Product

Folder

Order

Now

Support &

Community

Tools &

Software

Technical

Documents

DRV8343-Q1

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

DRV8343-Q1 12-V / 24-V Automotive Gate Driver Unit (GDU) with Independent Half Bridge

Control and Three Integrated Current Sense Amplifiers

1 Features

3 Description

•

The DRV8343-Q1 device is an integrated gate driver

for three-phase applications. The device provides

three half-bridge gate drivers, each capable of driving

high-side and low-side N-channel power MOSFETs.

The dedicated Source and Drain pins enable the

independent

MOSFET

control

for

solenoid

application. The DRV8343-Q1 generates the correct

gate drive voltages using an integrated charge pump

sufficient for the high-side MOSFETs and a linear

regulator for the low-side MOSFETs. The Smart Gate

Drive architecture supports peak gate drive currents

up to 1-A source and 2-A. The DRV8343-Q1 can

operate from a single power supply and supports a

wide input supply range of 5.5 to 60 V for the gate

driver.

•

•

•

•

•

•

•

•

•

•

AEC-Q100 qualified for automotive applications

– Temperature grade 1: –40°C ≤ TA ≤ 125°C

Three independent half-bridge gate driver

– Dedicated source (SHx) and drain (DLx) pins

to support independent MOSFET control

– Drives 3 high-side and 3 low-side N-channel

MOSFETs (NMOS)

Smart gate drive architecture

– Adjustable slew rate control

– 1.5-mA to 1-A peak source current

– 3-mA to 2-A peak sink current

Charge-pump of gate driver for 100% Duty Cycle

3 Integrated current sense amplifiers (CSAs)

– Adjustable gain (5, 10, 20, 40 V/V)

– Bidirectional or unidirectional support

SPI (S) and hardware (H) interface available

6x, 3x, 1x, and independent PWM modes

Supports 3.3-V, and 5-V logic inputs

Charge pump output can be used to drive the

reverse supply protection MOSFET

Linear voltage regulator, 3.3 V, 30 mA

Integrated protection features

– VM undervoltage lockout (UVLO)

– Charge pump undervoltage (CPUV)

– Short to battery (SHT_BAT)

– Short to ground (SHT_GND)

– MOSFET overcurrent protection (OCP)

– Gate driver fault (GDF)

– Thermal warning and shutdown (OTW/OTSD)

– Fault condition indicator (nFAULT)

The 6x, 3x, 1x, and independent input PWM modes

allow for simple interfacing to controller circuits. The

configuration settings for the gate driver and device

are highly configurable through the SPI or hardware

(H/W) interface. The DRV8343-Q1 device integrates

three low-side current sense amplifiers that allow

bidirectional current sensing on all three phases of

the drive stage.

A low-power sleep mode is provided to achieve low

quiescent current. Internal protection functions are

provided for undervoltage lockout, charge pump fault,

MOSFET overcurrent, MOSFET short circuit, phasenode short to supply and ground, gate driver fault,

and overtemperature. Fault conditions are indicated

on the nFAULT pin with details through the device

registers for the SPI device variant.

Device Information(1)

PART NUMBER

DRV8343-Q1

Simplified Schematic

5.5 to 60 V

PWM

Controller

12-V and 24-V Automotive Motor-Control

Applications

– BLDC and BDC motor modules

– Fans and blowers

– Fuel and water pumps

– Solenoid drive

BODY SIZE (NOM)

7.00 mm × 7.00 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

2 Applications

•

PACKAGE

HTQFP (48)

SPI or H/W

nFAULT

Sense output

3.3 V

30 mA

DRV8343-Q1

Three-Phase

Smart Gate Driver

Protection

Gate Drive

N-Channel

MOSFETs

1

Current

Sense

3x Sense Amplifiers

3.3-V LDO

Copyright © 2017, Texas Instruments Incorporated

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�DRV8343-Q1

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Device Comparison Table.....................................

Pin Configuration and Functions .........................

Specifications.........................................................

7.1

7.2

7.3

7.4

7.5

7.6

7.7

8

1

1

1

2

3

3

7

Absolute Maximum Ratings ...................................... 7

ESD Ratings.............................................................. 7

Recommended Operating Conditions....................... 8

Thermal Information .................................................. 8

Electrical Characteristics........................................... 9

SPI Timing Requirements ....................................... 15

Typical Characteristics ............................................ 16

Detailed Description ............................................ 17

8.1

8.2

8.3

8.4

8.5

Overview .................................................................

Functional Block Diagram .......................................

Feature Description.................................................

Device Functional Modes........................................

Programming...........................................................

17

18

20

51

52

8.6 Register Maps ......................................................... 54

9

Application and Implementation ........................ 69

9.1 Application Information............................................ 69

9.2 Typical Application ................................................. 69

10 Power Supply Recommendations ..................... 78

10.1 Power Supply Consideration in Generator Mode . 78

10.2 Bulk Capacitance Sizing ....................................... 78

11 Layout................................................................... 80

11.1 Layout Guidelines ................................................. 80

11.2 Layout Example .................................................... 81

12 Device and Documentation Support ................. 82

12.1

12.2

12.3

12.4

12.5

12.6

12.7

Device Support......................................................

Documentation Support ........................................

Receiving Notification of Documentation Updates

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

82

82

82

82

82

83

83

13 Mechanical, Packaging, and Orderable

Information ........................................................... 83

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Original (March 2018) to Revision A

•

Page

Changed device status to Production Data ........................................................................................................................... 1

PP

2

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

�DRV8343-Q1

www.ti.com

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

5 Device Comparison Table

DEVICE

VARIANT (1)

INTERFACE (1)

DRV8343H

Hardware

DRV8343S

SPI

DRV8343-Q1

(1)

For more information on the device name and device options, see the Device Nomenclature section.

6 Pin Configuration and Functions

NC

PGND

INLC

INHC

INLB

INHB

INLA

INHA

nDIAG

DVDD

AGND

CAL

48

47

46

45

44

43

42

41

40

39

38

37

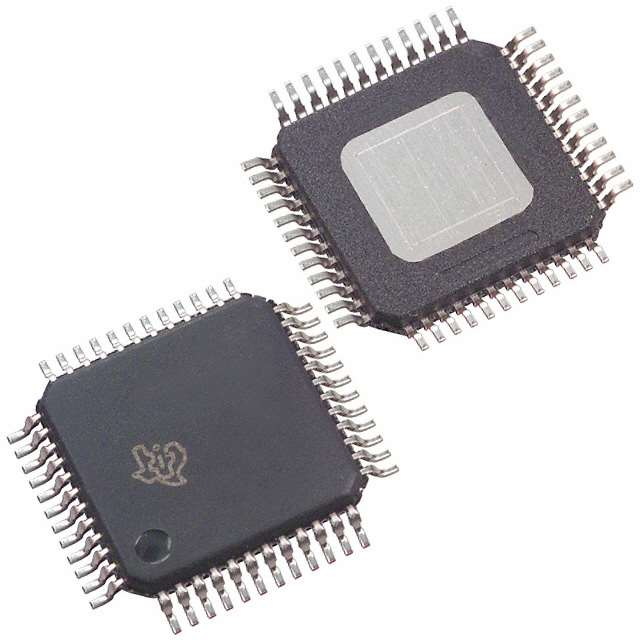

DRV8343H PHP PowerPAD™ Package

48-Pin HTQFP With Exposed Thermal Pad

Top View

CPL

1

36

ENABLE

CPH

2

35

GAIN

VCP

3

34

VDS

VM

4

33

IDRIVE

VDRAIN

5

32

MODE

GHA

6

31

nFAULT

SHA

7

30

VREF

Thermal

Pad

SNC

SNA

12

25

SPC

Not to scale

SLC

GLC

DLC

SHC

GHC

GHB

DLB

SHB

GLB

SLB

SPB

SNB

24

26

23

11

22

SPA

21

SOC

20

27

19

10

18

SLA

17

SOB

16

SOA

28

15

29

9

14

8

13

DLA

GLA

Pin Functions—DRV8343H

PIN

NO.

NAME

TYPE (1)

DESCRIPTION

1

CPL

PWR

Charge pump switching node. Connect a flying capacitor between the CPH and CPL pins

2

CPH

PWR

Charge pump switching node. Connect a flying capacitor between the CPH and CPL pins

3

VCP

PWR

Charge pump output. Connect a bypass capacitor between the VCP and VM pins

4

VM

PWR

Gate driver power supply input. Connect to the bridge power supply. Connect bypass capacitors VM and PGND pins

5

VDRAIN

I

High-side MOSFET drain sense input. Connect to the common point of the MOSFET drains

6

GHA

O

High-side gate driver output. Connect to the gate of the high-side power MOSFET

7

SHA

I

High-side source sense input. Connect to the high-side power MOSFET source. If high-side power MOSFET is not used,

connect to GND

8

DLA

I

Low-side MOSFET drain sense input. Connect to the low-side MOSFET drain

(1)

PWR = power, I = input, O = output, NC = no connection, OD = open-drain output

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

3

�DRV8343-Q1

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

www.ti.com

Pin Functions—DRV8343H (continued)

PIN

NO.

NAME

TYPE (1)

DESCRIPTION

9

GLA

O

Low-side gate driver output. Connect to the gate of the low-side power MOSFET

10

SLA

I

Low-side source sense input. Connect to the low-side power MOSFET source

11

SPA

I

Low-side current shunt amplifier input. Connect to the low-side power MOSFET source and high-side of the current shunt

resistor

12

SNA

I

Current sense amplifier input. Connect to the low-side of the current shunt resistor

13

SNB

I

Low-side source sense input. Connect to the low-side power MOSFET source

14

SPB

I

Low-side current shunt amplifier input. Connect to the low-side power MOSFET source and high-side of the current shunt

resistor

15

SLB

I

Low-side source sense input. Connect to the low-side power MOSFET source

16

GLB

O

Low-side gate driver output. Connect to the gate of the low-side power MOSFET

17

DLB

I

Low-side MOSFET drain sense input. Connect to the low-side MOSFET drain

18

SHB

I

High-side source sense input. Connect to the high-side power MOSFET source. If high-side power MOSFET is not used,

connect to GND

19

GHB

O

High-side gate driver output. Connect to the gate of the high-side power MOSFET

20

GHC

O

High-side gate driver output. Connect to the gate of the high-side power MOSFET

21

SHC

I

High-side source sense input. Connect to the high-side power MOSFET source. If high-side power MOSFET is not used,

connect to GND

22

DLC

I

Low-side MOSFET drain sense input. Connect to the low-side MOSFET drain

23

GLC

O

Low-side gate driver output. Connect to the gate of the low-side power MOSFET

24

SLC

I

Low-side source sense input. Connect to the low-side power MOSFET source

25

SPC

I

Low-side current shunt amplifier input. Connect to the low-side power MOSFET source and high-side of the current shunt

resistor

26

SNC

I

Current sense amplifier input. Connect to the low-side of the current shunt resistor

27

SOC

O

Current sense amplifier output

28

SOB

O

Current sense amplifier output

29

SOA

O

Current sense amplifier output

30

VREF

PWR

31

nFAULT

OD

32

MODE

I

PWM input mode setting. This pin is a 7-level input pin set by an external resistor

33

IDRIVE

I

Gate drive output current setting. This pin is a 7-level input pin set by an external resistor

34

VDS

I

VDS monitor trip point setting. This pin is a 7-level input pin set by an external resistor

35

GAIN

I

Amplifier gain setting. The pin is a 4-level input pin set by an external resistor

36

ENABLE

I

Gate driver enable. When this pin is logic low the device goes to a low-power sleep mode. An 20-μs (typ) low pulse can be

used to reset fault conditions

Amplifier calibration input. Set logic high to internally short amplifier inputs

Current sense amplifier power supply input and reference. Connect a bypass capacitor between VREF and AGND

Fault indicator output. This pin is pulled logic low during a fault condition and requires an external pullup resistor

37

CAL

I

38

AGND

PWR

Device analog ground. Connect to system ground

39

DVDD

PWR

3.3-V internal regulator output. Connect a bypass capacitor between the DVDD and AGND pins. This regulator can externally

source up to 30 mA.

40

nDIAG

I

Control pin for open load diagnostic and offline short-to-battery and short-to-ground diagnostic. To enable the diagnostics at

device power-up, do not connect this pin (or tie it to ground). To disable the diagnostics, connect this pin to the DVDD pin.

41

INHA

I

High-side gate driver control input. This pin controls the output of the high-side gate driver

42

INLA

I

Low-side gate driver control input. This pin controls the output of the low-side gate driver

43

INHB

I

High-side gate driver control input. This pin controls the output of the high-side gate driver

44

INLB

I

Low-side gate driver control input. This pin controls the output of the low-side gate driver

45

INHC

I

High-side gate driver control input. This pin controls the output of the high-side gate driver

46

INLC

I

Low-side gate driver control input. This pin controls the output of the low-side gate driver

47

PGND

PWR

48

NC

NC

—

Thermal

Pad

PWR

4

Device power ground. Connect to system ground

No connect. Do not connect anything to this pin

Must be connected to ground

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

�DRV8343-Q1

www.ti.com

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

NC

PGND

INLC

INHC

INLB

INHB

INLA

INHA

VSDO

DVDD

AGND

CAL

48

47

46

45

44

43

42

41

40

39

38

37

DRV8343S PHP PowerPAD™ Package

48-Pin HTQFP With Exposed Thermal Pad

Top View

CPL

1

36

ENABLE

CPH

2

35

nSCS

VCP

3

34

SCLK

VM

4

33

SDI

VDRAIN

5

32

SDO

GHA

6

31

nFAULT

SHA

7

30

VREF

DLA

8

29

SOA

GLA

9

28

SOB

SLA

10

27

SOC

SPA

11

26

SNC

SNA

12

25

SPC

Thermal

24

Not to scale

SLC

23

GLC

22

DLC

20

21

SHC

GHC

19

GHB

18

SHB

17

DLB

16

GLB

14

15

SLB

SPB

SNB

13

Pad

Pin Functions—DRV8343S

PIN

NO.

NAME

TYPE (1)

DESCRIPTION

1

CPL

PWR

Charge pump switching node. Connect a flying capacitor between the CPH and CPL pins

2

CPH

PWR

Charge pump switching node. Connect a flying capacitor between the CPH and CPL pins

3

VCP

PWR

Charge pump output. Connect a bypass capacitor between the VCP and VM pins

4

VM

PWR

Gate driver power supply input. Connect to the bridge power supply. Connect bypass capacitors between the VM and PGND

pins

5

VDRAIN

I

High-side MOSFET drain sense input. Connect to the common point of the MOSFET drains

6

GHA

O

High-side gate driver output. Connect to the gate of the high-side power MOSFET

7

SHA

I

High-side source sense input. Connect to the high-side power MOSFET source. If high-side power MOSFET is not used,

connect to GND

8

DLA

I

Low-side MOSFET drain sense input. Connect to the low-side MOSFET drain

9

GLA

O

Low-side gate driver output. Connect to the gate of the low-side power MOSFET

10

SLA

I

Low-side source sense input. Connect to the low-side power MOSFET source

11

SPA

I

Low-side current shunt amplifier input. Connect to the low-side power MOSFET source and high-side of the current shunt

resistor

12

SNA

I

Current sense amplifier input. Connect to the low-side of the current shunt resistor

13

SNB

I

Low-side source sense input. Connect to the low-side power MOSFET source

14

SPB

I

Low-side current shunt amplifier input. Connect to the low-side power MOSFET source and high-side of the current shunt

resistor

15

SLB

I

Low-side source sense input. Connect to the low-side power MOSFET source

16

GLB

O

Low-side gate driver output. Connect to the gate of the low-side power MOSFET

17

DLB

I

Low-side MOSFET drain sense input. Connect to the low-side MOSFET drain

(1)

PWR = power, I = input, O = output, NC = no connection, OD = open-drain output, PP = push-pull

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

5

�DRV8343-Q1

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

www.ti.com

Pin Functions—DRV8343S (continued)

PIN

NO.

NAME

TYPE (1)

DESCRIPTION

SHB

I

High-side source sense input. Connect to the high-side power MOSFET source. If high-side power MOSFET is not used,

connect to GND

19

GHB

O

High-side gate driver output. Connect to the gate of the high-side power MOSFET

20

GHC

O

High-side gate driver output. Connect to the gate of the high-side power MOSFET

21

SHC

I

High-side source sense input. Connect to the high-side power MOSFET source. If high-side power MOSFET is not used,

connect to GND

18

22

DLC

I

Low-side MOSFET drain sense input. Connect to the low-side MOSFET drain

23

GLC

O

Low-side gate driver output. Connect to the gate of the low-side power MOSFET

24

SLC

I

Low-side source sense input. Connect to the low-side power MOSFET source

25

SPC

I

Low-side current shunt amplifier input. Connect to the low-side power MOSFET source and high-side of the current shunt

resistor

26

SNC

I

Current sense amplifier input. Connect to the low-side of the current shunt resistor

27

SOC

O

Current sense amplifier output

28

SOB

O

Current sense amplifier output

29

SOA

O

Current sense amplifier output

30

VREF

PWR

31

nFAULT

OD

Fault indicator output. This pin is pulled logic low during a fault condition and requires an external pullup resistor

32

SDO

PP

Serial data output. Data is shifted out on the rising edge of the SCLK pin. VSDO determines logic level on the output

33

SDI

I

Serial data input. Data is captured on the falling edge of the SCLK pin

34

SCLK

I

Serial clock input. Serial data is shifted out and captured on the corresponding rising and falling edge on this pin

35

nSCS

I

Serial chip select. A logic low on this pin enables serial interface communication

36

ENABLE

I

Gate driver enable. When this pin is logic low the device goes to a low-power sleep mode. An 20-μs (typ) low pulse can be

used to reset fault conditions

Amplifier calibration input. Set logic high to internally short amplifier inputs

Current sense amplifier power supply input and reference. Connect a bypass capacitors between VREF and AGND

37

CAL

I

38

AGND

PWR

Device analog ground. Connect to system ground

39

DVDD

PWR

3.3-V internal regulator output. Connect a bypass capacitor between the DVDD and AGND pins. This regulator can externally

source up to 30 mA.

40

VSDO

PWR

Supply pin for SDO output. Connect to 5-V or 3.3-V depending on the desired logic level. Connect a bypass capacitors

between VSDO and AGND

41

INHA

I

High-side gate driver control input. This pin controls the output of the high-side gate driver

42

INLA

I

Low-side gate driver control input. This pin controls the output of the low-side gate driver

43

INHB

I

High-side gate driver control input. This pin controls the output of the high-side gate driver

44

INLB

I

Low-side gate driver control input. This pin controls the output of the low-side gate driver

45

INHC

I

High-side gate driver control input. This pin controls the output of the high-side gate driver

46

INLC

I

Low-side gate driver control input. This pin controls the output of the low-side gate driver

47

PGND

PWR

48

NC

NC

—

Thermal

Pad

PWR

6

Device power ground. Connect to system ground

No connect. Do not connect anything to this pin

Must be connected to ground

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

�DRV8343-Q1

www.ti.com

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

7 Specifications

7.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted) (1)

MIN

MAX

UNIT

GATE DRIVER

Power supply pin voltage (VM)

–0.3

65

V

Voltage differential between ground pins (AGND, BGND, DGND, PGND)

–0.3

0.3

V

MOSFET drain sense pin voltage (VDRAIN)

–0.3

65

V

Charge pump pin voltage (CPH, VCP)

–0.3

VVM + 13.5

V

Charge-pump negative-switching pin voltage (CPL)

–0.3

VVM

V

Internal logic regulator pin voltage (DVDD)

–0.3

3.8

V

Voltage difference between VM and VDRAIN

–10

10

V

Digital pin voltage (CAL, ENABLE, GAIN, IDRIVE, INHx, INLx, MODE, nFAULT, nSCS, SCLK, SDI,

SDO, VDS, nDIAG)

–0.3

5.75

V

Continuous high-side gate drive pin voltage (GHx)

–5 (2)

VVCP + 0.5

V

–7

VVCP + 0.5

V

Transient 200-ns high-side gate drive pin voltage (GHx)

High-side gate drive pin voltage with respect to SHx (GHx)

–0.3

13.5

V

Continuous high-side source sense pin voltage (SHx, DLx)

–5 (2)

VVM + 5

V

–7

VVM + 7

V

–5 (2)

VDRAIN + 5

V

–7

VDRAIN + 7

V

–0.5

15

V

Transient 200-ns high-side source sense pin voltage (SHx, DLx)

Continuous high-side source sense pin voltage (SHx, DLx)

Transient 200-ns high-side source sense pin voltage (SHx, DLx)

Continuous low-side gate drive pin voltage (GLx)

Gate drive pin source current (GHx, GLx)

Internally limited

Gate drive pin sink current (GHx, GLx)

Internally limited

A

A

Continuous low-side source sense pin voltage (SLx)

–1

1

V

Transient 200-ns low-side source sense pin voltage (SLx)

–3

3

V

Continuous shunt amplifier input pin voltage (SNx, SPx)

–1

1

V

Transient 200-ns shunt amplifier input pin voltage (SNx, SPx)

–3

3

V

Reference input pin voltage (VREF)

–0.3

5.75

V

Shunt amplifier output pin voltage (SOx)

–0.3

VVREF + 0.3

0

8

–0.3

5.75

0

10

Open drain pullup voltage (nFAULT)

–0.3

5.75

Open drain output current (nFAULT)

0

10

mA

Operating junction temperature, TJ

–40

150

°C

Storage temperature, Tstg

–65

150

°C

Shunt amplifier output current (SOx)

Push-pull output buffer reference voltage (VSDO)

Push-pull output current (SDO)

(1)

(2)

V

mA

V

mA

V

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

Continuous high-side gate pin (GHx) and phase node pin voltage (SHx) should be limited to –2 V minimum for an absolute maximum of

65 V on VM. At 60 V and below, the full specification of –5 V continuous on GHx and SHx is allowable.

7.2 ESD Ratings

VALUE

Human-body model (HBM), per AEC Q100-002

V(ESD)

(1)

Electrostatic

discharge

Charged-device model (CDM), per AEC Q100011

(1)

±2000

All pins

±500

Corner pins (1, 10, 11, 20, 21, 30, 31, and 40)

±750

UNIT

V

V

AEC Q100-002 indicates that HBM stressing shall be in accordance with the ANSI/ESDA/JEDEC JS-001 specification.

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

7

�DRV8343-Q1

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

www.ti.com

7.3 Recommended Operating Conditions

MIN

MAX

UNIT

5.5

50

V

5.5

60

V

0

5.5

V

(3)

kHz

GATE DRIVER

Power supply voltage (VM) Continuous

VVM

(1)

Power supply voltage (VM) Transient over voltage

(2)

Input voltage (CAL, ENABLE, GAIN, IDRIVE, INHx, INLx, MODE, nSCS, SCLK, SDI,

VDS, VSDO, nDIAG)

VI

fPWM

Applied PWM signal (INHx, INLx)

0

IGATE_HS

High-side average gate-drive current (GHx)

0

25 (3)

mA

IGATE_LS

Low-side average gate-drive current (GLx)

0

25 (3)

mA

IDVDD

External load current (DVDD)

0

30 (3)

mA

VVREF

Reference voltage input (VREF)

3

5.5

V

VSDO

Push-pull voltage (SDO)

3

5.5

V

VOD

Open drain pullup voltage (nFAULT)

0

5.5

V

TA

Operating ambient temperature

–40

125

°C

(1)

(2)

(3)

200

Operation at VM = 5.5V only when coming from higher VM. The minimum VM voltage for startup is greater than VUVLO (rising) voltage.

VM recommended operating condition for electrical characteristic table. Product life time depends on VM voltage. The device is intended

for 12–V and 24–V battery automotive system with life-time nominal voltage of 5.5 V - 50 V. The device can be operated during

additional overvoltage events as specified in ISO16750-2:2012

Power dissipation and thermal limits must be observed

7.4 Thermal Information

DRV8343-Q1

THERMAL METRIC (1)

PHP (HTQFP)

UNIT

48 PINS

RθJA

Junction-to-ambient thermal resistance

26.5

°C/W

RθJC(top)

Junction-to-case (top) thermal resistance

16.3

°C/W

RθJB

Junction-to-board thermal resistance

6.7

°C/W

ψJT

Junction-to-top characterization parameter

0.2

°C/W

ψJB

Junction-to-board characterization parameter

6.8

°C/W

RθJC(bot)

Junction-to-case (bottom) thermal resistance

1.0

°C/W

(1)

8

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

�DRV8343-Q1

www.ti.com

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

7.5 Electrical Characteristics

Over recommended operating conditions 5.5 ≤ VVM ≤ 60 V (unless otherwise noted). Typical limits apply for VVM = 24 V

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

VVM = 24 V, ENABLE = 3.3 V, INHx/INLx = 0 V, SHx = 0

V

12

16

ENABLE = 0 V, VVM = 24 V, TA = 25°C

12

20

UNIT

POWER SUPPLIES (DVDD, VCP, VM)

IVM

VM operating supply current

IVMQ

VM sleep mode supply current

tRST

Reset pulse time

ENABLE = 0 V period to reset faults

tWAKE (1)

Turnon time

ENABLE = 3.3 V to outputs ready, VVM > VUVLO

tSLEEP

Turnoff time

ENABLE = 0 V to device sleep mode

VDVDD

DVDD regulator voltage

VCP operating voltage

with respect to VM

VVCP

ENABLE = 0 V, VVM = 24 V, TA = 125°C

50

4.4

mA

µA

43

µs

1

ms

1

ms

VVM > 6 V, IDVDD = 0 to 30 mA

3

3.3

3.6

V

VVM = 5.5 to 6 V, IDVDD = 0 to 20 mA

3

3.3

3.6

V

VVM = 13 V, IVCP = 0 to 25 mA

8.4

11

12.5

VVM = 10 V, IVCP = 0 to 20 mA

6.3

9

10

VVM = 8 V, IVCP = 0 to 15 mA

5.4

7

8

VVM = 5.5 V, IVCP = 0 to 5 mA

4

5

6

V

LOGIC-LEVEL INPUTS (CAL, ENABLE, INHx, INLx, SCLK, SDI)

VIL

Input logic low voltage

VIH

Input logic high voltage

VHYS

Input logic hysteresis

IIL

Input logic low current

VVIN = 0 V; INHx, INLx, SDI(IDRIVE), SCLK(VDS),

ENABLE

IIH

Input logic high current

VVIN = 5 V; INHx, INLx, SDI(IDRIVE), SCLK(VDS)

IIH

Input logic high current

VVIN = 5 V; ENABLE

RPD

Pulldown resistance

To AGND; INHx, INLx, SDI(IDRIVE), SCLK(VDS)

RPD

Pulldown resistance

To AGND; ENABLE

Propagation delay

INHx/INLx input buffer and digital core propagation

delay. Dead time is excluded.

tPD

0

0.7

1.6

5.5

182

–5

V

V

mV

5

µA

50

90

µA

80

110

µA

50

100

200

kΩ

30

60

110

kΩ

105

ns

LOGIC LEVEL INPUT (nSCS)

VIL,nSCS

Input logic low voltage

VIH,nSCS

Input logic high voltage

RPU,nSCS

Pullup resistance

To DVDD

0

0.7

1.6

5.5

V

90

kΩ

25

50

V

FOUR-LEVEL H/W INPUT (GAIN)

VI1

Input mode 1 voltage

Tied to AGND

VI2

Input mode 2 voltage

47 kΩ ± 5% to tied AGND

0

V

1.2

V

VI3

Input mode 3 voltage

Hi-Z ( > 500 kΩ to AGND)

VI4

Input mode 4 voltage

Tied to DVDD

2

V

RPU

Pullup resistance

Internal pullup to DVDD

25

50

80

kΩ

RPD

Pulldown resistance

Internal pulldown to AGND

40

84

130

kΩ

3.3

V

SEVEN-LEVEL H/W INPUTS (MODE, IDRIVE, VDS)

VI1

Input mode 1 voltage

Tied to AGND

0

V

VI2

Input mode 2 voltage

18 kΩ ± 5% tied to AGND

0.5

V

VI3

Input mode 3 voltage

75 kΩ ± 5% tied to AGND

1.1

V

VI4

Input mode 4 voltage

Hi-Z ( > 1.5 MΩ )

1.65

V

VI5

Input mode 5 voltage

75 kΩ ± 5% tied to DVDD

2.2

V

VI6

Input mode 6 voltage

18 kΩ ± 5% tied to DVDD

2.8

V

VI7

Input mode 7 voltage

MODE : 0.47 kΩ ± 5% tied to DVDD

VDS, IDRIVE : Tied to DVDD

3.3

V

RPU

Pullup resistance

Internal pullup to DVDD

35

73

125

kΩ

RPD

Pulldown resistance

Internal pulldown to AGND

35

73

125

kΩ

PUSH-PULL OUTPUT (SDO)

(1)

Does not include OLP/Shorts diagnostic delay time in the H/W device

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

9

�DRV8343-Q1

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

www.ti.com

Electrical Characteristics (continued)

Over recommended operating conditions 5.5 ≤ VVM ≤ 60 V (unless otherwise noted). Typical limits apply for VVM = 24 V

PARAMETER

RPU,SDO

Internal pullup

RPD,SDO

Internal pulldown

TYP

MAX

To VSDO = 5 V

TEST CONDITIONS

MIN

40

90

To VSDO = 3.3 V

60

120

To GND

30

50

UNIT

Ω

Ω

OPEN DRAIN OUTPUT (nFAULT)

VOL

Output logic low voltage

IO = 5 mA

IOZ

Output high impedance leakage

VO = 5 V

–1

0.15

V

9

µA

VVM = 13 V, IVCP = 0 to 25 mA, GHx no output load

8.4

11

12.5

VVM = 10 , IVCP = 0 to 20 mA, GHx no output load

6.3

9

10

VVM = 8 V, IVCP = 0 to 15 mA, GHx no output load

5.4

7

8

VVM = 5.5 V, IVCP = 0 to 5 mA, GHx no output load

4

5

6

VVM = 12 V, IVCP = 0 to 25 mA, GLx no output load

9

11

12

VVM = 10 V, IVCP = 0 to 20 mA, GLx no output load

9.9

10.0

10.1

VVM = 8 V, IVCP = 0 to 15 mA, GLx no output load

7.9

8.0

8.1

VVM = 5.5 V, IVCP = 0 to 5 mA, GLx no output load

5.4

5.5

5.6

GATE DRIVERS (GHx, GLx)

High-side gate drive voltage

with respect to SHx

VGSH

Low-side gate drive voltage

with respect to PGND

VGSL

Gate drive

dead time

tDEAD

SPI Device

DEAD_TIME = 00b

500

DEAD_TIME = 01b

1000

DEAD_TIME = 10b

2000

DEAD_TIME = 11b

4000

H/W Device

Peak current

gate drive time

tDRIVE

SPI Device

10

Peak current gate drive max time

V

ns

1000

TDRIVE = 00b

500

TDRIVE = 01b

1000

TDRIVE = 10b

2000

TDRIVE = 11b

3000

H/W Device

tDRIVE_MAX

V

ns

3000

IDRIVEP_Hx = 0000b, 0001b, 0010b, 0011b

Submit Documentation Feedback

20

µs

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

�DRV8343-Q1

www.ti.com

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

Electrical Characteristics (continued)

Over recommended operating conditions 5.5 ≤ VVM ≤ 60 V (unless otherwise noted). Typical limits apply for VVM = 24 V

PARAMETER

TEST CONDITIONS

SPI Device

IDRIVEP

Peak source

gate current

H/W Device

MIN

TYP

MAX

IDRIVEP_Hx = 0000b (GHx), VVM = 24 V

0.45

1.5

3.0

IDRIVEP_Lx = 0000b (GLx), VVM = 24 V

0.81

2.7

5.4

IDRIVEP_Hx = 0001b (GHx), VVM = 24 V

1.05

3.5

7

IDRIVEP_Lx = 0001b (GLx), VVM = 24 V

1.17

3.9

7.8

IDRIVEP_Hx = 0010b (GHx), VVM = 24 V

1.5

5

10

IDRIVEP_Lx = 0010b (GLx), VVM = 24 V

1.95

6.5

13

IDRIVEP_Hx or IDRIVEP_Lx = 0011b (GHx/GLx), VVM =

24 V

3

10

20

IDRIVEP_Hx or IDRIVEP_Lx = 0100b (GHx/GLx), VVM =

24 V

4.5

15

30

IDRIVEP_Hx or IDRIVEP_Lx = 0101b (GHx/GLx), VVM =

24 V

15

50

100

IDRIVEP_Hx or IDRIVEP_Lx = 0110b (GHx/GLx), VVM =

24 V

18

60

120

IDRIVEP_Hx or IDRIVEP_Lx = 0111b (GHx/GLx), VVM =

24 V

19.5

65

130

IDRIVEP_Hx or IDRIVEP_Lx = 1000b (GHx/GLx), VVM =

24 V

76

200

400

IDRIVEP_Hx or IDRIVEP_Lx = 1001b (GHx/GLx), VVM =

24 V

79.8

210

420

IDRIVEP_Hx or IDRIVEP_Lx = 1010b (GHx/GLx), VVM =

24 V

98.8

260

520

IDRIVEP_Hx or IDRIVEP_Lx = 1011b (GHx/GLx), VVM =

24 V

100.7

265

530

IDRIVEP_Hx or IDRIVEP_Lx = 1100b (GHx/GLx), VVM =

24 V

279.3

735

1470

IDRIVEP_Hx or IDRIVEP_Lx = 1101b (GHx/GLx), VVM =

24 V

304

800

1600

IDRIVEP_Hx or IDRIVEP_Lx = 1110b (GHx/GLx), VVM =

24 V

355.3

935

1870

IDRIVEP_Hx or IDRIVEP_Lx = 1111b (GHx/GLx), VVM =

24 V

380

1000

2000

IDRIVE = Tied to AGND (GHx), VVM = 24 V

0.45

1.5

3.0

IDRIVE = Tied to AGND (GLx), VVM = 24 V

0.81

2.7

5.4

IDRIVE = 18 kΩ ± 5% tied to AGND (GHx), VVM = 24 V

1.5

5

10

IDRIVE = 18 kΩ ± 5% tied to AGND (GLx), VVM = 24 V

1.95

6.5

13

3

10

20

IDRIVE = Hi-Z (GHx/GLx), VVM = 24 V

18

60

120

IDRIVE = 75 kΩ ± 5% tied to DVDD (GHx/GLx), VVM = 24

V

76

200

400

IDRIVE = 18 kΩ ± 5% tied to DVDD (GHx/GLx), VVM = 24

V

98.8

260

520

IDRIVE = Tied to DVDD (GHx/GLx), VVM = 24 V

380

1000

2000

IDRIVE = 75 kΩ ± 5% tied to AGND (GHx/GLx), VVM = 24

V

mA

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

UNIT

11

�DRV8343-Q1

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

www.ti.com

Electrical Characteristics (continued)

Over recommended operating conditions 5.5 ≤ VVM ≤ 60 V (unless otherwise noted). Typical limits apply for VVM = 24 V

PARAMETER

TEST CONDITIONS

SPI Device

IDRIVEN

Peak sink

gate current

H/W Device

SPI Device

MIN

TYP

MAX

IDRIVEN_Hx or IDRIVEN_Lx = 0000b, VVM = 24 V

0.9

3

5.4

IDRIVEN_Hx or IDRIVEN_Lx = 0001b, VVM = 24 V

2.09

7

12.6

IDRIVEN_Hx or IDRIVEN_Lx = 0010b, VVM = 24 V

3

10

18

IDRIVEN_Hx or IDRIVEN_Lx = 0011b, VVM = 24 V

6

20

36

IDRIVEN_Hx or IDRIVEN_Lx= 0100b, VVM = 24 V

9

30

54

IDRIVEN_Hx or IDRIVEN_Lx = 0101b, VVM = 24 V

30

100

180

IDRIVEN_Hx or IDRIVEN_Lx = 0110b, VVM = 24 V

36

120

216

IDRIVEN_Hx or IDRIVEN_Lx = 0111b, VVM = 24 V

39

130

234

IDRIVEN_Hx or IDRIVEN_Lx = 1000b, VVM = 24 V

120

400

720

IDRIVEN_Hx or IDRIVEN_Lx = 1001b, VVM = 24 V

126

420

756

IDRIVEN_Hx or IDRIVEN_Lx = 1010b, VVM = 24 V

156

520

936

IDRIVEN_Hx or IDRIVEN_Lx = 1011b, VVM = 24 V

159

530

954

IDRIVEN_Hx or IDRIVEN_Lx = 1100b, VVM = 24 V

441

1470

2646

IDRIVEN_Hx or IDRIVEN_Lx = 1101b, VVM = 24 V

480

1600

2880

IDRIVEN_Hx or IDRIVEN_Lx = 1110b, VVM = 24 V

561

1870

3366

IDRIVEN_Hx or IDRIVEN_Lx = 1111b, VVM = 24 V

600

2000

3600

IDRIVE = Tied to AGND, VVM = 24 V

0.9

3

5.4

IDRIVE = 18 kΩ ± 5% tied to AGND, VVM = 24 V

3

10

18

IDRIVE = 75 kΩ ± 5% tied to AGND, VVM = 24 V

6

20

36

36

120

216

IDRIVE = 75 kΩ ± 5% tied to DVDD, VVM = 24 V

120

400

720

IDRIVE = 18 kΩ ± 5% tied to DVDD, VVM = 24 V

156

520

936

IDRIVE = Tied to DVDD, VVM = 24 V

600

2000

3600

IDRIVEP_Hx = 0000b, VVM = 24 V

0.45

1.5

3.8

IDRIVEP_Hx = 0001b, VVM = 24 V

1.05

3.5

7

IDRIVEP_Hx = 0010b, VVM = 24 V

1.5

5

10

IDRIVE = Hi-Z, VVM = 24 V

IDRIVEP_Hx = 0011b, VVM = 24 V

IHOLDP

Gate holding source

current after tDRIVE

All other IDRIVE settings, VVM = 24 V

IDRIVE tied to AGND, VVM = 24 V

H/W Device

SPI Device

IHOLDN

Gate holding sink

current after tDRIVE

10

20

15

30

mA

mA

0.45

1.5

3.8

IDRIVE = 18 kΩ ± 5% tied to AGND, VVM = 24 V

1.5

5

10

IDRIVE = 75 kΩ ± 5% tied to AGND, VVM = 24 V

3

10

20

All other IDRIVE settings, VVM = 24 V

4.5

15

30

IDRIVEP_Hx = 0000b, VVM = 24 V

0.9

3

5.4

IDRIVEP_Hx = 0001b, VVM = 24 V

2

7

12.6

IDRIVEP_Hx = 0010b, VVM = 24 V

3

10

18

IDRIVEP_Hx = 0011b, VVM = 24 V

6

20

36

All other IDRIVE settings, VVM = 24 V

9

30

54

0.9

3

5.4

IDRIVE = 18 kΩ ± 5% tied to AGND, VVM = 24 V

3

10

18

IDRIVE = 75 kΩ ± 5% tied to AGND, VVM = 24 V

6

20

36

All other IDRIVE settings, VVM = 24 V

9

30

54

9

30

54

0.6

2

3.6

A

IDRIVE tied to AGND, VVM = 24 V

H/W Device

3

4.5

UNIT

mA

ISTRONG

Gate strong pulldown current

(GHx to SHx and GLx to PGND)

IDRIVEP_Hx = 0000b, 0001b, 0010b, 0011b, VVM = 24 V

ROFF

Gate hold off resistor

GHx to SHx

150

280

kΩ

ROFF

Gate hold off resistor

GLx to PGND

150

280

kΩ

All other IDRIVE settings, VVM = 24 V

mA

CURRENT SHUNT AMPLIFIER (SNx, SOx, SPx, VREF)

12

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

�DRV8343-Q1

www.ti.com

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

Electrical Characteristics (continued)

Over recommended operating conditions 5.5 ≤ VVM ≤ 60 V (unless otherwise noted). Typical limits apply for VVM = 24 V

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

4.9

5

5.1

CSA_GAIN = 01b, CSA_FET = 0b

9.8

10

10.2

CSA_GAIN = 10b, CSA_FET = 0b

19.6

20

20.4

CSA_GAIN = 11b, CSA_FET = 0b

39.2

40

40.8

CSA_GAIN = 00b, CSA_FET = 1b

4.85

5

5.15

CSA_GAIN = 01b, CSA_FET = 1b

9.7

10

10.3

CSA_GAIN = 10b, CSA_FET = 1b

19.4

20

20.6

CSA_GAIN = 11b, CSA_FET = 1b

38.8

40

41.2

CSA_GAIN = 00b, CSA_FET = 0b

SPI Device

GCSA

Amplifier gain

SPI Device

H/W Device

GAIN = Tied to AGND

4.9

5

5.1

GAIN = 47 kΩ ± 5% tied to AGND

9.8

10

10.2

GAIN = Hi-Z

19.6

20

20.4

GAIN = Tied to DVDD

39.2

40

40.8

VO_STEP = 0.5 V, GCSA = 5 V/V

150

VO_STEP = 0.5 V, GCSA = 10 V/V

300

VO_STEP = 0.5 V, GVSA = 20 V/V

600

tSET

Settling time to ±1%

VCOM

Common mode input range

VDIFF

Differential mode input range

VOFF

Input offset error

VSP = VSN = 0 V, VREF = 3.3 V, GCSA = 10, 20, 40 V/V

VOFF

Input offset error

VSP = VSN = 0 V, VREF = 3.3 V, GCSA = 5 V/V

VDRIFT

Drift offset

VSP = VSN = 0 V

VLINEAR

SOx output voltage linear range

VO_STEP = 0.5 V, GCSA = 40 V/V

VBIAS

SOx output voltage

bias

V/V

ns

1200

–0.15

0.15

–0.3

0.3

–4

4

–5

-45

10

VSP = VSN = 0 V, CAL = 3.3 V, VREF_DIV = 0b

VVREF –

0.3

VSP = VSN = 0 V, CAL = 3.3 V, VREF_DIV = 1b

VVREF /

2

VSP = VSN = 0 V, CAL = 3.3 V

VVREF /

2

IBIAS

SPx/SNx input bias current

VSLEW

SOx output slew rate

60-pF load

10

IVREF

VREF input current

VVREF = 5 V

2

UGB

Unity gain bandwidth

60-pF load

8

V

V

mV

5

mV

45

µV/°C

VVREF –

0.25

0.25

SPI Device

H/W Device

UNIT

V

V

100

µA

V/µs

3

mA

MHz

PROTECTION CIRCUITS

VM falling, UVLO report

5.2

5.4

VM rising, UVLO recovery

5.4

5.9

VM undervoltage hysteresis

Rising to falling threshold

200

VM undervoltage deglitch time

VM falling, UVLO report

VUVLO

VM undervoltage lockout

VUVLO,DVDD

DVDD undervoltage lockout

VUVLO_HYS

tUVLO_DEG

VCPUV

Charge pump undervoltage lockout

VGS_CLAMP

High-side gate clamp

VOLA

Open load active mode detection

threshold

IOL

Open load current

tOLP

Open load passive

diagnostic delay

2.9

11.5

µs

VCP falling, CPUV report

VVM +

2.5

VVM +

3.1

Positive clamping voltage

15

16.5

19

–0.7

DLx – VDRAIN

150

300

430

SLx – SHx, –1 < SLx < 0

150

300

500

2.5

SPI Device

H/W Device

OLP_SHRT_DLY = 00b

0.25

OLP_SHRT_DLY = 01b

1.25

OLP_SHRT_DLY = 10b

5

OLP_SHRT_DLY = 11b

11.5

After tWAKE and tSHORTS elapse

Product Folder Links: DRV8343-Q1

V

V

mV

mA

ms

5

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

V

mV

VVM +

1.4

Negative clamping voltage

V

13

�DRV8343-Q1

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

www.ti.com

Electrical Characteristics (continued)

Over recommended operating conditions 5.5 ≤ VVM ≤ 60 V (unless otherwise noted). Typical limits apply for VVM = 24 V

PARAMETER

Offline short-tobattery and short-toGND diagnostic delay

tSHORTS

TEST CONDITIONS

SPI Device

H/W Device

SPI Device

VVDS_OCP

VDS overcurrent

trip voltage

H/W Device

MIN

0.1

OLP_SHRT_DLY = 01b

0.5

OLP_SHRT_DLY = 10b

2

OLP_SHRT_DLY = 11b

4.4

After tWAKE elapses

VDS and VSENSE

overcurrent deglitch

time

SPI Device

2

0.06

0.11

VDS_LVL = 0001b

0.08

0.13

0.18

VDS_LVL = 0010b

0.15

0.2

0.25

VDS_LVL = 0011b

0.2

0.26

0.32

VDS_LVL = 0100b

0.24

0.31

0.38

VDS_LVL = 0101b

0.38

0.45

0.52

VDS_LVL = 0110b

0.45

0.53

0.61

VDS_LVL = 0111b

0.51

0.6

0.69

VDS_LVL = 1000b

0.59

0.68

0.77

VDS_LVL = 1001b

0.64

0.75

0.86

VDS_LVL = 1010b

0.81

0.94

1.07

VDS_LVL = 1011b

0.97

1.13

1.29

VDS_LVL = 1100b

1.14

1.3

1.46

VDS_LVL = 1101b

1.34

1.5

1.66

VDS_LVL = 1110b

1.52

1.7

1.88

VDS_LVL = 1111b

1.69

1.88

2.07

VDS = Tied to AGND

0.01

0.06

0.11

VDS = 18 kΩ ± 5% tied to AGND

0.08

0.13

0.18

VDS = 75 kΩ ± 5% tied to AGND

0.2

0.26

0.32

VDS = Hi-Z

0.51

0.6

0.69

VDS = 75 kΩ ± 5% tied to DVDD

0.97

1.13

1.29

VDS = 18 kΩ ± 5% tied to DVDD

1.69

1.88

2.07

SPI Device

V

Disabled

OCP_DEG=000b

2.5

OCP_DEG = 001b

4.75

OCP_DEG = 010b

6.75

OCP_DEG = 011b

8.75

OCP_DEG = 100b

10.25

OCP_DEG = 101b

11.5

OCP_DEG = 110b

16.5

OCP_DEG = 111b

20.5

µs

4.75

SEN_LVL = 00b

VSENSE overcurrent

trip voltage

UNIT

ms

0.01

H/W Device

VSEN_OCP

MAX

VDS_LVL = 0000b

VDS = Tied to DVDD

tOCP_DEG

TYP

OLP_SHRT_DLY = 00b

0.25

SEN_LVL = 01b

0.5

SEN_LVL = 10b

0.75

SEN_LVL = 11b

1

H/W Device

V

1

TRETRY = 00b

2

TRERTY = 01b

4

TRETRY = 10b

6

tRETRY

Overcurrent fault retry

time

THYS

Thermal hysteresis

Die temperature, TJ

TOTSD

Thermal shutdown temperature

Die temperature, TJ

150

170

188

°C

TOTW

Thermal warning temperature

Die temperature, TJ

130

150

169

°C

SPI Device

TRETRY = 11b

14

Submit Documentation Feedback

ms

8

20

°C

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

�DRV8343-Q1

www.ti.com

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

7.6 SPI Timing Requirements

Over recommended operating conditions unless otherwise noted. Typical limits apply for VVM = 24 V

MIN

tREADY

SPI ready after enable

tCLK

SCLK minimum period

tCLKH

NOM

MAX

VM > UVLO, ENABLE = 3.3 V

1

UNIT

ms

100

ns

SCLK minimum high time

50

ns

tCLKL

SCLK minimum low time

50

ns

tSU_SDI

SDI input data setup time

20

ns

tH_SDI

SDI input data hold time

30

tD_SDO

SDO output data delay time

tSU_nSCS

nSCS input setup time

50

ns

tH_nSCS

nSCS input hold time

50

ns

tHI_nSCS

nSCS minimum high time before active low

500

ns

tDIS_nSCS

nSCS disable time

tHI_nSCS

ns

SCLK high to SDO valid, CL = 20 pF

30

nSCS high to SDO high impedance

ns

10

tSU_nSCS

ns

tH_nSCS

nSCS

tCLK

SCLK

tCLKH

SDI

X

tCLKL

MSB

LSB

X

tSU_SDI tH_SDI

SDO

Z

MSB

LSB

tD_SDO

Z

tDIS_nSCS

Figure 1. SPI Slave Mode Timing Diagram

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

15

�DRV8343-Q1

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

www.ti.com

7.7 Typical Characteristics

30

VM sleep mode supply current I VMQ (µA)

VM Operating supply current IVM (mA)

13.5

13.25

13

12.75

12.5

12.25

12

11.75

11.5

11.25

TA = -40°C

TA = 25°C

TA = 125°C

11

10.75

10.5

25

20

Ta -40

Ta 125

15

10

5

0

5

10

15

20

25

30 35

VM (V)

40

45

50

55

60

5

No PWM Switching

12

9

6

3

IVCP = 0mA

IVCP = 12.5mA

IVCP = 25mA

29

37

VM (V)

45

53

45

55

60

D002

10

Ta = -40

Ta = 25

Ta = 125

8

6

4

2

0

0

60

3

6

9

12

IVCP (mA)

D003

TA = 25°C

15

D004

VM = 8V

Figure 4. VCP w.r.t VM over VM voltage > 13V

16

35

VM (V)

Figure 3. VM Sleep Mode Supply Current

VCP operating voltage with respect to VM (V)

VCP operating voltage with respect to VM (V)

Figure 2. VM Operating Supply Current

21

25

ENABLE = 0V

15

0

13

15

D001

Figure 5. VCP w.r.t VM over output load IVCP

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

�DRV8343-Q1

www.ti.com

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

8 Detailed Description

8.1 Overview

The DRV8343-Q1 device is an integrated gate driver for three-phase motor driver automotive applications. These

devices decrease system complexity by integrating three independent half-bridge gate drivers, charge pump, and

linear regulator for the supply voltages of the high-side and low-side gate drivers.The device also integrates three

current shunt (or current sense) amplifiers. A standard serial peripheral interface (SPI) provides a simple method

for configuring the various device settings and reading fault diagnostic information through an external controller.

Alternatively, a hardware interface (H/W) option allows for configuring the most common settings through fixed

external resistors.

The gate drivers support external N-channel high-side and low-side power MOSFETs and can drive up to 1-A

source, 2-A sink peak currents. A doubler charge pump generates the supply voltage of the high-side gate drive.

This charge pump architecture regulates the VCP output voltage for driving high-side power MOSFET. The

supply voltage of the low-side gate driver is generated using a linear regulator from the VM power supply that

regulates for driving low-side power MOSFET. A Smart Gate Drive architecture provides the ability to

dynamically adjust the strength of the gate drive output current which lets the gate driver control the VDS

switching speed of the power MOSFET. This feature lets the user remove the external gate drive resistors and

diodes, reducing the component count in the bill of materials (BOM), cost, and area of the printed circuit board

(PCB). The architecture also uses an internal state machine to protect against short-circuit events in the gate

driver, control the half-bridge dead time, and protect against dV/dt parasitic turnon of the external power

MOSFET.

The DRV8343-Q1 device integrates three bidirectional current sense amplifiers for monitoring the current level

through each of the external half-bridges using a low-side shunt resistor. The gain setting of the current sense

amplifiers can be adjusted through the SPI or hardware interface. The SPI method providing additional flexibility

to adjust the output bias point.

In addition to the high level of device integration, the DRV8343-Q1 device provides a wide range of integrated

protection features. These features include power supply undervoltage lockout (UVLO), charge pump

undervoltage lockout (CPUV), short to supply (SHT_BAT), short-to-ground (SHT_GND), open-load detection

(OLD), VDS overcurrent monitoring (OCP), gate driver short-circuit detection (GDF), and overtemperature

shutdown (OTW and OTSD). Fault events are indicated by the nFAULT pin with detailed information available in

the SPI registers on the SPI device version.

The DRV8343-Q1 device is available in a 0.5-mm pin pitch, 7 × 7 mm, HTQFP surface-mount package.

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

17

�DRV8343-Q1

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

www.ti.com

8.2 Functional Block Diagram

VM

VM

VDRAIN

VM

VCP

VCP

>10 …F 4.7 …F 1 …F

47 nF

GHA

HS

SHA

VCP

Charge

Pump

CPH

DLA

VGLS

CPL

GLA

LS

VGLS

30 mA

1 …F

VGLS

Linear

Regulator

SLA

Gate Driver

VM

DVDD

AGND

PGND

VCP

DVDD

Linear

Regulator

GHB

HS

SHB

Power

DLB

VGLS

Digital

Core

ENABLE

GLB

LS

INHA

SLB

Gate Driver

INLA

VM

Smart Gate

Drive

INHB

VCP

GHC

HS

Protection

INLB

SHC

Control

Inputs

DLC

VGLS

INHC

GLC

LS

INLC

VCC

Gate Driver

RnFAULT

MODE

IDRIVE

nFAULT

Fault Output

VDS

SLC

GAIN

VCC

SPC

VREF

0.1 …F

AV

SNC

RSEN

SOC

SPB

SOB

SOA

Output

Offset

Bias

AV

SNB

RSEN

SPA

CAL

AV

SNA

RSEN

Figure 6. Block Diagram for DRV8343H

18

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

�DRV8343-Q1

www.ti.com

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

Functional Block Diagram (continued)

VM

VM

VDRAIN

VM

VCP

VCP

>10 …F 4.7 …F 1 …F

47 nF

GHA

HS

SHA

VCP

Charge

Pump

CPH

DLA

VGLS

CPL

GLA

LS

VGLS

30 mA

1 …F

SLA

VGLS

Linear

Regulator

Gate Driver

VM

DVDD

VCP

DVDD

Linear

Regulator

AGND

GHB

HS

Power

PGND

SHB

VCC

DLB

Digital

Core

VSDO

0.1 …F

VGLS

GLB

LS

ENABLE

SLB

Gate Driver

INHA

Smart Gate

Drive

INLA

Protection

Control

Inputs

INHB

VM

VCP

GHC

HS

SHC

DLC

INLB

VGLS

GLC

LS

INHC

VCC

INLC

Gate Driver

RPU

VSDO

SDI

SPI

Fault Output

SDO

nFAULT

SLC

SCLK

DVDD

VCC

nSCS

SPC

VREF

0.1 …F

AV

SNC

RSEN

SOC

SOB

SOA

Output

Offset

Bias

SPB

AV

SNB

RSEN

SPA

CAL

AV

SNA

RSEN

Figure 7. Block Diagram for DRV8343S

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

19

�DRV8343-Q1

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

www.ti.com

8.3 Feature Description

8.3.1 Three Phase Smart Gate Drivers

The DRV8343-Q1 device integrates three, half-bridge gate drivers, each capable of driving high-side and lowside N-channel power MOSFETs. A doubler charge pump provides the correct gate bias voltage to the high-side

MOSFET across a wide operating voltage range in addition to providing 100% support of the duty cycle. An

internal linear regulator provides the gate bias voltage for the low-side MOSFETs. The half-bridge gate drivers

can be used in combination to drive a three-phase motor or separately to drive other types of loads.

The DRV8343-Q1 device implements a Smart Gate Drive architecture which allows the user to dynamically

adjust the gate drive current without requiring external resistors to limit the gate current. Additionally, this

architecture provides a variety of protection features for the external MOSFETs including automatic dead time

insertion, prevent of parasitic dV/dt gate turnon, and gate fault detection.

8.3.1.1 PWM Control Modes

The DRV8343-Q1 device provides eight different PWM control modes in the SPI device and seven different

modes in the H/W device to support various commutation and control methods. Texas Instruments does not

recommend changing the MODE pin or PWM_MODE register during operation of the power MOSFETs. Set all

INHx and INLx pins to logic low before making a MODE pin or PWM_MODE register change. Table 1 shows the

different mode settings for the SPI device. The MODE bit setting of 100b is not available in the H/W device.

Table 1. 6x PWM Mode Truth Table

H/W DEVICE

SPI DEVICE

MODE SETTINGS

Tied to AGND

000b

6x PWM

18 kΩ to AGND

001b

3x PWM

75 kΩ to AGND

010b

1x PWM

Hi-Z

011b

Independent half-bridge (for all three half-bridges)

Not Available

100b

Phases A and B are independent half-bridges, Phase C is independent FET

75 kΩ to DVDD

101b

Phases B and C are independent half-bridges, Phase A is independent FET

18 kΩ to DVDD

110b

Phases A is independent half-bridge, Phase B and C are independent FET

0.47 kΩ to DVDD

111b

Independent MOSFET (for all three half-bridges)

8.3.1.1.1 6x PWM Mode (PWM_MODE = 000b or MODE Pin Tied to AGND)

In 6x PWM mode, each half-bridge supports three output states: low, high, or high-impedance (Hi-Z). The

corresponding INHx and INLx signals control the output state as listed in Table 2.

Table 2. 6x PWM Mode Truth Table

20

INLx

INHx

GLx

GHx

SHx + DLx

0

0

0

1

L

L

Hi-Z

L

H

1

H

0

H

L

L

1

1

L

L

Hi-Z

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

�DRV8343-Q1

www.ti.com

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

6-PWM

INHA

MCU PWM

INLA

MCU PWM

INHB

MCU PWM

INLB

MCU PWM

INHC

MCU PWM

INLC

MCU PWM

Figure 8. 6-PWM Mode

8.3.1.1.2 3x PWM Mode (PWM_MODE = 001b or MODE Pin = 18 kΩ to AGND)

In 3x PWM mode, the INHx pin controls each half-bridge and supports two output states: low or high. The INLx

pin is used to put the half bridge in the Hi-Z state. If the Hi-Z state is not required, tie all INLx pins to logic high.

The corresponding INHx and INLx signals control the output state as listed in Table 3.

Table 3. 3x PWM Mode Truth Table

INLx

INHx

GLx

GHx

SHx + DLx

0

1

X

L

L

Hi-Z

0

H

L

1

L

1

L

H

H

3-PWM

INHA

MCU PWM

INLA

INHB

MCU PWM

INLB

INHC

MCU PWM

INLC

Figure 9. 3-PWM Mode

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

21

�DRV8343-Q1

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

www.ti.com

8.3.1.1.3 1x PWM Mode (PWM_MODE = 010b or MODE Pin = 75 kΩ to AGND)

In 1x PWM mode, the DRV8343-Q1 device uses 6-step block commutation tables that are stored internally. This

feature allows for a three-phase BLDC motor to be controlled using one PWM sourced from a simple controller.

The PWM is applied on the INHA pin and determines the output frequency and duty cycle of the half-bridges.

The half-bridge output states are managed by the INLA, INHB, and INLB pins which are used as state logic

inputs. The state inputs can be controlled by an external controller or connected directly to the digital outputs of

the Hall effect sensor from the motor (INLA = HALL_A, INHB = HALL_B, INLB = HALL_C). The 1x PWM mode

usually operates with synchronous rectification (low-side MOSFET recirculation); however, the mode can be

configured to use asynchronous rectification (MOSFET body diode freewheeling) on SPI devices. This

configuration is set using the 1PWM_COM bit in the SPI registers.

The INHC input controls the direction through the 6-step commutation table which is used to change the direction

of the motor when Hall effect sensors are directly controlling the state of the INLA, INHB, and INLB inputs. Tie

the INHC pin low if this feature is not required.

The INLC input brakes the motor by turning off all high-side MOSFETs and turning on all low-side MOSFETs

when the INLC pin is pulled low. This brake is independent of the state of the other input pins. Tie the INLC pin

high if this feature is not required. In the SPI device, the brake and coast mode can also be selected by the

1PWM_BRAKE register (see Table 21).

Table 4. Synchronous 1x PWM Mode

GATE DRIVE OUTPUTS (1)

LOGIC AND HALL INPUTS

STATE

INHC = 0

INHC = 1

PHASE A

INLA

INHB

INLB

INLA

INHB

INLB

GHA

PHASE B

GLA

GHB

PHASE C

GLB

GHC

GLC

DESCRIPTION

Stop

0

0

0

0

0

0

L

L

L

L

L

L

Stop

Align

1

1

1

1

1

1

PWM

!PWM

L

H

L

H

Align

1

1

1

0

0

0

1

L

L

PWM

!PWM

L

H

B→C

2

1

0

0

0

1

1

PWM

!PWM

L

L

L

H

A→C

3

1

0

1

0

1

0

PWM

!PWM

L

H

L

L

A→B

4

0

0

1

1

1

0

L

L

L

H

PWM

!PWM

C→B

5

0

1

1

1

0

0

L

H

L

L

PWM

!PWM

C→A

6

0

1

0

1

0

1

L

H

PWM

!PWM

L

L

B→A

(1)

!PWM is the inverse of the PWM signal.

Table 5. Asynchronous 1x PWM Mode 1PWM_COM = 1 (SPI Only)

LOGIC AND HALL INPUTS

STATE

INHC = 0

GATE DRIVE OUTPUTS

INHC = 1

PHASE A

INLA

INHB

INLB

INLA

INHB

INLB

PHASE B

GHA

GLA

GHB

PHASE C

GLB

GHC

GLC

DESCRIPTION

Stop

0

0

0

0

0

0

L

L

L

L

L

L

Stop

Align

1

1

1

1

1

1

PWM

L

L

H

L

H

Align

1

1

1

0

0

0

1

L

L

PWM

L

L

H

B→C

2

1

0

0

0

1

1

PWM

L

L

L

L

H

A→C

3

1

0

1

0

1

0

PWM

L

L

H

L

L

A→B

4

0

0

1

1

1

0

L

L

L

H

PWM

L

C→B

5

0

1

1

1

0

0

L

H

L

L

PWM

L

C→A

6

0

1

0

1

0

1

L

H

PWM

L

L

L

B→A

Figure 10 and Figure 11 show the different possible configurations in 1x PWM mode.

22

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

�DRV8343-Q1

www.ti.com

MCU_PWM

MCU_GPIO

MCU_GPIO

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

INHA

INLA

INHB

INLB

MCU_GPIO

MCU_GPIO

MCU_GPIO

INHC

INLC

INHA

MCU_PWM

PWM

INLA

STATE0

INHB

STATE1

INLB

BLDC Motor

STATE2

INHC

MCU_GPIO

DIR

INLC

MCU_GPIO

PWM

H

STATE0

STATE1

H

BLDC Motor

STATE2

H

DIR

nBRAKE

nBRAKE

Figure 10. 1x PWM—Simple Controller

Figure 11. 1x PWM—Hall Effect Sensor

8.3.1.1.4 Independent Half-Bridge PWM Mode (PWM_MODE = 011b or MODE Pin is > 1.5 MΩ to AGND or Hi-Z)

In independent half-bridge PWM mode, the INHx pin controls each half-bridge independently and supports two

output states: low or high. The corresponding INHx and INLx signals control the output state as listed in Table 6.

The INLx pin is used to change the half-bridge to high impedance. If the high-impedance (Hi-Z) state is not

required, tie all INLx pins logic high.

Table 6. Independent Half-Bridge Mode Truth Table

INLx

INHx

GLx

GHx

0

X

L

L

1

0

H

L

1

1

L

H

8.3.1.1.5 Phases A and B are Independent Half-Bridges, Phase C is Independent FET (MODE = 100b)

In this mode, phases A and B are independent half-bridge control, with independent fault handling and dead time

enforcement by the device. Phase C is independent FET mode where the dead time inserted by the device is

bypassed and both MOSFETs can be turned-on at the same time. This mode is not available in the H/W version.

8.3.1.1.6 Phases B and C are Independent Half-Bridges, Phase A is Independent FET (MODE = 101b or MODE Pin is

75 kΩ to DVDD)

In this mode, phases B and C are independent half-bridge control, with independent fault handling and dead time

enforcement by the device. Phase A is independent FET mode where the dead time inserted by the device is

bypassed and both MOSFETs can be turned-on at the same time.

8.3.1.1.7 Phases A is Independent Half-Bridge, Phases B and C are Independent FET (MODE = 110b or MODE Pin is

18 kΩ to DVDD)

In this mode, phase A is independent half-bridge control, with dead time enforcement by the device. Phases B

and C are independent FET mode where the dead time is bypassed and both MOSFETs in a given phase can

be turned-on at the same time. Fault handling is also done independently for each FET in phases B and C.

8.3.1.1.8 Independent MOSFET Drive Mode (PWM_MODE = 111b or MODE Pin = 0.47 kΩ to DVDD)

In independent MOSFET drive mode, the INHx and INLx pins control the outputs, GHx and GLx, respectively.

This control mode lets the DRV8343-Q1 device drive separate high-side and low-side loads with each halfbridge. These types of loads include unidirectional brushed DC motors, solenoids, and low-side and high-side

switches. In this mode, turning on both the high-side and low-side MOSFETs at the same time in a given halfbridge gate driver is possible to use the device as a high-side or low-side driver. The dead time (tDEAD) is

bypassed in the mode and must be inserted by the external MCU.

Table 7. Independent PWM Mode Truth Table

INLx

INHx

GLx

0

0

L

GHx

L

0

1

L

H

1

0

H

L

1

1

H

H

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

23

�DRV8343-Q1

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

www.ti.com

Figure 12 shows how the DRV8343-Q1 device can be used to connect a high-side load and a low-side load at

the same time with one half-bridge and drive the loads independently. In this mode, the VDS monitors are active

for both the MOSFETs to protect from an overcurrent condition.

VDS

+

±

VM

VDRAIN

VCP

GHx

HS

INHx

Load

SHx

INLx

DLx

VGLS

GLx

LS

Load

SLx/SPx

Gate Driver

VDS

+

±

Figure 12. Independent PWM High-Side and Low-Side Drivers

If the half-bridge is used to implement only a high-side or low-side driver, using the VDS monitors to help protect

from an overcurrent condition is possible as shown in Figure 13 or Figure 14. The unused gate driver can stay

disconnected.

VDS

+

±

VDS

VM

+

±

VCP

VCP

INHx

GHx

HS

GHx

HS

INHx

DLx

VGLS

DLx

INLx

VGLS

GLx

LS

Load

SHx

SHx

INLx

VM

VDRAIN

VDRAIN

GLx

Load

LS

SLx/SPx

Gate Driver

+

VDS ±

+

VDS ±

Figure 13. One High-Side Driver

24

SLx/SPx

Gate Driver

Figure 14. One Low-Side Driver

Submit Documentation Feedback

Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: DRV8343-Q1

�DRV8343-Q1

www.ti.com

SLVSE12A – MARCH 2018 – REVISED APRIL 2019

Figure 15 shows how the DRV8343-Q1 device can be used to connect a solenoid load where both the high-side

and low-side MOSFETs can be turned on at the same time to drive the load without causing shoot-through. TI

recommends having the external diodes for current recirculation. If a half-bridge is not used, the gate pins (GHx

and GLx) can stay unconnected and the sense pins (SHx and DLx) can be tied directly or with a resistor to GND.

VDRAIN

VDRAIN

HS_VSD

HS_VSD

+

±

GHx

HS_VSD

+

±

GHx

+

±

SHx

SHx

GHx

SHx

PH_B

PH_A

PH_C

DLx

DLx

LS_VSD

VDRAIN

GLx

LS_VSD

+

DLx

GLx

LS_VSD

+

±

±

SLx

GLx

+

±

SLx

SLx

Figure 15. Solenoid Drive Configuration

8.3.1.2 Device Interface Modes

The DRV8343-Q1 device supports two different interface modes (SPI and hardware) to let the end application

design for either flexibility or simplicity. The two interface modes share the same four pins, allowing the different