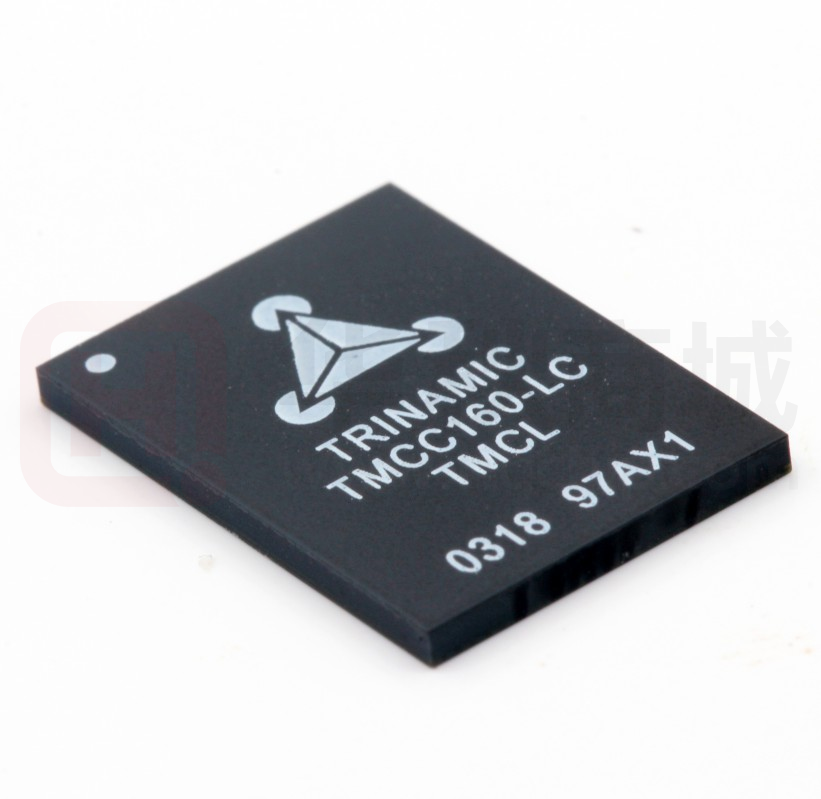

motionCookie SYSTEM IN A PACKAGE

motionCookie™

TMCC160 DATASHEET

Integrated motionCookie™ microsystem with 3-Phase BLDC/PMSM gate driver for up to 24V and 1A

gate current with a complete servocontroller software stack.

Applications

Robotics

Pump, Fan Applications

Industrial Automation

Medical, Lab Automation

CNC Machines

E-Bikes

Battery Powered Devices

Features & Benefits

Description

Integrated BLDC or PMSM Servo Controller

Integrated Gate Driver up to 1A Gate Current

Voltage Range 7…24V

Integrated FOC Controller

UART, CAN or SPI Interface

Hall Interface

ABN Incremental Encoder Interface

Integrated Switching Regulator

The TMCC160 is a ready to use PMSM/

BLDC motor controller in a miniaturized

12x17mm² system in a package. It

integrates a powerful programmed

microcontroller with efficient state of

the art commutation algorithm, gate

driver, different interface options as well

as a step down converter which

generates the digital power supply,

measurement and diagnostic features.

Block Diagram

Ref.

Switches

I_U, I_V

Power Bridge

TMCC160

VM

Motor

UART

CAN

SPI0

SPI1

U

PWM

Microcontroller

AIN

DIAG

Gatedriver

V

W

Current

ABN

Power

Supply

HALL

DC/DC

(3.3V)

ABN

HALL

I_U, I_V

Figure 1: TMCC160 System Block Diagram

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical

change reserved. Download newest version at: www.trinamic.com

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

1

Table of Contents

TMCC160 DATASHEET ......................................... 1

Applications ....................................................... 1

Features & Benefits .......................................... 1

Description ........................................................ 1

Block Diagram ................................................... 1

1 Table of Contents ......................................... 2

PRODUCT DETAILS ....................................... 1

2 Pin Assignments ........................................... 1

2.1

Package Pin Numbering ....................... 1

2.2

Package Pin Description ....................... 2

2.3

Wide Range of Control Algorithms ..... 3

3 System Overview .......................................... 5

3.1

Block Diagram ....................................... 5

3.2

System Architecture.............................. 5

3.3

Hall-Sensor Configuration.................... 6

3.4

Encoder Configuration ......................... 7

4 External Components .................................. 8

4.1

Gate Driver Charge Pump (TMC6130) 8

4.2

DC/DC Converter (3.3V) ...................... 10

4.3

CORTEX M4 Crystal ............................. 12

4.4

Supply Filter ......................................... 12

4.5

Power MOSFET Bridge ........................ 15

4.5.1 Direct Coil Current Measurement 15

4.5.2 Recommended Schematic for Direct

Coil Measurement ...................................... 15

4.5.3 Sense Resistor Selection ............... 16

4.5.4 Calculating Power Losses ............. 17

4.5.5 Current Amplifier ........................... 17

4.5.6 Single Shunt Measurement .......... 17

4.5.7 Sense Resistor Selection ............... 18

4.5.8 Dead Time Logic............................. 18

4.5.9 Power MOSFET Selection .............. 18

4.5.10 Gate Driver Clamp Diodes ............ 19

5

6

7

8

4.5.11 Power

Supply

Filtering

Capacitors .................................................... 21

4.6

Interface ............................................... 21

4.6.1 RS232 ............................................... 21

4.6.2 RS485 ............................................... 22

4.6.3 RS485 Bus Structure ...................... 23

4.6.4 RS485 Bus Termination................. 23

4.6.5 No Floating Bus Lines .................... 23

4.6.6 CAN 2.0B Interface ........................ 24

4.6.7 CAN Bus Structure ......................... 24

4.6.8 CAN Bus Termination .................... 25

4.6.9 Number of Nodes .......................... 25

4.6.10 Analog Input ................................... 26

4.7

EEPROM ................................................ 27

4.8

Brake Chopper .................................... 28

4.8.1 Brake resistor selection ................ 28

4.8.2 Brake Chopper Example ............... 29

4.9

Absolute Maximum Ratings............... 30

Operational Ratings ................................... 31

Mechanical Dimensions ............................. 33

6.1

TMCC160 Package Footprint ............. 33

6.1.1 Soldering Profile ............................ 35

SUPPLEMENTAL DIRECTIVES ..................... 36

7.1

ESD Sensitive Device ........................... 36

7.2

Disclaimer ............................................ 36

Revision History .......................................... 37

8.1

Document Revision ............................. 37

8.2

Hardware Revision .............................. 37

8.3

Software Revision ............................... 37

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

2/39

�motionCookie SYSTEM IN A PACKAGE

motionCookie™

PRODUCT DETAILS

2

Pin Assignments

TMCC160 has two pad sizes. The pads on the edges measure 0.43mm x 0.43mm with 1mm pitch.

The inner pads measure 1.93mm x 1.93mm.

Please refer to chapter TMCC160 Package Footprint for further information about the package

dimensions.

LS2

BM2

HS2

RS+

Package Pin Numbering

RS-

2.1

XTAL

EXTAL

CAN_TXD

CAN_RXD

TXD

RXD

Figure 1 TMCC160 pin assignments / bottom view

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical

change reserved. Download newest version at: www.trinamic.com

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

2.2

Package Pin Description

Package Pin Description

Pad

Number

Type

Name

Function

1

2

Out (D)

In (D)

RS485_DIR

CSN_SPI1

RS485 transceiver direction output.

SPI1 chip select input (low active) (slave interface).

3

4

In (D)

In (D)

SCLK_SPI1

MOSI_SPI1

SPI1 serial clock input (slave interface).

SPI1 serial input (slave interface).

5

6

Out (D)

In (A)

MISO_SPI1

I_V

SPI1 serial output (slave interface).

Analog current sense amplifier input for PMSM phase V.

7

In (A)

I_U

Analog current sense amplifier input for PMSM phase U.

8

9

In (A)

In (A)

TEMP

AIN

Analog input for temperature measurement.

General purpose analog input.

10

11

Out (D)

In (D)

Brake

REFL

PWM output for brake chopper circuit.

Left reference switch input.

12

In (D)

REFR

Right reference switch input.

13

14

Out

Out

DA

SW

3.3V switch regulator diode anode.

3.3V switch regulator switch cathode.

15

16

Out

In

LS1

BM1

Low side N-channel MOSFET gate output phase 1 (U).

MOSFET bridge output phase 1 (U).

17

18

Out

Out

HS1

HS3

High side N-channel MOSFET gate output phase 1 (U).

High side N-channel MOSFET gate output phase 3 (W).

19

In

BM3

MOSFET bridge output phase 3 (W).

20

21

Out

Out

LS3

VCP_REG

22

In

VCP

Low side N-channel MOSFET gate output phase 3 (W).

Gate driver linear regulator output. Connect 4.7µF

capacitor.

Gate driver charge pump input.

23

Out

VCP_SW

24

25

In (D)

In (D)

HALL_1

HALL_2

Gate driver charge pump output.

Hall sensor 1 input.

Hall sensor 2 input.

26

27

In (D)

In (D)

HALL_3

ENC_N

Hall sensor 3 input.

Encoder N (index) input.

28

In (D)

ENC_B

Encoder B input.

29

30

In (D)

Out (D)

ENC_A

MOSI_SPI0

Encoder A input.

SPI0 serial output (EEPROM master).

31

32

In (D)

Out (D)

MISO_SPI0

SCLK_SPI0

SPI0 serial input (EEPROM master).

SPI0 serial clock output (EEPROM master).

33

34

Out (D)

IO (D)

CSN_SPI0

ENABLE

35

Out

XTAL

SPI0 chip select output (low active) (EEPROM master).

Motor driver enable (high active). ENABLE signal is also

connected to the internal µC. Please connect ENABLE pin

only to open drain outputs.

Crystal oscillator output.

36

37

In

Out (D)

EXTAL

CAN_TXD

Crystal oscillator input.

CAN interface output. Connect to CAN transceiver.

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

2/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

Package Pin Description

Pad

Number

38

In (D)

CAN_RXD

CAN interface input. Connect to CAN transceiver.

39

40

Out (D)

In (D)

TXD

RXD

UART output. Connect to RS232/RS485 transceiver.

UART input. Connect to RS232/RS485 transceiver.

41

42

In (D)

IO (D)

SWDCLK

SWDIO

Please do not connect.

Please do not connect.

In

VM

VCC

Motor supply voltage.

3.3V digital supply voltage.

45

GND

System ground connection.

46

47

Out

GND

LS2

System ground connection.

Low side N-channel MOSFET gate output phase 2 (V).

48

49

In

Out

BM2

HS2

MOSFET bridge output phase 2 (V).

High side N-channel MOSFET gate output phase 2 (V).

50

In (A)

RS+

51

In (A)

RS-

Positive current sense input

measurement.

Negative current sense input

measurement.

43

44

Type

Name

Function

for

single

shunt

for

single

shunt

Table Key: (D): digital IO, (A): analog IO

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

3/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

2.3

Wide Range of Control Algorithms

The TMCC160 is a ready to use PMSM/ BLDC motor controller in a miniaturized 12x17mm²

package. It integrates a powerful programmed microcontroller with efficient state of the art

commutation algorithm, gate driver, measurement and diagnostic features, different interface

options as well as a step down converter which generates the digital power supply.

TMCC supports

FOC and six-step

mode

TMCC160 supports state of the art field oriented control algorithm (FOC) using

hall or encoder signals for PMSM motors as well as block hall commutation (six

step mode) for BLDC motors. Current-, velocity- and position controller are

implemented for all commutation modes. They can be parameterized via the

installed TMCL protocol.

Scope of TMCL

Operating System

Only few external hardware components are needed to build a complete servo

drive without spending time developing complicated control and

communication software. With the programmed operating system, TMCL, it is

possible to directly connect a host PC to the TMCC160 via one of the supported

interface connections. All parameters for motion control and global functions

can be configured by only reading or writing registers.

i

Software customization and custom package labeling are available upon request.

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

4/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

3

System Overview

3.1

Block Diagram

Ref.

Switches

I_U, I_V

Power Bridge

TMCC160

VM

Motor

UART

CAN

SPI0

SPI1

U

PWM

Microcontroller

AIN

DIAG

Gatedriver

V

W

Current

ABN

Power

Supply

HALL

DC/DC

(3.3V)

ABN

HALL

I_U, I_V

Figure 2: TMCC160 System Block Diagram

3.2

System Architecture

Only a few external components are needed to build a complete closed-loop system with

maximum flexibility. To interconnect TMCC160 with a host PC or microcontroller, the following

interfaces are available: UART(RS232, RS485), CAN, SPI. An analog input supports simple

standalone applications.

Avoiding Power

Overshoots

To avoid power supply overshoots during deceleration/ energy feedback from

the motor, TMCC160 provides a brake chopper output which can be connected

to a low side N-channel MOSFET. The brake chopper duty cycle will be

automatically controlled depending on the supply voltage.

TMCL storage in

external EEPROM

TMCL programs can be stored in an external EEPROM. Programs can be

automatically executed after power up or triggered from the host system.

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

5/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

3.3

Hall-Sensor Configuration

For applications with reduced requirements concerning positioning accuracy and low speed

behavior a hall-sensor configuration is the most cost efficient option. Most BLDC/ PMSM motors

already include hall-sensors for commutation.

TMCC160 Block Diagram in Hall-Sensor Configuration

Optional Brake

Circuit

Ref.

Switches

35

36

11

12

VM

R

10

22

23

43

21

VM

6/ 7

UART

CAN

Host PC

or

microcontroller

I_U, I_V

or

RS+, RS-

39/40

Motor

50/ 51

37/38

U

PWM

30/31/32/33

SPI1

2/3/4/5

AIN

9

Microcontroller

DIAG

Gatedriver

V

HSx, LSx, BMx

9

W

Current

15/16/17

18/19/20

47/48/49

SPI0

DC/DC

(3.3V)

14

13 44

HALL

VM

TMCC160

3.3V

24/25/26

Power Bridge

3

3

EEPROM

3.3V

Figure 3: TMCC160 Hall-Sensor Block Diagram

Special

Areas of

Concern

!

Depending on the used motor, the customer can use a direct coil current

measurement with external current sensors for field oriented control; typically

used for Permanent Magnet Synchronous Motors (PMSM) or single shunt

measurement if block hall/six step mode is configured in TMCC160 software

(typical used for Brushless DC motors, BLDC).

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

6/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

3.4

Encoder Configuration

For applications which requires high positioning accuracy and a smooth run at low speed a motor

with encoder is mandatory. TMCC160 supports incremental ABN encoders with a resolution of

up to 16000 lines. Additional hall-sensors or encoder N-channel can be used for encoder

initialization after power up.

TMCC160 Block Diagram in Encoder Configuration

Optional Brake

Circuit

Ref.

Switches

35

36

11

VM

R

12

10

22

23

43

21

VM

6/ 7

2

Motor

UART

CAN

37/38

PWM

2/3/4/5

AIN

9

9

Microcontroller

DIAG

Gatedriver

V

15/16/17

18/19/20

47/48/49

Current

W

VM

SPI0

DC/DC

(3.3V)

14

13 44

TMCC160

3.3V

27/

28/

29

24/

25/

26

Power Bridge

3

3

3

EEPROM

3.3V

Figure 4: TMCC160 Encoder Block Diagram

i

If encoder configuration is used motor will be controlled by field oriented control, FOC.

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

7/39

Encoder

SPI1

U

HSx, LSx, BMx

30/31/32/33

Optional HALL

Host PC

or

microcontroller

39/40

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

4

External Components

4.1

Gate Driver Charge Pump (TMC6130)

For the external N-channel power MOSFET bridge, TMCC160 generates a 12V gate source voltage

for high and low side MOSFETs (N-channel). The gate source voltage will also be maintained if the

supply voltage falls below 12V. External component example is shown in schematic below. Buffer

capacitor for charge pump linear regulator (C3) should not be smaller than 4.7µF.

If the supply voltage does not fall below 12V charge pump circuitry can be left away without

performance loss (connect VCP to VM, omit D1, D2, C2, VCP_SW not connected).

VM

D1

C1

D2

C3

C2

VM

VCP_REG

VCP

VCP_SW

VM

VREG

40V

1µF/25V

1µF/25V

Trickle

Charge Pump

HSx

BMx

TMCC160

LSx

GND

Figure 5: Charge Pump Example Schematic

i

A component list example is provided on the next page.

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

8/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

Charge Pump Component List Example

COMPONENT

DESCRIPTION

C1

2 X 4.7µF/35V ceramic capacitor

C2

C3

D1, D2

33nF/50V ceramic capacitor

4.7µF/25V ceramic capacitor

60V/1A

VENDOR

Murata

Electronics

TDK

Multicomp

AVX

Corporation

Kemet

Murata

Electronics

TDK

Vishay

ORDER CODE

GRM219R6YA475MA73D

C2012X7R1V475K125AC

MC0603B333J500CT

06035C333JAT2A

C0805C475K3PACTU

GRM21BR61E475KA12L

CGA4J1X7R1E475K125AC

MSS1P6 (assembled on EVAL

board)

Table 1: Charge Pump Component List Example

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

9/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

4.2

DC/DC Converter (3.3V)

The 3.3V digital supply is generated with an internal step down switch regulator from VM. The

step down converter works with a PWM frequency of 2.2MHz and supports a maximum output

current of 500mA. A collection of external components like coils and diodes are listed below.

Equivalent components can be used. The 3.3V can also be used to supply further external

components like current-, hall sensors etc. if the consumption does not exceed 400mA.

NOTE:

→ Place D1, L1, C1-C2 close to the TMCC160 pins SW, DA and VCC

3.3V

L1

C1

D1

SW

DA

C2

VCC

DC/DC

TMCC160

Figure 6: DC/DC Converter Example Schematic

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

10/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

DC/DC Component List Example

COMPONENT

DESCRIPTION

C1

100nF/16V ceramic capacitor

C2

10µF/16V ceramic capacitor

L1

6.8µH/700mA

D1

40V/500mA low capacitance

VENDOR

Series

Murata

Electronics

LQH43C (assembled on EVAL

board)

Würth Elektronik

WE-TPC, WE-PD2

Toko

A916CY

Vishay

MSS1P6 (assembled on EVAL

board)

Diodes Inc.

SBR1U40LP

ON Semi

MBRM140

Diodes Inc.

DFLS140

Table 2:DC/DC Component List Example

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

11/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

4.3

CORTEX M4 Crystal

For system clock generation an external crystal is mandatory. As default, a crystal with 16MHz

frequency and a frequency stability of ±50ppm should be used. Crystal frequency can be

modified for customized firmware versions. Load capacitors C1, C2 depends on the used crystal.

Values are typically in a range of 8-22pF.

NOTE:

→ Place C1-C2, Q1 close to the TMCC160 pins

Q1

C1

C2

EXTAL

XTAL

Microcontroller

TMCC160

Figure 7: Crystal Example Schematic

Crystal Component List Example

COMPONENT

DESCRIPTION

C1

15pF/50V ceramic capacitor

C2

15pF/50V ceramic capacitor

Q1

16MHz crystal

VENDOR

Series

NDK

NX3225SA

Table 3: Crystal Component List Example

4.4

Supply Filter

To ensure proper operation VM and 3.3V supply voltage must be stable. TMCC160 already

includes small buffer capacitors to stabilize the supply voltages. Nevertheless are additional

capacitors mandatory.

NOTE:

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

12/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

→ Place C1 –C4 close to the TMCC160 pins VCC and VM.

Configuration for

step down

converter output

For a step down converter output current of 500mA a minimal total capacity of

10µF (C1 + C2) should be selected.

i

VM should be stabilized with minimum 2pcs. 4.7µF ceramic capacitors.

VM

3.3V Output

C4

C3

C1

C2

SW

VCC

VM

2X100nF

470nF

100nF

Microcontroller

DC/DC

Gate Driver

TMCC160

Figure 8: Supply Filter Example Schematic

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

13/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

Supply Filter Component List Example

COMPONENT

C1

C2

DESCRIPTION

100nF/16V ceramic capacitor

10µF/16V ceramic capacitor

C3

4.7µF/35V ceramic capacitor

C4

4.7µF/35V ceramic capacitor

VENDOR

Murata

Electronics

TDK

Murata

Electronics

TDK

Series

GRM219R6YA475MA73D

C2012X7R1V475K125AC

GRM219R6YA475MA73D

C2012X7R1V475K125AC

Table 4: Supply Filter Component List Example

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

14/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

4.5

Power MOSFET Bridge

TMCC160 provides a powerful gate driver for a three phase bridge using N-channel MOSFETs only.

The system is capable to drive MOSFETs with up to 350nC gate charge. The gates of the MOSFETs

will be charged with a current of ±1A. This helps to reduce dynamic losses and to building high

efficient systems in a wide power range.

4.5.1

Direct Coil Current

Measurement

A power MOSFET schematic including two phase direct coil current amplifier

(e.g. AD8418) is shown below. The coil current measurement amplifiers can be

powered by the 3.3V supply of the TMCC160.

NOTE:

→ Integrate coil current amplifiers in motor coil connection U and V.

4.5.2

Recommended

Schematic for

Direct Coil

Measurement

VM

C1

C3

C4

C5

C6

I_U

HS1

HS2

-

+

C2

HS3

BM1

R

BM2

R

U

V

BM3

LS2

-

+

LS1

BLDC

W

LS3

I_V

Figure 9: Direct Coil Current Measurement Schematic

i

Direct coil current measurement is recommended for field oriented control

(FOC) in hall- or encoder mode. It can also be used in block hall commutation

(six step mode).

NOTE:

→ Please note that the current amplifier has to be configured for bidirectional

measurement. A sample schematic for direct coil current measurement

with AD8418 is published in the TMCC160-EVAL board schematic.

Current Sense

Inputs

The input voltage range of the TMCC160 current sense inputs I_U, I_V is 0..VCC.

Both signals will be routed to the TMCC160 microcontroller and converted with

a resolution of 12 bits. For a symmetric motor current measurement in positive

and negative direction, the current amplifier must output VCC/2 at zero motor

current to meet the TMCC160 offset configured.

NOTE:

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

15/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

→ Keep a safety margin for the current control of about 10% in order to avoid

reaching the internal TMCC160 ADC limits. This margin shall be respected

for the current limit setting.

Vcc

(3.3V)

+I target_peak

0A

TMCC160 ADC Value

I_U, I_V Input Voltage

Motor Current U, V

TMCC160 Direct Coil Current Signal Example

4095

Safety Margin

3890

Vcc/2

(1.65V)

-I target_peak

2048

205

0V

Safety Margin

0

Figure 10: Direct Coil Current Signal Example

4.5.3

Sense Resistor

Selection

Use formula below to calculate the sense resistors for direct coil current

measurement.

𝑅𝑅𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆 =

1.48𝑉𝑉

𝐺𝐺

𝐼𝐼𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝

1.48𝑉𝑉

𝐺𝐺

=

√2 ∗ 𝐼𝐼𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑅𝑅𝑅𝑅𝑅𝑅

(𝐺𝐺 = 𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴 𝐺𝐺𝐺𝐺𝐺𝐺𝐺𝐺)

G=20 (AD8418)

Formulae 1: Direct Coil Current Sense Resistor Calculation

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

16/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

4.5.4

Calculating Power

Losses

The power losses which are generated in the sense resistor can be calculated

with formula below.

2

𝑃𝑃𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆 = 𝐼𝐼𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡_𝑅𝑅𝑅𝑅𝑅𝑅 2 ∗ 𝑅𝑅𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆 = �𝐼𝐼𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡_𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝 /√2� ∗ 𝑅𝑅𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆

Formulae 2: Direct Coil Current Sense Resistor Losses

4.5.5

Current Amplifier

Current Amplifier

COMPONENT

4.5.6

Single Shunt

Measurement

DESCRIPTION

VENDOR

AD8418

ANALOG

DEVICES

AD8206

ANALOG

DEVICES

Series

The single shunt measurement uses only one resistor in the bottom GND

connection of the power MOSFET bridge. TMCC160 supports a high speed, high

bandwidth, and low offset current sense amplifier with configurable input range

for signal conditioning.

VM

C1

C2

HS1

C3

C4

C5

HS2

C6

HS3

BM1

U

BM2

V

BM3

W

LS1

LS2

RS+

BLDC

LS3

100Ω

100pF

R

100pF

RS-

100Ω

Figure 11: Single Shunt Measurement Schematic

NOTE:

→ Single shunt measurement is only possible for block hall (six step mode)

commutation.

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

17/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

→ A low pass with cut off frequency of approximately 16MHz should be placed

on TMCC160 input RS+, RS- to filter high frequency.

→ Place RC low pass close to the TMCC160.

4.5.7

Sense Resistor

Selection

Gain of the internal current sense amplifier can be configured by software.

Following gain values are available:

Gain values: 8/ 10.3/ 13.3/ 17.2/ 22.2/ 28.7/ 37/ 47.8

The accuracy of the amplifier is ±3%. The maximum input voltage between RS+

and RS- depends on the configured amplifier gain:

𝑈𝑈𝑀𝑀𝑀𝑀𝑀𝑀 =

1.48𝑉𝑉

𝐺𝐺𝐺𝐺𝐺𝐺𝐺𝐺

Formulae 3: Maximum Input Voltage Calculation

With the given 𝑈𝑈𝑀𝑀𝑀𝑀𝑀𝑀 it is possible to calculate the sense resistor for a given

maximum target current. Calculation formula for 𝑅𝑅𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆 is given below. The

maximum current can be measured in both directions depending on the power

MOSFET state.

𝑅𝑅𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆 =

1.48𝑉𝑉

𝐺𝐺𝐺𝐺𝐺𝐺𝐺𝐺

𝐼𝐼𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡_𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝

Formulae 4: Single Shunt Sense Resistor Calculation

4.5.8

Dead Time Logic

To protect each half bridge against cross-conduction during switching high- and

low-side MOSFETs, TMCC160 includes a programmable dead time delay between

high- and low-side MOSFET of the same phase. During the dead time high- and

low-side MOSFETs are off. The dead time can be configured in software.

Dead time:

0.00µS/ 0.51µS/ 0.80µS/ 1.10µS/ 1.67µS/ 2.30µS/ 3.40µS/ 6.9µS

i

4.5.9

Power MOSFET

Selection

To avoid high losses during switch event a proper dead time adaption is

needed. A value of 1.1µS is a good start value for further tuning.

TMCC160 provides an integrated 3-phase gate driver for pure N-channel

MOSSFET bridge. The gate driver is capable to drive the high- and low-side gate

with up to 1A source, sink. This allows fast and high efficient switching of power

MOSFETs with a gate charge up to 350nC. To drive the high- and low-side

MOSFETs down to a supply voltage of 7V a charge pump is integrated. Gatesource voltage of high- and low-side gate driver output is 12V.

The duration of the switching event depends on the total gate charge of the

MOSFET and can be calculated with the formula below.

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

18/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

𝑡𝑡𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆 =

𝑄𝑄𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀

±1𝐴𝐴

Formulae 5: MOSFET Switch Slope Calculation

Rdson drain source resistance [R]

Vgs gate to source voltage [V]

Diagram: MOSFET

Parameters

During Switch

Event

QMiller

Rdson

Qg gate charge [nC]

Figure 12: MOSFET Parameters During Switch Event

4.5.10

Gate Driver Clamp

Diodes

To avoid that negative voltage spikes (high frequency oscillation) reach the

TMCC160 gate driver output pins during switch events, high- and low-side gate

series resistors (R) as well as optional clamp diodes (D) on low-side gate output

are recommend.

The negative voltage oscillation roots from the recovery effect of the MOSFETs

body diodes during switching. A clamp circuit for BMx pins is integrated in the

TMCC160.

Depending on the gate charge, the following gate series resistors are recommended:

Gate Charge Resistors Table

GATE CHARGE:

MIN GATE SERIES RESISTOR [Ω]:

LOW SIDE CLAMP DIODE:

100nC

2.2R

required

Table 5: Gate Charge Resistor and Clamp Diode Recommendation

NOTE:

→ Values in table above have to be validated in layout.

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

19/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

→ It is important to place the clamp diode close to LSx pin.

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

20/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

Diagram

VCP

VCP_REG

40V

VREG

1µF/25V

VM

HSx

R

BMx

2R2

40V

U, V, W

LSx

R

TMCC160

D

Figure 13: Gate Charge Resistor and Clamp Diode Example Schematic

4.5.11

Power Supply

Filtering

Capacitors

To ensure stable power supply voltage, please ensure that enough power supply

filtering capacitors are available in the system to absorb kinetic energy during

deceleration and load control. Additional a regulated power supply is

recommended, especially if the system is operated close to the maximum supply

voltage or a long power supply line is used.

For power supply filtering capacitor value, the following rule of thumb can

be used to calculate the system capacity (depending on the motor velocity

𝑰𝑰𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺 varies between 10% to 100% of the motor current):

i

4.6

𝐶𝐶𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹𝐹 = 1000µ𝐹𝐹 ∗ 𝐼𝐼𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆

To reduce power losses in the capacitors and increase voltage stability use

low ESR-capacitor type.

Interface

The TMCC160 system in a package supports RS232, RS485, CAN and SPI interface as well as an

analog input which can be used for control and parameterization.

4.6.1

RS232

For easy intercommunication with a microcontroller or a host PC TMCC160

system in a package provides a 3.3V UART interface which can be directly

connected to a microcontroller UART (3.3V TTL level) or connected to an external

RS232 transceiver supporting a full RS232 signal interface.

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

21/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

100nF

C1+

3.3V

C1100nF

16

15

RS232 TXD

RS232 RXD

VCC

C2+

GND

C2-

1

100nF

3

4

100nF

5

14

11

TXD

13

12

RXD

7

10

8

9

TMCC160

MAX3232CSE

Figure 14: RS232 Interface Example Schematic

NOTE:

→ Circuit above shows an example of a RS232 interface configuration with

external transceiver powered by the TMCC160 internal generated 3.3V

supply voltage. Circuit above only shows an example, many other RS232

transceivers are available.

4.6.2

RS485

For remote control and host communication the TMCC160 provides a two wire

RS485 bus interface. An external RS485 transceiver is required to integrate the

TMCC160 into a RS485 bus structure. An example circuit is shown below, several

other RS485 transceivers are available.

3.3V

100nF

8

RS485+

RS485-

6

7

5

VCC

REN

A

R

B

D

GND

DE

2

RS485_DIR

1

RXD

4

TXD

TMCC160

3

SN65HVD1781D

Figure 15: RS485 Interface Example Schematic

NOTE:

→ TMCC160 is capable to supply a RS485 transceiver with the internal 3.3V

power supply.

→ For a proper RS485 operation following items should be taken into account

when setting up an RS485 network:

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

22/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

4.6.3

RS485 Bus

Structure

The network topology should follow a bus structure as closely as possible. That

is, the connection between each node and the bus itself should be as short as

possible. Basically, it should be short compared to the length of the bus.

Host

c:>

Slave

Slave

Slave

node

1

node

n-1

node

n

}

termination

resistor

(120 Ohm)

termination

resistor

(120 Ohm)

keep distance as

short as possible

RS485

Figure 16: RS485 Bus Interface Structure

4.6.4

RS485 Bus

Termination

Especially for longer busses and/or multiple nodes connected to the bus and/or

high communication speeds, the bus should be properly terminated at both

ends. Therefore, a 120 Ohm termination resistors at both ends of the bus have

to be added.

4.6.5

No Floating Bus

Lines

Avoid floating bus lines while neither the host/master nor one of the slaves along

the bus line is transmitting data (all bus nodes switched to receive mode).

Floating bus lines may lead to communication errors. In order to ensure valid

signals on the bus it is recommended to use a resistor network connecting both

bus lines in order to define logic levels appropriately.

Two configuration options can be recommended. They are explained on the next

page.

Configuration

Option 1

Add resistor (Bias) network on one side of the bus, only (120R termination

resistor still at both ends):

termination

resistor

(220R)

Slave

Slave

node

n- 1

node

n

+5V

pull-up (680R)

RS485+ / RS485A

termination

resistor

(120R)

RS485- / RS485B

pull-down (680R)

GND

Bus lines with resistor (Bias) network on one side, only

Configuration

Option 2

Or add resistor (bias) network at both ends of the bus (like Profibus™

termination):

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

23/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

+5V

pull-up (390R)

Slave

Slave

node

n- 1

node

n

+5V

pull-up (390R)

RS485+ / RS485A

termination

resistor

(220R)

termination

resistor

(220R)

RS485- / RS485B

pull-down (390R)

pull-down (390R)

GND

GND

Figure 17: Bus lines with resistor (Bias) network at both ends

Certain RS485 interface converters available for PCs already include these

additional resistors (e.g. USB-2-485 with bias network at one end of the bus).

4.6.6

CAN 2.0B Interface

TMCC160 supports a full CAN 2.0B interface with up to 1Mbit/s. An external CAN

transceiver is needed to integrate TMCC160 into a CAN bus network. It is possible

to use TMCC160 internal generated 3.3V supply to power the IO voltage of a CAN

transceiver like in picture below.

4.6.7

CAN Bus Structure

5V

3.3V

100nF

100nF

3

7

CANL

6

CANH

2

VCC

VIO

CANL

TXD

CANH

RXD

GND

S

5

1

CAN_TXD

4

CAN_RXD

TMCC160

8

TJA1051T/3

Figure 18: CAN Interface Example Schematic

NOTE:

→ The network topology should follow a bus structure as closely as possible.

The connection between each node and the CAN bus itself should be as

short as possible to avoid signal reflections.

Host

c:>

Slave

Slave

Slave

node

1

node

n-1

node

n

}

termination

resistor

(120 Ohm)

CAN

termination

resistor

(120 Ohm)

keep distance as

short as possible

Figure 19: CAN Bus Structure

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

24/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

4.6.8

CAN Bus

Termination

CAN bus must be properly terminated at both ends with a resistor of 120R

between CANH, CANL signal.

4.6.9

Number of Nodes

TMCC160 software supports CAN addresses up to 0x7FF (2047) but the

maximum number of nodes highly depends on the used transceiver and the bus

structure itself.

i

Please see datasheet of used CAN transceiver for maximum number of CAN

nodes.

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

25/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

4.6.10 Analog Input

The analog input signal of the TMCC160 can be used as a target value to e.g. control torque, velocity or

other parameters. The analog input voltage is routed directly to the TMCC160 µC and will be converted

with a resolution of 12 bit. AIN is designed for a voltage range between 0 and Vcc (3.3V). For higher

voltages use a voltage divider plus optional protection diode as in example below.

3.3V

0..10V

22k

AIN

TMCC160

10k

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

26/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

4.7

EEPROM

To store and execute TMCL programs a EEPROM is needed. Interconnection between TMCC160

and EEPROM is done via SPI_0 interface. To ensure compatibility between TMCC160 default

firmware and EEPROM, please use dedicated Atmel EEPROM listed below. It is possible to use

TMCC160 internal generated 3.3V supply to power the EEPROM.

EEPROM

Connection

Schematic

3.3V

IC1

3.3V

8

VCC

1

CS

3

WP

7

HOLD

CSN_SPI0 33

6

SCK

5

SI

2

SO

4

GND

SCLK_SPI0 32

MOSI_SPI0 30

MISO_SPI0 31

TMCC160

100nF

Figure 20: EEPROM Connection Schematic

COMPONENT

DESCRIPTION

AT25128B-SSHL

VENDOR

Atmel

Series

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

27/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

4.8

Brake Chopper

A servo system feeds back energy to the power supply line during deceleration and load control.

The energy can lead to a voltage rise on the power supply system if it is not dissipated. The

voltage overshoot of a system without brake chopper depends on the motor deceleration time,

kinetic energy and the servo module buffer capacity. The brake chopper dissipates this energy

from the system, and thus avoids system damage.

Brake Chopper

Output

TMCC160 provides a continuous motor voltage monitoring (20kHz) as well as a

brake chopper output. The brake chopper output pin is controlled from a

comparator implemented in TMCC160 software. Voltage threshold, hysteresis,

enable/ disable is configurable via software.

Motor voltage should be limited to 90% - 95% of the maximum possible

operation voltage.

Brake Chopper

Example

Schematic

VM

VM

R

Brake (10)

Gate Driver

Software voltage threshold

Software hysteresis

TMCC160

Figure 21: Brake Chopper Example Schematic

4.8.1

Brake resistor

selection

For a full speed ramp stop, the brake resistor should be able to dissipate the

complete kinetic energy which is fed back during deceleration ramp (𝑡𝑡𝑑𝑑𝑑𝑑𝑑𝑑. ).

Kinetic energy:

1

2

[𝐽𝐽 = 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑜𝑜𝑜𝑜 𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖, 𝜔𝜔 = 𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎 𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠]

𝐸𝐸𝐾𝐾𝐾𝐾𝐾𝐾 = ∗ 𝐽𝐽 ∗ 𝜔𝜔𝑚𝑚𝑚𝑚𝑚𝑚.

2

Deceleration time:

𝑡𝑡𝑑𝑑𝑑𝑑𝑑𝑑.

Electrical energy:

𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸. = 𝑃𝑃 ∗ 𝑡𝑡𝑑𝑑𝑑𝑑𝑑𝑑. =

Brake resistor:

𝑅𝑅𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵 =

2

�𝑈𝑈𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 �

𝑅𝑅

∗ 𝑡𝑡𝑑𝑑𝑑𝑑𝑑𝑑.

2

�𝑈𝑈𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 � ∗𝑡𝑡𝑑𝑑𝑑𝑑𝑑𝑑.

𝐸𝐸𝐾𝐾𝐾𝐾𝐾𝐾

Formulae 6: Brake Chopper Resistor Calculation

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

28/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

4.8.2

Brake Chopper

Example

The figure below shows brake chopper in operation. The supply voltage

threshold is configured at approximately 26V. The yellow line represents the

supply voltage of the TMCC160.

Start

decceleration

Activate brake

chopper

Figure 22: Supply Voltage Monitoring (Activated Brake Chopper)

© 2015 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Read entire DATASHEET USER MANUAL before use of product. Terms of delivery and rights to technical change

reserved. Download newest version at: www.trinamic.com

29/39

�TMCC160 motionCookie™ (Rev. 1.00 / 2015-Nov-16)

4.9

Absolute Maximum Ratings

NOTE:

→ The maximum values must NOT be exceeded; under no circumstance.

Absolute Maximum Ratings

Parameter

SYMBOL

MIN

Supply voltage, t