LTC3824

High Voltage Step-Down

Controller With 40µA

Quiescent Current

Description

Features

Wide Input Range: 4V to 60V

Current Mode Constant Frequency PWM

Very Low Dropout Operation: 100% Duty Cycle

Programmable Switching Frequency:

200kHz to 600kHz

Selectable High Efficient Burst Mode® Operation:

40µA Quiescent Current

Easy Synchronization

8V, 2A Gate Drive (VCC > 10V) for Industrial High

Voltage P-Channel MOSFET

n Programmable Soft-Start

n Programmable Current Limit

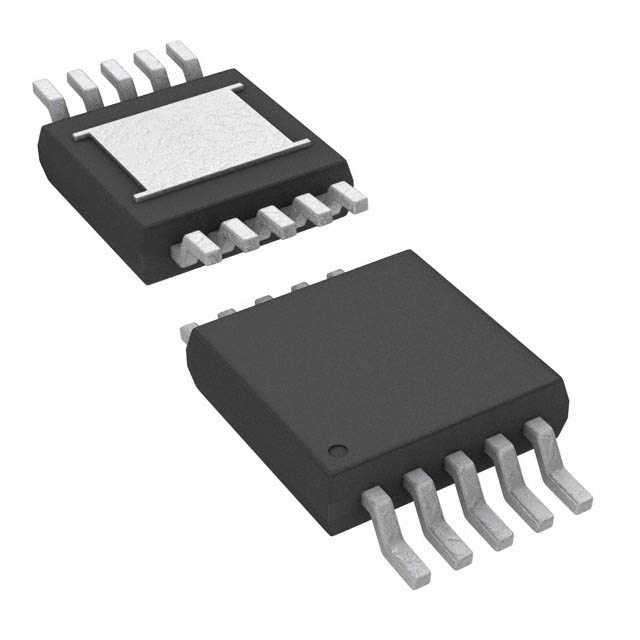

n Available in a Small 10-Pin Thermally Enhanced

MSE Package

n

n

n

n

n

n

The LTC®3824 is a step-down DC/DC controller designed

to drive an external P-channel MOSFET. With a wide input

range of 4V to 60V and a high voltage gate driver, the

LTC3824 is suitable for many industrial and automotive

high power applications. Constant frequency current mode

operation provides excellent performance.

n

The LTC3824 can be configured for Burst Mode operation.

Burst Mode operation enhances low current efficiency

(only 40µA quiescent current) and extends battery run

time. The switching frequency can be programmed up to

600kHz and is easily synchronizable.

Other features include current limit, soft-start, micropower

shutdown, and Burst Mode disable.

The LTC3824 is available in a 10-lead MSE power package.

Applications

L, LT, LTC, LTM and Burst Mode are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners. Protected by U.S. Patents

including 5731964.

Industrial and Automotive Power Supplies

Telecom Power Supplies

n Distributed Power Systems

n

n

Typical Application

5V/2A Buck Converter

Efficiency and Power Loss vs Load Current

100

CCAP

0.1µF

+

CAP

SENSE

LTC3824

GATE

392k

22µH

COUT

100µF

×2

GND

100pF

51Ω

SYNC/MODE

SS

0.1µF

EFFICIENCY

422k

VOUT

5V

2A

1.5

70

1.0

VIN = 40V

60

POWER LOSS

50

10

80.6k

10k

2.0

VIN = 40V

80

VFB

VC

VIN = 12V

POWER LOSS (W)

RS

0.025Ω

RSET

2.5

90

VCC

EFFICIENCY (%)

VIN

5.5V TO 60V

CIN

33µF

100V

0.5

VIN = 12V

100

LOAD CURRENT (mA)

1000

0

2000

3824 TA01a

3824 TA01

3.3nF

3824fh

For more information www.linear.com/LTC3824

1

�LTC3824

Absolute Maximum Ratings

Pin Configuration

(Note 1)

VCC ............................................................................65V

SS, RSET, VFB ..............................................................4V

VC ...............................................................................3V

SYNC/MODE................................................................6V

VCC – VSENSE ...............................................................1V

Operating Junction Temperature Range

(Note 2)................................................... –55°C to 150°C

Storage Temperature Range...................... –65° to 150°C

Lead Temperature (Soldering, 10 sec)................... 300°C

TOP VIEW

GND

SYNC/MODE

RSET

VC

VFB

1

2

3

4

5

11

GND

10

9

8

7

6

CAP

GATE

VCC

SENSE

SS

MSE PACKAGE

10-LEAD PLASTIC MSOP

TJMAX = 150°C, θJA = 43°C/W, θJC = 3°C/W

EXPOSED PAD (PIN 11) IS GND, MUST BE SOLDERED TO PCB

order information

LEAD FREE FINISH

TAPE AND REEL

PART MARKING*

PACKAGE DESCRIPTION

TEMPERATURE RANGE

LTC3824EMSE#PBF

LTC3824EMSE#TRPBF

LTBRZ

10-Lead Plastic MSOP

–40°C to 125°C

LTC3824IMSE#PBF

LTC3824IMSE#TRPBF

LTCGZ

10-Lead Plastic MSOP

–40°C to 125°C

LTC3824HMSE#PBF

LTC3824HMSE#TRPBF

LTCGZ

10-Lead Plastic MSOP

–40°C to 150°C

LTC3824MPMSE#PBF

LTC3824MPMSE#TRPBF LTCGZ

10-Lead Plastic MSOP

–55°C to 150°C

LEAD BASED FINISH

TAPE AND REEL

PART MARKING*

PACKAGE DESCRIPTION

TEMPERATURE RANGE

LTC3824EMSE

LTC3824EMSE#TR

LTBRZ

10-Lead Plastic MSOP

–40°C to 125°C

LTC3824IMSE

LTC3824IMSE#TR

LTCGZ

10-Lead Plastic MSOP

–40°C to 125°C

LTC3824HMSE

LTC3824HMSE#TR

LTCGZ

10-Lead Plastic MSOP

–40°C to 150°C

LTC3824MPMSE

LTC3824MPMSE#TR

LTCGZ

10-Lead Plastic MSOP

–55°C to 150°C

Consult LTC Marketing for parts specified with wider operating temperature ranges. *The temperature grade is identified by a label on the shipping container.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifications, go to: http://www.linear.com/tapeandreel/. Some packages are available in 500 unit reels through

designated sales channels with #TRMPBF suffix.

2

3824fh

For more information www.linear.com/LTC3824

�LTC3824

electrical characteristics

The l denotes the specifications which apply over the specified operating

junction temperature range, otherwise specifications are at TA = 25°C (Note 2). VCC = 12V, RSET = 392k, CCAP = 0.1µF. No load on any

outputs, unless otherwise specified.

PARAMETER

CONDITIONS

Supply Voltage (VCC)

Supply Current (IVCC)

MIN

l

TYP

4

MAX

UNITS

60

V

1.3

mA

VC ≤ 0.4V (Switching Off), VCC ≤ 60V

VSYNC = 0V (Burst Mode operation Disable)

0.8

Supply Current (IVCC) Burst Mode Operation

VCC ≤ 60V, SYNC/MODE Open, VC = 0.6V

40

65

µA

Supply Current in Shutdown

VC ≤ 25mV, VCC ≤ 60V

9

20

30

µA

µA

5

10

15

µA

µA

0.792

0.788

0.788

0.8

0.808

0.812

0.816

V

V

V

220

260

370

µmho

10

10

30

60

nA

nA

0.5

V

l

VC ≤ 25mV, VCC = 12V

l

Voltage Amplifier gm

Reference Voltage (VREF)

LTC3824E/LTC3824I

LTC3824MP/LTC3824H

l

l

Transconductance

VC = 0.8V, ∆IVC = ±2µA

FB Input Current

VFB = VREF (Note 3): LTC3824E/LTC3824I

LTC3824MP/LTC3824H

VC High

IVC = 0

1.6

VC Low

IVC = 0

0.35

l

l

V

VC Source Current

VVC = 0.5V to 1.3V, VFB = VREF –100mV (VSYNC = 0V)

15

µA

VC Sink Current

VVC = 0.7V to 1.3V, VFB = VREF +100mV (VSYNC = 0V)

15

µA

VC Threshold for Switching Off

VSYNC/MODE = 0V (Note 4)

Soft-Start Current ISS

VSS = 0.1V to 1.5V

l

l

3

2.5

5

0.4

V

7.5

8

µA

µA

VC Burst Mode Threshold

VCC ≤ 60V, VC Rising, SYNC/MODE Open

0.84

V

VC Burst Mode Threshold Hysteresis

VCC ≤ 60V

0.04

V

SENSE Voltage at Burst Mode Operation

(VCC–VSENSE) at 30% Duty Cycle

70% Duty Cycle

Current Limit Threshold (VCC–VSENSE)

VCC ≤ 60V: LTC3824E/LTC3824I

LTC3824MP/LTC3824H

FB Overvoltage Threshold

VC = 1.6V

Sense Input Current

VSENSE = VCC

30

20

l

l

80

75

100

100

mV

mV

120

120

8

mV

mV

%

0.1

2

µA

Oscillator

Switching Frequency

RSET = 392k: LTC3824E/LTC3824I

LTC3824MP/LTC3824H

l

l

170

170

200

200

230

240

kHz

kHz

RSET = 200k

l

320

400

460

kHz

1.3

V

300

600

kHz

kHz

Synchronization Pulse Threshold

on SYNC Pin

Rising Edge VSYNC

Synchronization Frequency Range

RSET = 392k

RSET = 200k

VRSET

RSET = 392k

Minimum On-Time (Measured at GATE Pin)

CCM Operation (Note 5)

Switching Frequency Foldback

VFB = 0.3V

l

l

230

460

1.2

V

350

l

35

50

ns

75

kHz

3824fh

For more information www.linear.com/LTC3824

3

�LTC3824

Electrical

Characteristics

The

l denotes the specifications which apply over the specified operating

junction temperature range, otherwise specifications are at TA = 25°C (Note 2). VCC = 12V, RSET = 392k, CCAP = 0.1µF. No load on any

outputs, unless otherwise specified.

PARAMETER

CONDITIONS

MIN

TYP

MAX

7.9

7.9

8.8

8.9

UNITS

Gate Driver

GATE Bias Voltage (VCC–VCAP)

GATE Bias Voltage (VCAP–GND)

GATE High Voltage (VCC–VGATE)

9V ≤ VCC ≤ 60V, IGATE = 10mA: LTC3824E/LTC3824I

LTC3824MP/LTC3824H

l

l

7.0

6.8

VCC = 12V, IGATE = 15mA

l

6.8

4V ≤ VCC ≤ 8V, IGATE = 10mA

6V ≤ VCC ≤ 8V, IGATE = 15mA

l

0.2

4V ≤ VCC ≤ 60V, IGATE = –15mA

V

0.85

1.5

2.8

V

V

0.5

0.8

V

0.5

V

V

GATE Peak Source Current

CGATE = 10nF

2.5

GATE Low Voltage (VGATE–VCAP)

8V ≤ VCC ≤ 60V, IGATE = 15mA

4V ≤ VCC < 8V, IGATE = 10mA

0.1

0.05

GATE Peak Sink Current

CGATE = 10nF

2.5

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: The LTC3824 is tested under pulsed load conditions such that

TJ ≈ TA. The LTC3824E is guaranteed to meet performance specifications

from 0°C to 85°C operating junction temperature. Specifications over

the –40°C to 125°C operating junction temperature range are assured by

design characterization and correlation with statistical process controls.

The LTC3824I is guaranteed over the –40°C to 125°C operating junction

temperature range. The LTC3824H is guaranteed over the –40°C to 150°C

operating junction temperature range. The LTC3824MP is guaranteed

and tested over the full –55°C to 150°C operating junction temperature

range. High junction temperatures degrade operating lifetimes; operating

lifetime is derated for junction temperatures greater than 125°C. Note that

the maximum ambient temperature consistent with these specifications

is determined by specific operating conditions in conjunction with board

4

V

V

A

A

layout, the rated package thermal impedance and other environmental

factors. The junction temperature (TJ, in °C) is calculated from the ambient

temperature (TA, in °C) and power dissipation (PD, in Watts) according to

the formula:

TJ = TA + (PD • θJA)

where θJA (in °C/W) is the package junction to ambient thermal

impedance.

Note 3: This parameter is tested in a feedback loop that servos VFB to the

reference voltage with the VC pin forced to 1V.

Note 4: This specification represents the maximum voltage on VC where

switching (GATE pin) is guaranteed to be off. The nominal value of VC

where switching turns off is 0.7V.

Note 5: The LTC3824 typically enters Burst Mode operation when the load

is less than one third the current limit. If minimum on-time is violated,

cycle skipping may occur at higher current levels.

3824fh

For more information www.linear.com/LTC3824

�LTC3824

Typical Performance Characteristics

8.5

(VCC – VCAP) vs IGATE at VDRIVE Low

3

TA = 25°C unless otherwise noted.

ICC vs VCC

3

8.4

2

8.2

ΔFREQUENCY (kHz)

8.3

VCC-VCAP (V)

Switching Frequency Change

vs VCC at RSET = 392kΩ

2

ICC (mA)

8.1

8.0

7.9

VFB = 0.75V

1

VFB = 0.85V

1

0

–1

7.8

–2

7.7

7.6

0

20

30

IGATE (mA)

10

40

0

50

0

10

20

3824 G01

VREF Change vs VCC

30

VCC (V)

40

50

–3

60

3824 G02

Switching Frequency vs RSET

0.4

5

600

4

400

300

0

10

20

30

VCC (V)

40

50

60

100

100

40

50

60

3824 G03

2

1

–1

200

300

RSET(kΩ)

3824 G04

30

VCC (V)

0

200

–0.4

20

3

500

∆VREF (mV)

FREQUENCY (kHz)

ΔVREF (mV)

–0.2

10

ΔVREF vs Temperature

700

0.2

0

0

400

–2

–75 –50 –25 0 25 50 75 100 125 150

DIE TEMPERATURE (°C)

3824 G05

3824 G06

3824fh

For more information www.linear.com/LTC3824

5

�LTC3824

Typical Performance Characteristics TA = 25°C unless otherwise noted.

Burst Mode Disabled at

ILOAD = 200mA, VOUT = 5V

Burst Mode Operation VOUT = 3V

ILOAD = 200mA

VIN =12V, VOUT= 3V, ILOAD = 200mA

VOUT

50mV/DIV

VOUT

10mV/DIV

INDUCTOR

CURRENT

1A/DIV

INDUCTOR

CURRENT

1A/DIV

4µs/DIV

20µs/DIV

3824 G07

Burst Mode Operation VOUT = 5V

3824 G08

Load Current Step Response

VIN =12V, VOUT= 5V, ILOAD = 200mA

VOUT

50mV/DIV

OUTPUT VOLTAGE

AC COUPLED

100mV/DIV

INDUCTOR

CURRENT

1A/DIV

INDUCTOR

CURRENT

2A/DIV

50µs/DIV

6

3824 G09

100µs/DIV

3824 G10

3824fh

For more information www.linear.com/LTC3824

�LTC3824

pin functions

GND (Pin 1, Exposed Pad Pin 11): Ground. Exposed pad

must be soldered to PCB with expanded metal trace for

rated thermal performance.

SYNC/MODE (Pin 2): Synchronization Input and Burst

Mode Operation Enable/Disable. If this pin is left open

or pulled higher than 2V, Burst Mode operation will be

enabled at light load and the typical threshold of entering

Burst Mode operation is one third of current limit. If this

pin is grounded or the synchronization pulse is present

with a frequency greater than 20kHz then Burst Mode

operation is disabled and the LTC3824 goes into pulse

skipping at light loads. To synchronize the LTC3824, the

duty cycle of the synchronizing pulse can range from 10%

to 70% and the synchronizing frequency has to be higher

than the programmed frequency.

RSET (Pin 3): A resistor from RSET to ground sets the

LTC3824 switching frequency.

VC (Pin 4): The Output of the voltage error amplifier gm

and the control signal of the current mode PWM control

loop. Switching starts at 0.7V, and higher VC corresponds

to higher inductor current. When VC is pulled below 25mV,

the LTC3824 goes into micropower shutdown.

VFB (Pin 5): Error Amplifier Inverting Input. A resistor

divider to this pin sets the output voltage. When VFB is

less than 0.5V, the switching frequency will fold back to

50kHz to reduce the minimum on-cycle.

SS (Pin 6): Soft-Start Pin. A capacitor on this pin sets

the output ramp-up rate. The typical time for SS to

reach the programmed level is (C • 0.8V)/5µA. Connect

a 1MΩ to 10MΩ resistor from SS to ground to reset

the soft-start capacitor if shutdown mode is used.

SENSE (Pin 7): Current Sense Input Pin. A sense resistor, RS, from VIN to SENSE sets the current limit to

100mV/RS.

VCC (Pin 8): Chip Power Supply. Power supply bypassing is required.

GATE (Pin 9): Gate Drive for The External P-channel

MOSFET. Typical peak drive current is 2.5A and the drive

voltage is clamped to 8V when VCC is higher than 9V.

CAP (Pin 10): A Low ESR Capacitor of at Least 0.1µF is

required from this pin to VCC to bypass the internal regulator for biasing the gate driver circuitry.

3824fh

For more information www.linear.com/LTC3824

7

�LTC3824

block diagram

SENSE

1.1V

VCC

+

+

SS

VIN

Burst Mode

DISABLE

–

REFERENCE

RS

100k

VREF

GATE

Q1

B1

1.8V

L

VOUT

0.3µA

100k

–

M2

–

50pF

+

+

Y1

S

Q

R

–

–

+

1

2V

CAP D1

+

C2

RF1

COUT

E1

M1

1.5V

RF2

OR1

Y2

RFREQ

–

OSC

+

RSET

+

0.1V

–

Y6

+

SHUTDOWN

+

50KHz FOLDBACK

SYNC DISABLE

6

++

+

0.5V

SLOPE

COMP

0.025V

+

PWM

GND

Y5

–

+

+

250k

8V

+

SYNC/

MODE

+

2.5V

CCAP

0.1µF

–

GM

Burst Mode

OPERATION

CONTROL

FB

D6

–

D7

+

VREF

0.8V

D4

5µA

VC

SS

R1

2k

C1

470pF

2.5V

3824 BD

CSS

0.1µF

applications information

Operation

The LTC3824 is a constant frequency current mode buck

controller with programmable switching frequency up to

600kHz.

Referring to the Block Diagram, the LTC3824’s basic

functions include a transconductance amplifier gm to

regulate the output voltage and control the current mode

PWM current loop, the necessary logic to control the

PWM switching cycles, a high speed gate driver to drive

an external high power P-channel MOSFET and a voltage

regulator to bias the gate driver circuit.

8

In normal operation each switching cycle starts with switch

turn-on and the inductor current is sampled through the

current sense resistor. This current is amplified and then

compared to the error amplifier output VC to turn the

switch off. Voltage loop regulates the output voltage to

the programmed level through the output resistor divider

and the error amplifier. Amplifier E1 regulates the gate

drive low to approximately 8V below VCC for VCC higher

than 9V, and CCAP stabilizes the voltage. Note that when

VCC is lower than 9V, gate drive high will be within 0.5V

of VCC and gate drive low within 1V of ground.

Important features include shutdown, current limit, softstart, synchronization and low quiescent current.

3824fh

For more information www.linear.com/LTC3824

�LTC3824

applications information

Burst Mode Operation

The LTC3824 can be configured for Burst Mode operation

to enhance light load efficiency (only 40µA quiescent current) and extend battery run time by leaving the SYNC/

MODE pin open or pulling it higher than 2V. In this mode,

when output load drops the loop control voltage VC also

drops and when VC reaches approximately 0.9V at low

duty cycle the LTC3824 goes into sleep mode with the

switch turned off. During sleep mode the output voltage

drops and VC rises up. When VC goes up to around 70mV

the LTC3824 will turn on the switch and the burst cycle

repeats. If the SYNC/MODE pin is grounded the Burst

Mode operation will be disabled and the LTC3824 skips

cycles at light load.

Oscillation Frequency Setting and Synchronization

The switching frequency of the LTC3824 can be set up to

600kHz by a resistor, RFREQ, from the RSET pin to ground.

For 200kHz, RFREQ = 392k. See the Switching Frequency

vs RFREQ graph in the Typical Performance Characteristics section. With a 100ns one-shot timer on-chip, the

LTC3824 provides flexibility on the sync pulse width. The

sync pulse threshold voltage level is about 1.2V.

Short-Circuit Protection

In normal operation when the output voltage is in regulation,

VFB is regulated to 0.8V. If the output is shorted to ground

and VFB drops below 0.5V the switching frequency will be

reduced to 50kHz to allow the inductor current to discharge

and prevent current runaway. Note that synchronization

is enabled only when VFB is above 0.5V.

Soft-Start

During soft-start, the voltage on the SS pin (VSS) is the

reference voltage that controls the output voltage and the

output ramps up following VSS. The effective range of VSS

is from 0V to 0.8V. The typical time for the output to reach

the programmed level is:

C • 0.8V

t SS = SS

5μA

where CSS is the capacitor connected from the SS pin to

GND.

If shutdown mode will be invoked after startup, it is

recommended to connect a 1MΩ to 10MΩ resistor from

SS to ground to reset the SS capacitor during shutdown.

This ensures proper soft-start operation when exiting

shutdown mode.

Overvoltage Protection

To achieve good output regulation in Burst Mode operation,

an overvoltage comparator, OVP, with a threshold adaptive to the VC voltage is used to monitor the FB voltage.

In Burst Mode operation with low VC voltage, the OVP

threshold is approximately 2% above VREF and the VREF

is also shifted lower by 2% to contain the output ripple

and to keep output regulation constant. As output load

increases, OVP threshold increases with VC voltage to up

to 8% above VREF.

Shutdown Mode Quiescent Current

When the VC pin is pulled down below 25mV the LTC3824

goes into micropower shutdown mode and only draws 7µA.

For proper operation, shutdown mode should not be

engaged again too soon after exiting shutdown mode.

This minimum time is a function of CSS and is calculated

by tMIN = 5.5e5 • CSS. For example, if CSS = 0.1μF, then

a minimum of 55ms must elapse after exiting shutdown

before engaging it again.

Output Voltage Programming

With a 0.8V feedback reference voltage, VREF, the output

voltage, VOUT, is programmed by a resistor divider as

shown in the Block Diagram.

VOUT = 0.8V (1+RF1/RF2)

Current Sense Resistor RS and Current Limit

The maximum current the LTC3824 can deliver is determined by:

IOUT(MAX) = 100mV/RS – IRIPPLE/2

where 100mV is the internal 100mV threshold across VCC

and VSENSE, and IRIPPLE is the inductor peak-to-peak ripple

current. RS should be placed very close to the power switch

with very short traces. Good kelvin sensing is required for

accurate current limit.

3824fh

For more information www.linear.com/LTC3824

9

�LTC3824

applications information

Inductor Selection

The maximum inductor current is determined by :

IRIPPLE

2

(V – V ) • D

where IRIPPLE = IN OUT

f •L

+V

V

and Duty Cycle D = OUT D

VIN + VD

The power dissipated by the MOSFET when the LTC3824

is in continuous mode is given by :

PMOSFET =

IL(MAX) =IOUT(MAX) +

VD is the catch diode D1 forward voltage and f is the

switching frequency.

A small inductance will result in larger ripple current,

output ripple voltage and also larger inductor core loss.

An empirical starting point for the inductor ripple current

is about 40% of maximum DC current.

L=

(VIN– VOUT ) • D

f • 0.4 •IOUT(MAX)

The saturation current level of the inductor should be

sufficiently larger than IL(MAX).

Power MOSFET Selection

Important parameters for the power MOSFET include the

drain-to-source breakdown voltage (BVDSS), the threshold

voltage (VGS(TH)), the on-resistance (RDS(ON)) versus gateto-source voltage, the gate-to-source and gate-to-drain

charges (QGS and QGD, respectively), the maximum drain

current (ID(MAX)) and the MOSFET’s thermal resistance

(RTH(JC)) and RTH(JA).

The gate drive voltage is set by the 8V internal regulator.

Consequently, at least 10V VGS rated MOSFETs are required

in high voltage applications.

In order to calculate the junction temperature of the power

MOSFET, the power dissipated by the device must be known.

This power dissipation is a function of the duty cycle, the

load current and the junction temperature itself (due to the

positive temperature coefficient of RDS(ON)). The power

dissipation calculation should be based on the worst-cast

specifications for VSENSE(MAX), the required load current at

maximum duty cycle, the voltage and temperature ranges,

and the RDS(ON) of the MOSFET listed in the data sheet.

10

+ K(VIN )2 (IOUT )(CRSS )(f)

The first term in the equation represents the I2R losses in

the device and the second term is the switching losses. K

(estimated as 1.7) is an empirical factor inversely related

to the gate drive current and has the unit of 1/Amps. The δ

term accounts for the temperature coefficient of the RDS(ON)

of the MOSFET, which is typically 0.4%/°C. CRSS is the

MOSFET reverse transfer capacitance. Figure 1 illustrates

the variation of normalized RDS(ON) over temperature for

a typical power MOSFET.

2.0

δ NORMALIZED ON-RESISTANCE

VOUT+ VD

(IOUT )2 (1+ δ)RDS(ON)

VIN + VD

1.5

1.0

0.5

0

–50

50

100

0

JUNCTION TEMPERATURE (°C)

150

3824 F01

Figure 1. Normalized RDS(ON) vs Temperature

From a known power dissipated in the power MOSFET, its

junction temperature can be obtained using the following

formula:

TJ = TA + PMOSFET • RTH(JA)

The RTH(JA) to be used in this equation normally includes

the RTH(JC) for the device plus the thermal resistance from

the case to the ambient temperature (RTH(CA)). This value

of TJ can then be compared to the original assumed value

used in the calculation.

Output Diode Selection

The catch diode carries load current during the switch

off-time. The average diode current is therefore dependent

For more information www.linear.com/LTC3824

3824fh

�LTC3824

Applications Information

on the P-channel switch duty cycle. At high input voltages

the diode conducts most of the time. As VIN approaches

VOUT the diode conducts only a small fraction of the time.

The worst condition for the diode is when the output is

shorted to ground. Under this condition the diode must

safely handle the maximum current at close to 100% of

the time. Therefore, the diode must be carefully chosen

to meet the worst case voltage and current requirements.

Under normal conditions, the average current conducted

by the diode is:

ID = IOUT • (1 – D)

A fast switching Schottky diode must be used to optimize

efficiency.

CIN and COUT Selection

A low ESR input capacitor, CIN, sized for the maximum

RMS P-channel switch current is required to prevent large

input voltage transients. The maximum RMS capacitor

current is given by:

IRMS =IOUT(MAX)

VOUT

VIN

VIN

–1

VOUT

Efficiency Considerations

The efficiency of a switching regulator is equal to the output

power divided by the input power. Percentage efficiency

can be expressed as:

% Efficiency = 100%–(L1 + L2 + L3 +......)

This formula has a maximum at VIN = 2VOUT, where IRMS =

IOUT/2. This simple worst-case condition is commonly used

for design because even significant deviations do not offer

much relief. Note that ripple current ratings from capacitor

manufacturers are often based on only 2000 hours of life

which makes it advisable to further derate the capacitor,

or choose a capacitor rated at a higher temperature than

required. Several capacitors may also be paralleled to meet

size or height requirements in the design.

The selection of COUT is determined by the effective series

resistance (ESR) that is required to minimize voltage ripple

and load step transients as well as the amount of bulk

capacitance that is necessary to ensure that the control

loop is stable.

The output ripple, ∆VOUT , is determined by:

1

ΔVOUT ≤ ΔIL ESR+

8fCOUT

The output ripple is highest at maximum input voltage

since ∆IL increases with input voltage. Multiple capacitors

placed in parallel may be needed to meet the ESR and

RMS current handling requirements. Dry tantalum, special

polymer, aluminum electrolytic and ceramic capacitors are

all available in surface mount packages. Special polymer

capacitors offer very low ESR but have lower capacitance

density than other types. Tantalum capacitors have the

highest capacitance density but it is important to only

use types that have been surge tested for use in switching

power supplies. Aluminum electrolytic capacitors have

significantly higher ESR, but can be used in cost-sensitive

applications provided that consideration is given to ripple

current ratings and long-term reliability. Ceramic capacitors have excellent low ESR characteristics but can have

a high voltage coefficient and audible noise.

where L1, L2, L3...are the individual loss components as a

percentage of the input power. It is often useful to analyze

individual losses to determine what is limiting the efficiency

and which change would produce the most improvement.

Although all dissipative elements in the circuit produce

losses, the following are the main sources:

1. The supply current into VCC. The VCC current is the sum

of the DC supply current and the MOSFET driver and

control currents. The DC supply current into the VCC pin

is typically about 1mA. The driver current results from

switching the gate capacitance of the power MOSFET;

this current is typically much larger than the DC current.

Each time the MOSFET is switched on and off, a packet

of gate charge QG is transferred from the CAP pin to

VCC throughout the external bypass capacitor, CCAP.

The resulting dQ/dt is a current that must be supplied

to the capacitor by the internal regulator.

IQ = 1mA + f • QG

PIC = VIN • IQ

3824fh

For more information www.linear.com/LTC3824

11

�LTC3824

applications information

2. Power MOSFET switching and conduction losses:

PMOSFET =

VOUT + VD

(I )2 (1+ δ)RDS(ON)

VIN + VD OUT

+ K(VIN )2 (IOUT )(CRSS )(f)

3. The I2R losses of the current sense resistor:

P(SENSE R) = (IOUT)2 • R • D

where D is the duty cycle

4. The inductor loss due to winding resistance:

P(WINDING) = (IOUT)2 • RW

Place the LTC3824 and associated components tightly

together and next to the section with power components.

Use a local via to ground plane for all pads that connect to

ground. Use multiple vias for power components.

Connect the current sense input directly to the current

sense resistor pad. VCC and SENSE are the inputs of the

internal current sense amplifier and should be connected

as close to the sense resistor pads as possible. A 100pF

capacitor is required across the VCC and sense pins for

noise filtering and should be placed as close to the pins

as possible.

Design Example

5. Loss of the catch diode:

P(DIODE) = IOUT • VD • (1–D)

6. Other losses, including CIN and COUT ESR dissipation

and inductor core losses, generally account for less

than 2% of total losses.

As an example, the LTC3824 is designed for an automotive 5V power supply with the following specifications:

Maximum IOUT = 2A, typical VIN = 6V to 18V and can reach

60V briefly during load dump condition, and operating

switching frequency = 400kHz.

PCB Layout Considerations

For f = 400kHz, RSET is chosen to be 180k.

To achieve best performance from a LTC3824 circuit, the PC

board layout must be carefully designed. For lower power

applications, a 2-layer PC board is sufficient. However, at

higher power levels, a multiple layer PC board is recommended. Using a solid ground plane under the circuit is

the easiest way to ensure that switching noise does not

affect the operation.

Allow inductor ripple current to be 0.8A (40% of the

maximum output current) at VIN = 18V,

In order to help dissipate the power from the MOSFET and

diode, keep the ground plane on the layers closest to the

layers where power components are mounted. Use power

planes for the MOSFET and diode in order to improve the

spreading of heat from these components into the PCB.

For best electrical performance the LTC3824 circuit should

be laid out as following:

Place all power components in a tight area. This will

minimize the size of high current loops. Orient the input

and output capacitors and current sense resistor in a way

that minimizes the distance between the pads connected

to ground plane.

12

L=

(18V – 5V)5V

= 12μH

(400kHz • 0.8A)18V

COUT will be selected based on the ESR that is required

to satisfy the output voltage ripple requirement and the

bulk capacitance needed for loop stability. For this design

a 220µF tantalum capacitor is used.

For worse-case conditions CIN should be rated for at least

1A ripple current (half of the maximum output current). A

47µF tantalum capacitor is adequate.

A current limit of 3.3A is selected and RSENSE can be

calculated by :

RSENSE =

100mV

= 0.03Ω

3.3A

and a 25mΩ resistor can be used.

3824fh

For more information www.linear.com/LTC3824

�LTC3824

typical application

12V 2A Buck Converter

VIN

12.5V TO 60V

CIN1

33µF

100V

+

CCAP

0.1µF

CIN2

2.2µF

100V

CAP

VCC

SYNC/MODE SENSE

100pF

CIN1: SANYO 63MV68AX

CIN2: TDK C4532X7R2A225M

COUT: SANYO OSCON, 16SP270M, TDKC2012X7RIC105K

L1: D104C919AS-330M

D1: SS3H9

Q1: Si7465DP

RS

0.025Ω

LTC3824

RSET

GATE

301k

Q1 L1

33µH

GND

+

1000pF

D1

68k

SS

0.1µF

113k

COUT

270µF

VOUT

12V

1µF 2A

16V

X7R

VFB

VC

8.06k

15k

3824 TA02

1000pF

3824fh

For more information www.linear.com/LTC3824

13

�LTC3824

package description

Please refer to http://www.linear.com/product/LTC3824#packaging for the most recent package drawings.

MSE Package

10-Lead Plastic MSOP, Exposed Die Pad

(Reference LTC DWG # 05-08-1664 Rev I)

BOTTOM VIEW OF

EXPOSED PAD OPTION

1.88 ±0.102

(.074 ±.004)

5.10

(.201)

MIN

1

0.889 ±0.127

(.035 ±.005)

1.68 ±0.102

(.066 ±.004)

0.05 REF

10

0.305 ± 0.038

(.0120 ±.0015)

TYP

RECOMMENDED SOLDER PAD LAYOUT

3.00 ±0.102

(.118 ±.004)

(NOTE 3)

DETAIL “B”

CORNER TAIL IS PART OF

DETAIL “B” THE LEADFRAME FEATURE.

FOR REFERENCE ONLY

NO MEASUREMENT PURPOSE

10 9 8 7 6

DETAIL “A”

0° – 6° TYP

1 2 3 4 5

GAUGE PLANE

0.53 ±0.152

(.021 ±.006)

DETAIL “A”

0.18

(.007)

SEATING

PLANE

1.10

(.043)

MAX

0.17 – 0.27

(.007 – .011)

TYP

0.50

(.0197)

NOTE:

BSC

1. DIMENSIONS IN MILLIMETER/(INCH)

2. DRAWING NOT TO SCALE

3. DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH, PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

4. DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

5. LEAD COPLANARITY (BOTTOM OF LEADS AFTER FORMING) SHALL BE 0.102mm (.004") MAX

6. EXPOSED PAD DIMENSION DOES INCLUDE MOLD FLASH. MOLD FLASH ON E-PAD

SHALL NOT EXCEED 0.254mm (.010") PER SIDE.

14

0.497 ±0.076

(.0196 ±.003)

REF

3.00 ±0.102

(.118 ±.004)

(NOTE 4)

4.90 ±0.152

(.193 ±.006)

0.254

(.010)

0.29

REF

1.68

(.066)

3.20 – 3.45

(.126 – .136)

0.50

(.0197)

BSC

1.88

(.074)

0.86

(.034)

REF

0.1016 ±0.0508

(.004 ±.002)

MSOP (MSE) 0213 REV I

3824fh

For more information www.linear.com/LTC3824

�LTC3824

Revision History

(Revision history begins at Rev F)

REV

DATE

DESCRIPTION

F

12/10

E-grade Ordering Information updated to 125°C

2

EC header corrected to Operation Junction Temperature

2

Updated/corrected Note 2

3

Updated Block Diagram

7

G

3/11

PAGE NUMBER

Shutdown section updated

8

Package updated

12

Related Parts updated per Marketing request

14

Updated Temperature Range for MP-grade part

2

Added LTC3824MP to Electrical Characteristics tables

H

01/16

2, 3

Updated Note 2

3

Updated Typical Application

14

Updated soft-start and ground pin descriptions

6

Block Diagram updated

7

Added additional shutdown mode application information

9

Revised schematic

16

3824fh

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection

of its information

circuits as described

herein will not infringe on existing patent rights.

For more

www.linear.com/LTC3824

15

�LTC3824

Typical Application

3V 2A Buck Converter

VIN

4.5V TO 60V

CIN1

33µF

100V

CIN2

2.2µF

100V

+

CIN1: SANYO 63MV68AX

CIN2: TDK C4532X7R2A225M

COUT: SANYO OSCON, 16SP270M, TDKC2012X7RIC105K

L1: D104C919AS-330M

D1: SS3H9

Q1: Si7465DP

Q2: 2N7002

CCAP

0.1µF

CAP

VCC

100pF

RS

0.025Ω

SYNC/MODE SENSE

LTC3824

RSET

GATE

Q1 L1

33µH

301k

GND

+

100pF

D1

51Ω

SS

4.7MΩ*

COUT

270µF

VOUT

3.3V

1µF 2A

16V

255k

VFB

VC

80.6k

Q2*

0.1µF

15k

SHUTDOWN

3824 TA02a

1000pF

* OPTIONAL, SEE PAGE 9 FOR MORE INFORMATION

Related Parts

PART NUMBER

DESCRIPTION

COMMENTS

LTC3864

60V Low IQ Step-Down DC/DC Controller with

100% Duty Cycle Capability

3.5V ≤ VIN ≤ 60V, 0.8V ≤ VOUT ≤ VIN, IQ = 40µA, Selectable Fixed

Frequency 50kHz to 850kHz, 3mm × 4mm DFN-12, MSOP-12E

LTC3891

60V, Low IQ, Synchronous Step-Down DC/DC Controller

4V ≤ VIN ≤ 60V, 0.8V ≤ VOUT ≤ 24V, IQ = 50µA,

Phase-Lockable Fixed Frequency 50kHz to 900kHz, 3x4 QFN-20

LTC3892/LTC3892-1

60V, Low IQ, Dual 2-Phase Synchronous Step-Down

DC/DC Controller with Adj Gate Drive Voltage

4.5V ≤ VIN ≤ 60V, 0.8V ≤ VOUT ≤ 0.99VIN, IQ = 29µA,

PLL Fixed Frequency 50kHz to 900kHz,

4V ≤ VIN ≤ 60V, 0.8V ≤ VOUT ≤ 24V, IQ = 50µA,

LTC3890/LTC3890-1/ 60V, Low IQ, Dual 2-Phase Synchronous

LTC3890-2/LTC3890-3 Step-Down DC/DC Controller with Fixed Gate Drive Voltage PLL Fixed Frequency 50kHz to 900kHz

LT3845A

60V, Low IQ , Single Output Synchronous

Step-Down DC/DC Controller

LT3840

60V Wide Input Range Synchronous Regulator Controller 2.5V≤ VIN ≤ 60V, 1.23V ≤ VOUT ≤ 60V, IQ = 120µA, Synchronizable

Integrated Buck-Boost Supply for 7.5V MOSFET Gate Drive Fixed Frequency 50kHz to 1MHz, TSSOP-28, 4x6 QFN-38

LTC7860

High Efficiency Switching Surge Stopper

High Efficiency VOUT Clamp Stops High Voltage Input Surges,

MSOP-12E

LTC3886

60V Dual Output Step-Down Controller

with Digital Power System Management

4.5V ≤ VIN ≤ 60V, 0.5V ≤ VOUT0,1 (±0.5%) ≤ 13.8V, 70mS Start-Up,

I2C/PMBus Interface, Input Current Sense

LTC3810

100V Synchronous Step-Down DC/DC Controller

Constant On-time Valley Current Mode 4V ≤ VIN ≤ 60V,

0.8V ≤ VOUT ≤ 0.93VIN, SSOP-28

LTC3638

High Efficiency, 140V 250mA Step-Down Regulator with

Adjustable 20mA to 250mA Maximum Output Current

4V≤ VIN ≤ 140V, 0.8V ≤ VOUT ≤ VIN, IQ = 12µA,

No Compensation Required, MSOP-16E (12)

LTC7138

High Efficiency, 140V 400mA Step-Down Regulator with

Adjustable 100mA to 400mA Maximum Output Current

4V≤ VIN ≤ 140V, 0.8V ≤ VOUT ≤ VIN, IQ = 12µA, MSOP-16(12)

No Compensation Required, MSOP-16E (12)

16 Linear Technology Corporation

4V≤ VIN ≤ 60V, 1.23V ≤ VOUT ≤ 36V, IQ = 120µA,

Synchronizable Fixed Frequency 100kHz to 600kHz, TSSOP-16

1630 McCarthy Blvd., Milpitas, CA 95035-7417

For more information www.linear.com/LTC3824

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com/LTC3824

3824fh

LT 0116 REV H • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 2006

�