Click here for production status of specific part numbers.

MAX25612/MAX25612B

General Description

The MAX25612/MAX25612B are single-channel highbrightness LED (HB LED) drivers for automotive frontlight applications such as high beam, low beam, daytime

running light (DRL), turn indicator, fog light and other LED

lights. They can take an input voltage from 5V to 48V and

can drive a string of LEDs with a maximum output voltage

of 60V. The MAX25612/MAX25612B are fully synchronous

and are suitable for boost, buck-boost, SEPIC, and highside buck applications that need synchronous rectification

providing efficiencies greater than 90%.

The MAX25612/MAX25612B sense output current at

the high side of the LED string. High-side current

sensing is required to protect against shorts from the

output to the ground or battery input. It is also the most

flexible scheme for driving LEDs, allowing boost, highside buck, or buck-boost mode configurations. The

PWM input provides LED dimming ratios of up to

5000:1, and the ICTRL input provides additional analog

dimming capability in the MAX25612/MAX25612B.

The MAX25612/MAX25612B also include a FLT flag

that indicates open string, shorted string, and thermal

shutdown. The MAX25612/MAX25612B have built-in

spread-spectrum modulation for improved electromagnetic

compatibility

performance. The MAX25612/

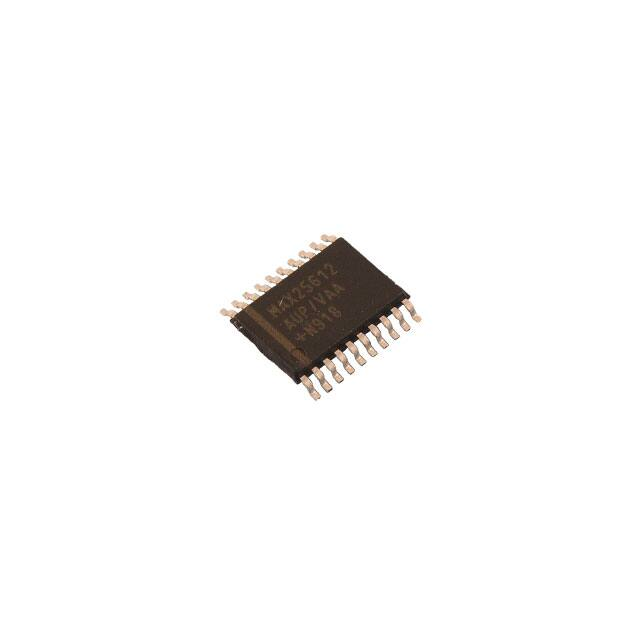

MAX25612B are available in a space-saving (4mm x

4mm), 20-pin side-wettable TQFN or a 20-pin TSSOP

package and are specified to operate over the -40°C to

+125°C automotive temperature range.

Applications

●● Automotive Exterior Lighting:

• High-Beam/Low-Beam/Signal/Position Lights

• Daytime Running Lights (DRLs)

• Fog Light and Adaptive Front-Light Assemblies

Automotive Synchronous

High Voltage LED Controller

●● Simple to Optimize for Efficiency, Board Space, and

Input Operating Range

• Synchronous MOSFET Driver Improves Efficiency

by up to 5% for High-Current Boost, Buck-Boost,

SEPIC, and High-Side Buck Applications

• Programmable Switching Frequency (200kHz to

2.2MHz)

• 20-Pin TSSOP Package with Exposed Pad

and Thermally Enhanced 4mm x 4mm, 20-Pin

Side-Wettable TQFN Packages

●● Protection Features Increase System Reliability

• Short Circuit, Overvoltage and Thermal Protection

• Fault Diagnosis through Fault Flag

●● Automotive Ready

• -40ºC to +125ºC Operating Temperature Range

• AEC-Q100 Qualified

Simplified Typical Operating Circuit

L1

VIN

ROVP1

CBST

IN

UVEN

VCC

BST

DH

LX

MAX25612/

MAX25612B

P1

COUT

N1

DL

CSP

RCS_LED

N2

RSC

ROVP2

RCS_FET

CSN

PGND

OVP

ISENSE+

FLT

ISENSEPWMDIM

DIMOUT

ICTRL

COMP

RT

SGND EP

RCOMP

CCOMP_HF

CCOMP

●● Commercial, Industrial, and Architectural Lighting

Benefits and Features

●● Integration Minimizes BOM and Cost

• +5.0V to +48V Wide Input Voltage Range with a

Maximum +65V Boost Output

• Integrated pMOS Dimming FET Driver

• ICTRL Input for Analog Dimming

• Integrated High-Side Current-Sense Amplifier

• 200Hz Ramp Generator Simplifies PWM Dimming

19-100543; Rev 4; 1/20

Ordering Information appears at end of data sheet.

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

Absolute Maximum Ratings

IN, UVEN to PGND................................................-0.3V to +52V

ISENSE+, ISENSE-, DIMOUT to PGND................-0.3V to +65V

ISENSE- to ISENSE+............................................-0.6V to +0.3V

BST, DH to PGND..................................................-0.3V to +70V

LX to PGND...........................................................-0.3V to +65V

BST to LX.................................................................-0.3V to +6V

DH to LX........................................................ -0.3V to VCC+0.3V

DL to PGND.................................................. -0.3V to VCC+0.3V

CSP, CSN to SGND...................................... -0.3V to VCC+0.3V

CSP-CSN..............................................................-0.3V to +0.3V

COMP, RT to SGND........................................-0.3V to Vcc+0.3V

VCC to SGND...........................................................-0.3V to +6V

SGND to PGND.....................................................-0.3V to +0.3V

OVP, FLT, ICTRL, PWMDIM to SGND.....................-0.3V to +6V

Continuous Current on IN.................................................100mA

Continuous Current on DL.................................................+50mA

Short Circuit Duration on VCC....................................Continuous

Continuous Power Dissipation (20-Pin TSSOP) (TA =

+70°C, derate 26mW/°C above +70°C.)....................2122mW

Continuous Power Dissipation (20-Pin TQFN SW) (TA =

+70°C, derate 25.6mW/°C above +70°C.).................2050mW

Operating Temperature Range.......................... -40°C to +125°C

Junction Temperature.......................................................+150°C

Storage Temperature Range............................. -65°C to +150°C

Lead Temperature (Soldering, 10s).................................. +300ºC

Soldering Temperature (Reflow).......................................+260°C

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these

or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended periods may affect

device reliability.

Package Information

20-TSSOP

PACKAGE CODE

U20E+3C

Outline Number

21-100132

Land Pattern Number

90-100049

Thermal Resistance, Single-Layer Board:

Junction to Ambient (θJA)

46ºC/W

Junction to Case (θJC)

2ºC/W

Thermal Resistance, Four-Layer Board:

Junction to Ambient (θJA)

37ºC/W

Junction to Case (θJC)

2ºC/W

20-TQFN SW

PACKAGE CODE

T2044Y+3C

Outline Number

21-100068

Land Pattern Number

90-0037

Thermal Resistance, Single-Layer Board:

Junction to Ambient (θJA)

59ºC/W

Junction to Case (θJC)

6ºC/W

Thermal Resistance, Four-Layer Board:

Junction to Ambient (θJA)

39ºC/W

Junction to Case (θJC)

6ºC/W

For the latest package outline information and land patterns (footprints), go to www.maximintegrated.com/packages. Note that a “+”,

“#”, or “-” in the package code indicates RoHS status only. Package drawings may show a different suffix character, but the drawing

pertains to the package regardless of RoHS status.

Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-layer board.

For detailed information on package thermal considerations, refer to www.maximintegrated.com/thermal-tutorial.

www.maximintegrated.com

Maxim Integrated │ 2

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

Electrical Characteristics

(VIN = 12V, CIN = CVCC = 1μF, DL = COMP = DIMOUT = PWMDIM = FLT = unconnected, VOVP = VCS = VPGND = VSGND = 0V,

VISENSE+ = VISENSE- = 45V, VICTRL = 1.40V, TA = TJ = -40ºC to +125ºC, unless otherwise noted. Typical values are at TA = +25ºC

(Note 2))

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

Supply Voltage

Operational Supply Voltage

VIN

Supply Current

IINQ

5

VOVP = 1.5V, no switching

48

V

1.8

5

mA

1.24

1.37

V

Undervoltage Lockout

Undervoltage Lockout Rising

VUVEN_THUP

Undervoltage Lockout Hysteresis

Hys

VUVEN rising

1.12

106

mV

VCC Regulator

Regulator Output Voltage

Undervoltage Lockout

VCC

VCC_UVLOR

IVCC = 0.1mA to 50mA,

6V < VIN < 16V

4.875

rising

Undervoltage Lockout Hysteresis

5.0

5.125

V

4.0

V

0.4

V

Oscillator (RT)

Switching Frequency Range

fSW

Bias Voltage at RT

VRT

Minimum OFF time

VCOMP = HIGH, VCS = 0V

Oscillator Frequency Accuracy

Frequency Dither

200

(dither disabled)

fDITH

Dither enabled, fsw = 200kHz to 2.2MHz

ISLOPE

Peak current ramp added to CS input per

switching cycle

2200

kHz

1.25

V

85

ns

-10

+10

±6

%

%

Slope Compensation

Slope-Compensation Current

Ramp Height

42.5

50

57.5

μA

1.2

V

V

Analog Dimming

ICTRL Input Control Voltage

Range

ICTRL Zero Current Threshold

ICTRL Clamp Voltage

ICTRL Input Bias Current

ICTRLRNG

ICTRLZC_VTH

0.2

(VISENSE+ - VISENSE-) < 5mV

0.16

0.18

0.2

ICTRLCLMP

ICTRL sink = 1μA

1.25

1.30

1.35

V

ICTRLIIN

VICTRL < = 5.5V

-500

20

500

nA

-0.2

+60

V

0

225

mV

LED Current-Sense Amp

Common-Mode Input Range

Differential Signal Range

ISENSE+ Input Bias Current

IBISENSE+

(VISENSE+ - VISENSE-) = 200mV, VISENSE+ = 60V

ISENSE- Input Bias Current

IBISENSE-

(VISENSE+ - VISENSE-) = 200mV, VIBSENSE- = 60V

Voltage Gain

www.maximintegrated.com

(VISENSE+ - VISENSE-) = 200mV,

3V < [VISENSE+, VISENSE-] < 60V

4.9

350

550

μA

22

60

μA

5.0

5.1

V/V

Maxim Integrated │ 3

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

Electrical Characteristics (continued)

(VIN = 12V, CIN = CVCC = 1μF, DL = COMP = DIMOUT = PWMDIM = FLT = unconnected, VOVP = VCS = VPGND = VSGND = 0V,

VISENSE+ = VISENSE- = 45V, VICTRL = 1.40V, TA = TJ = -40ºC to +125ºC, unless otherwise noted. Typical values are at TA = +25ºC

(Note 2))

PARAMETER

LED Current-Sense Regulation

Voltage

SYMBOL

VSENSE

LED Current-Sense Regulation

Voltage (Low Range)

VSENSE

Common-Mode Input Range

Selector

RNGSEL

CONDITIONS

MIN

TYP

MAX

VICTRL = 1.3V,

3V < [VISENSE+, VISENSE-] < 60V

213.8

220

226.2

VICTRL = 1.2V,

3V < [VISENSE+, VISENSE-] < 60V

194

200

206

VICTRL = 0.4V,

3V < [VISENSE+, VISENSE-] < 60V

36

40

44

VICTRL = 1.2V,

0V < [VISENSE+, VISENSE-] < 3V

192

200

208

VICTRL = 0.4V,

0V < [VISENSE+, VISENSE-] < 3V

35

40

45

VISENSE+ rising

2.72

2.85

2.98

VISENSE+ falling

2.48

2.6

2.72

(VISENSE+ - VISENSE-) = 200mV

1170

1800

2430

UNITS

mV

mV

V

ERROR AMP

Transconductance

gM

μS

COMP Sink Current

COMPISINK

VCOMP = 5V

300

μA

COMP Source Current

COMPISRC

VCOMP = 0V

300

μA

1

V

PWM Comparator

Input Offset Voltage

CS Limit Comparator

Current-Limit Threshold

VCS_LIMIT

190

210

230

mV

Gate Drivers (DH and DL)

RDS(ON) Pullup pMOS

1.3

Ω

RDS(ON) Pulldown nMOS

0.9

Ω

PWM Dimming

Internal Ramp Frequency

fRAMP

160

External Sync Frequency

Range

fDIM

60

External Sync Low-Level Voltage

VLTH

External Sync High-Level Voltage

VHTH

2.0

DIM Comparator Offset Voltage

VDIMOFS

170

DIM Voltage for 100% Duty

Cycle

www.maximintegrated.com

3.3

200

240

Hz

2000

Hz

0.4

V

V

200

230

mV

V

Maxim Integrated │ 4

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

Electrical Characteristics (continued)

(VIN = 12V, CIN = CVCC = 1μF, DL = COMP = DIMOUT = PWMDIM = FLT = unconnected, VOVP = VCS = VPGND = VSGND = 0V,

VISENSE+ = VISENSE- = 45V, VICTRL = 1.40V, TA = TJ = -40ºC to +125ºC, unless otherwise noted. Typical values are at TA = +25ºC

(Note 2))

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

pMOS Gate Driver (DIMOUT)

Peak Pullup Current

IDIMOUTPU

VPWMDIM = 0V, (VISENSE+ - VDIMOUT)

= 7V

40

73

120

mA

Peak Pulldown Current

IDIMOUTPD

(VISENSE+ - VDIMOUT) = 0V

15

35

65

mA

-8.4

-7.4

-6.1

V

1.23

1.29

V

DIMOUT Low Voltage with

Respect to ISENSE+

Overvoltage Protection (OVP)

OVP Threshold Rising

VOVP

Output rising

1.17

IBOVP

VOVP = 1.235V

-500

(VISENSE+ - VISENSE-)

369

Hysteresis

Input Bias Current

70

mV

+500

nA

427

mV

Short-Circuit Hiccup Mode

Short-Circuit Threshold

Hiccup Time

VSHORT-HIC

THICCUP

398

Clock

Cycles

8192

Buck-Boost Short Detect

Buck-Boost Short Detect

Threshold (MAX25612 only)

VSHORT-VOUT (VISENSE+ - VIN) falling, VIN = 12V

1.15

1.55

1.95

V

VIN = 4.75V, VOVP = 2V, ISINK = 5mA

68.6

200

mV

Temperature rising

165

ºC

10

ºC

Open-Drain Fault (FLT)

Output Voltage Low

VOL-FLT

Thermal Shutdown

Thermal Shutdown Temperature

TSHDN

Thermal Shutdown Hystersis

Note 1: All devices are 100% tested at TA = +25ºC. Limits over temperature are guaranteed by design

www.maximintegrated.com

Maxim Integrated │ 5

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

Typical Operating Characteristics

(VIN = 13.5V, TA = 25ºC unless otherwise noted.)

www.maximintegrated.com

Maxim Integrated │ 6

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

Typical Operating Characteristics (continued)

(VIN = 13.5V, TA = 25ºC unless otherwise noted.)

www.maximintegrated.com

Maxim Integrated │ 7

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

ISENSE+

IN

BST

DH

LX

VCC

DL

PGND

CSP

CSN

Pin Configurations

20

19

18

17

16

15

14

13

12

11

TOP VIEW

MAX25612/

MAX25612B

EP

www.maximintegrated.com

9

SGND

10

COMP

8

ICTRL

OVP

7

TSSOP

PGND

PWMDIM

RT

UVEN

6

DL

DIMOUT

TOP VIEW

5

VCC

4

FLT

3

LX

2

DH

1

ISENSE-

+

15

14

13

12

11

BST

16

10

CSP

IN

17

9

CSN

ISENSE+

18

8

COMP

ISENSE-

19

7

SGND

DIMOUT

20

6

ICTRL

MAX25612/

MAX25612B

1

2

3

4

5

UVEN

PWMDIM

FLT

RT

OVP

+

TQFN

4mm × 4mm

Maxim Integrated │ 8

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

Pin Description

PIN

NAME

FUNCTION

19

ISENSE-

Negative LED Current-Sense Input. A 100Ω resistor is recommended to be placed in series

with ISENSE- input and the negative terminal of the LED current-sense resistor.

20

DIMOUT

External Dimming pMOS Gate Driver

TSSOP

TQFN

1

2

3

1

UVEN

Undervoltage-Lockout (UVLO) Threshold/Enable Input. UVEN is a dual-function adjustable UVLO threshold input with an enable feature. Connect UVEN to VIN through a resistive

voltage-divider to program the UVLO threshold. Observe the absolute maximum value for

this pin.

Dimming Control Input. Connect PWMDIM to an external PWM signal for PWM dimming.

For analog-voltage-controlled PWM dimming, connect PWMDIM to VCC through a resistive

voltage-divider. The dimming frequency is 200Hz under these conditions. Connect PWMDIM to SGND to turn off the LEDs.

4

2

PWMDIM

5

3

FLT

Active-Low, Open-Drain Fault Indicator Output. See the Fault Indicator (FLT) section.

6

4

RT

PWM Switching Frequency Programming. Connect a resistor (RRT) from RT to SGND to

set the internal clock frequency.

7

5

OVP

Overvoltage Protection Input. Connect a resistive divider between the converter output,

OVP, and ground. When the voltage on OVP exceeds 1.23V, a fast-acting comparator immediately stops PWM switching. This comparator has hysteresis of 70mV.

8

6

ICTRL

Analog Dimming Control Input. The voltage at ICTRL sets the LED current level when

VICTRL < 1.25V. This voltage reference can be set using a resistor-divider from VCC to

SGND. For VICTRL > 1.25V, the internal reference sets the LED current.

9

7

SGND

Signal Ground

10

8

COMP

Compensation Network Connection. For proper compensation connect a suitable RC network from COMP to SGND.

11

9

CSN

Current-Sense Amplifier Negative Input for the Switching Regulator

12

10

CSP

Current-Sense Amplifier Positive Input for the Switching Regulator. Add a series resistor

from CSP to the switching MOSFET current-sense resistor terminal for programming the

slope compensation.

13

11

PGND

14

12

DL

15

13

VCC

16

14

LX

Switch Node of the Converter

17

15

DH

High-Side nMOS Gate Driver Output

18

16

BST

Bootstrap Supply Input for the High-Side Driver

19

17

IN

20

18

ISENSE+

Positive LED Current-Sense Input. The voltage between ISENSE+ and ISENSE- is proportionally regulated to the lesser of (VICTRL, 1.23V).

-

-

EP

Exposed Pad. Connect EP to the ground plane for heatsinking. Do not use EP as the only

electrical connection to ground

www.maximintegrated.com

Power Ground

Low-Side nMOS Gate Driver Output

5V Low-Dropout Voltage Regulator Output. VCC supplies the bias current for the gate drive

and internal control logic. Bypass VCC to GND with a 4.7µF and a 0.1µF ceramic capacitor.

Positive Power-Supply Input. Bypass with a 1µF ceramic capacitor to PGND.

Maxim Integrated │ 9

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

Functional Diagrams

UVEN

MAX25612/

MAX25612B

1.24V

EN

5V REG

IN

THERMAL TSHDN

SHUTDOWN

VCC

VCC

UVLO

BG

VCC

S

0.21V

CSN

ICTRL

ISENSE+

ISENSE-

LX

BST

DH

LX

LX

Q

BLANKING

x2

PWM

COMP

VCC

VCC

R

ISLOPE

CSP

BST

R-DOM

RT

OSCILLATOR

RT

BST

MAX DUTY

CYCLE

DL

VCC

PGND

1.0V

VICTRLCLMP

MIN

OUT

LPF

gM

COMP

x5

0.2V

PWMDIM

VISENSE+

BUCK-BOOST

SHORT DETECTION

(MAX25612 ONLY)

DIMOUT

200Hz

VISENSE+ - 7V

0.32V

2.2V

S

8192 x TOSC

HICCUP TIMER

Q

R

FLT

OVP

TSHDN

SGND

1.23V

www.maximintegrated.com

Maxim Integrated │ 10

�MAX25612/MAX25612B

Detailed Description

The MAX25612/MAX25612B are single-channel HBLED

drivers for automotive front-light applications such as high

beam, low beam, daytime running light (DRL), turn

indicator, fog light, and other LED lights. They can take

an input voltage from 5V to 48V and can drive a string

of LEDs with a maximum output voltage of 60V. The

MAX25612/MAX25612B feature both low- and high-side

nMOS drivers for synchronous rectification. Synchronous

rectification greatly improves efficiency compared to

asynchronous switching converters, especially in highcurrent applications. Reverse recovery losses of the

synchronous MOSFET will increase at higher output

voltages; therefore, the efficiency benefit may be reduced

when driving large numbers of LEDs. Refer to the Typical

Operating Characteristics section for comparisons of

synchronous and asynchronous switching efficiency with

different currents and voltages.

The MAX25612/MAX25612B sense output current at the

high side of the LED string. High-side current sensing is

required to protect against shorts from the output to the

ground or battery input. It is also the most flexible scheme

for driving LEDs, allowing boost, high-side buck, SEPIC,

or buck-boost mode configurations. The PWMDIM input

provides LED dimming ratios of up to 5000:1, and the ICTRL

input provides additional analog dimming capability in the

MAX25612/MAX25612B. The MAX25612/MAX25612B

also include a FLT flag that indicates open string, shorted

string and thermal shutdown. The MAX25612/MAX25612B

have built-in spread-spectrum modulation for improved

electromagnetic compatibility performance.

Functional Operation

The operation of the MAX25612/MAX25612B is best

understood by referring to the block diagram of the

device. The devices are enabled when the UVEN pin

goes above 1.24V. In addition to the UVEN input, the

5V regulator input also needs to be above its respective

UVLO limit before switching on DL and DH can start.

The MAX25612/MAX25612B are constant-frequency,

current-mode controllers with low-side and high-side

NMOS gate drivers for synchronous switching. Switching

is initiated when PWM goes high. The RT oscillator can

be programmed from 200kHz to 2.2MHz by the resistor

between RT and SGND. Spread-spectrum dithering is

added to the oscillator to alleviate EMI problems in the

www.maximintegrated.com

Automotive Synchronous

High Voltage LED Controller

LED driver. The RT oscillator is synchronized to the

positive edge of the PWM pulse. This means that the

DL pulse goes high at the same instant as the positive

pulse on PWMDIM. Synchronizing the RT oscillator to

the PWMDIM pulse also guarantees that the switching

frequency variation over a period of a PWMDIM pulse

is the same from one PWMDIM pulse to the next. This

prevents flicker during PWM dimming when spread

spectrum is added to the RT oscillator.

Once PWMDIM transitions high, the external low-side

switching MOSFET is turned on. A current flows through

the low-side MOSFET, and this current is sensed by

the voltage across the current-sense resistor from the

source of the external low-side MOSFET to PGND.

The MOSFET source is connected to the CSP input

of the MAX25612/MAX25612B through a slopecompensation resistor (RSC). See the Typical Application

Circuits section. The ground side of the current-sense

resistor is connected to the CSN input. The slopecompensation current flows out of CSP and through the

RSC resistor. The differential voltage across CSP and

CSN is the voltage across the current-sense resistor

(RCS_FET) + (slope-compensation current x RSC). Slope

compensation prevents sub-harmonic oscillation when the

duty cycle exceeds 50%. Current in the external inductor

increases steadily when the external low-side MOSFET

is on. The differential voltage across CSP and CSN is fed

to the input of the current-limit comparator. This currentlimit comparator is used to protect the external low-side

switch from overcurrent and will cause switching to stop

for that particular cycle if (VCSP - VCSN) exceeds 0.21V.

The differential current-sense voltage signal is amplified

by a gain factor of two. The output of the amplifier has

a 1.0V offset added before being applied to the positive

input of a PWM comparator. The negative input of this

comparator is a control voltage from the error amplifier

that regulates the LED current. When the positive input

of the PWM comparator exceeds the control voltage

from the error amplifier, the switching is stopped for that

particular cycle and the external low-side nMOS stays off

until the next switching cycle. The inductor current decays

when the low-side nMOS is turned off. The inductor

current starts ramping back up when the next switching

cycle starts and the external low-side MOSFET turns

back on. Through this repetitive action, the PWM control

Maxim Integrated │ 11

�MAX25612/MAX25612B

algorithm establishes a switch duty cycle to regulate the

current in the LED load.

When PWMDIM transitions high, the external dimming

MOSFET that is driven by DIMOUT is also turned

on. This external dimming MOSFET is a p-channel

MOSFET and is connected on the high side of the LED

load. The source of this pMOS is connected to ISENSEand the gate is connected to DIMOUT. The drain of this

MOSFET is connected to the anode of the external LED

string. In certain applications it is not necessary to use this

dimming MOSFET, and in these cases the DIMOUT output is left open. The external pMOS is turned on when

PWMDIM is high and is turned off when PWMDIM is

low. During normal operation when PWMDIM is high, the

voltage across the resistor from ISENSE+ to ISENSE- is

regulated to a programmed voltage. This programmed

voltage is 0.2 x (VICTRL - 0.2). The external pMOS switch

is also used for fault protection. Once a fault condition is

detected, DIMOUT is pulled high to turn off the pMOS

switch. This isolates the LED string from the fault condition and prevents excessive voltage or current from damaging the LEDs.

Input Voltage (IN)

The input supply (IN) must be locally bypassed with a

minimum of 1μF capacitance close to the pin. All the input

current that is drawn by the MAX25612/MAX25612B goes

through this input.

UVLO

The MAX25612/MAX25612B feature an adjustable UVLO

using the undervoltage enable input (UVEN). Connect

UVEN to IN through a resistive divider to set the UVLO

threshold. The MAX25612/MAX25612B are enabled

when VUVEN exceeds the 1.24V (typ) threshold. UVEN

also functions as an enable/disable input to the device.

Drive UVEN low to disable the device. Drive UVEN

high to enable the device.

VCC Regulator

The VCC supply is the low-voltage analog supply for the

chip and derives power from the input voltage from IN

to PGND. An internal power-on reset (POR) monitors

the VCC voltage and the IN voltage. The input voltage to

the VCC regulator is disconnected when the voltage at

IN goes below the UVLO threshold. A POR is generated

when VCC goes below its UVLO threshold, causing the

www.maximintegrated.com

Automotive Synchronous

High Voltage LED Controller

IC to reset. The chip will come out of reset state once the

input voltage goes back up and the VCC regulator output

is back in regulation.

Dimming MOSFET Driver (DIMOUT)

The IC requires an external p-channel MOSFET for

PWM dimming. For normal operation, connect the gate

of the MOSFET to the output of the dimming driver

(DIMOUT). The dimming driver can sink up to 35mA or

source up to 73mA of peak current for fast charging and

discharging of the p-MOSFET gate. When the PWMDIM

signal is high, this driver pulls the p-MOSFET gate to 7V

below VISENSE+ to completely turn on the p-channel dimming MOSFET. The DIMOUT output inverts and level-shifts

the signal on PWMDIM to drive the gate of the external

PMOS. In some applications, the dimming FET is not used.

In this case, the DIMOUT output can be left open.

LED Current-Sense Inputs (ISENSE+/ISENSE-)

The differential voltage from ISENSE+ to ISENSE- is

fed to an internal current-sense amplifier. This amplified signal is then connected to the negative input of the

transconductance error amplifier. The voltage-gain factor

of this amplifier is 5. The offset voltage for this amplifier

is +1mV. A resistor is connected between ISENSE+ and

ISENSE- to program the maximum LED current. The

full-scale signal is 200mV. The ISENSE+ input should be

connected to the positive terminal of the current-sense

resistor and the ISENSE- input should be connected to

the negative terminal of the current-sense resistor (LED

string anode side).

Internal Oscillator (RT)

The internal oscillator of the MAX25612/MAX25612B are

programmable from 200kHz to 2.2MHz using a single

resistor at RT. Use the following formula to calculate the

switching frequency:

fOSC(kHz) = 34200/RRT(kΩ)

where RRT is the resistor from RT to SGND. This equation

is a linear approximation of the relationship between

fOSC and RRT. See Table 1 and the Typical Operating

Maxim Integrated │ 12

�MAX25612/MAX25612B

Characteristics section for more data points showing the

relationship between RRT and fOSC. The MAX25612/

MAX25612B have built-in frequency dithering of ±6% of

the programmed frequency to alleviate EMI problems.

Spread Spectrum

The devices have an internal spread-spectrum option to

optimize EMI performance. The switching frequency is

varied ±6%, centered on the oscillator frequency (fOSC).

The modulation signal is a triangular wave with a period

of 418 clocks. Therefore, fOSC ramps down 6% and back

to the set frequency in 418 clocks, and also ramps up 6%

and back to the set frequency in another 418 clocks.

Synchronous MOSFET Switch Driver

(DH and DL)

The IC drives an external high-side and low-side n-channel switching MOSFET. DH and DL can sink/source 2A

of peak current, allowing the ICs to switch MOSFETs in

high-power applications. The average current demanded

from the supply to drive the external MOSFETs depends

on the total gate charge (QG) and the operating frequency

of the converter, fSW. Use the following equation to calculate the driver supply current IDRIVER required for the

switching MOSFET:

IDRIVER = QG x fSW

The low-side gate driver (DL) drives an external nMOS (N1)

with either VCC or VPGND to turn the MOSFET on or off,

respectively. The high-side gate driver (DH) drives an external nMOS (N2) with either VBST or VLX to turn the MOSFET

on or off, respectively. During normal operation, DH will be

driven high while the DL is driven low. Likewise, DH will be

driven low while DL is driven high, thereby achieving synchronous switching. There is a small break-before-make

delay between the transitions to prevent any shoot-through

current that would occur as a result of both low- and highside MOSFETs being turned on at the same time.

Boost Capacitor Node (BST)

The BST input is used to provide a drive voltage to the

high-side switching MOSFET that is higher than LX.

Connect a 0.1μF ceramic capacitor from BST to the LX

switch node. Connect a diode from VCC to BST. Place the

capacitor as close as possible to BST.

Switching MOSFET Current-Sense Input

(CSP and CSN)

CSP and CSN are part of the current-mode control loop.

The switching control uses the voltage across CSP and

CSN, set by RCS and RSC, to terminate the ON pulse

width of the switching cycle, thus achieving peak currentmode control. Internal leading-edge blanking of 50ns is

provided to prevent premature turn-off of the switching

MOSFET in each switching cycle. Resistor RCS is conwww.maximintegrated.com

Automotive Synchronous

High Voltage LED Controller

nected between the source of the n-channel switching

MOSFET and PGND. During switching, a current ramp

with a slope of 50μAxfSW is sourced from the CSP input.

This current ramp, along with resistor RSC, programs the

amount of slope compensation.

Overvoltage Protection Input (OVP)

OVP sets the overvoltage threshold limit across the LEDs.

Use a resistive divider from ISENSE+ to OVP to SGND

to set the overvoltage threshold limit. An internal overvoltage protection comparator senses the differential voltage across OVP and SGND. If the differential voltage is

greater than 1.23V, DL goes low, DH and DIMOUT go high,

and FLT asserts. When the differential voltage drops by

70mV, DL is enabled, DIMOUT goes low, and FLT deasserts.

Output Short-Circuit Protection

The MAX25612/MAX25612B feature output short-circuit

protection. This feature is most useful where the LEDs are

connected over long cables and there exists the possibility

of shorts occurring when connectors are exposed.

For the MAX25612, short circuit is detected when the following two conditions are met:

●● VISENSE+ is lower than VIN by the VSHORT_

VOUT threshold, 1.55V (typ)

●● The current-sense voltage across VISENSE+ - VISENSE- exceeds the VSHORT_HIC threshold, 398mV

(typ)

The MAX25612B has disabled the VSHORT_VOUT threshold flag for applications where (VISENSE+ - VIN) is expected to be less than 1.55V (typ) during normal operation. In

this case, the VSHORT_HIC threshold is the only criteria

for detecting a short circuit.

The MAX25612/MAX25612B respond by stopping DL and

DH switching and pulling DIMOUT high to VISENSE+ to

turn off the dimming FET, which disconnects the output

capacitors from the shorted output. The device waits

8192 clock cycles before attempting to drive the LEDs

again. The 8192-clock-cycle counter is only active while

PWMDIM is HIGH.

Internal Transconductance Error Amplifier

The IC has a built-in transconductance amplifier that

is used to amplify the error signal inside the feedback loop. When the dimming signal is low, COMP

is disconnected from the output of the error amplifier

and DIMOUT goes high. When the dimming signal is high,

the output of the error amplifier is connected to COMP

and DIMOUT goes low. This enables the compensation

capacitor to hold the charge when the dimming signal

has turned off the internal switching MOSFET gate drive.

To maintain the charge on the compensation capacitor

Maxim Integrated │ 13

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

CCOMP, the capacitor should be a low-leakage ceramic

type. When the internal dimming signal is enabled, the

voltage on the compensation capacitor forces the converter into steady state almost instantaneously. The transconductance of the amplifier is 1800μS.

Signal Ground (SGND)

Analog Dimming

Thermal Shutdown

The devices offer an analog dimming control input

(ICTRL). The voltage at ICTRL sets the LED current

level when VICTRL < 1.3V (typ). The LED current can be

linearly adjusted from zero with the voltage on ICTRL. For

VICTRL > 1.3V (typ), an internal reference sets the LED

current. The LED current is guaranteed to be at zero when

the ICTRL voltage is at or below ICTRLZC_VTH(MIN). The

LED current can be linearly adjusted from zero to full

scale for the ICTRL voltage in the range of 0.2V to 1.2V.

Pulse-Dimming Input

The PWMDIM input of the MAX25612/MAX25612B

functions with either analog or PWM control signals.

Once the internal pulse detector detects three successive

edges of a PWM signal with a frequency between 60Hz

and 2kHz, the MAX25612/MAX25612B synchronize to

the external signal and pulse-width modulates the LED

current at the external DIM input frequency with the same

duty cycle as the DIM input. PWM dimming outside this

frequency range is also possible, with the caveat that the

switching clock may not be synchronized to the PWM

rising edge. If an analog control signal is applied to DIM,

the MAX25612/MAX25612B compare the DC input to an

internally generated 200Hz ramp to pulse-width-modulate

the LED current (fDIM = 200Hz). The output-current duty

cycle is linearly adjustable from 0% to 100% (0.2V < VDIM

< 3.0V). Use the following formula to calculate the voltage,

VDIM, necessary for a given output-current duty cycle D

VDIM = (D x 2.8) + 0.2V

where VDIM is the voltage applied to DIM in volts.

Power Ground (PGND)

This is the analog ground pin for all of the control circuitry

of the LED driver. Connect the PGND (power ground) and

the SGND together at the negative terminal of the input

bypass capacitor.

The devices feature thermal protection. When the junction temperature exceeds +165°C, the external switching

MOSFET starts operating at the minimum pulse width

to reduce the power dissipation in the internal power

MOSFETs. The part returns to regulation mode once the

junction temperature goes below +155°C. This results

in a cycled output during continuous thermal-overload

conditions.

Fault Indicator (FLT)

The MAX25612/MAX25612B feature an active-low, opendrain fault indicator (FLT). FLT asserts when one of

the following conditions occur:

1) Overvoltage across the LED string

2) Short-circuit condition across the LED string

3) Overtemperature condition

When the output voltage drops below the overvoltage

set point minus the hysteresis, FLT deasserts. Similarly,

during overtemperature fault, the FLT signal remains

asserted until the junction temperature falls 10ºC below

the thermal-shutdown threshold.

Exposed Paddle

The MAX25612/MAX25612B package features an exposed

thermal pad on its underside that should be used as a heat

sink. This pad lowers the package’s thermal resistance by

providing a direct heat-conduction path from the die to the

PCB. Connect the exposed pad and GND to the system

ground using a large pad or ground plane, or multiple vias

to the ground plane layer.

The power ground (PGND) connection acts as the ground

reference for the switching power components. Connect

PGND as close as possible to the negative plate of the

VCC decoupling capacitor.

www.maximintegrated.com

Maxim Integrated │ 14

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

Applications Information

VCC Regulator

The internal 5V regulator is used to power the internal

control circuitry inside the MAX25612/MAX25612B, as

well as the low-side FET gate driver. This regulator can

provide a load of 10mA to external circuitry. The 5V

regulator requires an external ceramic capacitor for stable

operation. A 4.7µF ceramic capacitor is adequate for most

applications. Place the ceramic capacitor close to the IC

to minimize trace length to the internal VCC pin and also

to the IC ground. Choose a 10V rated low-ESR, X7R

ceramic capacitor for optimal performance.

Programming the UVLO Enable Threshold

The UVLO threshold is set by resistors RUVEN1 and

RUVEN2 (see the Typical Application Circuits section).

The MAX25612/MAX25612B turn on when the voltage

across RUVEN2 exceeds 1.24V, the UVLO threshold. Use

the following equation to set the desired UVLO enable

threshold:

VUVEN

=

1.24

×

(RUVEN1

+ RUVEN2

RUVEN2

)

where VUVEN is the rising undervoltage threshold in volts.

The UVEN input can also be used as a digital enable

by applying an external logic signal that can turn the

MAX25612/MAX25612B on and off.

Programming LED Current

Normal sensing of the LED current should be done on the

high side where the LED current-sense resistor is connected to the anode of the LED string. The LED current is

programmed using the resistor RCS_LED (see the Typical

Application Circuits section). When ICTRL is connected to

a voltage greater than 1.3V, the internal reference regulates the voltage across RCS_LED to 220mV. The current

is given by:

ILED

www.maximintegrated.com

=

0.22

RCS_LED

The LED current can also be programmed by adjusting

the voltage on ICTRL when VICTRL ≤ 1.2V (analog dimming). The current is given by:

ILED

=

(VICTRL − 0.2)

(5 × RCS_LED)

Programming the Switching Frequency

The internal oscillator of the MAX25612/MAX25612B

is programmable from 200kHz to 2.2MHz using a single resistor at RT. Use the following formula to calculate

the value of the resistor RRT:

R RT (kΩ) =

34200

f OSC

where fOSC is the desired switching frequency in kHz.

This equation is a linear approximation of the relationship between RRT and fOSC. See Table 1 and the Typical

Operating Characteristics section for more data points

showing the relationship between RRT and fOSC.

Additional ±6% spread spectrum is added internally to

the oscillator to improve EMI performance.

Setting the Overvoltage Threshold

The overvoltage threshold is set by resistors ROVP1 and

ROVP2 (see the Typical Application Circuits section). The

overvoltage circuit in the MAX25612/MAX25612B is

activated when the voltage on OVP with respect to GND

exceeds 1.23V. Use the following equation to set the

desired overvoltage threshold:

VOVP = 1.23 x (ROVP1 + ROVP2)/ROVP2

Table 1. Typical RRT Programming Values

R RT (kΩ)

fOSC (kHz)

188

200

34.2

1000

14.7

2200

Maxim Integrated │ 15

�MAX25612/MAX25612B

Inductor Selection

Boost Configuration

In the boost converter, the average inductor current varies with the line voltage. The maximum average current

occurs at the lowest line voltage. For the boost converter,

the average inductor current is equal to the input current.

Calculate maximum duty cycle using the equation below:

DMAX = (VLED - VFET2 - VINMIN)/

(VLED + VFET2 - VFET1)

where VLED is the forward voltage of the LED string

in volts, VINMIN is the minimum input supply voltage in

volts, and VFET1 and VFET2 are the average drain-to

source voltages of the MOSFETs N1 and N2 in volts when

they are on. Use an approximate value of 0.2V initially to

calculate DMAX. A more accurate value of the maximum

duty cycle can be calculated once the power MOSFET

is selected based on the maximum inductor current. Use

the following equations to calculate the maximum average inductor current ILAVG, peak-to-peak inductor current

ripple ∆IL, and the peak inductor current ILP in amperes:

ILAVG = ILED/(1 - DMAX)

Allowing the peak-to-peak inductor ripple to be

∆IL, the peak inductor current is given by:

ILP = ILAVG + 0.5 x ∆IL

The inductance value (L) of inductor L1 in Henries (H)

is calculated as:

L = (VINMIN - VFET1) x DMAX/(fSW x ∆IL)

where fSW is the switching frequency in Hertz, VINMIN and

VFET1 are in volts, and ∆IL is in amperes. Choose an

inductor that has a minimum inductance greater than the

calculated value. The current rating of the inductor should

be higher than ILP at the operating temperature.

Buck-Boost Configuration

In the buck-boost LED driver, the average inductor current is equal to the input current plus the LED current.

Calculate the maximum duty cycle using the following

equation:

DMAX = (VLED + VFET2)/

(VLED + VFET2 + VINMIN - VFET1)

where VLED is the forward voltage of the LED string in

volts, VINMIN is the minimum input supply voltage in volts,

and VFET1 and VFET2 are the average drain-to-source

www.maximintegrated.com

Automotive Synchronous

High Voltage LED Controller

voltages of the MOSFETs N1 and N2 in volts when they

are on. Use an approximate value of 0.2V initially to calculate DMAX. A more accurate value of maximum duty cycle

can be calculated once the power MOSFET is selected

based on the maximum inductor current.

Use the equations below to calculate the maximum average inductor current ILAVG, peak-to-peak inductor current

ripple ∆IL, and the peak inductor current ILP in amperes:

ILAVG = ILED/(1 - DMAX)

Allowing the peak-to-peak inductor ripple to be ∆IL

ILP = ILAVG + 0.5 x ∆IL

where ILP is the peak inductor current.

The inductance value (L) of inductor L1 in Henries is calculated as:

L = (VINMIN - VFET1) x DMAX/(fSW x ∆IL)

where fSW is the switching frequency in Hertz, VINMIN and

VFET1 are in volts, and ∆IL is in amperes. Choose an

inductor that has a minimum inductance greater than the

calculated value.

High-Side Buck Configuration

In the high-side buck LED driver, the average inductor

current is the same as the LED current. The peak inductor

current occurs at the maximum input line voltage where

the duty cycle is at the minimum.

DMIN = (VLED + VFET2)/(VINMAX - VFET1)

where VLED is the forward voltage of the LED string in

volts, VINMAX is the maximum input supply voltage in

volts, and VFET1 and VFET2 are the average drain-tosource voltages of the MOSFETs N1 and N2 in volts when

they are on. Use an approximate value of 0.2V initially

to calculate DMIN. The maximum peak-to-peak inductor

ripple ∆IL occurs at the maximum input line. The peak

inductor current is given by

ILP = ILED + 0.5 x ∆IL

The inductance value (L) of inductor L1 in Henries

is calculated as:

L = (VINMAX - VFET1 - VLED) x DMIN/(fSW x ∆IL)

where fSW is the switching frequency in Hertz, VINMAX and

VFET1 are in volts, and ∆IL is in amperes. Choose an

inductor that has a minimum inductance greater than the

calculated value.

Maxim Integrated │ 16

�MAX25612/MAX25612B

SEPIC Configuration

The SEPIC converter provides the option to use either a

coupled inductor or two separate inductors (see Typical

Application Circuits). The average L1 inductor current

is equal to the input current. The average L2 inductor

current is equal to the LED current. Neglecting voltage

drops across the FETs, the maximum duty cycle can be

calculated as follows:

D MAX =

VLED

(VINMIN + VLED )

Where VLED is the LED string voltage and VINMIN is the

minimum input voltage. The inductor value of L1 is given by:

L1 =

VINMIN × D MAX

f SW + ∆IL IN

Where ΔILIN is the desired maximum input current ripple.

The L1 peak inductor current, ILINPK, is given by:

=

IL INPK ILED

∆IL IN

D MAX

+

1 − D MAX

2

The average current in inductor L2 is the same as the

LED current. The desired maximum peak-to-peak output

current ripple is ΔILOUT. The value of the inductor L2 is

given by:

L2 =

VINMIN × D MAX

f SW × ∆IL OUT

The L2 peak inductor current, ILOUTPK, is given by:

∆IL OUT

IL OUTPK

= ILED +

2

To simplify further SEPIC calculations, use the following

values of L and ILAVG:

L=

L1× L2

L1 + L2

ILAVG = IL1AVG + IL2AVG

choose the value of CSEPIC such that the peak to peak

ripple on it is less than 2% of the minimum input supply

voltage. This ensures that the second‐order effects

created by the series resonant circuit comprising L1,

CSEPIC, and L2 does not affect the normal operation of

the converter. Use the following equation:

C SEPIC ≥

www.maximintegrated.com

ILED × D MAX

VINMIN × 0.02 × f SW

Automotive Synchronous

High Voltage LED Controller

Switching MOSFET (N1) Selection

The switching MOSFET (N1) should have a voltage rating sufficient to withstand the maximum output voltage

together with the voltage drop of synchronous high-side

nMOS (N2), and any possible overshoot due to ringing

caused by parasitic inductances and capacitances. Use a

MOSFET with a drain-to-source voltage rating higher than

that calculated by the following equations:

Boost configuration:

VDS_MAX = (VLED + VFET2 + VRCS_LED + VPFET) x 1.2

Buck-boost configuration:

VDS_MAX = (VLED +VINMAX+ VFET2 +

VRCS_LED + VPFET) x 1.2

The factor 1.2 provides 20% safety margin.

A resistor is also typically added in series with the gate

of the switching MOSFET (N1) to adjust the slew rate,

minimize ringing on the switch node, and improve EMI

performance.

Synchronous MOSFET (N2) Selection

The synchronous MOSFET (N2) should have a similar

voltage rating as N1, such that it can withstand the output voltage while N1 is on and the LX node is pulled to

ground, including any possible undershoot due to ringing.

Dimming MOSFET Selection

Select a dimming MOSFET (P1) with continuous current

rating at the operating temperature higher than the LED

current by 30%. The drain-to-source voltage rating of the

dimming MOSFET must be higher than VLED by 20%.

A resistor may also be added in series with the gate of the

dimming MOSFET to control the slew rate and help reduce

current spikes that can occur when the dimming FET turns

on and connects the switching converter output capacitor to any capacitors at the LED load. A capacitor may be

added across the gate and drain of the dimming FET to get

better control of the RC time constant that controls the slew

rate. Otherwise, the RC time constant is controlled by the

parasitic capacitance of the chosen pMOS.

Slope Compensation

Slope compensation should be added to converters

with peak current-mode-control operating in continuousconduction mode with more than 50% duty cycle to avoid

current-loop instability and subharmonic oscillations. The

minimum amount of slope compensation required for stability is given by the following equation:

VSLOPE(MIN) = 0.5 x (inductor current downslope inductor current upslope) x RCS_FET

Maxim Integrated │ 17

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

In the MAX25612/MAX25612B, the slope-compensating

ramp is added to the current-sense signal before it is fed

to the PWM comparator. Connect a resistor (RSC) from

CSP to the switch current-sense resistor terminal for programming the amount of slope compensation.

The devices generate a current ramp with a slope of 50μA/

tOSC for slope compensation. The current-ramp signal is

forced into an external resistor (RSC) connected between

CSP and the source of the external MOSFET, thereby

adding a programmable slope-compensating voltage

(VSLOPE) at the current-sense input CSP. Therefore:

dVSLOPE/dt = (RSLOPE x 50μA)/tOSC

The slope-compensation voltage that needs to be added

to the current signal at minimum line voltage, with margin

of 1.2x, is given by the following equation:

RCS_FET =

Buck-boost and SEPIC configuration:

VSLOPE = DMAX

(VLED − VINMIN) × RCS_FET × 1.2

(2 × L × fSW)

High-side buck configuration:

VSLOPE = DMAX

(2 × VLED − VINMIN) × RCS_FET × 1.2

(2 × L × fSW)

MOSFET Current-Sense Resistor

The minimum value of the peak current-limit comparator

is 0.19V. The current-sense resistor value is given by:

RCS_FET = (0.19 - DMAX x VSLOPE)/ILPK

where ILPK is the peak inductor current that occurs at low

line in the boost and buck-boost configurations.

For boost configuration:

www.maximintegrated.com

[

ILPK + 0.75DMAX

(VLED − 2VINMIN)

L × fSW

]

For buck-boost configuration:

RCS_FET =

[

0.19

ILPK + 0.75DMAX

(VLED − VINMIN)

L × fSW

]

For SEPIC configuration:

R CS

FET

Boost configuration:

(VLED − 2 × VINMIN) × RCS_FET × 1.2

VSLOPE = DMAX

(2 × L × fSW)

0.19

=

0.19

(VLED − VINMIN)

IL1PK + IL2 PK + 0.75D MAX

L × f SW

For high-side buck configuration:

R CS

FET

=

0.19

(2VLED − VINMIN)

IL1PK + 0.75D MAX

L × f SW

Input Capacitor Selection

The input-filter capacitor bypasses the ripple current drawn by the converter and reduces the amplitude

of high-frequency current conducted to the input supply.

The ESR, ESL, and bulk capacitance of the input capacitor contribute to the input ripple. Use a low-ESR input

capacitor that can handle the maximum input RMS ripple

current from the converter. For the boost configuration, the input current is the same as the inductor current. For buck-boost configuration, the input current is

the inductor current minus the LED current. However, for

both configurations, the ripple current that the input filter

capacitor has to supply is the same as the inductor ripple

current with the condition that the output filter capacitor should be connected to ground for buck-boost configuration. This reduces the size of the input capacitor, as

the inductor current is continuous with maximum ∆IL/2.

Neglecting the effect of LED current ripple, the calculation of the input capacitor for boost, as well as buck-boost

configurations is the same.

Maxim Integrated │ 18

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

Neglecting the effect of the ESL, the ESR, and the

bulk capacitance at the input contributes to the inputvoltage ripple. For simplicity, assume that the contribution

from the ESR and the bulk capacitance is equal. This

allows 50% of the ripple for the bulk capacitance. The

capacitance is given by:

CIN

≥

(4

∆ IL

×

∆ VIN × fSW

)

where ∆IL is in amperes, CIN is in Farads, fSW is in

Hertz, and ∆VIN is in volts. The remaining 50% of allowable ripple is for the ESR of the output capacitor.

Use X7R ceramic capacitors for optimal performance.

The selected capacitor should have the minimum required

capacitance at the operating voltage.

In buck mode, the input capacitor has large pulsed

currents due to the current flowing in the synchronous

MOSFET N2 when the switching MOSFET N1 is off. It is

very important to consider the ripple-current rating of the

input capacitor in this application.

Output Capacitor Selection

The function of the output capacitor is to reduce the output ripple to acceptable levels. The ESR, ESL, and bulk

capacitance of the output capacitor contribute to the output ripple. In most applications, the output ESR and ESL

effects can be dramatically reduced by using low-ESR

ceramic capacitors. To reduce the ESL and ESR effects,

connect multiple ceramic capacitors in parallel to achieve

the required bulk capacitance. To minimize audible noise

generated by the ceramic capacitors during PWM dimming, it may be necessary to minimize the number of

ceramic capacitors on the output. In these cases, an

additional electrolytic or tantalum capacitor provides most

of the bulk capacitance.

Boost and Buck-Boost Configurations

The calculation of the output capacitance is the same

for both boost and buck-boost configurations. The output

ripple is caused by the ESR and bulk capacitance of the

output capacitor if the ESL effect is considered negligible.

For simplicity, assume that the contributions from ESR

and bulk capacitance are equal, allowing 50% of the ripple for the bulk capacitance. The capacitance is given by:

ILED × 2 × DMAX

COUT = VOUT

www.maximintegrated.com

RIPPLE × fSW

The remaining 50% of allowable ripple is for the ESR of

the output capacitor.

Based on this, the ESR of the output capacitor is given by:

ESRCOUT =

VOUTRIPPLE

ILPK × 2

Feedback Compensation

The LED current-control loop comprising the switching

converter, LED current amplifier, and error amplifier should

be compensated for stable control of the LED current.

The switching converter small-signal transfer function

has a right half-plane (RHP) zero for boost, SEPIC, and

buck-boost configurations, as the inductor current is in

continuous-conduction mode. The RHP zero adds a 20dB/

decade gain together with a 90° phase lag, which is difficult

to compensate. The easiest way to avoid this zero is to roll

off the loop gain to 0dB at a frequency less than 1/5 of the

RHP zero frequency with a -20dB/decade slope.

The worst-case RHP zero frequency (fZRHP) is calculated

as follows:

Boost configuration:

fZRHP =

(

VLED × 1 − DMAX

2π × L × ILED

)2

Buck-boost configuration:

fZRHP =

(VLED + VINMIN) × (1 − DMAX)2

2π × L × ILED

SEPIC configuration:

f ZRHP =

VLED (1 − D MAX )

2

2π × L × ILED × D MAX

The switching converter small-signal transfer function

also has an output pole for both boost and buck-boost

configurations. The effective output impedance that determines the output pole frequency together with the output

filter capacitance is calculated as:

Boost configuration:

ROUT =

(RLED + RCS_LED) × VLED

(RLED + RCS_LED) × ILED + VLED

Maxim Integrated │ 19

�MAX25612/MAX25612B

Buck-boost configuration:

ROUT =

(RLED + RCS_LED) × VLED

(RLED + RCS_LED) × ILED × DMAX + VLED

where RLED is the dynamic impedance of the LED string

at the operating current.

The output pole frequency for both boost and buck-boost

configurations is calculated as follows:

1

fP = 2πR

OUTCOUT

The feedback-loop compensation is done by connecting

a resistor (RCOMP) and capacitor (CCOMP) in series from

COMP to SGND. RCOMP is chosen to set the high-frequency integrator gain for fast transient response, while

CCOMP is chosen to set the integrator zero to maintain

loop stability. For optimum performance, choose the components using the following equations:

fC = 0.2× fZRHP

The value of RCOMP and CCOMP can be calculated as:

RCOMP

=

2 x fZRHP x RCS_FET

fC x (1 − DMAX) x RCS_LED x 5 x GM

CCOMP

=

25

π x fZRHP x RCOMP

the CCOMP_HF capacitor will add a higher frequency pole,

which helps to ensure good gain margin and stability. It is

typically chosen to cancel the zero from the output capaci-

Automotive Synchronous

High Voltage LED Controller

tor ESR, or such that the pole is at one half the switching

frequency, whichever is lower.

1

fP2 = 2πR

COMPCCOMP_HF

A large resistor, such as 499kΩ or 1MΩ, should be added

from COMP to SGND in applications where the ICTRL

input is supplied by a programmed voltage source, which

may be less than 0.2V. For applications in which the

ICTRL is connected to a fixed voltage from a resistordivider, the COMP pulldown resistor is not needed.

High-Side Buck Compensation

The high-side buck configuration does not have a right halfplane zero to avoid, so in most cases a single capacitor

from COMP to GND will suffice to compensate the loop.

Calculate CCOMP according to the following equation:

G M × A V × R CS

C COMP =

2π × f C × R CS

FET

Where CCOMP is the compensation capacitor value in

nF, GM is the GM amplifier transconductance in μA/V,

AV is the LED current-sense voltage gain, and fC is the

desired crossover frequency in kHz. Choose a crossover

frequency that is lower than fSW/15.

The output pole is set by the dynamic resistance of the

LED string and the COUT capacitor

f POUT =

1

2π × R DYN × C OUT

If the output pole is within a decade of the crossover frequency, then it can be compensated by adding a resistor,

RCOMP, in series with CCOMP.

R=

COMP

www.maximintegrated.com

LED

C OUT

× R DYN

C COMP

Maxim Integrated │ 20

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

Typical Application Circuits

Boost LED Driver Using MAX25612

L1

VIN

N2

CBST

VCC

BST

IN

LX

CIN

COUT

DL

RUVEN1

CSP

UVEN

PWMDIM

C1

ISENSE+

FLT

ISENSE-

RCOMP

CCOMP_HF

ICTRL

www.maximintegrated.com

100Ω

COMP

R1

RRT

RCS_LED

DIMOUT

VCC

R2

ROVP2

P1

DH

OVP

MAX25612

VCC

RSC

CSN

PGND

VCC

RUVEN2

N1

RCS_FET

PWMDIM

ROVP1

RT

SGND

EP

CCOMP

Maxim Integrated │ 21

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

Typical Application Circuits (continued)

Buck-Boost LED Driver Using MAX25612

L1

VIN

N2

CBST

VCC

BST

IN

RUVEN1

LX

CIN

COUT

DL

CSP

UVEN

PWMDIM

C1

ISENSE+

FLT

ISENSE-

100Ω

COMP

R1

RCOMP

CCOMP_HF

ICTRL

RRT

P1

DIMOUT

VCC

R2

RCS_LED

ROVP2

DH

OVP

MAX25612

VCC

RSC

CSN

PGND

VCC

RUVEN2

N1

RCS_FET

PWMDIM

ROVP1

RT

SGND

EP

CCOMP

VIN

www.maximintegrated.com

Maxim Integrated │ 22

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

Typical Application Circuits (continued)

High-Side Buck LED Driver Using MAX25612B

COUT

L1

CBST

VCC

VIN

BST

IN

LX

CIN

DL

R3

CSP

UVEN

PWMDIM

R4

ISENSE+

FLT

ISENSE-

P1

100Ω

DIMOUT

VCC

COMP

R1

ROVP1

RCOMP

CCOMP_HF

ICTRL

RRT

RCS_LED

DH

OVP

MAX25612B

R2

RSC

CSN

PGND

VCC

C1

N1

RCS_FET

PWMDIM

VCC

RT

VIN

N2

LED-

SGND

EP

CCOMP

ROVP2

P2

LED-

www.maximintegrated.com

Maxim Integrated │ 23

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

Typical Application Circuits (continued)

SEPIC01 LED Driver Using MAX25612B

L1

N2

VIN

CBST

BST

IN

RGN2

LX

CIN

DL

R3

CSP

UVEN

PWMDIM

R4

CSEPIC

RSC

RCS_FET

PWMDIM

CDH

ROVP2

RCS_LED

ISENSE+

FLT

ISENSE-

C1

P1

DH

OVP

MAX25612B

100Ω

DIMOUT

VCC

COMP

R1

RCOMP

CCOMP_HF

ICTRL

RRT

ROVP1

CSN

PGND

VCC

R2

N1

COUT

RT

www.maximintegrated.com

SGND

EP

CCOMP

Maxim Integrated │ 24

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

Typical Application Circuits (continued)

SEPIC02 LED Driver Using MAX25612B

L2

L1

VIN

N2

CBST

VCC

BST

IN

CSEPIC

RGN2

LX

CIN

DL

R3

CSP

UVEN

PWMDIM

ISENSE+

FLT

ISENSE-

RCS_LED

100Ω

COMP

R1

RCOMP

CCOMP_HF

ICTRL

RRT

ROVP2

DIMOUT

VCC

R2

CDH

P1

DH

OVP

MAX25612B

C1

ROVP1

CSN

PGND

VCC

VCC

RSC

RCS_FET

PWMDIM

R4

N1

COUT

SGND

RT

CCOMP

EP

Ordering Information

TEMPERATURE

RANGE

PIN-PACKAGE

MAX25612AUP/V+

-40°C to +125°C

20-TSSOP-EP*

MAX25612ATP/VY+

-40°C to +125°C

20-TQFN-EP*

MAX25612BAUP/V+

-40°C to +125°C

20-TSSOP-EP*

MAX25612BATP/VY+

-40°C to +125°C

20-TQFN-EP*

PART

+Denotes a lead (Pb)-free/RoHS-compliant package.

/V denotes an automotive qualified part.

Y = Side-wettable package.

*EP = Exposed pad.

www.maximintegrated.com

Maxim Integrated │ 25

�MAX25612/MAX25612B

Automotive Synchronous

High Voltage LED Controller

Revision History

REVISION

NUMBER

REVISION

DATE

PAGES

CHANGED

DESCRIPTION

0

6/19

Initial release

—

1

6/19

Added future-product notation to MAX25612ATP/VY+** in Ordering Information

21

2

12/19

Updated title to add MAX25612B; updated General Description, Benefits and

Features, Electrical Characteristics, Functional Diagrams, Detailed Description,

Applications Information, Typical Application Circuits, and Ordering Information

1–21

3

12/19

Updated Absolute Maximum Ratings, Pin Configurations, and Applications

Information; removed future-product notation from MAX25612ATP/VY+ in Ordering

Information

4

1/20

Removed all remaining future-product notation in Ordering Information

2, 8, 15, 25

25

For pricing, delivery, and ordering information, please visit Maxim Integrated’s online storefront at https://www.maximintegrated.com/en/storefront/storefront.html.

Maxim Integrated cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim Integrated product. No circuit patent licenses

are implied. Maxim Integrated reserves the right to change the circuitry and specifications without notice at any time. The parametric values (min and max limits)

shown in the Electrical Characteristics table are guaranteed. Other parametric values quoted in this data sheet are provided for guidance.

Maxim Integrated and the Maxim Integrated logo are trademarks of Maxim Integrated Products, Inc.

© 2019 Maxim Integrated Products, Inc. │ 26

�