U2102B

Multifunction Timer

Description

The monolithic integrated bipolar circuit U2102B is a

MOSFET or IGBT control circuit which allows the

realization of an extremely wide range of timer and

dimmer functions. The integrated current monitoring

function additionally permits the power switch to be

reliably protected without an additional fuse.

Features

D Integrated reverse phase control

D Two- or three-wire applications

D Mode selection:

D Adjustable and retriggerable tracking time

D External window adjustment for sensor input

D Enable input for triggering

– Zero-voltage switch with static output

– Two-stage reverse phase control with switch-off

– Two-stage reverse phase control

Applications

D Motion detectors

D Time-delay relays

D Current monitoring:

– High-speed short-circuit monitoring with output

D Dimmers

– High-current monitoring with integrating buffer

D Reverse phase controls

D Timers

D Integrated chip temperature monitoring

Block Diagram

1

16

Voltage monitoring

VRef

2

3

4

5

Synchronization

15

Reverse

phase

control

Voltage limitation

Control

RC oscillator

14

Push

pull

Divider

logic

13

12

6

Current monitoring

Programing

Triggering with buffers

7

8

Temperature

monitoring

11

Test logic

10

9

Figure 1. Block diagram

Rev. A2, 09-Nov-99

1 (15)

�U2102B

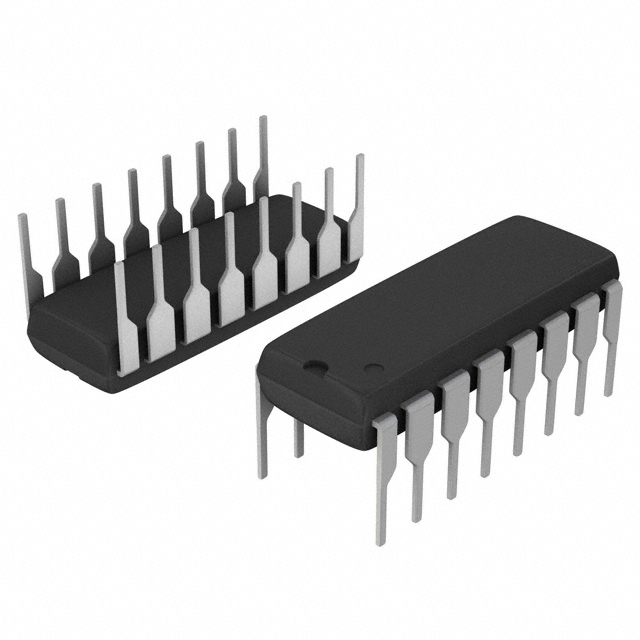

Ordering Information

Extended Type Number

U2102B-x

U2102B-xFP

U2102B-xFPG3

Package

DIP16

SO16

SO16

Remarks

Tube

Tube

Taped and reeled

Pin Description

VRef 1

16 Sync

CRamp 2

15 +VS

RRamp 3

14 VO

Control 4

13 GND

U2102B

Osc 5

12

Ioff

Prog. 6

11

II

EN 7

10 Test

Trigger 8

9

V9

Pin

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Symbol

VRef

CRamp

RRamp

Control

Osc

Prog.

EN

Trigger

V9

Test

II

Ioff

GND

VO

+ VS

Sync

Function

Reference voltage 5 V

Ramp, capacitance

Current setting for ramp

Control voltage

RC oscillator

Tri-state programming

Enable input

Trigger input (window)

Window adjustment

Test output

Input current monitoring

Fast output current monitoring

Ground

Output voltage

Supply voltage

Synchronization input

Figure 2. Pinning

2 (15)

Rev. A2, 09-Nov-99

�Rev. A2, 09-Nov-99

R1

Clock

VRef

1k

R2

W

10 nF

1M

W

Figure 3. Block diagram with typical circuit for dc loads

W

820 k

W

W

3

Control

4

Temp

monitoring

Rsh

GND

13

Control

–

5

RC oscillator

12

Q Q

R S

Divider

C2

220 nF

VRef

6

Voltage

monitoring

logic

+ VS 2 stage / out

GND

GND

Stat. ZVS

–

POR

+

Current monitoring

W

500 mV

11

1 nF

–

0.02xVRef

Enable

W

+

Buffer

120 ms

2 stage

100

1k

Control

VRef

IGBT

RG

Phase

100k

+ VS

Load

m

47 F/25 V

C1

Push pull

Reverse

+

m

15

W

14

R3

1 F

+Vs

Voltage

limitation

Vmains

230 V

68 k

Ramp

2

W /2W

16

Synchronization

C3

22 k

CRef

Clock

generator

X

33 k

1

100 mV

Test mode

7

Enable

0.1/0.4/

0.5 x VRef

Buffer

(spikefilter)

Clock

Test logic

10

Clock

VRef

0.55 x VRef + 0.2 V9

+

8

–

Trigger window

+

–

0.45 x VRef – 0.2 x V9

Window

adjustment

9

NTC

3 (15)

U2102B

Trigger

signal

�U2102B

Power Supply, Synchronization Pins 15 and 16

The voltage limitation circuit contained in the U2102B

enables simple power supply via a dropping resistor R1.

In the case of dc loads, practically all the supply current

flows into Pin 16 (the pull down resistor at Pin 16 is necessary in order to guarantee reliable synchronization) and

is supplied via an internal diode to Pin 15, where the resultant supply voltage is limited and smoothed by C1. As a

result, the rectified and divided line voltage appears at

Pin 16, where the amplitude is limited. The power supply

for the circuit can be realized in all modes for dc loads as

shown in figure 3. The voltage at Pin 16 is used to

synchronize the circuit with the mains and generate the

system clock required for the buffers. The circuit detects

a “zero crossing” when the voltage at Pin 16 falls below

an internal threshold of approximately 8 V.

Vmains

R1=Rsync

Sync.

16

+VS

Load

15

Voltage

limitation

C1

Push

pull

14

IGBT

RG

Temp.

monit.

Rsh

GND

13

Figure 4. Power supply for dc loads (R1 is identical with Rsync)

R1 is calculated here as follows:

V Nmin –V S

R 1max

0.85

(1)

I tot

+

where:

VNmin =

Vmains – 15%

VS

Supply voltage

4 (15)

=

Itot

=

ISmax + Ix

ISmax

=

Max. current consumption of the IC

Ix

=

Current consumption of the external

components

Rev. A2, 09-Nov-99

�U2102B

resistor, R1, is connected before the rectifier bridge and

therefore has only one mains half-wave. R1 is then calculated as follows:

In the case of ac loads, it is necessary to make a distinction

for power supply purposes between the individual

operating modes. In reverse phase control mode, figure 4,

Pin 15 must be additionally supplied with power via a

dropping resistor, since no current flows in Pin 16 when

the power switch is switched on. Here, the dropping

R 1max

+ 0.85

V Nmin –V S

2 I tot

Load

Rsync

Sync.

Vmains

D1

16

R1

+VS

Figure 5.

Power supply in reverse phase

control mode for ac loads

15

Voltage

limitation

C1

Push

pull

IGBT

14

RG

Temp.

monit.

Rsh

GND

13

In two-wire systems, the additional power supply at

Pin 15 is not possible (see figure 4, by omitting R1 and

Diode D1). In this case, the resistor Rsync is identical with

R1 and should be as low as the power dissipation allows

it. A sufficiently large residual phase angle must remain

in this case in order to guarantee the device supply.

The power supply is simplified if the device is operated

as a static zero-voltage switch for ac loads (see figure 5).

All delay times are twice as long here, since synchronization of the module is tapped before the rectifier

bridge.

Load

Vmains

R1= Rsync

Sync.

16

+VS

Figure 6.

Power supply as static zero

voltage switch for ac loads

15

Voltage

limitation

C1

Push

pull

14

Temp.

monit.

IGBT

RG

Rsh

GND

13

Rev. A2, 09-Nov-99

5 (15)

�U2102B

Voltage Monitoring

Reverse Phase Control, Pins 2, 3, 4

While the operating voltage is being built up or reduced,

uncontrolled conditions or output pulses of insufficient

amplitude are being suppressed by the internal monitoring circuit. All latches in the circuit, the divider and the

control logic are reset. When the supply voltage is

applied, the enable threshold (clamp voltage) of approximately 16 V must be reached so that the circuit is enabled.

The circuit is reset at approximately 11 V if the supply

voltage breaks down. A further threshold is activated in

reverse phase control mode. If the supply voltage breaks

down here after enabling of the circuit, the output stage

is switched off at approximately 12.5 V, while the other

parts of the circuit are not affected. The output stage can

then be switched on again only in the following halfwave. As a result, the residual phase angle remains just

large enough, (e.g., in two-wire systems), so that the

circuit can still be properly supplied with power. In all

operating modes, a single operating cycle is started after

the supply voltage is applied, independently of the trigger

inputs, in order to immediately demonstrate the overall

function.

In the case of normal phase controls, e.g., with a triac, the

load current is switched ON only at a certain phase angle

after the zero crossing of the mains voltage. In the

following zero crossing of the current, the triac gets extinguished (switched-off) automatically. Reverse phase

control differs from this in that the load current is always

switched-on by a semiconductor switch (e.g., IBGT) at

the zero crossing of the mains voltage and then switched

back off again after a certain phase angle a. This has the

advantage that the load current always rises with the

mains voltage in a defined manner and thus keeps the

required interference suppression to a minimum.

Chip Temperature Monitoring

The circuit possesses an integrated chip temperature

monitoring circuit which disables the output stage when

a temperature of approximately 140°C is reached. The

circuit is enabled again only after cooling down and additionally switched “off and on” of the operating voltage.

The charging current for the capacitor C3 at Pin 2 is set

with the resistor R3 at Pin 3. When the synchronization

circuit recognizes a zero crossing, an increased charging

current I2

4 I3 is enabled which then charges C3 up

to 0.45 V. The output stage is switched-on at this value

and the charging current for C3 is reduced to I2 = I3. Since

the actual zero crossing of the supply voltage occurs later

than recognized by the circuit, the load current starts to

flow quite close to the exact zero crossing of the supply

voltage. While the output stage is switched-on C3 is

charged until the control voltage, set externally at Pin 4,

is reached. When this condition is reached, the output

stage is switched off and C3 is charged again with the

increased current (I2 = 4 I3) to V2 5.5 V. The

charging current is switched off at this point and C3 is

discharged internally. The whole process then starts again

when the circuit recognizes another zero crossing (see

figure 6).

[

[

[

Vmains

t

V2

1.1 VRef

V4

0.09 VRef

t

V14

t

Figure 7. Signal characteristics of reverse phase control

6 (15)

Rev. A2, 09-Nov-99

�U2102B

Programing, Pin 6

Three operating modes can be programed with the tristate

input Pin 6:

D Zero-voltage switch (ZVS)with static output

(V6 = V1 = VRef):

The reverse phase control is inactive here. The output

stage is statically switched-on after triggering by the

timer and switched-off again after the running down

of the time (at the zero crossing of the supply voltage

in each case). This operating mode is not possible in

two–wire systems.

D Two-stage reverse phase control with switch-off

( V6 = V15 = VS):

The maximum current flow angle, amax, is set when

the timer has enabled the output stage. Switchover to

the phase angle a, which can be set arbitrarily at Pin 4,

takes place after expiry of 3/4 of the tracking time set

at Pin 5. The output stage switches off after expiry of

the whole tracking time.

D Two-stage reverse phase control ( V6 = V13 = GND):

The output stage switches to the maximum current

flow angle, amax, (adjustable) if the trigger condition

for both inputs (Pins 7, 8) is satisfied. Switchover to

the current flow angle, a, set at Pin 4 takes place after

expiry of 3/4 of the tracking time set at Pin 5. The

whole process is repeated from the beginning again if

renewed triggering takes place at Pin 8. The lamp is

switched-off in the following half-wave of the mains

voltage if the trigger condition at Pin 7 disappears. In

this mode, the output stage is switched-on even if only

Pin 7 is in the ON state. The current flow angle is then

determined by V4 (e.g., house no. illumination,

twilight switch).

This threshold is approximately 2 V in switched-off

condition and also during the second current flow angle,

a, in two-stage reverse phase control mode. Otherwise,

the blocking-or switch-off threshold is 0.5 V.

The input Pin 8 is designed as a window discriminator, its

window is set at Pin 9. The minimum window of approximately 250 mV is set with V9 = V13, and the maximum

window of approximately 1.25 V with V9 = Vl. The

window discriminator is in the OFF state when the

voltage at Pin 8 lies within the window set at Pin 9.

If a resistor divider with an NTC resistor is connected to

Pin 9, for example, it is possible to compensate for the

temperature dependence of the IR sensor, i.e. the range is

made independent of temperature.

Noise suppression for tON = 40 ms guarantees that there

is no peak noise signals at the inputs which could trigger

the circuit. Equally, renewed triggering is prevented for

tOFF = 640 ms after load switch-off in order to avoid any

self interference.

V7

VRef

ON

0.5 VRef

Hysteresis

0.1/0.4 VRef

OFF

0

Figure 8. Trigger condition Pin 7

Trigger Inputs, Pins 7 and 8

The trigger condition of the timer is determined by the

two inputs Pins 7 and 8. A Light Dependent Resistor

( LDR) can be connected to Pin 7, for example, and an IR

sensor to Pin 8. Both inputs must be in the ON state to

initiate triggering, since they are equal and AND-gated.

In the operating mode “2-stage reverse phase control”,

the output stage can additionally be switched-on and

switched-off by Pin 7 alone and independently of the

timer.

The enable input Pin 7 is implemented as a comparator

with hysteresis. The enable threshold is approximately

2.5 V. The blocking threshold is switched by the control

logic in order to avoid faults as a result of load switching.

Rev. A2, 09-Nov-99

V8

VRef

ON

0.5 VRef

0.05 VRef + 0.2 V9

OFF

0.05 VRef + 0.2 V9

ON

0

Figure 9. Trigger condition Pin 8

7 (15)

�U2102B

RC Oscillator, Pin 5

Current Monitoring, Pins 11 and 12

An internal RC oscillator with following divider stage

1:211 permits a very long and reproducible tracking time.

The current monitoring circuit integrated in the U2102B

represents a double electronic fuse. The circuit measures

the current flowing through the power switch by way of

the voltage drop across the shunt resistor Rsh. This voltage

is supplied to Pin 11. If this voltage exceeds a value of

500 mV because of a high load current (e.g., shortcircuit), the switch-off latch is set and the switching

output Pin 11 closes immediately. Pin 11 can be

connected to the gate via a resistor or network, depending

on load conditions, thus allowing the switch-off behavior

to be adapted to the respective requirements. The shortcircuit current is reduced to a problem-free value by this

procedure.

The RC values for a certain tracking time, tt, are calculated as follows:

W

R 2 (k )

m

C 2 ( F)

+ 1.4

t t(s) 10 3

2048 C 2 ( F)

+ 1.4

t t(s) 10 3

2048 R 2 (k )

m

W

In reverse phase control mode, switchover from maximum current flow angle to the value set at Pin 4 takes

place after expiry of 3/4 of the total tracking time tt.

There is a second threshold at 100 mV. The output stage

is disabled if the voltage at Pin 11 exceeds this value and

if it reaches this value for 120 ms in every half-wave

without exceeding the switch-off threshold of 500 mV.

Since high voltage peaks would be caused by switching

off due to the line and leakage inductances, the output

stage is not switched-off immediately but is simply not

enabled in the next half-wave. The circuit is designed so

that it also switches off in the case of changing overcurrents which do not occur in every half-wave. But in

this case the switch-off time is larger.

Absolute Maximum Ratings

Reference point Pin 13, unless otherwise specified

Parameters

Power supply

Current

m

Symbol

Value

Unit

Pin 15

IS

is

20

60

mA

mA

Pin 16

II

ii

20

60

mA

mA

Pin 1

– IRef

10

mA

10

60

1

8

0.2

1

20

0 to V1

0 to V15

– 40 to + 125

+ 125

– 10 to + 100

mA

mA

mA

mA

mA

mA

mA

V

V

°C

°C

°C

t < 10 s

Synchronization

Input current

v

m

t 10 s

Reference voltage source

Output current

Push-pull output stage

Output current

t 2 ms

Input currents

v

Input voltages

Storage temperature range

Junction temperature

Ambient temperature

8 (15)

Pin 14

Pin 14

Pin 2

Pin 2

Pin 3

Pin 10

Pin 12

Pins 4, 5, 7, 8, 9 and 11

Pins 6 and 12

"I

"i

O

o

–II

II

–II

II

II

VI

VI

Tstg

Tj

Tamb

"

Rev. A2, 09-Nov-99

�U2102B

Thermal Resistance

Junction ambient

Parameters

DIP 16

SO 16 on PC board

SO 16 on ceramic

Symbol

RthJA

RthJA

RthJA

Value

120

180

100

Unit

K/W

K/W

K/W

Electrical Characteristics

VS = 15.0 V, fmains = 50 Hz, Tamb = 25°C, reference point Pin 13, unless otherwise specified

Parameters

Supply voltage limitation

Current consumption

Voltage monitoring

Switch-on threshold

Switch-off threshold

Undervoltage threshold

Reference voltage

Synchronization

Voltage limitation

Input current

Zero crossing switch-on threshold

Zero crossing switch-off threshold

Reverse phase control

Ramp current setting

Input current

Input voltage

Ramp

Charging current 1

Charging current 2

Discharge impedance

Switch-on threshold, output stage

Discharge threshold voltage

Control voltage

Input voltage

Input current

Programing, tri state input

Input current

Operating mode:

Static zero-voltage switch

2-stage reverse phase control with

switch-off

it h ff

2-stage reverse phase control

RC oscillator

Input current

Upper threshold

Lower threshold

Discharge impedance

Rev. A2, 09-Nov-99

Test Conditions / Pin

Symbol

IS = 2 mA

Pin 15

VS

VS

IS = 5 mA

VS = 15 V

Pin 15

IS

Pin 15

VSON

VSOFF

V15

– I1 = 0 to 5 mA

Pin 1

VRef

I16 = 2 mA

V16 = 0 V

Pin 16-15

Pin 16

Pin 16

Pin 16

Pin 3

m

m

I3 = – 10 A

I3 = – 10 A

V13

V13

vV vV

vV vV

4

6

vV

Typ.

Max.

17

17.2

2

Unit

V

V

mA

16.5

11.6

13.3

5.25

V

V

V

V

14.8

10.4

11.7

4.75

11

12.5

5

Vlimit

– II

VTON

VTOFF

7.3

7.9

0.8

100

7.7

8.3

8.1

8.7

– II

V3

4.7

5

50

5.3

9

37

10

40

1

450

600

V

Pin 2

Pin 2-1

Pin 4

V13

Min.

15

15.2

– Ich1

– Ich2

Rdis

VTON

Vdis

"I

"I

Pin 6

15

Pin 5

5 < 3.6 V

V

V

mA

V

mA

mA

kW

490

mV

mV

I

VRef

500

V

nA

I

1

mA

VI

l

11

43

mA

410

0

1

VRef +1

+0 3

VRef+0.3

VI

VS

V

VI

0

0.3

V

500

4.4

1.1

nA

V

V

k

"

II

VTU

VTL

Rdis

3.6

0.9

4

1

1

W

9 (15)

�U2102B

Parameters

Window discriminator

Input current

Upper threshold

Lower threshold

Input current window adjustment

Minimum window:

Lower threshold

Upper threshold

Maximum window:

Lower threshold

Upper threshold

Enable Schmitt trigger

Input current

Enable threshold

Blocking threshold:

Output stage OFF

Output stage ON, except in the

case of two-stage reverse phase

control in second stage (a)

Threshold for test mode

Current monitoring

Input current

Switch-off threshold 1

Switch-off threshold 2

Switching output

Leakage current

Saturation voltage

Push-pull output stage

Upper saturation voltage,

ON state

Lower saturation voltage,

OFF state

Output current

10 (15)

Test Conditions / Pin

0V

vV vV

8

Pin 8

l

Pins 8 and 9

v vV

0 V V9

V9 = V13

1

V9 = V1

0V

0V

Pin 9

Pin 8

Symbol

Min.

"

Ii

VTU

VTL

Ii

"

0.55

0.45

Typ.

Max.

Unit

500

+

(0.2

V9)

Ref

–

(0.2

V

Ref

9)

500

nA

V

V

nA

@V

@V

@

@

VTL1

VTU1

2.05

2.55

2.75

3.75

2.45

2.95

V

V

VTL2

VTU2

1.1

3.4

1.25

3.75

1.4

4.1

V

V

nA

V

Pin 8

vV vV

7

Pin 7

l

vV vV

11

Pin 11

Pin 12

V15

v

I14 = – 10 mA

Pins 14 and 15

I14 = 10 mA

Pin 14

ON state

OFF state

VT

2.3

2.5

500

2.7

VT

VT

1.8

0.45

2

0.5

2.2

0.55

V

V

VT

85

100

115

mV

80

450

100

500

500

120

550

nA

mV

mV

Ilkg

1

mA

VSat

VSat

1.0

1.2

V

V

– VSat

2.4

V

VSatL

1.2

V

i

"

Ii

VT1

VT2

1

V11 < 450 mV, V12

V11 > 550 mV

I12 = 0.5 mA

I12 = 10 mA

"I

Pin 14

–IO

IO

50

50

mA

mA

Rev. A2, 09-Nov-99

�U2102B

Applications

Vmains

230 V

X

Load

GND

1 nF

Rsh

22 kW/2 W

R1

1 kW

IGBT

100 W

1N4007

Rsync

220 kW

RG

C1

47 mF/

25 V

100 kW

NTC

VRef

VS

16

15

14

13

12

11

10

9

6

7

8

U2102B

1

2

3

C3

10 nF

4

5

R3

820 kW

Control

100 kW

VS

GND

220 nF

22 kW

1 MW

R2

Enable

C2

CRef

Trigger

signal

1 mF

Figure 10. House number or staircase illumination for ac loads

House number illumination: V6 = V13

Staircase illumination: V6 = V15

Rev. A2, 09-Nov-99

11 (15)

�U2102B

Vmains

230 V

X

Load

GND

1 nF

Rsh

1 kW

IGBT

R1 = Rsync

18 kW/2 W

100 W

RG

68 kW

NTC

VRef

C1

47 mF/25 V

1N4007

VS

16

15

14

13

12

11

10

9

6

7

8

U2102B

1

2

3

C3

22 nF

4

5

R3

750 kW

C2

220 nF

Enable

22 kW

1 MW

Trigger

signal

R2

CRef

1 mF

Figure 11. Zero voltage switch mode for ac loads

12 (15)

Rev. A2, 09-Nov-99

�U2102B

Vmains

230 V

X

Load

1 nF

Rsh

R1

22 kW/2 W

1 kW

IGBT

100 W

VS

1N4007

Rsync

220 kW

RG

C1

47 mF/

25 V

100 kW

100 kW

VS

16

15

14

13

12

11

10

9

6

7

8

U2102B

1

2

4

3

5

C3

100 kW

10 nF

100 kW

R3

1 MW

VS

Control

100 kW

CRef

1 mF

Figure 12. Reverse phase control for ac loads

Rev. A2, 09-Nov-99

13 (15)

�U2102B

Package Information

Package DIP16

Dimensions in mm

7.82

7.42

20.0 max

4.8 max

6.4 max

0.5 min 3.3

1.64

1.44

Alternative

0.58

0.48

17.78

0.39 max

9.75

8.15

2.54

16

9

technical drawings

according to DIN

specifications

1

8

Package SO16

Dimensions in mm

5.2

4.8

10.0

9.85

3.7

1.4

0.25

0.10

0.4

1.27

6.15

5.85

8.89

16

0.2

3.8

9

technical drawings

according to DIN

specifications

1

14 (15)

8

Rev. A2, 09-Nov-99

�U2102B

Ozone Depleting Substances Policy Statement

It is the policy of TEMIC Semiconductor GmbH to

1. Meet all present and future national and international statutory requirements.

2. Regularly and continuously improve the performance of our products, processes, distribution and operating systems

with respect to their impact on the health and safety of our employees and the public, as well as their impact on

the environment.

It is particular concern to control or eliminate releases of those substances into the atmosphere which are known as

ozone depleting substances ( ODSs).

The Montreal Protocol ( 1987) and its London Amendments ( 1990) intend to severely restrict the use of ODSs and

forbid their use within the next ten years. Various national and international initiatives are pressing for an earlier ban

on these substances.

TEMIC Semiconductor GmbH has been able to use its policy of continuous improvements to eliminate the use of

ODSs listed in the following documents.

1. Annex A, B and list of transitional substances of the Montreal Protocol and the London Amendments respectively

2 . Class I and II ozone depleting substances in the Clean Air Act Amendments of 1990 by the Environmental

Protection Agency ( EPA) in the USA

3. Council Decision 88/540/EEC and 91/690/EEC Annex A, B and C ( transitional substances ) respectively.

TEMIC Semiconductor GmbH can certify that our semiconductors are not manufactured with ozone depleting

substances and do not contain such substances.

We reserve the right to make changes to improve technical design and may do so without further notice.

Parameters can vary in different applications. All operating parameters must be validated for each customer

application by the customer. Should the buyer use TEMIC Semiconductors products for any unintended or

unauthorized application, the buyer shall indemnify TEMIC Semiconductors against all claims, costs, damages,

and expenses, arising out of, directly or indirectly, any claim of personal damage, injury or death associated with

such unintended or unauthorized use.

TEMIC Semiconductor GmbH, P.O.B. 3535, D-74025 Heilbronn, Germany

Telephone: 49 ( 0 ) 7131 67 2594, Fax number: 49 ( 0 ) 7131 67 2423

Rev. A2, 09-Nov-99

15 (15)

�