LB11696V

Direct PWM Drive Brushless

Motor Predriver IC

Monolithic Linear IC

Overview

www.onsemi.com

The LB11696V is a direct PWM drive predriver IC designed for

three-phase power brushless motors. A motor driver circuit with the

desired output power (voltage and current) can be implemented by

adding discrete transistors in the output circuits. Furthermore, the

LB11696V provides a full complement of protection circuits allowing

it to easily implement high-reliability drive circuits. This device is

optimal for driving all types of large-scale motors such as those used in

air conditioners and on-demand water heaters.

SSOP30

CASE 565AT

Features

• Single-phase Full-wave Linear Drive with BTL Output

•

•

•

•

•

•

•

•

•

•

•

(Gain Resistance 1 kW−360 kW): Most Appropriate for Consumer

Appliances Power Supply, Namely Equipment that Requires Silence

because this has No Switching Noise

Three-phase Bipolar Drive

Direct PWM Drive (Controlled either by Control Voltage or PWM

Variable Duty Pulse Input)

Built−in Forward/Reverse Switching Circuit

Start/Stop Mode Switching Circuit

(Stop Mode Power Saving Function)

Built-in Input Amplifier

5 V Regulator Output (VREG Pin)

Current Limiter Circuit (Supports 0.25 V (Typical) Reference

Voltage Sensing Based High-precision Detection)

Undervoltage Protection Circuit

(The Operating Voltage can be Set with a Zener Diode)

Automatic Recovery Type Constraint Protection Circuit with

Protection Operating State Discrimination Output (RD Pin)

Four Types of Hall Signal Pulse Outputs

Supports Thermistor Based Thermal Protection of the Output

Transistors

© Semiconductor Components Industries, LLC, 2015

July, 2018 − Rev. 3

1

MARKING DIAGRAM

XXXXXXXX

YMDDD

XXXX

Y

M

DDD

= Specific Device Code

= Year

= Month

= Additional Traceability Data

ORDERING INFORMATION

See detailed ordering and shipping information on page 17 of

this data sheet.

Publication Order Number:

LB11696V/D

�LB11696V

SPECIFICATIONS

ABSOLUTE MAXIMUM RATINGS (TA = 25°C)

Symbol

VCC max

Parameter

Conditions

Ratings

Unit

Supply Voltage 1

VCC pin

18

V

Output Current

UL, VL, WL, UH, VH, and WH pins

30

mA

LVS max

LVS Pin Applied Voltage

LVS pin

18

V

Pd max 1

Allowable Power Dissipation 1

Independent IC

0.45

W

Pd max 2

Allowable Power Dissipation 2

When mounted on a 114.3 × 76.1 × 1.6 mm

glass epoxy board

1.05

W

IO max

Topr

Operating Temperature

–20 to +100

°C

Tstg

Storage Temperature

–55 to +150

°C

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

ALLOWABLE OPERATING RANGES (TA = 25°C)

Parameter

Symbol

Conditions

VCC1−1

Supply Voltage Range 1−1

VCC pin

VCC1−2

Supply Voltage Range 1−2

VCC pin, when VCC is shorted to VREG

Output Current

UL, VL, WL, UH, VH, and WH pins

IO

Ratings

Unit

8 to 17

V

4.5 to 5.5

V

25

mA

−30

mA

IREG

5 V Constant Voltage Output Current

VHP

HP Pin Applied Voltage

0 to 17

V

IHP

HP Pin Output Current

0 to 15

mA

VRD

RD Pin Applied Voltage

0 to 17

V

IRD

RD Pin Output Current

0 to 15

mA

Functional operation above the stresses listed in the Recommended Operating Ranges is not implied. Extended exposure to stresses beyond

the Recommended Operating Ranges limits may affect device reliability.

ELECTRICAL CHARACTERISTICS (TA = 25°C, VCC = 12 V)

Symbol

Parameter

ICC1

Current Drain 1

ICC2

Current Drain 2

Conditions

Stop mode

Min

Typ

Max

Unit

−

12

16

mA

−

2.5

4

mA

4.7

5.0

5.3

V

5 V CONSTANT VOLTAGE OUTPUT (VREG PIN)

VREG

Output Voltage

DVREG1

Line Regulation

VCC = 8 to 17 V

−

40

100

mV

DVREG2

Load Regulation

IO = −5 to −20 mA

−

10

30

mV

DVREG3

Temperature Coefficient

Design target value

−

0

−

mV/°C

OUTPUT BLOCK

VOUT1−1

Output Voltage 1−1

Low level, IO = 400 mA

−

0.2

0.5

V

VOUT1−2

Output Voltage 1−2

Low level, IO = 10 mA

−

0.9

1.2

V

VOUT2

Output Voltage 2

High level, IO = −20 mA

IO Leak

Output Leak Current

VCC − 1.1 VCC − 0.9

−

V

−

−

10

mA

−2

−0.5

−

mA

0.5

−

VCC − 2.0

V

HALL AMPLIFIER BLOCK

IHB (HA)

VICM1

Input Bias Current

Common-mode Input Voltage Range 1

When a Hall element is used

www.onsemi.com

2

�LB11696V

ELECTRICAL CHARACTERISTICS (TA = 25°C, VCC = 12 V) (continued)

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

0

−

VCC

V

Hall Input Sensitivity

80

−

−

mVp-p

DVIN (HA)

Hysteresis

15

24

40

mV

VSLH (HA)

Input Voltage Low → High

5

12

20

mV

VSHL (HA)

Input Voltage High → Low

−20

−12

−5

mV

Input Offset Voltage

−10

−

10

mV

Input Bias Current

−1

−

1

mA

Common-mode Input Voltage Range

0

−

VREG −

1.7

V

VREG −

1.2

VREG −

0.8

−

V

HALL AMPLIFIER BLOCK

VICM2

Common-mode Input Voltage Range 2

Single-sided input bias mode

(when a Hall IC is used)

CTL AMPLIFIER

VIO (CTL)

IB (CTL)

VICM

VOH (CTL)

VOL (CTL)

G (CTL)

High-level Output Voltage

ITOC = −0.2 mA

Low-level Output Voltage

ITOC = 0.2 mA

−

0.8

1.05

V

Open-loop Gain

f (CTL) = 1 kHz

45

51

−

dB

PWM OSCILLATOR (PWM PIN)

VOH (PWM)

High-level Output Voltage

2.75

3.0

3.25

V

VOL (PWM)

Low-level Output Voltage

1.2

1.35

1.5

V

−120

−90

−65

mA

ICHG

External Capacitor Charge Current

VPWM = 2.1 V

f (PWM)

Oscillator Frequency

C = 2000 pF

V (PWM)

Amplitude

−

22

−

kHz

1.4

1.6

1.9

Vp-p

TOC PIN

VTOC1

Input Voltage 1

Output duty: 100%

2.68

3.0

3.34

V

VTOC2

Input Voltage 2

Output duty: 0%

1.2

1.35

1.5

V

VTOC1L

Input Voltage 1 Low

Design target value,

when VREG = 4.7 V, 100%

2.68

2.82

2.96

V

VTOC2L

Input Voltage 2 Low

Design target value,

when VREG = 4.7 V, 0%

1.23

1.29

1.34

V

VTOC1H

Input Voltage 1 High

Design target value,

when VREG = 5.3 V, 100%

3.02

3.18

3.34

V

VTOC2H

Input Voltage 2 High

Design target value,

when VREG = 5.3 V, 0%

1.37

1.44

1.50

V

Output Saturation Voltage

IO = 10 mA

−

0.2

0.5

V

Output Leakage Current

VO = 18 V

−

−

10

mA

HP PIN

VHPL

IHPleak

CSD OSCILLATOR (CSD PIN)

VOH (CSD)

High-level Output Voltage

2.7

3.0

3.3

V

VOL (CSD)

Low-level Output Voltage

0.7

1.0

1.3

V

VCSD = 2 V

−3.15

−2.5

−1.85

mA

ICHG1

External Capacitor Charge Current

ICHG2

External Capacitor Discharge Current

VCSD = 2 V

0.1

0.14

0.18

mA

RCSD

Charge/Discharge Current Ratio

(Change current) / (Discharge

current)

15

18

21

times

www.onsemi.com

3

�LB11696V

ELECTRICAL CHARACTERISTICS (TA = 25°C, VCC = 12 V) (continued)

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

RD PIN

VRDL

Low-level Output Voltage

IO = 10 mA

−

0.2

0.5

V

IL (RD)

Output Leakage Current

VO = 18 V

−

−

10

mA

0.225

0.25

0.275

V

CURRENT LIMITER CIRCUIT (RF PIN)

VRF

Limiter Voltage

RF−RFGND

UNDERVOLTAGE PROTECTION CIRCUIT (LVS PIN)

VSDL

Operating Voltage

3.5

3.7

3.9

V

VSDH

Release Voltage

3.95

4.15

4.35

V

DVSD

Hysteresis

0.3

0.45

0.6

V

−

−

50

kHz

PWMIN PIN

f (PI)

Input Frequency

VIH (PI)

High-level Input Voltage

2.0

−

VREG

V

VIL (PI)

Low-level Input Voltage

0

−

1.0

V

VIO (PI)

Input Open Voltage

VREG −

0.5

−

VREG

V

VIS (PI)

Hysteresis

0.2

0.25

0.4

V

IIH (PI)

High-level Input Current

VPWMIN = VREG

−10

0

+10

mA

IIL (PI)

Low-level Input Current

VPWMIN = 0 V

−130

−90

−

mA

S/S PIN

VIH (SS)

High-level Input Voltage

2.0

−

VREG

V

VIL (SS)

Low-level Input Voltage

0

−

1.0

V

VIS (SS)

Hysteresis

0.2

0.25

0.4

V

IIH (SS)

High-level Input Current

VS/S = VREG

−10

0

+10

mA

IIL (SS)

Low-level Input Current

VS/S = 0 V

−10

−1

−

mA

F/R PIN

VIH (FR)

High-level Input Voltage

2.0

−

VREG

V

VIL (FR)

Low-level Input Voltage

0

−

1.0

V

VIO (FR)

Input Open Voltage

VREG −

0.5

−

VREG

V

VIS (FR)

Hysteresis

0.2

0.25

0.4

V

IIH (FR)

High-level Input Current

VF/R = VREG

−10

0

+10

mA

IIL (FR)

Low-level Input Current

VF/R = 0 V

−130

−90

−

mA

2.0

−

VREG

V

N1 PIN

VIH (N1)

High-level Input Voltage

VIL (N1)

Low-level Input Voltage

VIO (N1)

Input Open Voltage

IIH (N1)

High-level Input Current

IIL (N1)

Low-level Input Current

0

−

1.0

V

VREG

−0.5

−

VREG

V

VN1 = VREG

−10

0

+10

mA

VN1 = 0 V

−130

−100

−

mA

www.onsemi.com

4

�LB11696V

ELECTRICAL CHARACTERISTICS (TA = 25°C, VCC = 12 V) (continued)

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

N2 PIN

VIH (N2)

High-level Input Voltage

2.0

−

VREG

V

VIL (N2)

Low-level Input Voltage

0

−

1.0

V

VIO (N2)

Input Open Voltage

VREG −

0.5

−

VREG

V

IIH (N2)

High-level Input Current

VN2 = VREG

−10

0

+10

mA

IIL (N2)

Low-level Input Current

VN2 = 0 V

−130

−100

−

mA

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

THREE-PHASE LOGIC TRUTH TABLE (“IN = ‘H’” INDICATES THE STATE WHERE IN+ > IN−)

F/R = L

F/R = H

Output

IN1

IN2

IN3

IN1

IN2

IN3

PWM

−

1

H

L

H

L

H

L

VH

UL

2

H

L

L

L

H

H

WH

UL

3

H

H

L

L

L

H

WH

VL

4

L

H

L

H

L

H

UH

VL

5

L

H

H

H

L

L

UH

WL

6

L

L

H

H

H

L

VH

WL

S/S PIN

PWMIN PIN

Input State

State

Input State

State

H

Stop

High or Open

Output Off

L

Start

L

Output On

N1 AND N2 PINS

Input State

N1 Pin

N2 Pin

L

L

L

High or Open

High or Open

L

High or Open

High or Open

HP Output

Single Hall sensor period divided by 2

Single Hall sensor period

Three Hall sensor synthesized period divided by 2

Three Hall sensor synthesized period

converted to a pulsed output (one-Hall output), the one-Hall

output divided by two, the three-phase output synthesized

from the Hall inputs (three-Hall synthesized output) or the

three-Hall synthesized output divided by two.

Since the S/S pin does not have at internal pull-up resistor,

an external pull-up resistor or equivalent is required to set

the IC to the stop state. If either the S/S or PWMIN pins are

not used, th unused pin input must be set to the low-level

voltage.

The HP output can be selected (by the N1 an N2 settings)

to be one of the following four functions: the IN1 Hall input

www.onsemi.com

5

�Allowable Power Dissipation, Pd max − W

LB11696V

1.2

114.3 × 76.1 × 1.6 mm glass epoxy board

1.0

0.8

0.6

Independent

0.42

0.4

0.2

0

−20

0.18

0

20

40

60

80

100

120

Ambient Temperature, TA − 5C

Figure 1. Pd max − TA

PIN ASSIGNMENT

Figure 2. Pin Assignment

PIN FUNCTIONS

Pin No.

Pin Name

1

GND

2

RF GND

Equivalent Circuit

Description

Ground pin.

GND of output current detection, RF pin.

Connect to GND of external RF resistor.

www.onsemi.com

6

�LB11696V

PIN FUNCTIONS (continued)

Pin No.

Pin Name

Equivalent Circuit

Description

3

RF

Output current detection.

Implement small resistor between RF pin and

RFGND.

Set IOUT = 0.25/Rf as a maximum current.

4

6

8

5

7

9

WH

VH

UH

WL

VL

UL

Outputs (active by external Tr).

UH, VH, WH control the duty.

10

11

12

13

14

15

IN1−

NI1+

IN2−

IN2+

IN3−

IN3+

Hall signal input pin.

The state is “High” in IN+ > IN− and the state is

“Low” in opposite mode.

If the Hall signal noise is problem, put the

capacitor between IN+ and IN−.

16

17

EI+

EI−

CTL amplifier.

The PWMIN pin must be held at the “Low” to

use this input for motor control.

www.onsemi.com

7

�LB11696V

PIN FUNCTIONS (continued)

Pin No.

Pin Name

Equivalent Circuit

Description

18

TOC

CTL amplifier output.

When TOC voltage rises up, the PWM duty of

UH, VH, WH is changed and the torque force

rises up.

19

PWM

The PWM oscillator frequency setting and the

initial reset pulse setting pin. Connect

a capacitor between this pin and GND.

If C = 2000 pF, PWM set to about 22 kHz.

20

RD

Lock (motor constrained) detection state output.

This output is turned on when the motor is

turning and off when the lock protection function

detects the motor stop.

21

CSD

Sets the operating time for the lock protection

circuit.

Connect a capacitor between this pin and GND.

Connect this pin to GND if the lock protection

function is not used.

www.onsemi.com

8

�LB11696V

PIN FUNCTIONS (continued)

Pin No.

Pin Name

Equivalent Circuit

Description

22

S/S

23

PWM IN

24

F/R

Forward/reverse control input.

25

HP

Hall signal output (HP output). Open collector

type. This provides 4 output mode by the N1

and N2 settings.

Start/Stop input pin.

“L” = start, “H” = stop.

PWM pulse input pin. This pin is “Low”, the output goes to the drive state, and this pin is “High”

or “OPEN”, the output is off state. To use this

pin for the control, it is required that the CTL

amplifier inputs to make the TOC pin voltage

100% duty state.

www.onsemi.com

9

�LB11696V

PIN FUNCTIONS (continued)

Pin No.

Pin Name

Equivalent Circuit

Description

26

N1

Hall signal output (HP output) selection pin.

27

N2

Hall signal output (HP output) selection pin.

28

LVS

Low voltage protection detection. If the detection voltage is over 5 V, connect the Zener

diode to VCC in series and adjust the detection

voltage properly.

29

VREG

5 V regulator output used as the control circuit

power supply.

Connect a capacitor between this pin and GND

for 5 V output stabilization (about 0.1 mF).

30

VCC

Power supply. Connect a capacitor between this

pin and GND for VCC stabilization.

www.onsemi.com

10

�LB11696V

Hall Sensor Signal Input/Output Timing Chart

F/R = “L”

IN1

IN2

IN3

UH

VH

WH

UL

VL

WL

F/R = “H”

IN1

IN2

IN3

UH

VH

WH

UL

VL

WL

Section shown in gray are PWM output periods

Figure 3. Hall Sensor Signal Input/Output Timing Chart

www.onsemi.com

11

�LB11696V

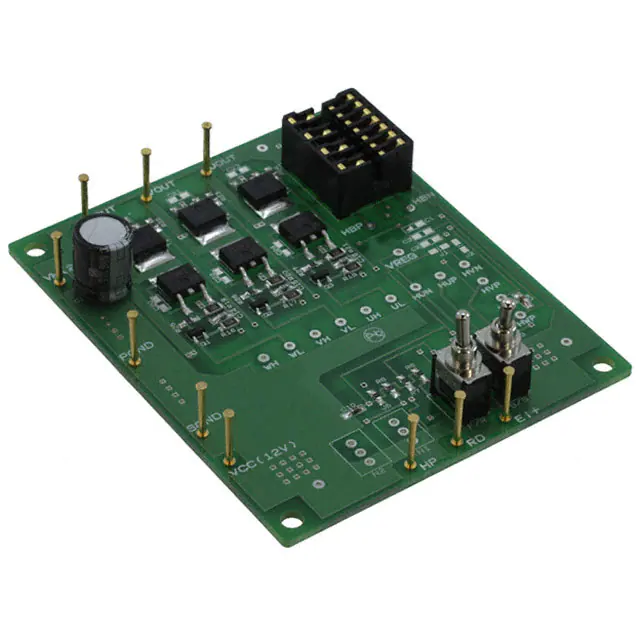

BLOCK DIAGRAM AND APPLICATION EXAMPLE 1

Bipolar transistor drive (high side PWM) using a 5 V power supply.

Figure 4. Application Example 1

www.onsemi.com

12

�LB11696V

APPLICATION EXAMPLE 2

MOS transistor drive (low side PWM) using a 12 V single-voltage power supply.

Figure 5. Application Example 2

www.onsemi.com

13

�LB11696V

APPLICATION EXAMPLE 3

N MOS transistor drive (low side PWM) using a VCC = 12 V and Thermistor.

Figure 6. Application Example 3

www.onsemi.com

14

�LB11696V

LB11696V FUNCTIONAL DESCRIPTION

1. Output Drive Circuit:

The LB11696V adopts direct PWM drive to

minimize power loss in the outputs. The output

transistors are always saturated when on, and the

motor drive power is adjusted by changing the on

duty of the output. The output PWM switching is

performed on the UH, VH, and WH outputs. Since

the UL to WL and UH to WH outputs have the

same output form, applications can select either

low side PWM or high side PWM drive by

changing the way the external output transistors

are connected. Since the reverse recovery time of

the diodes connected to the non-PWM side of the

outputs is a problem, these devices must be

selected with care. (This is because through

currents will flow at the instant the PWM side

transistors turn on if diodes with a short reverse

recovery time are not used.)

2. Current Limiter Circuit:

The current limiter circuit limits the output current

peak value to a level determined by the equation

I = VFR/Rf (VRF = 0.25 V typical, Rf: current

detection resistor). This circuit suppresses the

output current by reducing the output on duty.

To get shorter the distance between Rf and RF pin

and RF GND, to get the measurement more

precisely.

The current limiter circuit includes an internal

filter circuit to prevent incorrect current limiter

circuit operation due to detecting the output diode

reverse recovery current due to PWM operation.

Although there should be no problems with the

internal filter circuit in normal applications,

applications should add an external filter circuit

(such as an RC low-pass filter) if incorrect

operation occurs (if the diode reverse recovery

current flows for longer than 1 ms).

To VREG

To S/S

Hall

4. Notes on the PWM Frequency:

The PWM frequency is determined by the

capacitor C (F) connected to the PWM pin.

fPWM ≈ 1 / (22500 × C)

If a 2000 pF capacitor is used, the circuit will

oscillate at about 22 kHz. If the PWM frequency is

too low, switching noise will be audible from the

motor, and if it is too high, the output power loss

will increase. Thus a frequency in the range

15 kHz to 50 kHz must be used. The capacitor’s

ground terminal must be placed as close as

possible to the IC’s ground pin to minimize the

influence of output noise and other noise sources.

5. Control Methods:

The output duty can be controlled by either of the

following methods:

• Compare TOC Voltage and PWM Waveform:

The low side output transistor duty is

determined by the result of comparing the TOC

pin voltage to the PWM oscillator waveform.

When the TOC voltage is 1.35 V or lower, the

duty is set to 0% and when the TOC voltage is

3.0 V or higher, it is set to 100%. Because the

TOC pin is the output of the CTL amplifier, it is

not able to input the control voltage into it.

Hence, CTL amplifier is used as an all feedback

amplifier (connect the EI- and the TOC pin) and

DC voltage should be input through the EI+ pin

(the EI+ pin = the TOC pin voltage). The

increase of EI+ voltage increases the output

duty and when EI+ is open, the motor is in

rotation. To stop the motor rotation, the

pull-down register should be connected to EI+

pin.

When the TOC pin voltage control is used,

a low-level input must be applied to the

PWMIN pin or that pin connected to GND.

• Pulse Control Using the PWMIN Pin:

A pulse signal can be input to the PWMIN pin,

and the output can be controlled by the duty of

that signal.

The output is on when a low level is input to

To the RF Pin

Current Detection

Resistor

3. Power Save Circuit:

For this IC, the state of motor stop is power save

mode to decrease the power consumption. In this

mode, almost all of the circuit are off, though

VREG (5 V) output is active. If the bias current of

Hall element should be off, connect Hall element

and 5 V through PNP Tr.

www.onsemi.com

15

�LB11696V

VCC Pin

the PWMIN pin, and off when a high level is

input. When the PWMIN pin is open, the pin

goes to the high level and the output is turned

off. If inverted input logic is required, an

external transistor (NPN) can allow it.

When controlling motor operation from the

PWMIN pin, the EI- pin must be connected to

the GND and the EI+ pin must be connected to

the TOC pin.

Note that since the PWM oscillator is also used

as the clock for internal circuits, a capacitor

(about 2000 pF) must be connected to the PWM

pin even if the PWMIN pin is used for motor

control.

6. Hall Input Signals:

A signal input with an amplitude in excess of the

hysteresis (80 mV maximum) is required for the

Hall inputs.

Considering the possibility of noise and phase

displacement, an even larger amplitude is

desirable.

If disruptions to the output waveforms (during

phase switching) or to the HP output (Hall signal

output) occur due to noise, this must be prevented

by inserting capacitors across the inputs.

The constraint protection circuit uses the Hall

inputs to discriminate the motor constraint state.

Although the circuit is designed to tolerate

a certain amount of noise, care is required when

using the constraint protection circuit.

If all three phases of the Hall input signal system

go to the same input state, the outputs are all set to

the off state (the UL, VL, WL, UH, VH, and WH

outputs all go to the low level).

If the outputs from a Hall IC are used, fixing one

side of the inputs (either the + or – side) at

a voltage within the common-mode input voltage

range allows the other input side to be used as an

input over the 0 V to VCC range.

7. Under-voltage Protection Circuit:

The under-voltage protection monitors the LVS

pin voltage and the circuit turns off the outputs

(UH, VH, and WH) when the voltage falls below

the minimum operation voltage (see the Electrical

Characteristics). To prevent the reputation of the

output on and off close to the protection threshold

voltage, it has hysteresis which is 0.45 V (typical).

Hence to release the protection mode, plus 0.45 V

(typ.) to the operation voltage is needed.

To LVS Pin

The detection level of the protection voltage is 5 V

system. If it is needed to go up the detection level,

connect the Zenner diode to LVS pin in series to shift

the detection voltage level. The LVS input current

for the detection is about 75 mA. To increase the

current of the Zenner diode to stabilize the rising

voltage of it, insert the resistor between LVS pin and

GND.

When the LVS pin is open, it becomes GND level

and the output is off because of pull-down resistor

inside the circuit. Hence, when it turns off, the

voltage higher than 4.35 V should be input to LVS

pin as a release voltage. The maximum ratings of

LVS pin is 18 V.

8. Constraint Protection Circuit:

When the motor is physically constrained (held

stopped), the CSD pin external capacitor is

charged (to about 3.0 V) by a constant current of

about 2.5 mA and is then discharged (to about

1.0 V) by a constant current of about 0.14 mA.

This process is repeated, generating a saw-tooth

waveform. The constraint protection circuit turns

motor drive on and off repeatedly based on this

saw-tooth waveform. (The UH, VH, and WH side

outputs are turned on and off.) Motor drive is on

during the period the CSD pin external capacitor is

being charged from about 1.0 V to about 3.0 V,

and motor drive is off during the period the CSD

pin external capacitor is being discharged from

about 3.0 V to about 1.0 V.

The IC and the motor are protected by this

repeated drive on/off operation when the motor is

physically constrained.

The motor drive on and off times are determined

by the value of the connected capacitor C (in mF).

TCSD1 (drive on period) ≈ 0.8 × C (seconds)

TCSD2 (drive off period) ≈ 14.3 × C (seconds)

When a 0.47 mF capacitor is connected externally

to the CSD pin, this iterated operation will have

a drive on period of about 0.38 seconds and a drive

www.onsemi.com

16

�LB11696V

off period of about 6.7 seconds.

While the motor is turning, the discharge pulse

signal (generated once for each Hall input period)

that is created by combining the Hall inputs

internally in the IC discharges the CSD pin

external capacitor. Since the CSD pin voltage does

not rise, the constraint protection circuit does not

operate.

When the motor is physically constrained, the Hall

inputs do not change and the discharge pulses are

not generated.

As a result, the CSD pin external capacitor is

charged by a constant current of 2.5 mA to about

3.0 V, at which point the constraint protection

circuit operates. When the constraint on the motor

is released, the constraint protection function is

released.

Connect the CSD pin to ground if the constraint

protection circuit is not used.

9. Forward/Reverse Direction Switching:

This IC is designed so that through currents

(due to the output transistor off delay time when

switching) do not flow in the output when

switching directions when the motor is turning.

However, if the direction is switched when the

motor is turning, current levels in excess of the

current limiter value may flow in the output

transistors due to the motor coil resistance and the

motor back EMF state when switching. Therefore,

designers must consider selecting external output

transistors that are not destroyed by those current

levels or only switching directions after the speed

has fallen below a certain speed.

10. Handling Different Power Supply Types:

When this IC is operated from an externally

supplied 5 V power supply (4.5 to 5.5 V), short the

VCC pin to the VREG pin and connect them to the

external power supply.

When this IC is operated from an externally

supplied 12 V power supply (8 to 17 V), connect

the VCC pin to the power supply. (The VREG pin

will generate a 5 V level to function as the control

circuit power supply.)

11. Power Supply Stabilization:

Since this IC uses a switching drive technique, the

power supply line level can be disturbed easily.

Therefore capacitors with adequate capacitance to

stabilize the power supply line must be inserted

between VCC and ground.

If diodes are inserted in the power supply lines to

prevent destruction if the power supply is

connected with reverse polarity, the power supply

lines are even more easily disrupted, and even

larger capacitors are required.

If the power supply is turned on and off by

a switch, and if there is a significant distance

between that switch and the stabilization capacitor,

the supply voltage can be disrupted significantly

by the line inductance and surge current into the

capacitor. As a result, the withstand voltage of the

device may be exceeded. In application such as

this, the surge current must be suppressed and the

voltage rise prevented by not using ceramic

capacitors with a low series impedance, and by

using electrolytic capacitors instead.

12. VREG Stabilization:

To stabilize the VREG voltage, which is the

control circuit power supply, a 0.1 mF or larger

capacitor must be inserted between the VREG pin

and ground. The ground side of this capacitor must

connected to the IC ground pin with a line that is

as short as possible.

ORDERING INFORMATION

Package

Wire Bond

Shipping† (Qty / Packing)†

LB11696V−MPB−E

SSOP30 (275mil)

(Pb−Free)

Au wire

48 / Fan-Fold

LB11696V−TLM−E

SSOP30 (275mil)

(Pb−Free)

Au wire

1,000 / Tape & Reel

LB11696V−TRM−E

SSOP30 (275mil)

(Pb−Free)

Au wire

1,000 / Tape & Reel

LB11696V−TLM−H

SSOP30 (275mil)

(Pb−Free / Halogen Free)

Au wire

1,000 / Tape & Reel

LB11696V−W−AH

SSOP30 (275mil)

(Pb−Free / Halogen Free)

Cu wire

1,000 / Tape & Reel

Device

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

www.onsemi.com

17

�MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SSOP30 (275mil)

CASE 565AT

ISSUE A

DATE 31 OCT 2013

1.00

SOLDERING FOOTPRINT*

(Unit: mm)

7.00

GENERIC

MARKING DIAGRAM*

0.65

XXXXX = Specific Device Code

Y = Year

M = Month

DDD = Additional Traceability Data

0.32

NOTE: The measurements are not to guarantee but for reference only.

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

DOCUMENT NUMBER:

DESCRIPTION:

98AON66071E

SSOP30 (275MIL)

XXXXXXXXXX

YMDDD

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

ON Semiconductor and

are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

www.onsemi.com

�ON Semiconductor and

are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. ON Semiconductor reserves the right to make changes without further notice to any products herein.

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

◊

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

www.onsemi.com

1

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

�Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

ON Semiconductor:

LB11696V-TRM-E LB11696VGEVB

�