CAT871, CAT872

Dual Input Reset Generator

Description

CAT871, CAT872 are dual input reset generators designed to restart

microprocessor and microcontroller based systems when the

watchdog timer or other resetting mechanisms have become disabled

or failed.

CAT871, CAT872 monitor two inputs and output an active low reset

pulse after both inputs have been active (logic low) for a factory preset

minimum time. The reset pulse width is 2.2 ms for CAT871 and 70 ms

for CAT872. Releasing either input from its active state before the

minimum timeout period resets the internal timer and both inputs must

return to being active before the timer will restart with a fresh count

down.

CAT871, CAT872’s open drain output is capable of sinking up to

3 mA of current and may be wire−OR’d with other open drain devices

to drive a common reset input.

http://onsemi.com

1

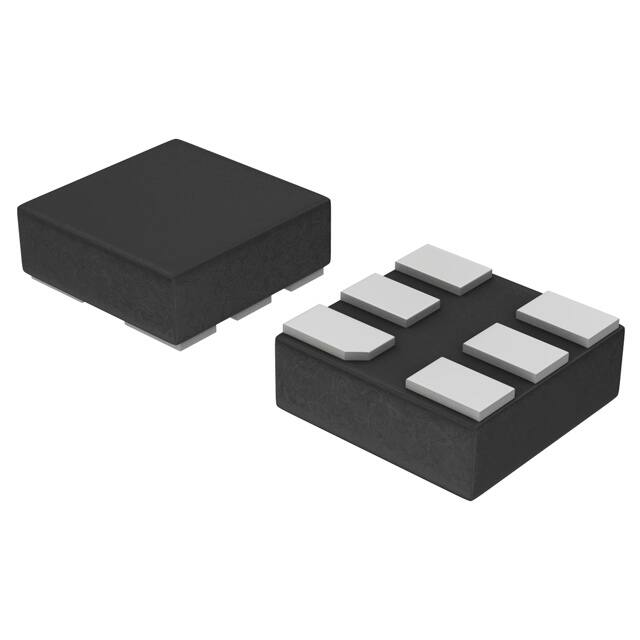

ULLGA−6

UL SUFFIX

CASE 613AF

MARKING DIAGRAM

Features

•

•

•

•

•

•

Operate on 1.65 V to 5.5 V Power Supplies

Ultra Low Quiescent Current: 10 nA (typical)

Schmitt Trigger Inputs

8 Factory Preset Delay Times from 0.5 s to 5 s to Choose From

Small mLLGA−6 Package: 1.45 x 1.0 x 0.4 mm

These Devices are Pb−Free, Halogen Free/BFR Free and are RoHS

Compliant

Typical Applications

•

•

•

•

XM

X = Specific Device Code

X = (J = CAT871, K = CAT872)

M = Date Code

PIN CONNECTIONS

MR1

Mobile Phones

PDAs

MP3 Players

Personal Navigation Devices

1

VDD

RESET

MR2

GND

NIC

(Top View)

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 9 of this data sheet.

Figure 1. Application Schematic

© Semiconductor Components Industries, LLC, 2011

November, 2011 − Rev. 0

1

Publication Order Number:

CAT871/D

�CAT871, CAT872

FUNCTIONAL BLOCK DIAGRAM

VDD

RESET

MR2

RESET

Pulse

Generator

Delay Timer

MR1

GND

Figure 2. Functional Block Diagram

Table 1. PIN FUNCTION DESCRIPTION

Pin No.

Pin Name

Description

1

MR1

Manual reset input #1. CMOS input.

2

MR2

Manual reset input #2. CMOS input.

3

NIC

No Internal Connection. A voltage or signal applied to this pin will have no effect on device operation.

4

GND

System Ground.

5

RESET

6

VDD

Reset Output. Active−low open drain output.

Positive Power Supply.

Table 2. ABSOLUTE MAXIMUM RATINGS

Rating

Symbol

Value

Unit

Input Voltage Range

VDD

−0.3 to 6

V

Output Voltage Range

VOUT

−0.3 to 6

or (VDD + 0.3), whichever is lower

V

VIN

−0.3 to 6

or (VDD + 0.3), whichever is lower

V

TJ(max)

150

°C

Output Current; RESET

IOUT

10

mA

Storage Temperature Range

TSTG

−65 to 150

°C

ESD Capability, Human Body Model (Note 1)

ESDHBM

2

kV

ESD Capability, Machine Model (Note 1)

ESDMM

200

V

TSLD

260

°C

Input Voltage; MR2, MR1

Maximum Junction Temperature

Lead Temperature Soldering

Reflow (SMD Styles Only), Pb−Free Versions (Note 2)

Stresses exceeding Maximum Ratings may damage the device. Maximum Ratings are stress ratings only. Functional operation above the

Recommended Operating Conditions is not implied. Extended exposure to stresses above the Recommended Operating Conditions may affect

device reliability.

1. This device series incorporates ESD protection and is tested by the following methods:

ESD Human Body Model tested per AEC−Q100−002 (EIA/JESD22−A114)

ESD Machine Model tested per AEC−Q100−003 (EIA/JESD22−A115)

Latch−up Current Maximum Rating: ≤150 mA per JEDEC standard: JESD78

2. For information, please refer to our Soldering and Mounting Techniques Reference Manual, SOLDERRM/D

http://onsemi.com

2

�CAT871, CAT872

Table 3. RECOMMENDED OPERATING CONDITIONS

Rating

Symbol

Min

Max

Unit

Input Voltage; VDD

VDD

1.65

5.5

V

Input Voltage; MR1, MR2

VIN

0

VDD

V

Output Current; RESET

IOUT

0

3

mA

TA

−40

85

°C

Ambient Temperature

Table 4. ELECTRICAL OPERATING CHARACTERISTICS

(VDD = 1.65 V to 5.5 V. For typical values TA = 25°C, for min/max values TA = −40°C to +85°C unless otherwise noted.)

Test Conditions

Parameter

Symbol

Min

VDD

1.65

Typ

Max

Unit

5.5

V

10

1000

nA

50

mA

POWER

VDD Supply Voltage

IDD

Quiescent Supply Current

MR1 = MR2 = VDD.

Operating Supply Current

MR1 = MR2 = 0 V

Measured during setup period. Measurement

includes current through internal 200 kΩ

pull−up resistor on MR2

LOGIC INPUTS AND OUTPUTS

Input Voltage; HIGH

MR1, MR2

VIH

Input Voltage; LOW

MR1, MR2

VIL

Hysteresis

VHYS

0.7 x VDD

V

0.25xVDD

−

250

Input Current

MR1 = 0 V; VDD = 5 V (no internal pull−up)

IPU

50

Input Current

MR2 = 0 V; VDD = 5 V

(internal 200 kW pull−up resistor)

IPU

25

Output Voltage; HIGH

External 10 kW pull−up resistor to VDD

VOH

Output Voltage; LOW

ISINK = 3 mA, VDD = 1.8 V

VOL

V

mV

300

nA

mA

VDD – 0.1

V

0.1

0.4

V

0.41

0.50

0.59

s

CAT87x−10

0.82

1.00

1.18

s

CAT87x−15

1.23

1.50

1.77

s

CAT87x−20

1.64

2.00

2.36

s

CAT87x−25

2.05

2.50

2.95

s

CAT87x−30

2.46

3.00

3.54

s

CAT87x−40

3.28

4.00

4.72

s

CAT87x−50

4.1

5.00

5.9

s

1.8

2.2

2.6

ms

57

70

83

TIMING

Timeout

Reset Output Pulse Width

tLOW_DELAY

CAT87x−05

tR

CAT871

CAT872

TEST MODE (at TA = 25°C) (Note 3)

tST

Start TEST window

35

ms

Test Mode delay

MR1=0 V, MR2→8 cycles, delay measured

after 8th rising edge of the MR2 clock pulse

tD

250

ms

Test Mode Clock Frequency

Clock applied to MR2

ftm

1

MHz

MR2 Test mode clock setup

time

Measured from MR1 falling edge to first

falling edge of MR2

tP

MR2 Input Voltage; LOW

MR2, Test mode operation

1

ms

VIL_TM

MR2 Pulse Width

tpw

3. “Test Mode” parameters are not tested in production.

http://onsemi.com

3

0.2xVDD

500

V

ns

�CAT871, CAT872

TIMING WAVEFORMS (Note 4)

Figure 3. Timing Waveforms

4. The order of the MR inputs going low does not matter. The last input to go low marks the beginning of tLOW_DELAY

1.75

1.75

1.70

1.70

1.65

1.65

1.60

1.50

25°C

1.45

90°C

tLOW_DELAY (s)

−40°C

1.55

1.40

1.60

1.55

1.45

1.30

1.25

1.30

1.25

−50

2

3

4

6

5

3.2 V

1.40

1.35

1

5.6 V

1.50

1.35

1.6 V

−25

0

25

50

75

100

125 150

VDD (V)

TEMPERATURE (°C)

Figure 4. tLOW_DELAY vs. VDD (CAT87x−1.5)

Figure 5. tLOW_DELAY vs. Temperature

(CAT87x−1.5)

3.5

3.4

3.3

tLOW_DELAY (s)

tLOW_DELAY (s)

TYPICAL CHARACTERISTICS

3.2

3.1

−40°C

3.0

25°C

2.9

90°C

2.8

2.7

2.6

2.5

0

1

2

3

4

5

VDD (V)

Figure 6. tLOW_DELAY vs. VDD (CAT87x−3.0)

http://onsemi.com

4

6

�CAT871, CAT872

TYPICAL CHARACTERISTICS

30

25

25

20

IMR2 (mA)

IDD (mA)

20

15

85°C

10

25°C

5

1

2

3

4

5

0

6

3

4

5

Figure 7. IDD vs. VDD (MR1 = MR2 = 0)

Figure 8. IMR2 @ MR2 = 0

2.6

2.5

2.5

2.4

2.4

−40°C

2.2

25°C

6

2.3

tR (ms)

2.3

2.1

85°C

2.2

5.6 V

2.1

3.2 V

2.0

1.6 V

1.9

1.9

1.8

2

VDD (V)

2.6

2.0

1

VDD (V)

1

2

3

5

4

1.8

−50

6

−25

0

25

50

75

100

125

VDD (V)

TEMPERATURE (°C)

Figure 9. tR vs. VDD for CAT871

Figure 10. tR vs. Temperature for CAT871

tR (ms)

tR (ms)

0

10

−40°C

5

0

15

83

81

79

77

75

73

71

69

67

65

63

61

59

57

−40°C

25°C

90°C

0

1

2

3

4

5

VDD (V)

Figure 11. Reset Pulse Width for CAT872

http://onsemi.com

5

6

150

�CAT871, CAT872

SYSTEM DESCRIPTION AND APPLICATIONS INFORMATION

General

Reset Output

CAT871, CAT872 are designed for the manual resetting of

microprocessors and microcontrollers when normal

resetting mechanisms have failed. To prevent accidental

resets, CAT871, CAT872 require both manual reset inputs

be held low for a prescribed period before a reset pulse is

issued to the system processor.

CAT871, CAT872 provide an active−low open drain

output to be wire−OR’d with other open drain reset devices.

This output will sink up to 3 mA and as such will not be

loaded down by low value (strong) pull−up resistors. The

reset pulse is typically 2 ms long for CAT871 and 70 ms long

for CAT872 and is issued at the conclusion of the delay

timer’s countdown sequence.

CAT871, CAT872 will not generate a reset pulse at

power−up.

Manual Reset Inputs

MR1 and MR2 are Schmitt trigger CMOS inputs. Both

inputs must go low and stay low for a predetermined period

(tLOW_DELAY) to generate a single reset pulse on the output.

MR1 and MR2 operate independently and may be brought

low at any time and in any order. The last input to reach 0 V

starts the delay timer.

MR1 is a standard CMOS input and MR2 is also a CMOS

input with an internal 200 kW pull−up resistor, thus MR2 can

be left floating whereas MR1 must be biased by a pull−up

resistor, powered switch or some other means external to the

IC. (Consult factory for other input biasing options)

Delay Timer Testing

To aid in−circuit testing of the delay timer, a special test

function has been included in CAT871, CAT872. This test

mode, TOC, allows the delay timer to clock at an accelerated

rate. Upon the conclusion of the countdown a standard width

reset pulse will be issued and the chip will exit test mode.

To initiate TOC, MR1→ 0 V and a fast external CLK

(typically 1 MHz) is applied on MR2, with the falling edge

of the first clock pulse on MR2 delayed with tP from MR1→

0 V. CAT871, CAT872 look for 8 sequential pulses to appear

on MR2 within 35 ms to confirm TOC is desired. After the

rising edge of the 8’th pulse, there will be a delay of 250 ms

typical followed by a standard reset pulse at the reset output.

This delay is independent of the normal timeout delay

setting.

After issuing the reset pulse, CAT871, CAT872 exit TOC

mode and returns to normal operation. If at any time during

TOC both MR1 and MR2 are HIGH, CAT871, CAT872 will

immediately exit TOC mode.

Delay Timer

When both MR1 and MR2 go low, an internal timing cycle

is initiated. If any input goes high before the countdown

timer has concluded its cycle, the timer will reset and will

restart from the beginning when MR1 and MR2 return to

being low.

If both manual reset inputs (MR1 and MR2) remain low

after a reset pulse is issued, no second reset pulse will be

issued after that.

Figure 12. TOC Mode

http://onsemi.com

6

�CAT871, CAT872

APPLICATION INFORMATION

Reset Pulse Operation

than the VDD rail (1.8 V). MR1 and MR2 inputs are

activated here by two separate switches connected to GND

and pulling the inputs low when pressed. The Schottky diode

provides the supply isolation needed between the

CAT871/CAT872 (VDD) and the microcontroller (VBAT).

When both MR1 and MR2 inputs are kept low, a single

reset pulse is generated after the delay tLOW_DELAY. Even

with both MR1 and MR2 maintained low continuously after

that time, no second reset pulse will be generated. The delay

timer restarts if either MR1 or MR2 (or both) input

transitions from high to low, as shown in the timing diagram

in Figure 13.

Operation with Low VDD Voltage and Brownout

Condition

The CAT871, CAT872 reset generators require a

minimum supply voltage VDD of 1.65 V to guarantee the

normal operation within the specification. To prevent small

VDD supply glitch, a small ceramic capacitor can be added

between the VDD pin and GND.

System with Two Different Power Supply Voltages

The reset generator can be used in a system where the

supply VDD is different than the MR1, MR2 input logic.

Figure 14 shows an application schematic where the

microcontroller uses a supply VBAT (3.6 V) that is higher

Figure 13. Reset Timing Diagram

Figure 14. Application Schematic in Dual Supply System

http://onsemi.com

7

�CAT871, CAT872

PACKAGE DIMENSIONS

ULLGA6, 1.45x1.0, 0.5P

CASE 613AF−01

ISSUE A

PIN ONE

REFERENCE

0.10 C

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b APPLIES TO PLATED TERMINAL

AND IS MEASURED BETWEEN 0.15 AND

0.30 mm FROM THE TERMINAL TIP.

4. A MAXIMUM OF 0.05 PULL BACK OF THE

PLATED TERMINAL FROM THE EDGE OF THE

PACKAGE IS ALLOWED.

A

B

D

ÉÉÉ

ÉÉÉ

ÉÉÉ

E

DIM

A

A1

b

D

E

e

L

L1

TOP VIEW

0.10 C

0.05 C

MILLIMETERS

MIN

MAX

−−−

0.40

0.00

0.05

0.15

0.25

1.45 BSC

1.00 BSC

0.50 BSC

0.25

0.35

0.30

0.40

A

6X

0.05 C

SEATING

PLANE

SIDE VIEW

MOUNTING FOOTPRINT

SOLDERMASK DEFINED*

C

A1

5X

0.49

e

5X

L

6X

0.30

NOTE 4

3

1

L1

1.24

6

4

BOTTOM VIEW

6X

0.53

b

0.10 C A B

0.05 C

1

PKG

OUTLINE

0.50

PITCH

DIMENSIONS: MILLIMETERS

NOTE 3

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

http://onsemi.com

8

�MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

ULLGA6, 1.45x1.0, 0.5P

CASE 613AF−01

ISSUE A

1

SCALE 8:1

PIN ONE

REFERENCE

0.10 C

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b APPLIES TO PLATED TERMINAL

AND IS MEASURED BETWEEN 0.15 AND

0.30 mm FROM THE TERMINAL TIP.

4. A MAXIMUM OF 0.05 PULL BACK OF THE

PLATED TERMINAL FROM THE EDGE OF THE

PACKAGE IS ALLOWED.

A

B

D

ÉÉÉ

ÉÉÉ

DATE 06 FEB 2008

E

DIM

A

A1

b

D

E

e

L

L1

TOP VIEW

0.10 C

0.05 C

MILLIMETERS

MIN

MAX

−−−

0.40

0.00

0.05

0.15

0.25

1.45 BSC

1.00 BSC

0.50 BSC

0.25

0.35

0.30

0.40

A

6X

0.05 C

SEATING

PLANE

SIDE VIEW

C

A1

MOUNTING FOOTPRINT

SOLDERMASK DEFINED*

5X

0.49

e

5X

L

6X

0.30

NOTE 4

3

1

L1

1.24

6

4

BOTTOM VIEW

DOCUMENT NUMBER:

DESCRIPTION:

6X

b

0.10 C A B

0.05 C

NOTE 3

98AON24011D

ULLGA6, 1.45X1.0, 0.5P

0.53

1

PKG

OUTLINE

0.50

PITCH

DIMENSIONS: MILLIMETERS

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

ON Semiconductor and

are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

www.onsemi.com

�onsemi,

, and other names, marks, and brands are registered and/or common law trademarks of Semiconductor Components Industries, LLC dba “onsemi” or its affiliates

and/or subsidiaries in the United States and/or other countries. onsemi owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property.

A listing of onsemi’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. onsemi reserves the right to make changes at any time to any

products or information herein, without notice. The information herein is provided “as−is” and onsemi makes no warranty, representation or guarantee regarding the accuracy of the

information, product features, availability, functionality, or suitability of its products for any particular purpose, nor does onsemi assume any liability arising out of the application or use

of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages. Buyer is responsible for its products

and applications using onsemi products, including compliance with all laws, regulations and safety requirements or standards, regardless of any support or applications information

provided by onsemi. “Typical” parameters which may be provided in onsemi data sheets and/or specifications can and do vary in different applications and actual performance may

vary over time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. onsemi does not convey any license

under any of its intellectual property rights nor the rights of others. onsemi products are not designed, intended, or authorized for use as a critical component in life support systems

or any FDA Class 3 medical devices or medical devices with a same or similar classification in a foreign jurisdiction or any devices intended for implantation in the human body. Should

Buyer purchase or use onsemi products for any such unintended or unauthorized application, Buyer shall indemnify and hold onsemi and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that onsemi was negligent regarding the design or manufacture of the part. onsemi is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

onsemi Website: www.onsemi.com

◊

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

�