Sample &

Buy

Product

Folder

Support &

Community

Tools &

Software

Technical

Documents

LM27403

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

LM27403 Synchronous Buck Controller With Temperature-Compensated, Inductor-DCRBased Overcurrent Protection and Programmable Thermal Shutdown

1 Features

2 Applications

•

•

•

•

•

•

•

1

•

•

•

•

•

•

•

•

•

•

•

•

•

Up to 97% Efficiency and 93% Duty Cycle

Wide Input Voltage Range of 3 V to 20 V

Switching Frequency From 200 kHz to 1.2 MHz

Inductor-DCR-Based Overcurrent Protection With

Thermal Compensation

0.6-V Reference With 1% Feedback Accuracy

30-ns Min On-Time for Low VOUT

Integrated High-Current MOSFET Drivers

– Adaptive Deadtime Control

Ultrafast Line and Load Transient Response

– High GBW Error Amplifier

– PWM Line Feedforward

Integrated VDD Bias Supply LDO Subregulator

Programmable System-Level OTP

Precision Enable With Hysteresis

Frequency Synchronization

Monotonic Prebiased Start-up

Programmable Soft-Start With Tracking

Output Remote Sense

Open-Drain Power Good Indicator

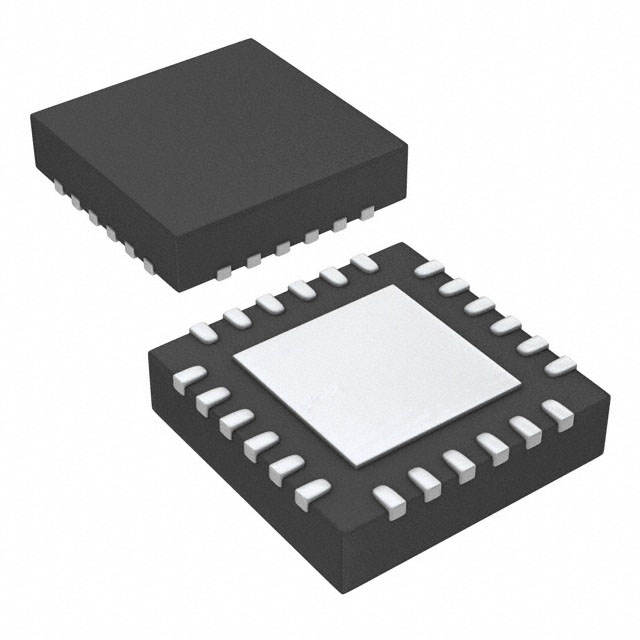

4-mm x 4-mm WQFN-24 PowerPAD™ Package

DC-DC Converters and POL Modules

Telecommunications Infrastructure

Embedded Computing, Servers, Storage

3 Description

The LM27403 is a feature-rich, easy-to-use,

synchronous buck controller offering exceptional

levels of integration and performance for superior

efficiency in high power density, point-of-load (POL)

DC-DC

regulator

solutions.

The

resistorprogrammable switching frequency from 200 kHz to

1.2 MHz and integrated, high-current MOSFET gate

drivers with adaptive deadtime offer flexibility to

optimize solution size and maximize conversion

efficiency.

High precision and low output voltage are easily

obtained with a 0.6-V, 1% accurate voltage reference

together with a 30-ns high-side MOSFET minimum

controllable on-time. Using lossless inductor dc

resistance (DCR) current sensing and an inexpensive

2N3904 BJT to sense temperature remotely at the

inductor, the LM27403 supports accurate and

thermally compensated overcurrent protection (OCP).

Device Information(1)

PART NUMBER

LM27403

PACKAGE

BODY SIZE (NOM)

WQFN (24)

4.00 mm x 4.00 mm

(1) For all available packages, see the orderable addendum at

the end of the datasheet.

Typical Application Diagram

VDD

24

23

CS±

CS+

VOUT+

1

SS/TRACK

2

RS

HG 17

3

FB

SW 16

4

COMP

5

FADJ

6

SYNC

VIN

CBOOT 18

LM27403

VOUT+

LG 15

UVLO

/EN

OTP

D+

D±

PGOOD

VIN

VDD 14

7

8

9

10

11

12

D± D+

GND 13

VOUT±

VIN

GND

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�LM27403

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

www.ti.com

Table of Contents

1

2

3

4

5

6

7

8

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Description (Continued) ........................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

3

5

7.1

7.2

7.3

7.4

7.5

7.6

5

5

5

6

6

9

Absolute Maximum Ratings ......................................

Handling Ratings.......................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Typical Characteristics ..............................................

Detailed Description ............................................ 13

8.1 Overview ................................................................. 13

8.2 Functional Block Diagram ....................................... 14

8.3 Feature Description................................................. 14

8.4 Device Functional Modes........................................ 28

9

Application and Implementation ........................ 30

9.1 Application Information............................................ 30

9.2 Typical Applications ................................................ 37

10 Power Supply Recommendations ..................... 44

11 Layout................................................................... 44

11.1 Layout Guidelines ................................................. 44

11.2 Layout Example .................................................... 47

12 Device and Documentation Support ................. 48

12.1

12.2

12.3

12.4

12.5

Device Support ....................................................

Documentation Support ........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

48

48

48

48

48

13 Mechanical, Packaging, and Orderable

Information ........................................................... 48

4 Revision History

Changes from Revision A (September 2013) to Revision B

•

2

Page

Added Pin Configuration and Functions section, Handling Rating table, Feature Description section, Device

Functional Modes, Application and Implementation section, Power Supply Recommendations section, Layout

section, Device and Documentation Support section, and Mechanical, Packaging, and Orderable Information

section ................................................................................................................................................................................... 1

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

�LM27403

www.ti.com

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

5 Description (Continued)

The LM27403 has a conventional voltage-mode control loop with high gain-bandwidth error amplifier and PWM

input voltage feedforward to simplify compensation design and enable excellent transient response throughout

the full line voltage and load current ranges. Forced-PWM (FPWM) operation eliminates frequency variation to

minimize EMI in sensitive applications. An open-drain Power Good circuit provides power-rail sequencing and

fault reporting. Other features include programmable system-level thermal shutdown with automatic recovery,

output voltage remote sense, configurable soft-start, monotonic start-up into prebiased loads, an integrated bias

supply low-dropout (LDO) regulator, external power supply tracking, precision enable with customizable

hysteresis for programmable line undervoltage lockout (UVLO), and synchronization capability for beat frequency

sensitive and multiregulator applications. The LM27403 is offered in a 4-mm x 4-mm thermally enhanced WQFN24 package with 0.5-mm pitch.

6 Pin Configuration and Functions

N.C.

N.C.

N.C.

N.C.

CS+

24

CS±

24-Pins

WQFN Package

(Top View)

19

18

1

CBOOT

SS/TRACK

RS

HG

FB

SW

COMP

LG

PowerPADTM

FADJ

VDD

SYNC

GND

6

VIN

PGOOD

D±

D+

OTP

7

UVLO/EN

13

12

Pin Functions

PIN

NAME

NO.

I/O/P (1)

DESCRIPTION

CBOOT

18

P

High-side bootstrap connection. This pin is the high-side N-FET gate driver power supply. Connect a

100-nF ceramic capacitor between CBOOT and SW.

COMP

4

O

Compensation node output. This pin is an output voltage control-loop error amplifier output. COMP is

connected to the FB pin through a compensation network to ensure stability.

CS–

24

I

Current-sense negative input. This pin is the inverting input to the current-sense comparator. 9.9 µA of

nominal offset current at room temperature is provided to adjust the current limit setpoint.

CS+

23

I

Current-sense positive input. This pin is the noninverting input to the current-sense comparator.

(1)

I=Input, O=Output, P=Power, G=Ground

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

3

�LM27403

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

www.ti.com

Pin Functions (continued)

PIN

NAME

NO.

I/O/P (1)

DESCRIPTION

D–

10

I

External temperature sense return. This pin is the return current path for the external NPN transistor

configured as a thermal diode. This trace should be routed as a differential pair with the D+ trace back

to the LM27403 to avoid excessive coupling from external noise sources. Connect D– to GND.

D+

9

I

External temperature sense. A 2N3904-type NPN transistor configured as a remote thermal diode with

the base and collector shorted should be connected to this pin to sense the inductor temperature. The

sensed temperature is used to compensate for the inductor DCR drift over temperature and to

implement system-level thermal shutdown protection.

UVLO/EN

7

I

Precision UVLO/enable input. To implement a VIN UVLO function, connect UVLO/EN to the tap of a

voltage divider between VIN and GND. UVLO/EN is initially pulled up by an internal 1.8-µA pullup

current source. UVLO/EN has both a 165-mV voltage hysteresis and an 8.7-µA pullup current

hysteresis. Thus, when a rising UVLO/EN voltage exceeds the 1.15-V enable threshold, the internal

pullup current becomes 10.5 µA and the falling threshold voltage is 0.985 V. Therefore, the effective

total hysteresis can be customized to suit the specific application.

EP

—

P

Exposed die attach pad. Connect this pad to the printed circuit board (PCB) ground plane using

multiple thermal vias.

FADJ

5

I

Frequency adjust input. The switching frequency is programmable between 200 kHz and 1.2 MHz by

virtue of the size of resistor connected to this pin and GND.

FB

3

I

Feedback input. This pin is a voltage-mode control-loop error amplifier inverting input to set the output

voltage. In closed-loop (output in regulation) operation, FB is at 0.6 V ±1%.

GND

13

G

Common ground connection. This pin provides the power and signal return connections for analog

functions, including low-side MOSFET gate return, soft-start capacitor, OTP resistor, and frequency

adjust resistor.

HG

17

O

High-side MOSFET gate drive output. This pin is the high-side N-FET gate connection.

LG

15

O

Low-side MOSFET gate drive output. This pin is the low-side N-FET gate connection.

NC

19-22

G

No connection. Connect directly to GND.

OTP

8

I

Overtemperature protection (OTP) output. A resistor and 0.1-µF capacitor from this pin to GND sets

the overtemperature protection setpoint for the DC-DC power supply solution using the temperature

sensed at a remotely connected thermal diode. Connect this pin to GND if the system level OTP

function is not required.

PGOOD

11

O

Power Good monitor output. This open-drain output goes low during overcurrent, short-circuit, UVLO,

output overvoltage and undervoltage, overtemperature, or when the output is not regulated (such as an

output prebias). An external pullup resistor to VDD or to an external rail is required. Included is a 20-µs

deglitch filter. The PGOOD voltage should not exceed 5.5 V.

RS

2

I

Negative remote sense input. This pin eliminates the voltage drop between GND and the local ground

adjacent to the load. In particularly noisy environments, connect an RC filter between RS and GND.

Connect RS to GND at the IC if not used.

SS/TRACK

1

I/O

Soft-start or tracking input. This pin allows a predetermined startup rate to be defined with the use of a

capacitor to GND. A 3-µA current source charges the capacitor until the reference reaches 0.6 V.

SS/TRACK can also be controlled with an external voltage source for tracking applications.

SW

16

P

Power stage switch-node connection. This pin is the high-side N-FET gate driver return.

SYNC

6

I

Synchronization input. This pin enables PLL synchronization to an external clock frequency. If a SYNC

signal is not present, the switching frequency defaults to the frequency set by the FADJ pin. This pin

should be tied to GND if not used.

VDD

14

P

Bias supply rail. This pin is a subregulated 4.7-V internal and gate drive bias supply rail. VDD also

supplies the current to CBOOT to facilitate high-side switching. Decouple VDD to GND locally with a

10-µF ceramic capacitor. VDD should not be used to drive auxiliary system loads because of gate

drive loading possibility.

VIN

12

P

Input voltage rail. This input is used to provide the feedforward modulation for output voltage control

and for generating the internal bias supply voltage. Decouple VIN to GND locally with a 1-µF ceramic

capacitor. For better noise rejection, connect to the power stage input rail with an RC filter.

4

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

�LM27403

www.ti.com

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

7 Specifications

7.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted) (1).

Voltage (2)

MIN

MAX

UNIT

VIN, CS+, CS–, SW (3) (4)

–0.3

22

V

VDD, PGOOD

–0.3

6

V

SS/TRACK, SYNC, FADJ, COMP, FB, RS

–0.3

VVDD + 0.3

V

UVLO/EN

–0.3

min (VVIN + 0.3, 6)

V

(5)

–0.3

24

V

–0.3

6

V

CS+ to CS–

–1

1

V

OTP, D+, D–

–0.3

VVDD

V

Operating junction temperature, TJ

–40

150

°C

CBOOT

CBOOT to SW

Thermal

(1)

(2)

(3)

(4)

(5)

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only and functional operation of the device at these or any other condition beyond those included under Recommended Operating

Conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods of time may affect device reliability.

All voltages are with respect to the network ground pin unless otherwise noted.

The SW pin can tolerate negative voltage spikes as low as –10 V and as high as 30 V for a duration up to 10 ns.

Body diode of the low-side MOSFET notwithstanding, parasitic inductance in a real application may result in the SW voltage ringing

negative.

The CBOOT pin can tolerate positive voltage spikes as high as 35 V for a duration up to 10 ns.

7.2 Handling Ratings

Tstg

Storage temperature range

V(ESD)

(1)

(2)

Electrostatic discharge

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001, all

pins (1)

Charged device model (CDM), per JEDEC specification

JESD22-C101, all pins (2)

MIN

MAX

UNIT

–65

150

°C

–2

2

kV

–500

500

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

7.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted) (1).

MIN

NOM

MAX

UNIT

VIN tied to VDD

3.0

5.5

V

VIN

3.0

20

V

SW pin voltage

–0.3

20

V

VDD

VDD pin voltage

2.6

5.5

V

PGOOD

PGOOD pin voltage

0

5.5

V

UVLO/EN

UVLO/EN pin voltage

0

min (VVIN, 5.5)

V

SS/TRACK

SS/TRACK pin voltage

0

VVDD

V

SYNC

SYNC pin voltage

0

5.5

V

RS

RS pin voltage

–0.1

0.1

V

TJ

Operating junction temperature

–40

+125

°C

TA

Operating free-air temperature

–40

+125

°C

VIN

Input voltage (2)

SW

(1)

(2)

4.7

Recommended Operating Conditions are conditions under which operation of the device is intended to be functional but does not

guarantee performance limits.

VDD is the output of the internal linear regulator bias supply. Under normal operating conditions, where VIN is greater than 5.5 V, VDD

must not be tied to any external voltage source. In an application where VIN is between 3.0 V and 5.5 V, connecting VIN to VDD

maximizes the bias supply rail voltage.

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

5

�LM27403

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

www.ti.com

7.4 Thermal Information

LM27403

THERMAL METRIC (1)

RTW

UNIT

24 PINS

θJA

Junction-to-ambient thermal resistance

32.7

θJCtop

Junction-to-case (top) thermal resistance

31.2

θJB

Junction-to-board thermal resistance

11.2

ψJT

Junction-to-top characterization parameter

0.2

ψJB

Junction-to-board characterization parameter

11.2

θJCbot

Junction-to-case (bottom) thermal resistance

1.4

(1)

°C/W

For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

7.5 Electrical Characteristics

Typical values correspond to TJ = 25°C. Minimum and maximum limits apply over –40°C to +125°C junction temperature

range unless otherwise stated (1), (2). VVIN = 12 V and all parameters at zero power dissipation (unless otherwise noted).

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

OPERATIONAL SPECIFICATIONS

IQ

Quiescent current

VFB = 0.6 V (not switching)

3.5

5.0

mA

IQ-SD

Shutdown quiescent current

VUVLO/EN = 0 V

25

45

µA

594

600

606

mV

–165

0

165

nA

2.7

2.8

REFERENCE

VFB

FB pin voltage accuracy

IFB

FB pin bias current

VFB = 0.65 V

INTERNAL UVLO

UVLO

Input undervoltage lockout

VVIN rising, VVDD rising

UVLO_hys

UVLO hysteresis

VVIN falling, VVDD falling

2.6

250

V

mV

SWITCHING

FSW

Switching frequency

RFADJ = 4.12 kΩ

925

1050

1150

kHz

RFADJ = 20 kΩ

435

500

555

kHz

RFADJ = 95.3 kΩ

185

215

250

kHz

90%

93%

110

150

190

ns

DMAX

Maximum duty cycle

FSW = 500 kHz

TOFF-MIN

Minimum off-time

VFB = 0.5 V, FSW = 500 kHz

TON-MIN

Minimum controllable on-time

VFB = 0.7 V, FSW = 500 kHz

30

ns

VDD SUBREGULATOR AND BOOT

VDD

Subregulator output voltage

IVDD = 25 mA

VDDVDO

Dropout voltage

IVDD = 15 mA, VVIN = 3.0 V

4.2

150

4.7

5.3

mV

V

VDDCL

VDD current limit

VVDD = 4.0 V

106

mA

IQBOOT

CBOOT pin leakage current

VCBOOT – VSW = 4.5 V

0.5

nA

ERROR AMPLIFIER

BW-3dB

Error amplifier open-loop bandwidth

6

MHz

AVOL

Error amplifier dc gain

70

dB

ISOURCE

COMP source current

VFB = 0.5 V

1

mA

ISINK

COMP sink current

VFB = 0.7 V

100

µA

VCOMP-MAX

Maximum COMP voltage

VFB = 0.5 V

3.9

V

VCOMP-MIN

Minimum COMP voltage

VFB = 0.7 V

0.5

V

OVERCURRENT PROTECTION

VCS_OFFSET

(1)

(2)

6

Current limit comparator offset

voltage

–3.5

0

3.5

mV

All hot and cold limits are specified by correlating the electrical characteristic to process and temperature variations and applying

statistical process control.

The junction temperature (TJ in °C) is calculated from the ambient temperature (TA in °C) and power dissipation (PD in Watts) as follows:

TJ = TA + (PD × θJA) where (°C/W) is the package thermal impedance provided in the Thermal Information section.

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

�LM27403

www.ti.com

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

Electrical Characteristics (continued)

Typical values correspond to TJ = 25°C. Minimum and maximum limits apply over –40°C to +125°C junction temperature

range unless otherwise stated(1),(2). VVIN = 12 V and all parameters at zero power dissipation (unless otherwise noted).

PARAMETER

ICS

Current limit offset current

ICS-CV1

ICS-CV2

ICS compliance voltage

ICS-TC

ICS temperature coefficient

TCL-DELAY

Current limit hiccup delay

MIN

TYP

MAX

UNIT

VCS– = 3 V, ΔVBE = 59.4 mV (3), TJ = 25°C

TEST CONDITIONS

9.3

9.9

10.5

µA

VCS– = 3 V, D+ shorted to D–

3.4

5.0

VVIN – VCS–, ΔICS < 5%

Referenced to ΔVBE

6.6

µA

VVIN = 12 V

800

mV

VVIN = 3 V

800

mV

212

nA/mV

(4)

160

187

5

ms

IHG = 0.1 A (pullup)

1.5

Ω

IHG = –0.1 A (pulldown)

1.0

Ω

Source current (pullup)

1.5

A

Sink current (pulldown)

2.0

A

ILG = 0.1 A (pullup)

1.5

Ω

ILG = –0.1 A (pulldown)

0.9

Ω

Source current (pullup)

1.5

A

Sink current (pulldown)

2.0

A

15

ns

GATE DRIVERS

RDS(ON)1

RDS(ON)2

IDRV-HG-SRC

IDRV-HG-SINK

RDS(ON)3

RDS(ON)4

IDRV-LG-SRC

High-side MOSFET driver on-state

resistance

VCBOOT – VSW = 4.5 V

High-side MOSFET driver peak

current

CLOAD = 3 nF

Low-side MOSFET driver on-state

resistance

VDD = 4.5 V

IDRV-LG-SINK

Low-side MOSFET driver peak

current

TDEAD

Adaptive dead-time

CLOAD = 3 nF

SOFT-START

ISS

Soft-start source current

VSS/TRACK = 0 V

ISS-PD

Soft-start pulldown resistance

VSS/TRACK = 0.6 V

TSS-INT

Internal soft-start timeout

1.0

3.0

5.0

µA

330

Ω

1.28

ms

POWER GOOD

IPGS

PGOOD low sink current

VPGOOD = 0.2 V, VFB = 0.75 V

IPGL

PGOOD leakage current

VPGOOD = 5 V

OVT

Overvoltage threshold

VFB rising, RS tied to GND

OVTHYS

OVT hysteresis

VFB falling, RS tied to GND

UVT

Undervoltage threshold

VFB rising, RS tied to GND

UVTHYS

UVT hysteresis

VFB falling, RS tied to GND

tdeglitch

Deglitch time

VPGOOD rising and falling

70

100

µA

1

10

111% 116.5%

123%

µA

3.5%

86%

91%

97%

4%

20

µs

UVLO/ENABLE

VUVLO1

Logic low threshold

VUVLO/EN falling

0.94

0.985

1.03

V

VUVLO2

Logic high threshold

VUVLO/EN rising

1.11

1.15

1.18

V

VUVLO-HYS

UVLO/EN voltage hysteresis

VUVLO/EN falling

139

165

190

mV

IUVLO1

UVLO/EN pullup current, disabled

VUVLO/EN = 0 V

0.8

1.8

2.7

µA

IUVLO2

UVLO/EN pullup current, enabled

VUVLO/EN = 1.25 V

5.5

10.5

15.5

µA

CLOCK SYNCHRONIZATION

VIH-SYNC

SYNC pin VIH

VIL-SYNC

SYNC pin VIL

SYNCFSW-L

Minimum clock sync frequency

SYNCFSW-H

Maximum clock sync frequency

SYNCI

SYNC pin input current

2

V

0.8

200

V

kHz

1.2

MHz

1

µA

EXTERNAL TEMPERATURE SENSE AND THERMAL SHUTDOWN

ID+1

D+ pin state 1 current

10

µA

ID+2

D+ pin state 2 current

100

µA

(3)

(4)

The specified parameter is calculated based on a 2N3904 transistor at 25°C.

Multiply by 19.9 to scale from nA/mV to ppm/°C (assumes 2N3904 BJT temperature sensor with ideality factor η =1.004).

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

7

�LM27403

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

www.ti.com

Electrical Characteristics (continued)

Typical values correspond to TJ = 25°C. Minimum and maximum limits apply over –40°C to +125°C junction temperature

range unless otherwise stated(1),(2). VVIN = 12 V and all parameters at zero power dissipation (unless otherwise noted).

PARAMETER

IOTP

Remote thermal current

TEST CONDITIONS

ΔVBE = 79.3 mV (5)

Referenced to ΔVBE

(4)

MIN

TYP

MAX

UNIT

13.5

14.6

15.5

µA

187

213

nA/mV

IOTP-TC

IOTP temperature coefficient

VTRIP

Remote thermal trip point

1.15

VTRIP-HYS

Remote thermal trip point

hysteresis

80

ROTP

OTP resistance, thermal shutdown

TSHD

Internal thermal shutdown threshold Rising

TSHD-HYS

Internal thermal shutdown threshold

hysteresis

(5)

8

158

ROTP(nom) = 80.7 kΩ, ΔVBE = 79.3 mV (5), TJ =

125°C

–5%

V

mV

5%

150

°C

20

°C

The specified parameter is calculated based on a 2N3904 transistor at 125°C.

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

�LM27403

www.ti.com

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

7.6 Typical Characteristics

100

100

95

95

90

90

Efficiency (%)

Efficiency (%)

Unless otherwise stated, all datasheet curves were recorded using the circuit and powertrain designated in Figure 41 with

input and output voltages of 12 V and 1.2 V, respectively, and switching frequency of 250 kHz.

85

80

VIN = 3.3V

VIN = 5V

VIN = 12V

VIN = 20V

75

VOUT = 0.8V

85

VOUT = 1.2V

80

VOUT = 1.8V

VOUT = 3.3V

75

VOUT = 5.3V

70

70

0

5

10

15

20

25

Output Current (A)

0

15

20

25

C002

Figure 2. Efficiency Plot, VIN = 12 V

1.21

1.205

1.205

Output Voltage (V)

1.21

1.2

1.195

1.19

1.2

1.195

1.19

0

5

10

15

20

25

Output Current (A)

0

2

4

6

8

10

12

14

16

18

Input Voltage (V)

C003

Figure 3. Load Regulation

20

C005

Figure 4. Line Regulation

4

Quiescent Current (mA)

1.21

Output Voltage (V)

10

Output Current (A)

Figure 1. Efficiency Plot, VOUT = 1.2 V

Output Voltage (V)

5

C001

1.205

1.2

1.195

1.19

3.9

3.8

3.7

3.6

3.5

-50

-25

0

25

50

75

100

Temperature (C)

125

-50

Figure 5. Temperature Regulation

-25

0

25

50

75

100

Temperature (C)

C005

125

C006

Figure 6. Quiescent Current vs. Temperature, Nonswitching

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

9

�LM27403

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

www.ti.com

Typical Characteristics (continued)

Unless otherwise stated, all datasheet curves were recorded using the circuit and powertrain designated in Figure 41 with

input and output voltages of 12 V and 1.2 V, respectively, and switching frequency of 250 kHz.

340

Switching Frequency (kHz)

Shutdown Quiescent Current (PA)

40

30

20

10

0

-50

-25

0

25

50

75

100

Temperature (C)

330

320

310

300

290

280

125

-50

0

50

75

100

125

C008

Figure 8. Switching Frequency vs. Temperature

4.8

25

4.75

20

4.7

VVDD (V)

30

15

25

Temperature (C)

Figure 7. Shutdown Quiescent Current vs. Temperature

Deadtime (ns)

-25

C007

4.65

10

4.6

5

4.55

4.5

0

-50

-25

0

25

50

75

100

Temperature (C)

-50

125

-25

0

25

50

75

100

Temperature (C)

C009

Figure 9. Deadtime vs. Temperature

125

C010

Figure 10. VDD Voltage vs. Temperature

16

14

13

14

ICS (µA)

IOTP (PA)

12

12

10

11

10

9

8

8

6

7

-50

-25

0

25

50

75

100

Temperature (C)

125

±50

C011

Figure 11. OTP Current vs. Temperature

10

Submit Documentation Feedback

±25

0

25

50

75

100

Temperature (C)

125

C012

Figure 12. CS– Current vs. Temperature

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

�LM27403

www.ti.com

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

Typical Characteristics (continued)

Unless otherwise stated, all datasheet curves were recorded using the circuit and powertrain designated in Figure 41 with

input and output voltages of 12 V and 1.2 V, respectively, and switching frequency of 250 kHz.

29

14

VOUT = 3.3V

12

Current Limit (A)

28.8

ICS (PA)

10

8

6

-40°C

28.4

28.2

25°C

4

28.6

125°C

28

2

0.0

0.2

0.4

0.6

0.8

VIN ± VCS- (V)

1.0

-50

-25

0

Figure 13. CS– Current Source Compliance Voltage

25

50

75

100

Temperature (C)

C013

125

C014

Figure 14. Current Limit Inception vs. Temperature

100

IOUT

RFADJ (k:)

80

VIN = 12 V

VOUT = 1.2 V

IOUT = 0 A ± 10 A ± 0 A

FSW = 300 kHz

60

40

VOUT

20

0

200

400

600

800

1000

Switching Frequency (kHz)

1200

C015

Figure 15. Switching Frequency vs. Frequency Adjust

Resistance

Figure 16. 10-A Step Load Transient Response, 2.5-A/µs

Slew Rate

VOUT

UVLO/EN

VOUT

91% VOUT

91% VOUT

UVLO/EN

SS/TRACK

SS/TRACK

PGOOD

PGOOD

VIN = 12 V

VOUT = 1.2 V

IOUT = 0 A

FSW = 300 kHz

VIN = 12 V

VOUT = 1.2 V

IOUT = 0 A

FSW = 300 kHz

EN to SS delay

EN to SS delay

Figure 17. Start-up Characteristic

Figure 18. Prebias Start-up Characteristic

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

11

�LM27403

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

www.ti.com

Typical Characteristics (continued)

Unless otherwise stated, all datasheet curves were recorded using the circuit and powertrain designated in Figure 41 with

input and output voltages of 12 V and 1.2 V, respectively, and switching frequency of 250 kHz.

VIN = 12 V

VOUT = 1.2 V

IOUT = 7 A

FSW = 300 kHz

SW

VOUT

VOUT

UVLO/EN

IOUT

SW

VIN = 12 V

VOUT = 1.2 V

FSW = 300 kHz

IOUT

Figure 19. Shutdown Characteristic

Figure 20. Current Limit Hiccup Mode

VIN = 12 V

VOUT = 1.2 V

IOUT = 0 A

FSW = 500 kHz

VIN = 12 V

VOUT = 1.2 V

IOUT = 10 A

FSW = 500 kHz

SW

SW

SYNC

Deadtime 1

LG off to HG on

Figure 22. Switch Node Waveform

Figure 21. SYNC Waveform

12

Deadtime 2

HG off to LG on

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

�LM27403

www.ti.com

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

8 Detailed Description

8.1 Overview

The distributed power supply architecture, pervasive in myriad applications including communications

infrastructure equipment and computing systems, uses an intermediate bus and multiple downstream DC-DC

regulators dedicated and proximate to each “point-of-load.” The ASICs, FPGAs, and microprocessors that

comprise these loads have supply voltage requirements whose levels are decreasing on an absolute basis and

whose tolerance bands are decreasing on a percentage basis. The hallmarks of point-of-load (POL) DC-DC

regulators are efficiency, size, load transient response, and cost.

To this end, the LM27403 is a feature-rich, easy-to-use, synchronous PWM DC-DC step-down controller capable

of providing an ultrahigh current output for demanding, high power density POL applications. An input voltage

range of 3 V to 20 V is compatible with a wide range of intermediate bus system rails and battery chemistries;

especially 3.3-V, 5-V, and 12-V inputs. The output voltage is adjustable from 0.6 V to as high as 93% of the input

voltage, with better than ±1% feedback system regulation accuracy over the full junction temperature range. With

an accurate, adjustable and thermally compensated inductor DCR based current limit setpoint, ferrite and

composite core inductors with low DCR and small footprint can be specified to maximize efficiency and reduce

power loss. High-current gate drivers with adaptive deadtime are used for the high-side and low-side MOSFETs

to provide further efficiency gains.

The LM27403 employs a voltage-mode control loop with output voltage remote sense, input voltage feedforward

modulation, and a high gain-bandwidth error amplifier to accurately regulate the output voltage over substantial

load, line, and temperature ranges. The switching frequency is programmable between 200 kHz and 1.2 MHz

through a resistor or an external synchronization signal. The LM27403 is available in a 4-mm × 4-mm, thermally

enhanced, 24-lead WQFN PowerPad package. This device offers high levels of integration by including MOSFET

gate drivers, a low dropout (LDO) bias supply linear regulator, and comprehensive fault protection features to

enable highly flexible, reliable, energy-efficient, and high power density regulator solutions.

Multiple fault conditions are accommodated, including overvoltage, undervoltage, overcurrent, and

overtemperature. To improve overcurrent setpoint accuracy and enable easier filter inductor selection, the

LM27403 thermally compensates for the temperature coefficient (TC) of the inductor's winding resistance by

sensing the inductor temperature with an external NPN transistor configured as a thermal diode. The same

thermal diode also monitors the PCB temperature to initiate a thermal shutdown in the event that the sensed

temperature exceeds the programmed thermal shutdown setpoint.

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

13

�LM27403

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

www.ti.com

8.2 Functional Block Diagram

OTP

VIN

D+

TEMPERATURE

MONITOR

ICS 3720 ppm/°C

Thermal

Coefficient

I

IOTP

OTP

D±

1.15V

1.07V

VIN

VIN

VIN

1.8�A

+

8.7�A

2.7V

CBOOT

+

HG

ADAPTIVE DRIVER,

LEVEL SHIFTER

and

FAULT LOGIC

VIN UVLO

THERMAL

SHUTDOWN

SW

UVLO/EN

SWITCH = CLOSED

when VEN > 1.15V

+

1.15V

0.985V

4.73V

ENABLE

-

VDD

VIN

-

LG

VDD

UVLO

+

VDD

+

SYNC

GND

-

2.7V

HICCUP LOGIC

CLOCK

PLL & VCO

PGOOD

VIN

FADJ

KFF = 0.11

DIGITAL

SOFT-START

COUNTER

SS

-

546mV

+

PWM

RESET

-

RAMP

VDD

+

VIN

3�A

SS/TRACK

0.6V

REFERENCE

& LOGIC

EA

699mV

678mV

+

+

OV

ICS

+

+

UV

546mV

522mV

GND

RS

FB

OCP

Comparator

+

COMP

CS+

CS±

8.3 Feature Description

8.3.1 Input Range: VIN

The LM27403 operational input voltage range is from 3 V to 20 V. The device is intended for POL conversions

from 3.3-V, 5-V, and 12-V unregulated, semiregulated and fully regulated supply rails. It is also suitable for

connection to intermediate bus converters with output rails centered at 12 V and 9.6 V (derived from 4:1 and 5:1

primary-secondary transformer step-downs in nonregulated full-bridge converter topologies) and voltage levels

intrinsic to a wide variety of battery chemistries.

14

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

�LM27403

www.ti.com

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

Feature Description (continued)

The LM27403 uses an internal LDO subregulator to provide a 4.7-V bias rail for the gate drive and control circuits

(assuming the input voltage is higher than 4.7 V plus the necessary subregulator dropout specification).

Naturally, it can be more favorable to connect VDD directly to the input during low input voltage operation (VVIN <

5.5 V). In summary, connecting VDD to VIN during low input voltage operation provides a greater gate drive

voltage level and thus an inherent efficiency benefit. However, by virtue of the low subregulator dropout voltage,

this VDD to VIN connection is not mandatory, thus enabling input ranges from 3 V up to 20 V. The application

circuits shown below detail LM27403 configuration options suitable for several input rails.

CCS

VDD

VOUT

VIN

RC2

RFB1

CC3

23

1

SS/TRACK

2

RS

HG 17

3

FB

SW 16

4

COMP

CC1

RC1

24

CS+

CSS

CS±

DBOOT

CIN

RCS

CBOOT

CBOOT 18

RS

5

FADJ

LM27403

VOUT

QT

LG 15

6

SYNC

VDD 14

UVLO

/EN

OTP

D+

D±

PGOOD

VIN

CC2

RFADJ

CS

Q1

COUT

Q2

RFB2

RISET

7

8

9

10

11

12

D± D+

GND 13

GND

CVDD

RUV1

VIN

VIN

RUV2

COTP

ROTP

CVIN

RVIN

DEN

Figure 23. Schematic Diagram for VIN Operating Range of 3 V to 20 V

Figure 23 shows the schematic diagram for an input voltage ranging from 3 V to 20 V. Note that a finite

subregulator dropout voltage exists and is manifested to a larger extent when driving high gate charge (QG)

power MOSFETs at elevated switching frequencies. For example, at VVIN = 3 V, the VDD rail voltage is 2.8 V

with a dc operating current, IVDD, of 40 mA. Such a low gate drive rail may be insufficient to fully enhance the

power MOSFET gates. At the very least, MOSFET on-state resistance, RDS(ON), increases at such low gate drive

levels. Here are the main concerns when operating at a low input voltage:

• Increase of conduction losses (higher RDS(on) at lower VGS).

• Increase of switching losses associated with sluggish switching times when operating at low VGS levels.

• Deadtime may be larger as a result of the lower gate drive level and associated slower gate voltage slew rate.

This may become evident, for example, when using two high-side MOSFETs in a 3.3-V to 2.5-V converter

design.

• Dramatic reduction in the range of suitable MOSFETs that a designer can choose from (MOSFETs with

RDS(on) rated at VGS = 2.5 V become mandatory).

Note that the increased on-state resistance is compounded by an increase in MOSFET junction temperature,

bearing in mind the negative temperature coefficient of the MOSFET threshold voltage.

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

15

�LM27403

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

www.ti.com

Feature Description (continued)

In general, the subregulator is rated to drive the two internal gate driver stages in addition to the quiescent

current associated with LM27403 operation. Figure 24 shows the schematic diagram for lower input voltages

such as 3.0 V to 5.5 V. The LM27403's VDD and VIN pins can be tied together if the input voltage is guaranteed

not to exceed 5.5 V (absolute maximum 6 V). This short bypasses the internal LDO bias regulator and eliminates

the LDO dropout voltage and power dissipation. An RC filter from the input rail to the VIN pin, for example 2.2 Ω

and 1 µF, presents supplementary filtering at the VIN pin. Low gate threshold voltage MOSFETs are

recommended for this configuration.

CCS

VOUT

VIN

VDD

RC2

RFB1

CC3

23

1

SS/TRACK

2

RS

HG 17

3

FB

SW 16

4

COMP

CC1

RC1

24

CS+

CSS

CS±

DBOOT

CIN

RCS

CBOOT

CBOOT 18

RS

RISET

CS

Q1

LM27403

VOUT

QT

LG 15

COUT

Q2

5

FADJ

6

SYNC

VDD 14

D+

D±

PGOOD

VIN

RFADJ

OTP

RFB2

UVLO

/EN

CC2

7

8

9

10

11

12

D± D+

GND 13

CVDD

GND

VIN

COTP

ROTP

CVIN

RVIN

Figure 24. Schematic Diagram for VIN Operating Range of 3.0 V to 5.5 V

8.3.2 Output Voltage: FB Voltage and Accuracy

The reference voltage seen at the FB pin is set at 0.6 V, and a feedback system accuracy of ±1% over the full

junction temperature range is met. Junction temperature range for the device is –40°C to +125°C. While

somewhat dependent on frequency and load current levels, the LM27403 is generally capable of providing output

voltages in the range of 0.6 V to a maximum of greater than 90% VIN. The dc output voltage during normal

operation is set by the feedback resistor network, RFB1 and RFB2, connected to VOUT.

8.3.3 Input and Bias Rail Voltages: VIN and VDD

The LM27403 internal UVLOs ensure that the input rail (VIN) and bias supply rail (VDD) are charged and stable

at 2.7 V before switching begins. VDD and VIN have independent UVLO comparators, each with 250 mV of

hysteresis. There is a definite delay between UVLO power-on and switching power-on. This delay is related to

the fact that the LM27403 does not begin switching until the internal temperature sense circuitry is ready and

stabilized. The delay is four measurement cycles on D+, equivalent to 512 clock cycles.

The VDD bias supply LDO has a nominal current limit of 106 mA during normal operation. However, a lower

current limit is engaged at startup to control the rate of rise of the VDD voltage. Figure 25 shows the typical

scope waveforms of VDD and VOUT when the input voltage is instantaneously applied. Here, the VDD voltage

ramps in approximately 1.4 ms based on a 10-µF VDD decoupling capacitor and current-limited VDD feature. For

more details, please see the LM27403 EVM User's Guide, SNVU233.

16

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

�LM27403

www.ti.com

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

Feature Description (continued)

VIN

VDD

VOUT

VIN = 12 V

VOUT = 1.2 V

IOUT = 0 A

FSW = 300 kHz

VDD

startup time

Figure 25. Typical Startup Waveforms of VDD and VOUT With Controlled Ramp Rates

8.3.4 Precision Enable: UVLO/EN

The UVLO/EN pin represents a precision analog enable function for user-defined UVLO power-on input voltage

levels and to toggle the output on and off. The UVLO/EN pin is essentially a comparator-based input referenced

to a flat bandgap voltage with a fixed hysteresis of 165 mV.

The UVLO/EN pin has an internal pullup current of 1.8 µA, as shown in Figure 26. There is also a low IQ

shutdown mode when UVLO/EN is effectively pulled below a base-emitter voltage drop (approximately 0.7 V at

room temperature). This mode shuts down the bias currents of the LM27403, but the UVLO/EN pullup current

source is still available. If UVLO/EN is pulled below this hard shutdown threshold, the internal LDO regulator

powers off and the VDD rail collapses.

LM27403

VIN

VIN

VIN

1.8 �A

8.7 �A

RUV1

UVLO/EN

+

RUV2

1.15V

0.985V

UVLO

Comparator

Figure 26. Precision UVLO/Enable Circuit with Hysteretic Comparator and Pullup Current Sources

When the precision enable threshold of 1.15 V is exceeded, the UVLO/EN pullup current source increases from

1.8 µA to 10.5 µA (that is, an 8.7-µA hysteresis current). Use this feature to create a customizable UVLO

hysteresis (above the standard 165-mV fixed voltage hysteresis) based on the resistor divider from VIN to turn on

and off the LM27403 at the required input voltage levels. Also, use a capacitor from the UVLO/EN pin to GND to

implement a fixed time delay in power systems with timed sequencing requirements.

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

17

�LM27403

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

www.ti.com

Feature Description (continued)

Figure 27 shows an example using the circuit in Figure 23 where the input voltage is ramping from 0 V to 10 V in

100 ms. Here, the UVLO resistors, RUV1 and RUV2, are respectively set to 47.5 kΩ and 10 kΩ. Given these

resistances, the typical input UVLO turn-on and turn-off levels are 6.5 V and 5.2 V, respectively. The UVLO/EN

pin voltage steps at the rising and falling thresholds are defined by the UVLO/EN pin current hysteresis.

VOUT

VUVLO2

1.150V

VUVLO-HYS

VIN

VUVLO1

165mV

0.985V

UVLO/EN

Figure 27. Typical Input Voltage UVLO Turn On and Off Behavior

Given VIN(on) and VIN(off) as the input voltage turn-on and turn-off thresholds, respectively, select the UVLO

resistors using the following expressions:

V

VIN(on) UVLO1 � VIN(off)

VUVLO2

RUV1

V

IUVLO2 � IUVLO1 UVLO1

VUVLO2

(1)

RUV2

RUV1

VIN(on)

VUVLO2

� VUVLO2 � RUV1IUVLO1

(2)

The UVLO/EN pin has a maximum operating voltage rating equal to the input voltage or 5.5V, whichever is

lower. Do not exceed this rating. If the input UVLO level is set at low input voltage, it is possible that this

maximum UVLO/EN pin voltage could be exceeded at the higher end of the input voltage operating range. In this

case, use a small 4.7-V zener diode clamp, designated DEN in Figure 23, from UVLO/EN to GND, such that the

maximum operating level is never exceeded.

8.3.5 Switching Frequency

There are two options for setting the switching frequency of the LM27403, thus providing a power supply

designer a level of flexibility when choosing external components for multiple applications. To adjust the

frequency, use a resistor from the FADJ pin to GND, or synchronize the LM27403 to an external clock signal

through the SYNC pin.

8.3.5.1 Frequency Adjust: FADJ

Adjust the LM27403 free-running switching frequency by using a resistor from the FADJ pin to GND. The

switching frequency range of the device is from 200 kHz to 1.2 MHz. An open circuit at the FADJ pin forces the

frequency to the minimum value. FADJ shorted moves the frequency to its maximum value. The frequency set

resistance, RFADJ, is governed by Equation 3.

10000

RFADJ ¬ªk: ¼º

�7

0.99

Fsw ª¬kHz º¼

� 100

(3)

E96 resistors for common switching frequencies are given in Table 1.

18

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

�LM27403

www.ti.com

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

Table 1. Frequency Set Resistors

SWITCHING FREQUENCY

(kHz)

FREQUENCY SET RESISTANCE

(kΩ)

215

95.3

250

68.1

300

47.5

500

20

600

15

800

7.5

1050

4.12

1200

2.87

8.3.5.2 Clock Synchronization: SYNC

Apply an external clock synchronization signal to the LM27403 to synchronize switching in both frequency and

phase. Requirements for the clock SYNC signal are:

• Clock SYNC range: 200 kHz to 1.2 MHz

• SYNC frequency range from the FADJ frequency: up to 400 kHz (up only)

In applications where the external clock is not applied to the LM27403, use the external FADJ resistor to set the

minimum switching frequency. When the external clock is applied, it takes precedence only if the switching

frequency is greater than that set by the FADJ resistor. When the external clock is disconnected, the LM27403

switching frequency does not decrease below the minimum frequency set by the resistor. Setting a minimum

frequency in this way prevents the inductor ripple current from increasing dramatically. Externally tie SYNC to

GND if synchronization functionality is not required. The SYNC logic thresholds are based on an NMOS

threshold referenced to GND and, as such, are effectively independent of the VDD operating voltage.

Figure 28 shows a SYNC TTL signal at 600 kHz and the corresponding SW node waveform (VIN = 12 V, VOUT =

1.2 V, free-running frequency = 250 kHz). The synchronization is with respect to the rising edge of SYNC. The

rising edge of the SW voltage is phase delayed relative to SYNC by approximately 250 ns.

SW

SYNC

Figure 28. Typical 600-kHz SYNC Waveform

8.3.6 Temperature Sensing: D+ and D–

The LM27403 PWM controller offers low-cost programmable thermal protection by using remote thermal diode

temperature measurements based on the change in forward bias voltage of a diode when operated at two

different currents. The thermal diode is a discrete small-signal 2N3904 type silicon NPN BJT located (in good

thermal contact) adjacent the filter inductor.

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

19

�LM27403

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

www.ti.com

The ideality factor is a parameter in the diode I-V relationship that approaches 1.0 or 2.0 as carrier diffusion or

recombination current dominate current flow, respectively. The ideality factor for 2N3904 type diode-connected

BJTs available from several manufacturers is typically 1.004. Note that 3-terminal BJTs such as the 2N3904 are

vastly preferred over true 2-terminal diodes in this application. Discrete 2-terminal diodes with current largely

dictated by recombination have a much higher ideality factor (η = 1.2 to 1.5) than BJTs and, to such an extent,

would cause unacceptable temperature measurement error.

Switched capacitor technology is integrated in the LM27403 to sample and measure the base-emitter voltages

created by respective 10-µA and 100-µA bias currents flowing from the D+ to D– pins. The difference in these

voltages, termed ΔVBE, is readily extracted and the sensed temperature is calculated noting that ΔVBE is directly

proportional to temperature as follows:

hkT æ Ihigh ö

VBE(high) - VBE(low ) =

ln ç

÷÷

çI

q

è low ø

where

•

•

•

•

•

•

k = Boltzmann’s constant, 1.3806488 × 10-23J/K (Joules/Kelvin)

T = absolute temperature in Kelvin (K)

q = electron charge = 1.602176 x 10-19 C (Coulombs)

η = diode ideality factor = 1.004

Ilow = bias current in state 1 = 10 µA

Ihigh = bias current in state 2 = 100 µA

(4)

The source currents from the D+ pin during state 1 and state 2 are 10 µA and 100 µA, respectively. The sensed

temperature in Kelvin becomes:

qDVBE

T =

hk ln (10 )

(5)

Figure 29 shows the 2N3904 VBE voltage at ambient temperatures of –40°C, 25°C and 125°C. The low and high

states in VBE voltage correspond to the 10-µA and 100-µA currents sourced from D+, each of 64 clock cycle

duration. The voltage level is sampled at the end of each state. While the dc level of the VBE voltage decreases

logarithmically with increasing temperature, the ΔVBE amplitude increases with and is directly proportional to

temperature according to Equation 5.

ûVBE = 46.4 mV

-40°C

ûVBE = 59.4 mV

25°C

ûVBE = 79.3 mV

125°C

Figure 29. Typical 2N3904 Base-Emitter Voltage at –40°C, 25°C and 125°C

Note that D– is essentially a kelvin connection to the remote thermal diode. As such, the D– pin needs to be tied

to GND at the LM27403; the D– trace should not connect to any of the PCBs current-carrying ground planes.

20

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

�LM27403

www.ti.com

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

8.3.7 Thermal Shutdown: OTP

A current proportional to the sensed temperature is sourced from the OTP pin. The resultant voltage at the OTP

pin (set by a resistor connected from OTP to GND) is compared to an internal shutdown threshold of 1.15 V with

80-mV hysteresis. When the threshold is exceeded, the device stops switching until the sensed temperature

drops to a level where the OTP pin voltage falls to the restart threshold. The external thermal protection is

disabled by grounding the OTP pin. The thermal shutdown setpoint is governed by Equation 6:

398

ROTP = ROTP(125°C)

TOTP (°C) + 273

where

•

•

•

ROTP is the required resistance at the OTP pin for the desired thermal shutdown temperature

ROTP(125°C) is the nominal resistance at the OTP pin , 80.7 kΩ, for 125°C thermal shutdown, and

TOTP is the desired thermal shutdown temperature.

(6)

For example, the OTP resistor required for a thermal shutdown setpoint of 105°C is calculated as shown in

Equation 7:

398

ROTP

80.7 k

��� N

105 � 273

(7)

A 100-nF capacitor connected in parallel with ROTP is required. When the IC detects an overtemperature event, it

responds with the normal hiccup-mode sequence of events when going into shutdown. More specifically, the

following steps occur when an internal or external OTP event is detected:

1. The high-side MOSFET immediately turns off.

2. An internal zero-cross circuit is enabled to detect whether the inductor current is positive or negative:

(a) If the current is negative, the low-side MOSFET immediately turns off.

(b) If the current is positive, the low-side MOSFET turns off when the inductor current ramps down to zero.

Note that it is important to prevent water-soluble flux residues from contaminating the PCB during the

manufacturing process. Contaminants such as these can result in unexpected leakage currents and consequent

temperature-measurement errors.

8.3.8 Inductor-DCR-Based Overcurrent Protection

The LM27403 exploits the filter inductor DCR to detect overcurrent events. This technique enables lossless and

continuous monitoring of the output current using an RC sense network in parallel with the inductor. DCR current

sensing allows the system designer to use inductors specified with low tolerance DCRs to improve the current

limit setpoint accuracy. A dc current limit setpoint accuracy within the range of 10% to 15% is easily achieved

using inductors with low DCR tolerances.

8.3.9 Current Sensing: CS+ and CS–

As mentioned, the LM27403 implements an inductor DCR lossless current sense scheme designed to provide

both accurate overload (current limit) and short-circuit protection. Figure 30 shows the popular inductor DCR

current sense method. Figure 31 shows an implementation with current shunt resistor, RISNS.

Components RS and CS in Figure 30 create a low-pass filter across the inductor to enable differential sensing of

the inductor DCR voltage drop. When RSCS is equal to L/Rdcr, the voltage developed across the sense capacitor,

CS, is a replica of the inductor DCR's voltage waveform. Choose the capacitance of CS greater than 0.1 µF to

maintain low impedance of the sense network, thus reducing the susceptibility of noise pickup from the switch

node.

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

21

�LM27403

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

www.ti.com

VIN

VIN

CS

RS

L

L

Rdcr

RISNS

VOUT

VOUT

To Load

To Load

GND

GND

Figure 30. Current Sensing Using Inductor DCR

Figure 31. Current Sensing Using Shunt Resistor

The current limit circuit arrangement is portrayed in Figure 32. The current limit setpoint is set by a single

external resistor, RISET, connected from the CS– pin to the output voltage terminal. The current sourced from

CS– in combination with this series resistance sets the reference voltage to the current limit comparator, as

governed by Equation 8.

'i ·

§

Rdcr ¨ IOCP � L ¸

2 ¹

©

RISET

ICS

where

•

•

•

ICS is the CS– pin current, 9.9 µA typically at 25°C

IOCP is the dc overcurrent protection setpoint, and

ΔiL is the peak-to-peak inductor ripple current.

(8)

Inductor DCR temperature compensation is automatically provided using the remote-diode sensed temperature.

The temperature coefficient (TC) of the inductor winding resistance is typically 3720 ppm/°C. The current-limit

setpoint is maintained essentially constant over temperature by the slope of CS– pin current over temperature.

An increase in sensed DCR voltage associated with an increase of inductor winding temperature is matched by a

concomitant increase in current limit comparator reference voltage. The inductor temperature is measured by

placing an external diode-connected 2N3904 discrete NPN transistor, designated QT in Figure 32, in close

proximity to the inductor (see the Temperature Sensing: D+ and D– section for more details).

CCS

VIN CS±

CS+

24

12

+

VIN

23

RCS

RISET

CS

RS

ICS(T)

HG 17

L

Rdcr

+

SW 16

+

-

VOUT

QT

CL

Comparator

LM27403

±

LG 15

D+

D±

9

10

GND 13

GND

Cd

Figure 32. Current-Limit Setpoint Defined by Current Source ICS and Resistor RISET

22

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

�LM27403

www.ti.com

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

Note that the inductor DCR is shown schematically as a discrete element in Figure 30 and Figure 32. The

current-sense comparator inputs operate at common mode up to the input rail voltage. The comparator

incorporates a very low input-referred offset to reduce the SNR of the voltage detected across the inductor DCR.

The CS– pin current is specified down to a headroom compliance voltage of less than 0.8 V (that is, VVIN – VCS–)

and over the full operating temperature range (see the Electrical Characteristics Table and Figure 13). The

current source is powered from the input to allow the current limit circuit to work in high duty cycle applications.

With power inductors selected to provide lowest possible DCR to minimize power losses, the typical DCR ranges

from 0.4 mΩ to 4 mΩ. Then, given a load current of 25 A, the voltage presented across the CS+ and CS– pins

ranges between 10 mV and 100 mV. Note that this small differential signal is superimposed on a large commonmode signal that is the dc output voltage, which makes the current sense signal challenging to process. To aid in

rejection of high frequency common-mode noise, a series resistor, RCS, of same resistance as RISET, is added to

the CS+ signal path as shown in Figure 32. A small capacitor, CCS, added across CS+ and CS– provides

differential filtering.

A current sense (or current shunt) resistor in series with the inductor can also be implemented at lower output

current levels to provide accurate overcurrent protection, see Figure 31. Burdened by the unavoidable efficiency

penalty and/or additional cost implications, this configuration is not usually implemented in high-current

applications (except where OCP setpoint accuracy and stability over the operating temperature range are critical

specifications). However, if a shunt resistor is used, temperature compensation is not required. In this case, short

the D+ to D– pins to disable this function. The current sourced from CS– in this case becomes 5 µA (typical) and

is independent of temperature.

In the PCB layout, component pads are recommended to install a small capacitor, designated Cd in Figure 32,

between the D+ and D– pins as close to the LM27403 as possible. This capacitor should not exceed 1 nF for

2N3904-type devices. Locate an additional capacitor, typically 100 pF, at the BJT, when operating in noisy

environments (for example, where leakage flux from the airgap of a ferrite inductor may couple into the adjacent

circuit board traces).

8.3.10 Current Limit Handling

The LM27403 implements a hiccup mode to allow the device to cool down during overcurrent events. If five

overcurrent events are detected during any 32 clock cycle interval, the LM27403 shuts down and stops switching

for a period of 5 ms. During this time, negative inductor current is not allowed, and the output cannot swing

negative. After 5 ms, the LM27403 starts up in the normal startup routine at an output voltage ramp rate

determined by the internal soft-start function or the external soft-start capacitor (if one is used). With each

detected current limit event, the high-side MOSFET is turned off and the low-side MOSFET is turned on.

8.3.11 Soft-Start: SS/TRACK

After the UVLO/EN pin exceeds the rising threshold of 1.15 V, the LM27403 begins charging the output to the dc

level dictated by the feedback resistor network. The LM27403 features an adjustable soft-start (set by a capacitor

from the SS/TRACK pin to GND) that determines the charging time of the output. A 3-µA current source charges

this soft-start capacitor. Soft-start limits inrush current as a result of high output capacitance and avoids an

overcurrent condition. Stress on the input supply rail is also reduced. The soft-start time, tSS, for the output

voltage to ramp to its nominal level is set by Equation 9:

CSS VREF

t SS

ISS

where

•

•

•

CSS is the soft-start capacitance

VREF is the 0.6-V reference, and

ISS is the 3-µA current sourced from the SS/TRACK pin.

(9)

If a soft-start capacitor is not used, then the LM27403 defaults to a minimum internal soft-start time of 1.28 ms

and provides a resolution of 128 steps. Thus, the internal soft-start dictates the fastest startup time for the circuit.

When the SS/TRACK voltage exceeds 91% of the reference voltage, the Power Good flag transitions high.

Conversely, the Power Good flag goes low when the SS/TRACK voltage goes below 87% of the reference.

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

23

�LM27403

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

www.ti.com

8.3.11.1 Tracking

The SS/TRACK pin also doubles as a tracking pin when master-slave power-supply tracking is required. This

tracking is achieved by simply dividing down the master's output voltage with a simple resistor network.

Coincident, ratiometric, and offset tracking modes are possible.

If an external voltage source is connected to the SS/TRACK pin, the external soft-start capability of the LM27403

is effectively disabled (the internal soft-start is still enabled). The regulated output voltage level is reached when

the SS/TRACK pin reaches the 0.6-V reference voltage level. It is the responsibility of the system designer to

determine if an external soft-start capacitor is required to keep the device from entering current limit during a

startup event. Likewise, the system designer must also be aware of how fast the input supply ramps if the

tracking feature is enabled.

Figure 33 shows a triangular voltage signal directly driving SS/TRACK and the corresponding output voltage

tracking response. Nominal output voltage here is 1.2 V, with channel scales chosen such that the waveforms

overlap during tracking. As expected, the PGOOD flag transitions at thresholds of 91% (rising) and 87% (falling)

of the nominal output voltage setpoint.

PGOOD

SS/TRACK

91% VOUT

VOUT

87% VOUT

Figure 33. Typical Output Voltage Tracking Waveforms and PGOOD Flag

Two practical tracking configurations, ratiometric and coincident, are shown in Figure 34. The most common

application is coincident tracking, used in core vs. I/O voltage tracking in DSP and FPGA implementations.

Coincident tracking forces the master and slave channels to have the same output voltage ramp rate until the

slave output reaches its regulated setpoint. Conversely, ratiometric tracking sets the slave's output voltage to a

fraction of the master's output voltage during startup.

VOUTMASTER = 3.3 V

VOUTSLAVE2 = 1.2 V

VOUTSLAVE1 = 1.8 V

LM27403

LM27403

RTRACK1

41.2 k

1 SS/TRACK

0.65 V

RTRACK1

20 k

RFB1

20 k

FB

3

0.6 V

1

1.5 V

RFB2

10 k

RTRACK2

10 k

Slave Regulator #1

Ratiometric Tracking

RFB1

20 k

SS/TRACK

FB

RTRACK2

20 k

3

0.6 V

RFB2

20 k

Slave Regulator #2

Coincident Tracking

Figure 34. Tracking Implementation With Master, Ratiometric Slave and Coincident Slave Rails

24

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

�LM27403

www.ti.com

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

For coincident tracking, connect the slave regulator's SS/TRACK input to a resistor divider from the master's

output voltage that is the same as the divider used on the slave's FB pin. In other words, simply select RTRACK1 =

RFB1 and RTRACK2 = RFB2 as shown in Figure 34. As the master voltage rises, the slave voltage rises identically.

Eventually, the slave voltage reaches its regulation voltage, at which point the internal reference takes over the

regulation while the SS/TRACK input continues to increase, thus removing itself from changing the output

voltage.

In all cases, to ensure that the output voltage accuracy is not compromised by the SS/TRACK voltage being too

close to the 0.6-V reference voltage, the final value of the slave's SS/TRACK voltage should be at least 20 mV

above FB.

8.3.12 Monotonic Startup

The LM27403 has monotonic startup capability with no dips or flat spots in the output voltage waveform during

startup (including prebiased startup) and fault recovery. During the soft-start interval, FB follows SS/TRACK, and

the output voltage linearly increases to the nominal output setpoint. Figure 35 illustrates the output voltage

behavior during a monotonic startup to a nominal level of 1.2V. The UVLO/EN pin is driven high by a TTL logic

signal. As mentioned previously, the startup time is determined by the use of an external soft-start capacitor at

the SS/TRACK pin charged by an internally generated 3-µA constant current source. If a soft-start capacitor is

not used, the device automatically enables the internal 7-bit (128 step) digital soft-start. The PGOOD flag

transitions high when FB reaches its 91% threshold. As described previously, there is a calibration interval based

on four cycles on the D+ pin (that is, 512 clock cycles) that creates a delay from UVLO/EN crossing its precision

threshold to SS/TRACK being released.

VOUT

UVLO/EN

SS/TRACK

COMP

valley of PWM ramp

lower COMP clamp

EN to SS delay

Figure 35. Typical Monotonic Output Voltage Startup Waveforms, 1.2-V Output

8.3.13 Prebias Startup

In certain applications, the output voltage may have an initial voltage prebias before the LM27403 is powered on

or enabled. The LM27403 is able to startup into a prebiased load while maintaining a monotonic output voltage

startup characteristic.

The LM27403 does not allow switching until the SS/TRACK pin voltage has reached the feedback (FB) voltage

level. Once this level is reached, the controller begins to regulate and switch synchronously, allowing a certain

amount of negative current during PWM switching operation. Thereafter, the feedback voltage follows the softstart voltage up to 0.6 V. This is illustrated in Figure 36 where nominal output voltage is 1.2 V and the output

voltage waveform represents twice the FB level. The output is not pulled low during a prebiased startup

condition. Note that if the output is prebiased to a higher voltage than the nominal level (as set by the feedback

resistor divider), the LM27403 does not pull the output low, hence eliminating current flow through parasitic paths

in the system.

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

25

�LM27403

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

www.ti.com

VOUT

UVLO/EN

SS/TRACK

COMP

valley of PWM ramp

lower COMP clamp

EN to SS delay

Figure 36. Typical Startup Waveforms With 0.6-V Prebiased Output, 1.2-V Nominal Output

The LM27403 automatically pulls down the SS/TRACK pin to GND before the onset of switching and during a

restart from a fault condition. When SS/TRACK is initially released, subsequent to the temperature sense

calibration delay, the COMP voltage is released to the lower COMP clamp level and no switching occurs. Both

the LG and HG pins are held low while the SS/TRACK voltage stays below the FB voltage level. This action

ensures that a prebiased load is not pulled down by a negative dc output current component. When the

SS/TRACK pin voltage crosses above either FB or VREF, the COMP voltage slews up to the valley of the PWM

ramp and switching begins.

8.3.14 Voltage-Mode Control

The LM27403 incorporates a voltage-mode control loop implementation with input voltage feedforward to

eliminate the input voltage dependence of the PWM modulator gain. This configuration allows the controller to

maintain stability throughout the entire input voltage operating range and provides for optimal response to input

voltage transient disturbances. The constant gain provided by the controller greatly simplifies feedback loop

design because loop characteristics remain constant as the input voltage changes, unlike a buck converter

without voltage feedforward. An increase in input voltage is matched by a concomitant increase in ramp voltage

amplitude to maintain constant modulator gain. The input voltage feedforward gain, kFF, is 1/9, equivalent to the

ramp amplitude divided by the input voltage, VRAMP/VIN. See the Control Loop Compensation section for more

detail.

8.3.15 Output Voltage Remote Sense: RS

High-current switching power supplies typically use output voltage remote sensing to achieve the greatest

accuracy at the point of load. There are usually some finite bus structure resistances between the power supply

and load, denoted by lumped elements RBUS+ and RBUS– in Figure 37, that cause unwanted voltage drops or load

regulation errors, particularly at high output currents.

26

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: LM27403

�LM27403

www.ti.com

SNVS896B – AUGUST 2013 – REVISED NOVEMBER 2014

DC/DC Regulator

VIN

Bandgap

Reference

LM27403

PWM

Comparator

Error

Amplifier

13

GND

2

RS

3

CC2

FB

HG

Adaptive

Gate

Driver &

Logic

SW

LG

17

RBUS+

VOUT-

RBUS±

15

4

COMP

GND

CRS

VOUT+

16

LOAD

REF

+

CC1

RC1

CC3

RC2

RSENSE+

SENSE+

RFB1

RFB2

SENSE±

RSENSE±

Figure 37. LM27403 Output Remote Sense and Voltage Control Loop

Remote ground sensing is implemented in the LM27403 by bringing another amplifier input, designated RS,