Product

Folder

Sample &

Buy

Support &

Community

Tools &

Software

Technical

Documents

ADS1257

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

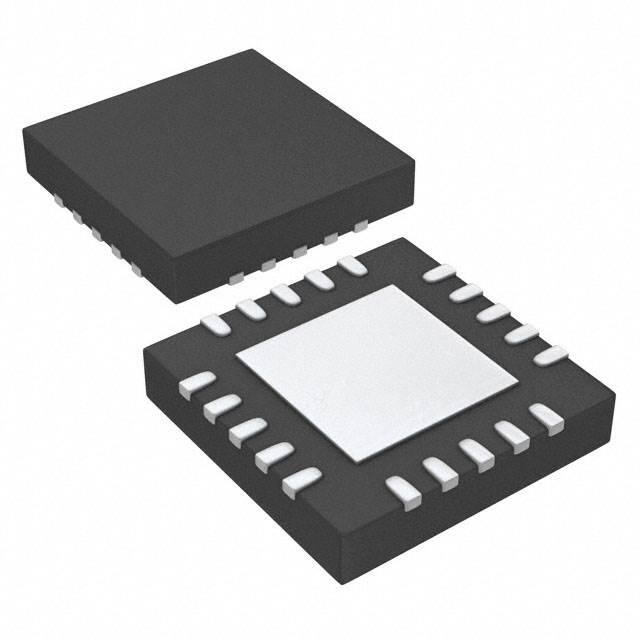

ADS1257 30-kSPS, 4-Channel, 24-Bit ADC with PGA in 5-mm × 5-mm VQFN Package

1 Features

3 Description

•

•

•

The ADS1257 is a low-noise, 30-kSPS, 24-bit, deltasigma (ΔΣ) analog-to-digital converter (ADC) with an

integrated multiplexer (mux), input buffer, and

programmable gain amplifier (PGA) in a small 20-pin,

5-mm × 5-mm VQFN package. The combination of

integration, high conversion rate, and 24-bit resolution

together in a small package makes the device ideally

suited for space-constrained applications.

1

•

•

•

•

•

•

•

•

•

•

Up to 23-Bits Noise-Free Resolution

Small 5-mm × 5-mm VQFN Package

4 Analog Inputs

– 2 Differential or 3 Single-Ended Measurements

Excellent DC Performance

– Offset Drift: 4 nV/°C (Gain = 64)

– Gain Drift: 0.8 ppm/°C

– Nonlinearity: 3 ppm (Gain = 1)

Programmable Data Rates: 2.5 SPS to 30 kSPS

Single-Cycle Settled Conversions (≤ 1000 SPS)

50-Hz and 60-Hz Rejection

High Impedance Input Buffer

Differential-Input PGA

Integrated Sensor Break Detection

2 General-Purpose Input/Outputs

Power Supplies:

– Analog: 5 V

– Digital: 1.8 V to 3.6 V

5-V Tolerant SPI™-Compatible Serial Interface

2 Applications

•

•

•

•

Factory Automation and Process Control

Test and Measurement

Medical Equipment

Scientific Instrumentation

The input multiplexer accepts either two differential or

three single-ended input measurements. The sensorbreak detection circuit verifies the input connection

continuity to the ADC. The selectable input buffer

greatly increases the input impedance, and in many

cases, eliminates the need for external buffers. The

buffer input voltage range includes AGND. The lownoise PGA provides gains from 1 to 64 to

accommodate a wide range of inputs signals. The

programmable digital filter optimizes ADC resolution

(up to 23 bits noise-free) and conversion rates (up to

30 kSPS). The digital filter provides single-cycle

settled conversions, and rejection of 50-Hz and 60-Hz

interference signals.

The SPI-compatible serial interface operates with as

little as three wires, simplifying connections to

external controllers. Integrated calibration features

support both self and system correction of offset and

gain errors for all PGA gain settings. Two

bidirectional digital I/Os pins control external circuits.

Device Information(1)

PART NUMBER

ADS1257

PACKAGE

BODY SIZE (NOM)

VQFN (20)

5.00 mm × 5.00 mm

(1) For all available packages, see the package option addendum

at the end of the data sheet.

Block Diagram

AVDD

REFP REFN

Output Data Histogram

(256 Readings, 2.5 SPS, Gain = 1)

DVDD

100

CLKIN

AIN0

1:64

AIN2

Mux

and

Sensor

Detect

Buffer

PGA

4th-Order

Modulator

Programmable

Digital Filter

Control

SYNC/PWDN

DRDY

AIN3

General-Purpose

Digital I/O

Serial

Interface

SCLK

DIN

DOUT

CS

ADS1257

AGND

D1

D0/CLKOUT

80

RESET

DGND

Population (%)

AIN1

60

40

20

0

-5

-4

-3

-2

-1

0

1

2

3

4

5

Output Code (LSB)

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�ADS1257

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Device Comparison Table.....................................

Pin Configuration and Functions .........................

Specifications.........................................................

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8

7.9

7.10

7.11

1

1

1

2

3

4

5

Absolute Maximum Ratings ...................................... 5

ESD Ratings.............................................................. 5

Recommended Operating Conditions....................... 6

Thermal Information .................................................. 6

Electrical Characteristics........................................... 7

Serial Interface Timing Requirements....................... 8

Serial Interface Switching Characteristics................. 8

RESET and SYNC/PWDN Timing Requirements..... 9

SCLK Reset Timing Requirements ........................... 9

DRDY Update Timing Characteristics..................... 9

Typical Characteristics .......................................... 10

8

Parameter Measurement Information ................ 13

9

Detailed Description ............................................ 16

8.1 Noise Performance ................................................. 13

9.1 Overview ................................................................. 16

9.2

9.3

9.4

9.5

9.6

Functional Block Diagram .......................................

Feature Description.................................................

Device Functional Modes........................................

Programming...........................................................

Register Map...........................................................

16

17

29

39

45

10 Applications and Implementation...................... 51

10.1 Application Information.......................................... 51

10.2 Typical Application ................................................ 56

10.3 Dos and Don'ts ..................................................... 61

11 Power Supply Recommendations ..................... 63

11.1 Power-Supply Sequencing.................................... 63

11.2 Power-Supply Decoupling..................................... 63

12 Layout................................................................... 64

12.1 Layout Guidelines ................................................. 64

12.2 Layout Example .................................................... 65

13 Device and Documentation Support ................. 67

13.1

13.2

13.3

13.4

13.5

Documentation Support ........................................

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

67

67

67

67

67

14 Mechanical, Packaging, and Orderable

Information ........................................................... 67

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision A (October 2015) to Revision B

Page

•

Changed front-page diagram; removed clock generator block for clarity............................................................................... 1

•

Changed all instances of "PDWN" to "PWDN" for consistency.............................................................................................. 4

•

Changed Recommended Operating Conditions "Specified ambient temperature" to "Operating ambient temperature,

TA" for clarity ........................................................................................................................................................................... 6

•

Added Timing Requirements and Switching Characteristics tables along with associated figures, and Typical

Characteristics, Parameter Measurement Information, Detailed Description, Applications and Implementation, Power

Supply Recommendations, and Layout sections.................................................................................................................... 8

Changes from Original (September 2015) to Revision A

•

2

Page

Changed from product preview to production data ................................................................................................................ 1

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

�ADS1257

www.ti.com

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

5 Device Comparison Table

DEVICE

SINGLE-ENDED INPUTS

DIFFERENTIAL INPUTS

NUMBER OF GPIOS

ADS1255

2

1

2

ADS1256

8

4

4

ADS1257

3

2

2

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

3

�ADS1257

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

www.ti.com

6 Pin Configuration and Functions

REFP

1

AIN0

2

REFN

AGND

AVDD

D1

D0/CLKOUT

20

19

18

17

16

RGW Package

20-Pin QFN

Top View (Not to Scale)

ThermalPad

15

SCLK

14

DIN

13

DOUT

CS

SYNC/PWDN

10

11

CLKIN

5

9

AIN3

DGND

DRDY

8

12

DVDD

4

7

AIN2

RESET

3

6

AIN1

Pin Functions

PIN

I/O

NAME

1

REFP

Analog input

Positive reference input

2

AIN0

Analog input

Analog input 0; Leave unconnected or connect to AVDD if not used (1)

3

AIN1

Analog input

Analog input 1; Leave unconnected or connect to AVDD if not used (1)

4

AIN2

Analog input

Analog input 2; Leave unconnected or connect to AVDD if not used (1)

5

AIN3

Analog input

Analog input 3; Leave unconnected or connect to AVDD if not used (1)

Digital input

(2) (3)

Synchronization or power-down input, active low; Connect to DVDD if not used (1)

RESET

Digital input

(2) (3)

Reset input, active low; Connect to DVDD if not used (1)

8

DVDD

Digital

Digital power supply; Connect decoupling capacitor to DGND

9

DGND

Digital

Digital ground

10

CLKIN

Digital input (3)

11

CS

Digital input (2) (3)

12

DRDY

Digital output

Data ready output; active low

13

DOUT

Digital output

Serial data output

14

DIN

Digital input (2) (3)

Serial data input

15

SCLK

Digital input (2) (3)

Serial clock input

16

D0/CLKOUT

Digital input/output (4)

General-purpose digital I/O 0 or clock output (1)

17

D1

Digital input/output (4)

General-purpose digital I/O 1 (1)

18

AVDD

Analog

Analog power supply; Connect decoupling capacitor to AGND

19

AGND

Analog

Analog ground

20

REFN

Analog input

6

7

SYNC/PWDN

Thermal Pad

(1)

(2)

(3)

(4)

4

DESCRIPTION

NO.

—

External clock input

Chip select, active low; Connect to DGND if not used

Negative reference input

Thermal power pad; Connect to AGND

See the Unused Inputs and Outputs section for additional details.

Schmitt-trigger digital input.

5-V tolerant digital input.

Schmitt-trigger digital input when the digital I/O is configured as an input.

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

�ADS1257

www.ti.com

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

7 Specifications

7.1 Absolute Maximum Ratings (1)

Power-supply voltage

Analog input voltage

Digital input voltage

Input current

Temperature

(1)

MIN

MAX

AVDD to AGND

–0.3

6.0

UNIT

DVDD to DGND

–0.3

3.6

AINx, REFP, REFN

AGND – 0.3

AVDD + 0.3

DIN, SCLK, CS, RESET, SYNC/PWDN, CLKIN

DGND – 0.3

DGND + 6.0

D0/CLKOUT, D1

DGND – 0.3

DVDD + 0.3

Continuous, any pins except power-supply pins

–10

10

Operating ambient, TA

–40

105

Junction, TJ

–40

150

Storage, Tstg

–60

150

V

V

V

mA

°C

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

7.2 ESD Ratings

VALUE

V(ESD)

(1)

(2)

Electrostatic discharge

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001 (1)

±2000

Charged-device model (CDM), per JEDEC specification JESD22-C101 (2)

±500

UNIT

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

5

�ADS1257

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

www.ti.com

7.3 Recommended Operating Conditions

over operating ambient temperature range (unless otherwise noted)

MIN

NOM

MAX

UNIT

5

5.25

V

3.6

V

0.1

V

V

POWER SUPPLY

Analog power supply

AVDD to AGND

4.75

Digital power supply

DVDD to DGND

1.8

Analog-to-digital ground potential

AGND to DGND

–0.1

0

ANALOG INPUTS

VIN

Differential input voltage

V(AINx)

VIN = V(AINP) – V(AINN)

Absolute input voltage

–2 VREF / Gain

2 VREF / Gain

Buffer off

AGND – 0.1

AVDD + 0.1

Buffer on

AGND

AVDD – 2.0

V

VOLTAGE REFERENCE INPUTS

VREF

Differential reference input voltage

V(REFN)

Absolute negative reference input voltage

V(REFP)

Absolute positive reference input voltage

VREF = V(REFP) – V(REFN)

Buffer off

0.5

2.5

2.6

AGND – 0.1

V(REFP) – 0.5

AGND

V(REFP) – 0.5

Buffer off

V(REFN) + 0.5

AVDD + 0.1

Buffer on (1)

V(REFN) + 0.5

AVDD – 2.0

Buffer on (1)

V

V

V

CLOCK SOURCE

f(CLKIN)

Clock frequency

Duty cycle

0.1

7.68

10

40%

50%

60%

MHz

DIGITAL INPUTS

Digital input voltage

DIN, SCLK, CS, RESET,

SYNC/PWDN, CLKIN

DGND

DGND + 5.25

D0/CLKOUT, D1

DGND

DVDD

–40

85

V

TEMPERATURE

TA

(1)

Operating ambient temperature

°C

The reference input range with buffer on is restricted only if self-calibration is used. If using system calibration or writing calibration

values directly to the registers, the buffer off range can be used for the reference input range.

7.4 Thermal Information

ADS1257

THERMAL METRIC

(1)

RGW (QFN)

UNIT

20 PINS

RθJA

Junction-to-ambient thermal resistance

32.0

°C/W

RθJC(top)

Junction-to-case (top) thermal resistance

24.7

°C/W

RθJB

Junction-to-board thermal resistance

10.4

°C/W

ψJT

Junction-to-top characterization parameter

0.3

°C/W

ψJB

Junction-to-board characterization parameter

10.4

°C/W

RθJC(bot)

Junction-to-case (bottom) thermal resistance

1.6

°C/W

(1)

6

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report, SPRA953.

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

�ADS1257

www.ti.com

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

7.5 Electrical Characteristics

Minimum and maximum specifications apply from TA = −40°C to +85°C. Typical specifications are at TA = 25°C.

All specifications at AVDD = 5 V, DVDD = 1.8 V, buffer on, f(CLKIN) = 7.68 MHz, gain = 1, and VREF = 2.5 V (unless otherwise

noted).

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

ANALOG INPUTS

Gain

PGA gain

1, 2, 4, 8, 16, 32, 64

Buffer off, gain = 1, 2, 4, 8, 16

Differential input impedance

V/V

150 / Gain

Buffer off, gain = 32, 64

4.7

Buffer on, DR ≤ 50 SPS (1)

80

kΩ

MΩ

SYSTEM PERFORMANCE

Resolution

DR

Data rate

INL

Integral nonlinearity

VIO

Input offset voltage

Offset drift

Gain error

Gain drift

CMRR

PSRR

Common-mode rejection ratio

Power-supply rejection ratio

All data rates and PGA gain settings

24

Bit

2.5

30,000

Differential input, gain = 1, buffer off

3

Differential input, gain = 64, buffer off

7

After calibration

SPS

10

ppm

On the level of the noise

Gain = 1

100

Gain = 64

nV/°C

4

After calibration, gain = 1, buffer on

±0.005%

After calibration, gain = 64, buffer on

±0.03%

Gain = 1

0.8

Gain = 64

0.8

ppm/°C

fCM = 60 Hz, DR = 30 kSPS (2)

95

110

dB

Analog, ±5% Δ in AVDD

60

70

dB

100

dB

18.5

kΩ

Digital, ±10% Δ in DVDD

VOLTAGE REFERENCE INPUTS

Reference input impedance

SENSOR DETECT CURRENT SOURCES

Current settings

0.5, 2, 10

µA

DIGITAL INPUTS/OUTPUTS

DIN, SCLK, CLKIN, SYNC/PWDN, CS, RESET

0.8 DVDD

5.25

D0/CLKOUT, D1

0.8 DVDD

DVDD

DGND

0.2 DVDD

VIH

High-level input voltage

VIL

Low-level input voltage

VOH

High-level output voltage

IOH = 4 mA

VOL

Low-level output voltage

IOL = 4 mA

0.8 DVDD

Input hysteresis

Input leakage

V

V

0.2 DVDD

V

10

µA

5

µA

0.5

0 < digital input voltage < DVDD

V

–10

V

POWER SUPPLY

Power-down mode

Standby mode

IAVDD

Analog supply current

20

7

10

mA

Normal mode, gain = 64, buffer off

16

24

mA

Normal mode, gain = 1, buffer on

13

19

mA

Normal mode, gain = 64, buffer on

36

50

mA

5

µA

mA

Power-down mode

IDVDD

PD

(1)

(2)

Digital supply current

Power dissipation

µA

Normal mode, gain = 1, buffer off

Standby mode, CLKOUT off, DVDD = 3.3 V

95

Normal mode, CLKOUT off, DVDD = 3.3 V

0.9

2

µA

Normal mode, gain = 1, buffer off, DVDD = 3.3 V

38

57

Standby mode, DVDD = 3.3 V

0.4

mW

See the Analog Input Buffer section for more information on input impedance.

fCM is the frequency of the common-mode input signal. Place a notch of the digital filter at 60 Hz by setting DR = 60 samples per

second.(SPS), 30 SPS, 15 SPS, 10 SPS, 5 SPS, or 2.5 SPS to further improve the common-mode rejection of this frequency.

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

7

�ADS1257

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

www.ti.com

7.6 Serial Interface Timing Requirements

over recommended operating conditions (unless otherwise noted)

MIN

MAX

UNIT

t(CLKIN) (1)

4

t1

SCLK period

t2H

Pulse duration, SCLK high

t2L

Pulse duration, SCLK low

200

ns

t3

Delay time, CS falling edge to first SCLK rising edge (3)

50

ns

t4

Setup time, DIN valid before SCLK falling edge

50

ns

t5

Hold time, DIN valid after SCLK falling edge

50

ns

t6

Delay time, last SCLK falling edge for DIN to first SCLK rising edge for DOUT: RDATA, RDATAC,

RREG Commands

50

t(CLKIN)

t10

Delay time, final SCLK falling edge to CS rising edge

8

t(CLKIN)

t11

Delay time, final SCLK falling edge of command to first SCLK

rising edge of next command

t11B

Pulse duration, CS high

(1)

(2)

(3)

10

t(DATA) (2)

9

t(DATA)

200

RREG, WREG, RDATA

RDATAC, SDATAC, SYNC

ns

4

t(CLKIN)

24

t(CLKIN)

4

t(CLKIN)

Master clock period: t(CLKIN) = 1 / f(CLKIN).

Output data period: t(DATA) = 1 / DR.

CS can be tied low.

7.7 Serial Interface Switching Characteristics

over recommended operating conditions (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

t7

Propagation delay time,

SCLK rising edge to valid new DOUT

t8

Propagation delay time,

SCLK rising edge to DOUT invalid

0

t9

Propagation delay time,

last SCLK falling edge to DOUT high impedance

6

10

t(CLKIN)

t11C

Propagation delay time,

CS rising edge to DOUT high impedance

0

50

ns

DOUT load = 20 pF || 100 kΩ to DGND

50

ns

ns

t11B

CS

t3

t2H

t1

t10

SCLK

t4

t5

t6

t11

t2L

DIN

t7

t11C

t8

t9

DOUT

Figure 1. Serial Interface Timing

8

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

�ADS1257

www.ti.com

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

7.8 RESET and SYNC/PWDN Timing Requirements

over recommended operating conditions (unless otherwise noted)

MIN

t16

Pulse duration, RESET, SYNC/PWDN low

t16B

Delay time, SYNC/PWDN rising edge to CLKIN rising edge

(1)

MAX

UNIT

t(CLKIN) (1)

4

–25

25

ns

MIN

MAX

UNIT

300

500

t(CLKIN) (1)

Master clock period: t(CLKIN) = 1 / f(CLKIN)

CLKIN

t16

t16B

RESET, SYNC/PWDN

SYNC/PWDN

Figure 2. RESET and SYNC/PWDN Timing

7.9 SCLK Reset Timing Requirements

over recommended operating conditions (unless otherwise noted)

t12

Pulse duration, first high pulse

t13

Pulse duration, low pulse

t14

Pulse duration, second high pulse

t15

Pulse duration, third high pulse

(1)

5

t(CLKIN)

550

750

t(CLKIN)

1050

1250

t(CLKIN)

MIN

MAX

Master clock period: t(CLKIN) = 1 / f(CLKIN)

t13

t13

SCLK

t14

t12

t15

Figure 3. SCLK Reset Timing

7.10 DRDY Update Timing Characteristics

over recommended operating conditions (unless otherwise noted)

t17

(1)

Pulse duration, conversion data invalid while updating

16

UNIT

t(CLKIN) (1)

Master clock period: t(CLKIN) = 1 / f(CLKIN)

t17

DRDY

NOTE: DRDY shown with no data retrieval.

Figure 4. DRDY Update Timing

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

9

�ADS1257

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

www.ti.com

7.11 Typical Characteristics

at TA = 25°C, AVDD = 5 V, DVDD = 1.8 V, f(CLKIN) = 7.68 MHz, and VREF = 2.5 V (unless otherwise noted)

30

25

25

Population (%)

Population (%)

20

15

10

5

20

15

10

5

0

-500

-450

-400

-300

-350

-250

-200

-150

-100

-50

0

50

100

150

200

250

300

350

400

450

500

-20

-18

-16

-14

-12

-10

-8

-6

-4

-2

0

2

4

6

8

10

12

14

16

18

20

0

Offset Drift (nV/°C)

Offset Drift (nV/°C)

Gain = 64, 90 units from three production lots

Gain = 1, 90 units from three production lots

Figure 6. Offset Drift Histogram

Figure 5. Offset Drift Histogram

25

30

20

20

Population (%)

15

10

10

5

5

0

-0.0100

-0.0095

-0.0090

-0.0085

-0.0080

-0.0075

-0.0070

-0.0065

-0.0060

-0.0055

-0.0050

-0.0045

-0.0040

-0.0035

-0.0030

-0.0025

-0.0020

-0.0015

-0.0010

-0.0005

0

0

15

-0.060

-0.057

-0.054

-0.051

-0.048

-0.045

-0.042

-0.039

-0.036

-0.033

-0.030

-0.027

-0.024

-0.021

-0.018

-0.015

-0.012

-0.009

-0.006

-0.003

0

Population (%)

25

Gain Error (%)

Gain Error (%)

Gain = 64, 90 units from three production lots

Gain = 1, 90 units from three production lots

Figure 8. Gain Error Histogram

25

20

20

Population (%)

25

15

10

15

10

5

0

0

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2.0

5

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2.0

Population (%)

Figure 7. Gain Error Histogram

Gain Drift (ppm/°C)

Gain Drift (ppm/°C)

Gain = 1, 90 units from three production lots

Gain = 64, 90 units from three production lots

Figure 9. Gain Drift Histogram

10

Figure 10. Gain Drift Histogram

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

�ADS1257

www.ti.com

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

Typical Characteristics (continued)

at TA = 25°C, AVDD = 5 V, DVDD = 1.8 V, f(CLKIN) = 7.68 MHz, and VREF = 2.5 V (unless otherwise noted)

80

20

Population (%)

25

Population (%)

100

60

40

15

10

5

20

0

-5

-4

-3

-2

-1

0

1

2

3

4

-20

-18

-16

-14

-12

-10

-8

-6

-4

-2

0

2

4

6

8

10

12

14

16

18

20

0

5

Output Code (LSB)

Output Code (LSB)

Gain = 1, data rate = 2.5 SPS, buffer = off, 256 readings

Gain = 64, data rate = 2.5 SPS, buffer = off, 256 readings

Figure 12. Noise Histogram

20

20

Population (%)

25

15

10

15

10

5

0

0

-150

-135

-120

-105

-90

-75

-60

-45

-30

-15

0

15

30

45

60

75

90

105

120

135

150

5

-20

-18

-16

-14

-12

-10

-8

-6

-4

-2

0

2

4

6

8

10

12

14

16

18

20

Population (%)

Figure 11. Noise Histogram

25

Output Code (LSB)

Output Code (LSB)

Gain = 1, data rate = 1 kSPS, buffer = off, 4096 readings

Gain = 64, data rate = 1 kSPS, buffer = off, 4096 readings

Figure 14. Noise Histogram

20

20

Population (%)

25

15

10

15

10

5

0

0

-600

-540

-480

-420

-360

-300

-240

-180

-120

-60

0

60

120

180

240

300

360

420

480

540

600

5

-100

-90

-80

-70

-60

-50

-40

-30

-20

-10

0

10

20

30

40

50

60

70

80

90

100

Population (%)

Figure 13. Noise Histogram

25

Output Code (LSB)

Output Code (LSB)

Gain = 1, data rate = 30 kSPS, buffer = off, 4096 readings

Gain = 64, data rate = 30 kSPS, buffer = off, 4096 readings

Figure 15. Noise Histogram

Figure 16. Noise Histogram

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

11

�ADS1257

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

www.ti.com

Typical Characteristics (continued)

at TA = 25°C, AVDD = 5 V, DVDD = 1.8 V, f(CLKIN) = 7.68 MHz, and VREF = 2.5 V (unless otherwise noted)

23

23

22

ENOB (rms)

ENOB (rms)

Data Rate = 1 kSPS

Data Rate = 1 kSPS

22

21

Data Rate = 30 kSPS

20

19

21

Data Rate = 30 kSPS

20

19

18

18

0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

-50

5.0

-30

10

-10

30

50

70

90

110

Temperature (°C)

Input Voltage, VIN (V)

Gain = 1

Gain = 1

Figure 18. Effective Number of Bits vs Temperature

Figure 17. Effective Number of Bits vs Input Voltage

0.0009

0.0006

0.0008

0.0002

- 40°C

+125°C

+85°C

0.0007

½INL½ (% of FSR)

INL (% of FSR)

0.0004

+25°C

0

-0.0002

Buffer Off

0.0006

0.0005

0.0004

Buffer On

0.0003

0.0002

-0.0004

0.0001

-0.0006

0

-5

-4

-3

-2

0

-1

1

2

3

4

5

1

2

4

Input Voltage, VIN (V)

8

16

32

64

PGA Gain Setting

Gain = 1

Figure 19. Integral Nonlinearity vs Input Signal

Figure 20. Integral Nonlinearity vs PGA Gain

40

50

Gain = 64, Buffer On

45

35

Buffer On

Analog Current (mA)

Analog Current (mA)

40

35

30

Gain = 64, Buffer Off

25

20

Gain = 1, Buffer On

15

Gain = 1, Buffer Off

10

25

Buffer Off

20

15

10

5

5

0

0

-50

12

30

-30

-10

10

30

50

70

90

110

1

2

4

8

16

32

64

Temperature (°C)

PGA Gain Setting

Figure 21. Analog Supply Current vs Temperature

Figure 22. Analog Supply Current vs PGA Gain

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

�ADS1257

www.ti.com

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

8 Parameter Measurement Information

8.1 Noise Performance

The ADS1257 offers outstanding noise performance that can be optimized by adjusting the data rate or PGA

gain setting. As the averaging is increased by reducing the data rate, the noise drops correspondingly. The PGA

reduces the input-referred noise when measuring lower level signals. Table 1 through Table 4 summarize the

typical noise performance with the inputs shorted externally.

In all four tables, the following conditions apply: TA = 25°C, AVDD = 5 V, DVDD = 1.8 V, VREF = 2.5 V, and

f(CLKIN) = 7.68 MHz.

Table 1 and Table 3 show the root-mean-square (RMS) value of the input-referred noise. Table 2 and Table 4

show the effective number of bits of resolution (ENOB), using the noise data from Table 1 and Table 3

respectively. ENOB is defined as shown in Equation 1:

ENOB =

In (FSR / RMS Noise )

In(2)

where FSR is the full-scale range: FSR = 4 · VREF / Gain

(1)

Table 2 and Table 4 also show the noise-free bits of resolution in parenthesis. Noise-free bits are calculated with

the same formula as ENOB except the peak-to-peak noise values are used instead of RMS noise.

Table 1. Input-Referred Noise (μVRMS) With Buffer On

PGA GAIN

DATA RATE

(SPS)

1

2

4

8

16

32

64

2.5

0.247

0.156

0.080

0.056

0.043

0.037

0.033

5

0.301

0.175

0.102

0.076

0.061

0.045

0.044

10

0.339

0.214

0.138

0.106

0.082

0.061

0.061

15

0.401

0.264

0.169

0.126

0.107

0.085

0.073

25

0.494

0.305

0.224

0.149

0.134

0.102

0.093

30

0.533

0.335

0.245

0.176

0.138

0.104

0.106

50

0.629

0.393

0.292

0.216

0.168

0.136

0.122

60

0.692

0.438

0.321

0.233

0.184

0.146

0.131

100

0.875

0.589

0.409

0.305

0.229

0.170

0.169

500

1.946

1.250

0.630

0.648

0.497

0.390

0.367

1000

2.931

1.891

1.325

1.070

0.689

0.512

0.486

2000

4.173

2.589

1.827

1.492

0.943

0.692

0.654

3750

5.394

3.460

2.376

1.865

1.224

0.912

0.906

7500

7.249

4.593

3.149

2.436

1.691

1.234

1.187

15,000

9.074

5.921

3.961

2.984

2.125

1.517

1.515

30,000

10.728

6.705

4.446

3.280

2.416

1.785

1.742

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

13

�ADS1257

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

www.ti.com

Table 2. Effective Number of Bits (Noise-Free Resolution) With Buffer On

DATA

RATE

(SPS)

(1)

PGA GAIN

1

(1)

2

4

8

16

32

64

2.5

24.5 (22.3)

24.9 (22.6)

24.9 (22.1)

24.4 (21.7)

23.8 (21.3)

23.0 (20.8)

22.2 (19.7)

5

24.2 (21.6)

24.8 (22.4)

24.5 (21.9)

24.0 (21.3)

23.3 (20.7)

22.7 (20.3)

21.8 (19.3)

10

24.1 (21.6)

24.5 (22.0)

24.1 (21.6)

23.5 (21.0)

22.9 (20.4)

22.3 (19.9)

21.3 (18.9)

15

23.8 (21.3)

24.2 (21.7)

23.8 (21.3)

23.2 (20.7)

22.5 (20.1)

21.8 (19.3)

21.0 (18.7)

25

23.5 (21.0)

24.0 (21.4)

23.4 (21.1)

23.0 (20.5)

22.2 (19.7)

21.5 (19.2)

20.7 (18.5)

30

23.4 (21.1)

23.8 (21.3)

23.3 (20.8)

22.8 (20.4)

22.1 (19.8)

21.5 (19.0)

20.5 (18.1)

50

23.2 (20.6)

23.6 (21.1)

23.0 (20.4)

22.5 (19.9)

21.8 (19.4)

21.1 (18.8)

20.3 (17.9)

60

23.0 (20.6)

23.4 (20.9)

22.9 (20.5)

22.4 (19.8)

21.7 (19.3)

21.0 (18.8)

20.2 (17.8)

100

22.7 (20.2)

23.0 (20.7)

22.5 (20.2)

22.0 (19.6)

21.4 (19.1)

20.8 (18.5)

19.8 (17.4)

500

21.6 (19.4)

21.9 (19.6)

21.5 (19.1)

20.9 (18.6)

20.3 (18.0)

19.6 (17.3)

18.7 (16.3)

1000

21.0 (18.3)

21.3 (18.6)

20.8 (18.1)

20.2 (17.5)

19.8 (17.2)

19.2 (16.5)

18.3 (15.6)

2000

20.5 (17.8)

20.9 (18.1)

20.4 (17.8)

19.7 (17.0)

19.3 (16.6)

18.8 (16.1)

17.9 (15.3)

3750

20.1 (17.4)

20.5 (17.8)

20.0 (17.3)

19.4 (16.6)

19.0 (16.2)

18.4 (15.7)

17.4 (14.7)

7500

19.7 (17.0)

20.1 (17.3)

19.6 (16.9)

19.0 (16.2)

18.5 (15.8)

17.9 (15.3)

17.0 (14.4)

15,000

19.3 (16.6)

19.7 (17.0)

19.3 (16.5)

18.7 (15.9)

18.2 (15.5)

17.7 (14.9)

16.7 (13.9)

30,000

19.1 (16.4)

19.5 (16.7)

19.1 (16.4)

18.5 (15.9)

18.0 (15.4)

17.4 (14.6)

16.5 (13.8)

The full FSR cannot be used when VREF = 2.5 V, gain = 1 V/V, and buffer enabled because of the limited absolute input voltage.

Therefore, the values in this column are calculated using a maximum FSR = 6 V.

Table 3. Input-Referred Noise (μVRMS) With Buffer Off

14

PGA GAIN

DATA RATE

(SPS)

1

2

4

8

16

32

64

2.5

0.247

0.149

0.097

0.058

0.036

0.031

0.027

5

0.275

0.176

0.109

0.07

0.046

0.039

0.038

10

0.338

0.201

0.129

0.084

0.063

0.048

0.047

15

0.401

0.221

0.15

0.109

0.07

0.063

0.057

25

0.485

0.279

0.177

0.136

0.093

0.076

0.076

30

0.559

0.315

0.202

0.142

0.107

0.093

0.082

50

0.644

0.39

0.238

0.187

0.129

0.108

0.103

60

0.688

0.417

0.281

0.204

0.134

0.109

0.111

100

0.815

0.53

0.36

0.233

0.169

0.123

0.122

500

1.957

1.148

0.772

0.531

0.375

0.276

0.259

1000

2.803

1.797

1.191

0.94

0.518

0.392

0.365

2000

4.025

2.444

1.615

1.31

0.7

0.526

0.461

3750

5.413

3.25

2.061

1.578

0.914

0.693

0.625

7500

7.017

4.143

2.722

1.998

1.241

0.914

0.857

15,000

8.862

5.432

3.378

2.411

1.569

1.149

1.051

30,000

10.341

6.137

3.873

2.775

1.805

1.313

1.211

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

�ADS1257

www.ti.com

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

Table 4. Effective Number of Bits (Noise-Free Resolution) With Buffer Off

DATA RATE

(SPS)

PGA GAIN

1

2

4

8

16

32

64

2.5

25.3 (23.0)

25.0 (22.4)

24.6 (22.0)

24.4 (21.9)

24.0 (21.3)

23.2 (21.1)

22.5 (20.0)

5

25.1 (22.4)

24.8 (22.1)

24.5 (21.9)

24.1 (21.5)

23.7 (21.2)

22.9 (20.4)

22.0 (19.4)

10

24.8 (22.3)

24.6 (22.1)

24.2 (21.7)

23.8 (21.5)

23.2 (20.8)

22.6 (20.3)

21.7 (19.2)

15

24.6 (22.0)

24.4 (21.8)

24.0 (21.4)

23.4 (20.8)

23.1 (20.6)

22.2 (19.9)

21.4 (19.0)

25

24.3 (21.8)

24.1 (21.7)

23.8 (21.1)

23.1 (20.7)

22.7 (20.3)

22.0 (19.5)

21.0 (18.6)

30

24.1 (21.6)

23.9 (21.4)

23.6 (21.1)

23.1 (20.4)

22.5 (20.0)

21.7 (16.4)

20.9 (18.5)

50

23.9 (21.3)

23.6 (21.3)

23.3 (20.7)

22.7 (20.1)

22.2 (19.8)

21.5 (19.1)

20.5 (18.2)

60

23.8 (21.2)

23.5 (21.0)

23.1 (20.6)

22.5 (20.0)

22.1 (19.8)

21.5 (19.1)

20.4 (18.1)

100

23.5 (21.1)

23.2 (20.5)

22.7 (20.3)

22.4 (19.9)

21.8 (19.5)

21.3 (19.0)

20.3 (17.9)

500

22.3 (20.0)

22.1 (19.7)

21.6 (19.3)

21.2 (18.9)

20.7 (18.3)

20.1 (17.8)

19.2 (16.9)

1000

21.8 (19.0)

21.4 (18.7)

21.0 (18.4)

20.3 (17.7)

20.2 (17.5)

19.6 (16.9)

18.7 (15.9)

2000

21.2 (18.5)

21.0 (18.3)

20.6 (17.9)

19.9 (17.4)

19.8 (17.0)

19.2 (16.4)

18.4 (15.6)

3750

20.8 (18.1)

20.6 (17.8)

20.2 (17.5)

19.6 (17.0)

19.4 (16.7)

18.8 (16.1)

17.9 (15.2)

7500

20.4 (17.7)

20.2 (17.6)

19.8 (17.0)

19.3 (16.6)

18.9 (16.2)

18.4 (15.7)

17.5 (14.8)

15,000

20.1 (17.4)

19.8 (17.1)

19.5 (16.8)

19.0 (16.3)

18.6 (15.9)

18.1 (15.3)

17.2 (14.4)

30,000

19.9 (17.1)

19.6 (17.0)

19.3 (16.6)

18.8 (16.0)

18.4 (15.6)

17.9 (15.0)

17.0 (14.3)

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

15

�ADS1257

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

www.ti.com

9 Detailed Description

9.1 Overview

The ADS1257 is a very low-noise ADC that supports four analog inputs and offers two general-purpose digital

I/Os. The Functional Block Diagram shows a block diagram of the ADS1257. The input multiplexer selects the

ADC input pin connection. Selectable current sources within the input multiplexer check for open- or short-circuit

conditions on the external sensor. A selectable input buffer greatly reduces the input circuitry loading by

providing up to 80 MΩ of impedance. A low-noise PGA provides gains of 1 V/V, 2 V/V, 4 V/V, 8 V/V, 16 V/V, 32

V/V, or 64 V/V. The ADS1257 is comprised of a fourth-order, delta-sigma modulator followed by a programmable

digital filter.

The modulator measures the amplified differential input signal, VIN · Gain = (V(AINP) – V(AINN)) · Gain, against the

differential reference, VREF = V(REFP) − V(REFN). The ADC requires an external reference voltage to operate. The

differential reference is scaled internally by a factor of two so that the full-scale input range is ±2 · VREF / Gain.

The digital filter receives the modulator signal and provides a low-noise digital output. The data rate of the filter is

programmable from 2.5 SPS to 30 kSPS, and allows tradeoffs between resolution and speed.

Communication is over an SPI-compatible serial interface with a set of commands providing control of the

ADS1257. The configuration registers store the various settings for the input multiplexer, sensor-detect current

sources, input buffer enable, PGA gain setting, output data rate, and more. The ADC requires an external clock

source to operate. General-purpose digital I/Os provide static read and write control of up to two pins. The D0 pin

is also used to supply a programmable clock output.

9.2 Functional Block Diagram

REFP

ADS1257

REFN

6

ADC

VREF

2

CLKIN

AIN0

2VREF

AIN1

AIN2

Input

Multiplexer AINP

and

Sensor

AINN

Detect

Buffer

PGA

1:64

6

VIN ‡ *DLQ

4th- Order

Modulator

Programmable

Digital Filter

RESET

Control

SYNC/PWDN

AIN3

DRDY

SPI

Serial

Interface

General-Purpose

Digital I/O

SCLK

DIN

DOUT

CS

D1

16

D0/CLKOUT

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

�ADS1257

www.ti.com

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

9.3 Feature Description

9.3.1 Input Multiplexer

Figure 23 shows a simplified diagram of the input multiplexer. Select any pin as the positive input (AINP) and any

pin as the negative input (AINN). Pin selection is controlled by the MUX register.

AVDD

AIN0

AVDD

AVDD

AVDD

AVDD

AVDD

AVDD

Sensor Detect

Current

Source

AIN1

AIN P

AIN2

AVDD

AVDD

Input

Buffer

AIN N

AIN3

Sensor Detect

Current

Source

Input Multiplexer

AGND

Figure 23. Simplified Diagram of the Input Multiplexer

The ADS1257 offers four analog inputs that can be configured as two independent differential inputs, three

single-ended inputs, or a combination of differential and single-ended inputs.

In general, there are no restrictions on input-pin selection. However, follow these recommendations for optimal

performance:

1. Preferably, use adjacent inputs for differential measurements. For example, use AIN0 and AIN1.

2. Leave any unused analog inputs floating, or connect them to AVDD in order to minimize the input-pin

leakage current.

ESD diodes protect the analog inputs. To keep these diodes from turning on, voltages on the input pins must not

go below AGND by more than 100 mV, and likewise, must not exceed AVDD by more than 100 mV: −100 mV <

(V(AINx)) < AVDD + 100 mV.

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

17

�ADS1257

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

www.ti.com

Feature Description (continued)

9.3.2 Analog Input Buffer

To increase the input impedance presented by the ADS1257, enable the low-drift, chopper-stabilized buffer using

the BUFEN bit in the STATUS register. As shown in Figure 24, the input impedance with the buffer enabled is

modeled by a resistor. Table 5 lists the values of Zeff for the different data-rate settings. The input impedance

scales inversely with the frequency of CLKIN. For example, if f(CLKIN) is reduced by half to 3.84 MHz, Zeff for a

data-rate setting of 50 SPS (actual data rate of 25 SPS) doubles from 80 MΩ to 160 MΩ.s

AIN0

AINP

AIN1

Input

Multiplexer

Zeff

AIN2

AINN

AIN3

Figure 24. Effective Impedance with Buffer On

Table 5. Input Impedance with Buffer On (1)

(1)

DATA RATE

(SPS)

Zeff

(MΩ)

≤ 50

80

60

40

100

40

500

40

1,000

20

2,000

10

3,750

10

7,500

10

15,000

10

30,000

10

f(CLKIN) = 7.68 MHz

NOTE

With the buffer enabled, the voltage on the analog inputs with respect to ground (listed in

the Recommended Operating Conditions as Absolute Input Voltage) must remain between

AGND and AVDD − 2.0 V. Exceeding this range reduces performance; in particular, the

linearity of the ADS1257. This same voltage range, AGND to AVDD − 2.0 V, applies to the

reference inputs when performing a self-gain calibration with the buffer enabled.

18

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

�ADS1257

www.ti.com

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

9.3.3 Programmable Gain Amplifier (PGA)

The ADS1257 is a very high resolution converter. To further complement converter performance, the low-noise

PGA increases the ADC resolution when measuring smaller input signals. For the best resolution, set the PGA to

the highest possible gain setting. The gain setting depends on the largest input signal to be measured. The

ADS1257 full-scale input voltage equals ±2 · VREF / Gain. Table 6 shows the full-scale input voltage for the

different PGA gain settings for VREF = 2.5 V. For example, if the largest signal to be measured is 1.0 V, the

optimum PGA gain setting is 4 V/V, producing a full-scale input voltage of 4 V with no ADC overrange.

Table 6. Full-Scale Input Voltage vs PGA Setting

PGA GAIN

SETTING

(1)

FULL-SCALE INPUT VOLTAGE VIN

(VREF = 2.5 V)

1

±5 V

2

±2.5 V

4

±1.25 V

8

±0.625 V

16

±312.5 mV

32

±156.25 mV

64

±78.125 mV

(1)

The input voltage (VIN) is the difference between the positive and

negative input voltage. Make sure that neither input violates the

absolute input voltage with respect to ground, as listed in the

Recommended Operating Conditions.

The PGA is controlled by the ADCON register. Recalibrate the ADC after changing the PGA gain setting. The

time required for self-calibration depends on the PGA gain setting; see the Calibration section for more details.

The analog current and input impedance (when the buffer is disabled) vary as a function of the PGA gain setting.

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

19

�ADS1257

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

www.ti.com

9.3.4 Modulator Input Circuitry

The ADS1257 modulator measures the input signal using internal capacitors that are continuously charged and

discharged. Figure 25 shows a simplified schematic of the ADS1257 input circuitry with the input buffer disabled.

The on and off timing of the S1 and S2 switches are shown in Figure 26. The S1 switch closes during the input

sampling phase. With S1 closed, CA1 charges to V(AINP), CA2 charges to V(AINN), and CB charges to

(V(AINP) – V(AINN)). For the discharge phase, S1 opens first and then S2 closes. CA1 and CA2 discharge to

approximately AVDD / 2 and CB discharges to 0 V. This two-phase sample and discharge cycle repeats with a

period of tSAMPLE. This time is a function of the PGA gain setting as shown in Table 7 along with the values of

capacitors CA1 = CA2 = CA and CB.

AVDD / 2 AGND

CA1

S2

AIN0

AINP

AIN1

S1

Input

Multiplexer

CB

S1

AIN2

AINN

AIN3

S2

CA2

AGND

AVDD / 2

Figure 25. Simplified Input Structure with Buffer Off

tSAMPLE

ON

S1

OFF

ON

S2

OFF

Figure 26. S1 and S2 Switch Timing for Figure 25

Table 7. Input Sampling Time (tSAMPLE), CA, and CB vs PGA Gain

PGA GAIN SETTING

tSAMPLE (1)

CA

CB

1

f(CLKIN) / 4 (521 ns)

2.1 pF

2.4 pF

2

f(CLKIN) / 4 (521 ns)

4.2 pF

4.9 pF

4

f(CLKIN) / 4 (521 ns)

8.3 pF

9.7 pF

(1)

20

8

f(CLKIN) / 4 (521 ns)

17 pF

19 pF

16

f(CLKIN) / 4 (521 ns)

33 pF

39 pF

32

f(CLKIN) / 2 (260 ns)

33 pF

39 pF

64

f(CLKIN) / 2 (260 ns)

33 pF

39 pF

tSAMPLE for f(CLKIN) = 7.68 MHz given in parenthesis.

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

�ADS1257

www.ti.com

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

The charging of the input capacitors draws a transient current from the sensor driving the ADS1257 inputs. The

average value of this current is used to calculate an effective impedance Zeff, where Zeff = VIN / IAVERAGE.

Figure 27 shows the input circuitry with the capacitors and switches of Figure 25 replaced by their effective

impedances. These impedances scale inversely with the CLKIN frequency. For example, if f(CLKIN) is reduced by

a factor of two, the impedances double. The impedance also changes with the PGA gain setting. Table 8 lists the

effective impedances with the buffer off for f(CLKIN) = 7.68 MHz.

AVDD / 2

AIN0

AINP

AIN1

AIN2

Input

Multiplexer

AINN

ZeffA = tSAMPLE / CA

ZeffB = tSAMPLE / CB

ZeffA = tSAMPLE / CA

AIN3

AVDD / 2

Figure 27. Analog Input Effective Impedances with Buffer Off

Table 8. Analog Input Impedances with Buffer Off (1)

PGA GAIN SETTING

ZeffA

(kΩ)

ZeffB

(kΩ)

1

260

220

2

130

110

4

65

55

8

33

28

16

16

14

32

8

7

64

8

7

(1)

f(CLKIN) = 7.68 MHz.

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

21

�ADS1257

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

www.ti.com

9.3.5 Voltage Reference Inputs (REFP, REFN)

The ADC requires a reference voltage for operation. The reference voltage for the ADS1257 is the differential

voltage between REFP and REFN: VREF = V(REFP) − V(REFN). The reference inputs use a structure similar to that

of the analog inputs with the circuitry on the reference inputs of Figure 28. The load presented by the switched

capacitor is modeled with an effective impedance (Zeff) of 18.5 kΩ for f(CLKIN) = 7.68 MHz. The temperature

coefficient of the effective impedance of the voltage reference inputs is approximately 35 ppm/°C.

REFP

REFN

AGND

AGND

AVDD

AVDD

ESD

Protection

Self-Gain

Calibration

Zeff = 18.5 k:(1)

AINP AINN

(1)

f(CLKIN) = 7.68 MHz

Figure 28. Simplified Reference Input Circuitry

ESD diodes protect the reference inputs. To keep these diodes from turning on, the voltages on the reference

pins must not go below AGND by more than 100 mV, and must not exceed AVDD by 100 mV:

AGND − 100 mV < (V(REFP) or V(REFN)) < AVDD + 100 mV

During self gain calibration, all the switches in the input multiplexer are opened, REFN is internally connected to

AINN, and REFP is connected to AINP. The input buffer can be disabled or enabled during calibration. When the

buffer is disabled, the reference pins drive the circuitry shown in Figure 25 during self gain calibration, resulting in

increased loading. To prevent this additional loading from introducing gain errors, the circuitry driving the

reference pins must have adequate drive capability. When the buffer is enabled, the loading on the reference

pins is much less. However, the buffer limits the allowable voltage range on REFP and REFN during self- or self

gain calibration because the reference pins must remain within the specified input range of the buffer in order to

establish proper gain calibration.

A high-quality reference voltage capable of driving the switched capacitor load presented by the ADS1257 is

essential for achieving the best performance. Noise and drift on the reference degrade overall system

performance. Take special care with the circuitry generating the reference voltages and their layout when

operating with low-noise settings (that is, with low data rates) in order to prevent the voltage reference from

limiting performance.

See the External Reference section for more details.

22

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

�ADS1257

www.ti.com

9.3.6

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

Clock Input (CLKIN)

The master clock for the ADS1257 must be applied to the CLKIN pin. Keep the external clock signal clean and

free of overshoot. Overshoot and glitches on the clock degrade overall performance. See the Recommended

Operating Conditions section for the recommended master clock frequency range. Some of the timing

requirements, as well as the output data rate, scale directly with the CLKIN frequency.

9.3.7 Clock Output (D0/CLKOUT)

Use the clock output pin (D0/CLKOUT) to clock another device, such as another ADS1257 or a microcontroller.

This clock operates at frequencies of f(CLKIN), f(CLKIN) / 2, or f(CLKIN) / 4 and is configured by setting the CLK[1:0]

bits in the ADCON register. If the output clock is enabled while driving an external load, the digital power

consumption increases. Standby mode does not affect the clock output status. That is, if standby is enabled, the

clock output continues to run during standby mode. If not needed, disable the clock output function by writing to

the CLK bits in the ADCON register after power-up or reset.

9.3.8 General-Purpose Digital I/O (D0, D1)

The ADS1257 offers two pins dedicated for general-purpose digital I/Os. All of the digital I/O pins can be

individually configured as either inputs or outputs through the IO register. The DIR bits of the IO register define

whether each pin is an input or output, and the DIO bits control the status of the pins. Reading back the DIO bits

shows the state of the digital I/O pins; that is, if configured as inputs or outputs by the DIR bits. When digital I/O

pins are configured as inputs, the DIO bits are used to read the state of these pins. When configured as outputs,

writing to the DIO bits sets the output value.

During standby and power-down modes, the GPIOs remain active. If configured as outputs, the GPIOs continue

to drive the pins. If configured as inputs, the GPIOs must be driven (not left floating) to prevent excess power

dissipation.

After power-up or reset, the D1 pin defaults to an input and the D0/CLKOUT pin defaults to the clock output. The

CLK[1:0] bits that control the clock output on D0/CLKOUT are only reset after power-up or RESET pin toggle. If

the digital I/O pins are not used, either leave them as inputs tied to ground, or configure them as outputs and

leave them floating to avoid excess power dissipation.

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

23

�ADS1257

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

www.ti.com

9.3.9 Open- and Short-Circuit Sensor Detection

The sensor detect current sources (SDCS) provide a means to verify the integrity of the external sensor

connected to the ADS1257. When enabled, the SDCS supply a current (ISDC) of approximately 0.5 μA, 2 μA, or

10 μA to the sensor through the input multiplexer. The SDCS bits in the ADCON register enable the SDCS and

set the value of ISDC.

When the SDCS are enabled, the ADS1257 automatically turns on the analog input buffer, regardless of the

BUFEN bit setting, in order to prevent the input circuitry from loading the SDCS. AINP must stay below 3 V to be

within the absolute input range of the buffer. To help meet this condition, a 3-V clamp starts sinking current from

AINP to AGND if AINP exceeds 3 V. Note that this clamp is activated only when the SDCS are enabled.

Figure 29 shows a simplified diagram of the ADS1257 input structure with the external sensor modeled as

resistance RSENS between two input pins. When enabled, the SDCS source ISDC to the input pin connected to

AINP, and sink ISDC from the input pin connected to AINN. The two 25-Ω series resistors, RMUX, model the

ADS1257 internal multiplexer switch on-resistances. The signal measured with the SDCS enabled equals the

total IR drop: ISDC × (2RMUX + RSENS). When the sensor is a direct short (that is, RSENS = 0 Ω), there is still a

small signal measured by the ADS1257 when the SDCS are enabled: ISDC · 2RMUX.

AVDD

Sensor Detect

Current Source

RMUX

25 W

AINP

3-V

Clamp

RSENS

Input

Buffer

RMUX

25 W

AINN

Sensor Detect

Current Source

NOTE: Arrows indicate switch positions when the SDCS are enabled.

Figure 29. Sensor Detect Circuitry

24

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

�ADS1257

www.ti.com

9.3.10

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

Digital Filter

The programmable low-pass digital filter receives the modulator output and produces a high-resolution digital

output. By adjusting the amount of filtering, tradeoffs can be made between resolution and data rate: filter more

for higher resolution, or filter less for higher data rate. The filter is comprised of two sections, a fixed filter

followed by a programmable filter. Figure 30 shows the block diagram of the analog modulator and digital filter.

Data are supplied to the filter from the analog modulator at a rate of f(MOD) = f(CLKIN) / 4. The fixed filter is a fifthorder sinc filter with a decimation value of 64 that outputs data at a rate of f(CLKIN) / 256. The second stage of the

filter is a programmable averager (first-order sinc filter) with the number of averages set by the DRATE register.

The data rate is a function of the number of averages (Num_Ave) and is given by Equation 2.

æ ƒ(CLKIN) ö æ

ö

1

Data Rate = ç

֍

÷

256

Num

_

Ave

ø

è

øè

(2)

Modulator Rate =

f(CLKIN) / 4

Analog

Modulator

1

f(CLKIN)

f(CLKIN)

DataRate 256 DataRate 256 Num_Ave

Sinc5

Filter

Programmable

Averager

Num_Ave

(set by DRATE)

Digital Filter

Figure 30. Block Diagram of the Analog Modulator and Digital Filter

Table 9 shows the averaging and corresponding data rate for each of the 16 valid DRATE register settings when

f(CLKIN) = 7.68 MHz. The data rate scales directly with the CLKIN frequency. For example, reducing f(CLKIN) from

7.68 MHz to 3.84 MHz reduces the data rate for DR[7:0] = 1111 0000 from 30,000 SPS to 15,000 SPS.

Table 9. Number of Averages and Data Rate for

Each Valid DRATE Register Setting

(1)

DRATE[7:0]

NUMBER OF AVERAGES FOR

PROGRAMMABLE FILTER

(Num_Ave)

DATA RATE (1)

(SPS)

0000 0011 (03h)

12,000

2.5

0001 0011 (13h)

6000

5

0010 0011 (23h)

3000

10

0011 0011 (33h)

2000

15

0100 0011 (43h)

1200

25

0101 0011 (53h)

1000

30

0110 0011 (63h)

600

50

0111 0010 (72h)

500

60

1000 0010 (82h)

300

100

1001 0010 (92h)

60

500

1010 0001 (A1h)

30

1000

1011 0000 (B0h)

15

2000

1100 0000 (C0h)

8

3750

1101 0000 (D0h)

4

7500

1110 0000 (E0h)

2

15,000

1111 0000 (F0h)

1 (averager bypassed)

30,000

For f(CLKIN) = 7.68 MHz.

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

25

�ADS1257

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

www.ti.com

9.3.10.1 Frequency Response

The low-pass digital filter sets the overall frequency response for the ADS1257. The filter response is the product

of the responses of the fixed and programmable filter sections, and is given by Equation 3:

5

§

§

Su ¦ ·

S u 1XP B $YH u ¦ ·

sin ¨

sin ¨

¸

¸

¨ ¦(CLKIN) ¸

¨

¸

¦(CLKIN)

©

¹

©

¹

+¦

+sinc ¦ u +Averager ¦

u

§ Su ¦ ·

§

Su ¦ ·

64 u sin ¨

Num _ Ave u sin ¨

¸

¸

¨ ¦(CLKIN) ¸

¨ ¦(CLKIN) ¸

©

¹

©

¹

(3)

The digital filter attenuates noise on the modulator output, including noise from within the ADS1257 and external

noise present on the ADS1257 input signal. Adjusting the filtering by changing the number of averages used in

the programmable filter changes the filter bandwidth. With a higher number of averages, bandwidth is reduced,

and more noise is attenuated.

The low-pass filter has notches (or zeros) at the data output rate and multiples thereof. At these frequencies, the

filter has zero gain. This feature is useful when trying to reject a particular interference signal. For example, to

reduce 60-Hz (and harmonic) noise coupling, set the data rate equal to 2.5 SPS, 5 SPS, 10 SPS, 15 SPS, 30

SPS, or 60 SPS. To help illustrate the filter characteristics, Figure 31 and Figure 32 show the responses at the

data-rate extremes of 30 kSPS and 2.5 SPS, respectively.

0

0

-6

-20

-12

-18

Gain (dB)

Gain (dB)

-40

-60

-80

-24

-30

-36

-42

-100

-48

-120

-54

-140

-60

0

15

30

45

60

75

Frequency (kHz)

90

105

120

0

Figure 31. Frequency Response for

Data Rate = 30 kSPS

26

Submit Documentation Feedback

5

10

15

20

25 30 35 40

Frequency (Hz)

45

50

55

60

Figure 32. Frequency Response for

Data Rate = 2.5 SPS

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

�ADS1257

www.ti.com

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

Table 10 summarizes the first-notch frequency and −3-dB bandwidth for the different data-rate settings.

Table 10. First Notch Frequency and

-3-dB Filter Bandwidth (1)

(1)

DATA RATE

(SPS)

FIRST NOTCH

(Hz)

-3 dB BANDWIDTH

(Hz)

2.5

2.5

1.1

5

5

2.21

10

10

4.42

15

15

6.63

25

25

11.1

30

30

13.3

50

50

22.1

60

60

26.5

100

100

44.2

500

500

221

1000

1000

441

2000

2000

878

3750

3750

1615

7500

7500

3003

15,000

15,000

4807

30,000

30,000

6106

f(CLKIN) = 7.68 MHz.

0

0

-20

-20

-40

-40

Gain (dB)

Gain (dB)

The digital filter low-pass characteristic repeats at multiples of the modulator rate of f(MOD) = f(CLKIN) / 4. Figure 33

and Figure 34 show the responses plotted out to 7.68 MHz at the data-rate extremes of 30 kSPS and 2.5 SPS.

Notice how the responses near dc, 1.92 MHz, 3.84 MHz, 5.76 MHz, and 7.68 MHz are the same. The digital filter

attenuates high-frequency noise on the ADS1257 inputs, except for frequencies where the filter response

repeats. External filtering is required to remove high-frequency input noise near these pass-band regions. See

the Analog Input Filtering section for more details.

-60

-80

-60

-80

-100

-100

-120

-120

-140

-140

0

1.92

3.84

5.76

7.68

0

1.92

3.84

5.76

7.68

Frequency (MHz)

Frequency (MHz)

Figure 33. Frequency Response Out to 7.68 MHz

for Data Rate = 30 kSPS

Figure 34. Frequency Response Out to 7.68 MHz

for Data Rate = 2.5 SPS

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

27

�ADS1257

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

www.ti.com

9.3.10.2 50-Hz and 60-Hz, Line Cycle Rejection

As a result of the proximity of the signal wires to industrial motors and conductors in some applications, coupling

of 50-Hz and 60-Hz power-line frequencies can occur. Coupled noise can interfere with the signal voltage leading

to inaccurate or unstable conversions. The digital filter rejects power-line interference for data rates of 60 SPS

and less. Program the filter to tradeoff data rate and conversion latency versus the desired level of line-cycle

rejection. Table 11 summarizes the 50-Hz and 60-Hz line-cycle rejection based on 2% tolerance of power-line

frequency to ADC clock frequency.

Table 11. Minimum 50-Hz and 60-Hz, Line-Cycle Rejection

MINIMUM DIGITAL-FILTER MAGNITUDE (dB)

DATA RATE

(SPS)

50 Hz ±2%

60 Hz ±2%

2.5

–36.2

–37.4

5

–34.4

–34.6

10

–33.9

–34.0

15

—

–33.9

25

–33.8

—

30

—

–33.8

50

–33.8

—

60

—

–33.8

9.3.10.3 Settling Time

The ADS1257 features a digital filter optimized for fast settling. The Conversion Control and Synchronization

section describes the settling time of the ADS1257 for various modes of operation.

28

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

�ADS1257

www.ti.com

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

9.4 Device Functional Modes

9.4.1 Power-Up

All configuration registers are initialized to default states at power-up. Self-calibration is then performed

automatically. For best performance, issue an additional self-calibration with the SELFCAL command or reset the

device after the power supplies and voltage reference have settled to their final values.

NOTE

A reset is required after power-up to avoid invalid device operation.

9.4.2 Reset

Three methods are used to reset the ADS1257: the RESET pin, the RESET command, and a special SCLK reset

pattern.

1. Take the RESET pin low to force a reset. Follow the minimum pulse-width timing specification (t16) before

taking the RESET pin high again (see Figure 2).

2. Issue the RESET command byte to force a reset (see the RESET section). The RESET command takes

effect after all eight bits are shifted into DIN. Afterwards, the reset automatically releases.

3. Reset The ADS1257 using a special pattern on SCLK (see Figure 3). Reset occurs on the falling edge of the

last SCLK edge in the pattern. CS must be low to perform the SCLK reset pattern. After performing the

operation, the reset automatically releases.

After the device resets, the configuration registers are initialized to their default state, except for the CLK[1:0] bits

in the ADCON register that control the D0/CLKOUT pin. The CLK[1:0] bits are only initialized to their default state

when reset is performed using the RESET pin. Reset also exits from the read-data continuous mode.

After a reset, the device self-calibrates, regardless of the reset method or the state of the ACAL bit before the

reset.

9.4.3 Standby Mode

Standby mode shuts down all of the analog circuitry and most of the digital features. To enter standby mode,

issue the STANDBY command. To exit standby mode, issue the WAKEUP command. DRDY stays high after

exiting standby mode until valid data are ready.

Use standby mode to perform single-shot conversions; see the Settling Time Using Single-Shot Mode section for

more information.

If configured as a clock output, the clock signal on the D0/CLKOUT pin continues to run during standby mode.

9.4.4 Power-Down Mode

Hold the SYNC/PWDN pin low for 20 DRDY cycles to activate power-down mode. During power-down mode, all

circuitry is disabled including the clock output.

To exit power-down mode, take the SYNC/PWDN pin high. After exiting from power-down mode, 8192 · t(CLKIN)

cycles are required before conversions begin.

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

29

�ADS1257

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

www.ti.com

Device Functional Modes (continued)

9.4.5 Conversion Control and Synchronization

Device synchronization is available to control the beginning of the analog-to-digital conversion with an external

event, and also to improve settling time after a multiplexer change. Two methods are provided to perform

synchronization, the SYNC/PWDN pin or the SYNC command:

• Method 1: Take the SYNC/PWDN pin low and then high, in accordance with timing specifications t16 and t16B.

Synchronization occurs when SYNC/PWDN is taken high. No communication is possible on the serial

interface while SYNC/PWDN is low. If the SYNC/PWDN pin is held low for 20 DRDY periods, the ADS1257

enters power-down mode.

• Method 2: First, issue the SYNC command. The SYNC command stops the operation of the ADS1257. When

ready to synchronize, issue the WAKEUP command. Synchronization occurs on the first rising edge of the

master clock after the first SCLK used to shift in the WAKEUP command.

After a synchronization operation, either with the SYNC/PWDN pin or the SYNC command, DRDY stays high

until valid data are ready.

The settling time (that is, the time required for a step change on the analog inputs to propagate through the filter)

for the different data rates is shown in Table 12 and Figure 35. The following sections highlight the single-cycle

settling ability of the filter, and show various ways to control the conversion process.

Table 12. Settling Time Versus Data Rate (1) (2)

(1)

(2)

30

DATA RATE

(SPS)

SETTLING TIME

(t18) (ms)

2.5

400.18

5

200.18

10

100.18

15

66.84

25

40.18

30

33.51

50

20.18

60

16.84

100

10.18

500

2.18

1000

1.18

2000

0.68

3750

0.44

7500

0.31

15,000

0.25

30,000

0.21

f(CLKIN) = 7.68 MHz.

Single-shot mode requires an additional delay of 256 · t(CLKIN) to

power up the device from standby mode.

Submit Documentation Feedback

Copyright © 2015–2016, Texas Instruments Incorporated

Product Folder Links: ADS1257

�ADS1257

www.ti.com

9.4.5.1

SBAS656B – SEPTEMBER 2015 – REVISED APRIL 2016

Settling Time Using Synchronization

The SYNC/PWDN pin and SYNC command allow direct control of conversion timing. Issue a SYNC command or

toggle the SYNC/PWDN pin after changing the analog inputs to restart conversions (see the Conversion Control

and Synchronization section for more information). The conversion begins when SYNC/PWDN is taken high, thus