the lead wire

at the point of 25mm. Length with each terminal, the resistors shall be arranged not much effected

mutually by the temperature of the resistors and the excessive ventilation shall not be performed, for 90

minutes on and 30 minutes off under this condition the rated D.C. voltage is applied continuously for

1000+48/-0 hours then left at no-load for 1hour, measured at this time the resistance value。

The change of the resistance value shall be within ± 5.0 % + 0.05 Ω .

There shall be no remarkable change in the appearance and the color code shall be legible after the test.

(11) Temperature Cycling Test

The temperature cycle shown in the following table shall be repeated 5 times consecutively. The

measurement of the resistance value is done before the first cycle and after ending the fifth cycle,

leaving in the room temperature for about 1 hour。

Temperature Cycling Conditions:

Step

Temperature(°C)

Time (minute)

1

-55 ± 3

30

2

25 ± 3

10 ~ 15

3

155 ± 3

30

4

25 ± 3

10 ~ 15

The change of the resistance value shall be within ± 2.0 % + 0.05 Ω

After the test the resistor shall be free from the electrical or mechanical damage.

(12) Resistance to Soldering Heat

The terminal lead shall be dipped into the solder pot at 260 ± 3 °C for 10 ± 1.0 seconds up to 2.5 ~ 3.5

mm.

The change of the resistance value shall be within ± 1.0 % + 0.05 Ω

(13) Overload Flame Retardant

At 4 times of the rated voltage. ( If the voltage exceeds the maximum load voltage, the maximum load

voltage will be used as the rated voltage ) applied for 1 minute

Overload Test Voltage =

4 * Power Rati ng Resistance Value

The resistor shall be able to no evidence of flaming arcing

Page-7

�7.

PACKING

Bulk

TYPE

Packing

Pieces

Pack. Code

TYPE

Packing

Pieces

PSP400

200

PSM400

200

PSP500

200

PSM500

200

PSP700

200

PSM700

200

PSP7WS

Bulk

200

PSM7WS

B

Bulk

200

PSP900

200

PSM900

200

PSP11A

100

PSM11A

200

PSP17A

100

PSM17A

100

Tape/Reel

Only for PSP type

TYPE

Packing

PSP400

PSP500

PSP700

PSP7WS

PSP900

Taped in

Reel

C

S

1000

95

10

1000

95

10

95

10

500

95

10

500

95

10

Pieces

1000

Pack. Code

R

Page-8

Pack. Code

B

�8.

Plant Address

A.

China Dongguan Plant

7-1, Gaoli Road, Gaoli Industrial Zone

Tangxia Zhen, Dongguan, Guangdong, China

(廣東省東莞市塘廈鎮高麗工業區高麗路 7-1 號)

Tel. 86-769-8772 0275

Fax. 86-769-8772 0275 #4333

B.

China Suzhou Plant

No.158, Jinchang Road, No.1 Building of Nan Bang IND. Zone,

Mu Du New District, Suzhou, China

(江蘇省蘇州市木瀆新區金長路 158 號南濱工業區 1 號)

Tel. 86-512-66518889

Fax. 86-512-66519889

Page-9

�