FPC402

FPC402

SNLS582C – JUNE 2017 – REVISED SEPTEMBER

2020

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

www.ti.com

FPC402 Quad Port Controller

1 Features

3 Description

•

The FPC402 quad port controller serves as a lowspeed signal aggregator for common port types such

as SFP, QSFP, Mini-SAS HD, and others. The

FPC402 aggregates all low-speed control and I2C

signals across four ports and presents a single easyto-use management interface to the host (I2C or SPI).

Multiple FPC402s can be used in high-port-count

applications with one common control interface to the

host. The FPC402 is designed to allow placement on

the bottom side of the PCB, underneath the press fit

connector, to simplify routing. This localized control of

the low-speed signals in the ports cuts system BOM

costs by enabling the use of smaller IO count control

devices (FPGAs, CPLDs, and MCUs) and by reducing

routing layer congestion.

•

•

•

•

•

•

•

•

•

•

Control Signal Management and I2C Aggregation

Across Four Ports

Combine Multiple FPC402s to Control 56 Total

Ports Through a Single Host Interface

Eliminate Need for Discrete I2C Muxes, LED

Drivers, and High-Pin-Count FPGA/CPLD Control

Devices

Reduce PCB Routing Complexity by Handling All

Low-Speed Control Signals Close to the Port

Selectable I2C (up to 1 MHz) or SPI (up to 10

MHz) Host Control Interface

Automatic Prefetching of Critical, User-Specified

Data From the Modules

Broadcast Mode Write to All Ports Simultaneously

Across All FPC402 Controllers

Advanced LED Features for Port Status Indication,

Including Programmable Blinking and Dimming

Customizable Interrupt Events

Separate Host-Side I/O Voltage: 1.8 V to 3.3 V

Small WQFN Package Enabling Placement on

Bottom Side of PCB Underneath Ports

2 Applications

•

•

•

•

•

ToR/Aggregation/Core Switch and Router

Wireless Infrastructure Base Band Unit and

Remote Radio Unit

Video Switch and Router

Storage Cards and Storage Racks

SFP, QSFP, QSFP-DD, OSFP, Mini-SAS HD Port

Management

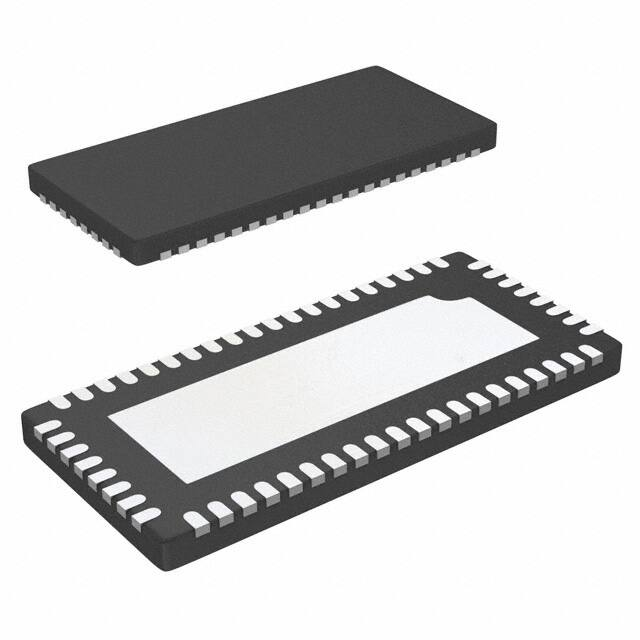

Device Information (1)

PART NUMBER

FPC402

(1)

PACKAGE

BODY SIZE (NOM)

WQFN (56)

5.00 mm × 11.00 mm

For all available packages, see the orderable addendum at

the end of the data sheet.

Device Comparison

PART

NUMBER

ACCESSIBLE DOWNSTREAM

ADDRESSES

PIN

COMPATIBLE

FPC402

All valid I2C addreses

Yes

FPC401

MSA Addresses: 0xA0, 0xA2

Yes

HOST

CONTROLLER

INT

SCL

SDA

FPC402 QUAD PORT CONTROLLER

PORT 0

PORT 1

PORT 2

FPC402 QUAD PORT CONTROLLER

PORT 3

PORT 0

PORT 1

PORT 2

I2C,

STATUS,

CONTROL

PORT 3

I2C,

STATUS,

CONTROL

SFP,

QSFP,

QSFP-DD,

OSFP

SFP,

QSFP,

QSFP-DD,

OSFP

SFP,

QSFP,

QSFP-DD,

OSFP

SFP,

QSFP,

QSFP-DD,

OSFP

SFP,

QSFP,

QSFP-DD,

OSFP

SFP,

QSFP,

QSFP-DD,

OSFP

PORT 0

PORT 1

PORT2

PORT 3

PORT 4

PORT 5

SFP,

QSFP,

QSFP-DD,

OSFP

SFP,

QSFP,

QSFP-DD,

OSFP

PORT 6

PORT 7

Copyright © 2017, Texas Instruments Incorporated

Simplified Block Diagram

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

Submit Document Feedback

Copyright

© 2020 Texas

Instruments

Incorporated

intellectual

property

matters

and other important disclaimers. PRODUCTION DATA.

Product Folder Links: FPC402

1

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

Table of Contents

1 Features............................................................................1

2 Applications..................................................................... 1

3 Description.......................................................................1

4 Revision History.............................................................. 2

5 Description (continued).................................................. 2

6 Pin Configuration and Functions...................................3

Pin Functions.................................................................... 3

7 Specifications.................................................................. 6

7.1 Absolute Maximum Ratings........................................ 6

7.2 ESD Ratings............................................................... 6

7.3 Recommended Operating Conditions.........................6

7.4 Thermal Information....................................................7

7.5 Electrical Characteristics.............................................7

7.6 Timing Requirements.................................................. 9

7.7 Switching Characteristics..........................................10

7.8 Typical Characteristics.............................................. 11

8 Detailed Description......................................................12

8.1 Overview................................................................... 12

8.2 Functional Block Diagram......................................... 12

8.3 Feature Description...................................................13

8.4 Device Functional Modes..........................................21

8.5 Programming............................................................ 27

9 Application and Implementation.................................. 28

9.1 Application Information............................................. 28

9.2 Typical Application.................................................... 28

10 Power Supply Recommendations..............................33

10.1 Power Supply Sequencing......................................33

11 Layout........................................................................... 34

11.1 Layout Guidelines................................................... 34

11.2 Layout Example...................................................... 35

11.3 Recommended Package Footprint..........................36

12 Device and Documentation Support..........................37

12.1 Documentation Support.......................................... 37

12.2 Receiving Notification of Documentation Updates..37

12.3 Support Resources................................................. 37

12.4 Trademarks............................................................. 37

12.5 Electrostatic Discharge Caution..............................37

12.6 Glossary..................................................................37

13 Mechanical, Packaging, and Orderable

Information.................................................................... 37

4 Revision History

Changes from Revision B (August 2018) to Revision C (September 2020)

Page

• Released the full production data data sheet to ti.com.......................................................................................1

• Updated the numbering format for tables, figures, and cross-references throughout the document..................1

• Added the recommended foot print for RHU package......................................................................................36

Changes from Revision A (October 2017) to Revision B (August 2018)

Page

• Changed MOD_SDA[0] pin number from: 16 to: 35 .......................................................................................... 3

• Changed MOD_SDA[1] pin number from: 5 to: 48............................................................................................. 3

• Changed MOD_SDA[2] pin number from: 48 to: 5............................................................................................. 3

• Changed MOD_SDA[3] pin number from: 35 to: 16........................................................................................... 3

Changes from Revision * (June 2017) to Revision A (October 2017)

Page

• Changed Advance Information to Production Data ........................................................................................... 1

• Updated TPOR (max) .......................................................................................................................................... 9

5 Description (continued)

The FPC402 is compatible with standard SFF-8431, SFF-8436, and SFF-8449 low-speed management

interfaces, including a dedicated 100- or 400-kHz I2C interface to each port. Additional general-purpose pins are

available to perform functions such as driving port status LEDs or controlling power switches. The LED drivers

have convenience features such as programmable blinking and dimming. The interface to the host controller can

operate on a separate supply voltage between 1.8 V and 3.3 V to support low-voltage I/Os.

The FPC402 can prefetch data from user-specified registers in each module, making the data readily accessible

to the host through a fast I2C (up to 1 MHz) or SPI (up to 10 MHz) interface. In addition, the FPC402 can trigger

an interrupt to the host whenever critical, user-configurable events occur associated with any of the ports the

device controls. This eliminates the need to continuously poll the modules.

2

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

OUT_A[2]

IN_A[2]

VDD1

GPIO[1]

OUT_D[1]

OUT_C[1]

IN_A[1]

MOD_SCL[1]

56

55

54

53

52

51

50

49

6 Pin Configuration and Functions

IN_B[2]

1

48

MOD_SDA[1]

OUT_B[2]

2

47

IN_B[1]

IN_C[2]

3

46

IN_C[1]

MOD_SCL[2]

4

45

OUT_B[1]

MOD_SDA[2]

5

44

OUT_A[1]

OUT_C[2]

6

43

VDD1

OUT_D[2]

7

42

GPIO[0]

GPIO[2]

8

41

IN_A[0]

VDD1

9

40

OUT_A[0]

IN_A[3]

10

39

IN_B[0]

OUT_A[3]

11

38

OUT_B[0]

IN_B[3]

12

37

IN_C[0]

OUT_B[3]

13

36

MOD_SCL[0]

IN_C[3]

14

35

MOD_SDA[0]

MOD_SCL[3]

15

34

OUT_C[0]

MOD_SDA[3]

16

33

OUT_D[0]

OUT_C[3]

17

32

CAPL

OUT_D[3]

18

31

PROTOCOL_SEL

GPIO[3]

19

30

SPI_LED_SYNC

VDD2

20

29

TEST_N

23

24

25

26

27

CTRL1

CTRL2

HOST_INT_N

VDD2

GND

28

22

EN

CTRL3

21

CTRL4

Die Attach Pad (DAP) =

GND

Figure 6-1. RHU Package 56-Pin WQFN Top View

Pin Functions

PIN

NAME

NO.

CAPL

32

I/O

O

DESCRIPTION

Connect a single 2.2-µF capacitor to GND.

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

3

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

PIN

I/O

NAME

NO.

CTRL1

23

I/O

CTRL2

24

I/O

CTRL3

28

I, Weak

internal

pullup

DESCRIPTION

Host-side control interface. These pins are used to implement I2C or SPI depending on the

PROTOCOL_SEL pin configuration.

I2C mode (PROTOCOL_SEL = Float or High):

CTRL1: SCL – I2C Clock input / open-drain output

CTRL2: SDA – I2C Data input / open-drain output

CTRL3: SET_ADDR_N – input, address assignment enable. Also used to receive external LED

clock.

CTRL4: ADDR_DONE_N – output, address assignment complete. Also used to transmit LED

clock.

CTRL4

21

O

SPI mode (PROTOCOL_SEL = GND):

CTRL1: SCK – Serial clock input

CTRL2: SS_N – Active-low slave select input

CTRL3: MOSI – Master output or slave input

CTRL4: MISO – Master input or slave output

EN

I, Weak

internal

pullup

22

Device enable. When EN = 0, the FPC402 is in a power-down state and does not respond to

the host-side control bus, nor does it perform port-side I2C accesses. When EN=VDD2 or

Float, the FPC402 is fully enabled and will respond to the host-side control bus provided VDD1

and VDD2 power has been stable for at least TPOR. VIH for this pin is referenced to VDD2.

The minimum required assert and deassert time is 12.5 µs.

GPIO[0]

42

GPIO[1]

53

GPIO[2]

8

GPIO[3]

19

GND

4

27, DAP

HOST_INT_N

25

IN_A[0]

41

IN_A[1]

50

IN_A[2]

55

IN_A[3]

10

IN_B[0]

39

IN_B[1]

47

IN_B[2]

1

IN_B[3]

12

IN_C[0]

37

IN_C[1]

46

IN_C[2]

3

IN_C[3]

14

MOD_SCL[0]

36

MOD_SCL[1]

49

MOD_SCL[2]

4

MOD_SCL[3]

15

I/O

General-purpose I/O. Output high voltage (VOH) and input high voltage (VIH) are based on

VDD1. Configured as input (high-Z) by default.

Power

Ground reference. The GND pins must be connected through a low-resistance path to the

board GND plane.

Open-drain 3.3-V tolerant active-low interrupt output. It asserts low to interrupt the host. The

O, Open- events which trigger an interrupt are programmable through registers. This pin can be

Drain

connected in a wired-OR fashion with other FPC402s’ interrupt pins. A single pullup resistor to

VDD1 or VDD2 in the 2-kΩ to 5-kΩ range is adequate for the entire net.

Low-speed port status input A.

I, Weak

internal

pullup

Example usage:

SFP: Mod_ABS[3:0]

QSFP: ModPrsL[3:0]

Low-speed port status input B.

I, Weak

internal

pullup

Example usage:

SFP: Tx_Fault[3:0]

QSFP: IntL[3:0]

Low-speed port status input C.

I, Weak

internal

pullup

Example usage:

SFP: Rx_LOS[3:0]

QSFP: N/A

I/O,

OpenDrain

I2C clock open-drain output to the module. External 2-kΩ to 5-kΩ pullup resistor is required.

This pin is 3.3-V LVCMOS tolerant.

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

PIN

NAME

NO.

MOD_SDA[0]

35

MOD_SDA[1]

48

MOD_SDA[2]

5

MOD_SDA[3]

16

OUT_A[0]

40

OUT_A[1]

44

OUT_A[2]

56

OUT_A[3]

11

I/O

I/O,

OpenDrain

DESCRIPTION

I2C data input or open-drain output to the module. External 2-kΩ to 5-kΩ pullup resistor is

required. This pin is 3.3-V LVCMOS tolerant.

Low-speed port control output A. OUT_A is disabled by default (high-Z) and when enabled

drives high logic unless reprogrammed. A 10-kΩ pullup or pulldown resistor is recommended to

set a default logic value before this output is enabled. See Section 8.3.3 for more details.

O

Example usage:

SFP: Tx_Disable[3:0]

QSFP: ResetL[3:0]

OUT_B[0]

38

OUT_B[1]

45

OUT_B[2]

2

OUT_B[3]

13

Low-speed port control output B. Output is disabled by default (high-Z) and when enabled

drives low logic unless reprogrammed. A 10-kΩ pullup or pulldown resistor is recommended to

set a default logic value before this output is enabled. See Section 8.3.3 for more details.

O

Example usage:

SFP: RS[3:0]

QSFP: LPMode[3:0]

OUT_C[0]

34

OUT_C[1]

51

OUT_C[2]

6

Low-speed port control output C. Can be used to drive port status LED. Special LED driving

features are available on this output. This output is enabled and high logic by default at power

up. See Section 8.3.2 for more details.

Example usage:

O

OUT_C[3]

SFP: LED_GRN[3:0]

QSFP: LED_GRN[3:0]

17

This pin requires a series resistor with a value of at least 33 Ω. The LED current-limiting

resistor can serve for this purpose.

OUT_D[0]

33

OUT_D[1]

52

OUT_D[2]

7

Low-speed port control output D. Can be used to drive port status LED. Special LED driving

features are available on this output. This output is enabled and high logic by default at power

up. See Section 8.3.2 for more details.

Example usage:

O

OUT_D[3]

SFP: LED_YLW[3:0]

QSFP: N/A

18

This pin requires a series resistor with a value of at least 33 Ω. The LED current-limiting

resistor can serve for this purpose.

PROTOCOL_SEL

31

I, Weak

internal

pullup

Used to select between I2C and SPI host-side control interface.

Float or High: Inter-IC Control (I2C)

GND: Serial Peripheral Interface (SPI)

LED clock synchronization pin for SPI mode only.

SPI_LED_SYNC

30

I/O

When using SPI as the host-side control interface (PROTOCOL_SEL=GND), connect all

FPC402 SPI_LED_CLK pins together. This ensures LED synchronization across all FPC402

devices.

When using I2C as the host-side control interface, this pin can be floating. LED

synchronization is ensured by other means in I2C mode.

TEST_N

VDD1

29

I, Weak

internal

pullup

TI test mode.

Float or High: Normal operation

GND: TI Test Mode

9, 43, 54

Power

Main power supply, VDD1 = 3.3 V ± 5%. TI recommends connecting at least one 1-µF and one

0.1-µF decoupling capacitors per VDD1 pin as close to the pin as possible.

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

5

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

PIN

NAME

NO.

VDD2

20, 26

I/O

DESCRIPTION

Power

Power supply for host-side interface I/Os (CTRL[4:1]). VDD2 can be 1.8 V to 3.3 V ± 5%. If the

host-side interface operates at 3.3 V, then VDD1 and VDD2 can be connected to the same 3.3V ± 5% supply. TI recommends connecting at least one 1-µF and one 0.1-µF decoupling

capacitors per VDD2 pin as close to the pin as possible.

7 Specifications

7.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)(1)

MIN

MAX

UNIT

VDD1ABSMAX

Supply voltage (VDD1)

–0.5

5

V

VDD2ABSMAX

Supply voltage (VDD2)

–0.5

5

V

V

VIOVDD1,ABSMAX

3.3-V LVCMOS I/O voltage (all pins except CTRL[4:1])

–0.5

5

VIOVDD2,ABSMAX

VDD2 LVCMOS I/O voltage (CTRL[4:1] pins only)

–0.5

5

V

TJ,ABSMAX

Junction temperature

150

°C

Tstg

Storage temperature

150

°C

(1)

–65

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under

Recommended Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device

reliability.

7.2 ESD Ratings

VALUE

V(ESD)

(1)

(2)

Electrostatic

discharge

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001(1)

±2500

Charged-device model (CDM), per JEDEC specification JESD22-C101(2)

±1500

UNIT

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

7.3 Recommended Operating Conditions

Over operating free-air temperature range (unless otherwise noted).

6

MIN

NOM

MAX

UNIT

VDD1

Supply voltage, VDD1 to GND. DC plus AC power should not exceed these limits.

3.135

3.3

3.465

V

VDD2

Host-side interface supply voltage, VDD2 to GND. 1.8 to 3.3 V typical. DC plus AC

power should not exceed these limits.

1.71

1.8, 2.5,

3.3

3.465

V

tRamp-VDD1 VDD1 supply ramp time, from 0 V to 3.135 V

1

ms

tRamp-VDD2 VDD2 supply ramp time, from 0 V to VDD2 – 5%

1

ms

TA

Operating ambient temperature

–40

85

°C

TJ

Operating junction temperature

–40

125

°C

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

7.4 Thermal Information

FPC402

THERMAL

METRIC(1)

UNIT

RHU (WQFN)

56 PINS

RθJA

Junction-to-ambient thermal resistance

30.1

°C/W

RθJC(top)

Junction-to-case (top) thermal resistance

13.3

°C/W

RθJB

Junction-to-board thermal resistance

6.5

°C/W

ψJT

Junction-to-top characterization parameter

0.3

°C/W

ψJB

Junction-to-board characterization parameter

6.4

°C/W

RθJC(bot)

Junction-to-case (bottom) thermal resistance

2.0

°C/W

(1)

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

7.5 Electrical Characteristics

TJ = –40°C to 125°C, VDD1 = 3.3 V ± 5%, VDD2 = 3.3 V ± 5% (unless otherwise noted).

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

VDD1 = VDD2 = 3.3 V, Outputs

sourcing maximum current, OUT_C

and OUT_D are OFF (Vout = High)

90

110

VDD1 = 3.3 V, VDD2 = 2.5 V,

Outputs sourcing maximum current,

OUT_C and OUT_D are OFF (Vout =

High)

100

110

VDD1 = 3.3 V, VDD2 = 1.8 V,

Outputs sourcing maximum current,

OUT_C and OUT_D are OFF (Vout =

High)

100

120

VDD1 = VDD2 = 3.3 V, OUT_C and

OUT_D are OFF (Vout = High)

26

31

VDD1 = VDD2 = 2.5 V, OUT_C and

OUT_D are OFF (Vout = High)

27

32

VDD1 = 3.3 V, VDD2 = 1.8 V,

OUT_C and OUT_D are OFF (Vout =

High)

29

34

VDD1 = VDD2 = 3.3 V, Outputs

sourcing maximum current, OUT_C

and OUT_D are OFF (Vout = High)

0.2

0.35

VDD1 = 3.3 V, VDD2 = 2.5 V,

Outputs sourcing maximum current,

OUT_C and OUT_D are OFF (Vout =

High)

0.1

0.3

VDD1 = 3.3 V, VDD2 = 1.8 V,

Outputs sourcing maximum current,

OUT_C and OUT_D are OFF (Vout =

High)

0.1

0.25

UNIT

POWER SUPPLY

WTOTAL

IVDD1

IVDD2

Itotal-idle

Total device power dissipation

Current consumption for VDD1

supply

Current consumption for VDD2

supply

Total device supply current

consumption in idle mode

6.5

mW

mA

mA

mA

LVCMOS I/O DC SPECIFICATIONS

VIH

High level input voltage

Applies to IN_A, IN_B, IN_C,

PROTOCOL_SEL, and GPIO[3:0]

Applies to EN

2

3.465

0.7 ×

VDD2

VDD2

V

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

7

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

TJ = –40°C to 125°C, VDD1 = 3.3 V ± 5%, VDD2 = 3.3 V ± 5% (unless otherwise noted).

PARAMETER

VIL

Low level input voltage

VOH

High level output voltage

VOL

Low level output voltage

TEST CONDITIONS

Applies to IN_A, IN_B, IN_C,

PROTOCOL_SEL, GPIO[3:0], and

EN

MIN

TYP

MAX

–0.3

0.8

Applies to OUT_A, OUT_B, and

GPIO[3:0], IOH = –2 mA

2.8

3.465

Applies to OUT_C and OUT_D, IOH

= –50 µA

2.5

UNIT

V

V

Applies to OUT_A, OUT_B, and

GPIO[3:0], IOL = 2 mA

GND

0.4

Applies to OUT_C and OUT_D, IOL =

18 mA

GND

0.4

–1

1

–220

–170

–1

1

30

50

µs

GND

0.4

V

–0.3

1.04

V

2.19

3.465

V

200

pF

VDD2

V

0.3 ×

VDD2

V

1

pF

GND

0.4

V

–1

1

μA

550

pF

Applies to IN_A, IN_B, IN_C, and

GPIO[3:0]

IIH

High level input current

IIL

Low level input current

tSP-LS

Pulse width of spikes that are

Pulses shorter than min are

suppressed by FPC402 input desuppressed, and pulses longer than

glitch filter on all IN_* low-speed pins the max are not suppressed.

Applies to IN_A, IN_B, IN_C

Applies to GPIO[3:0]

V

µA

µA

DOWNSTREAM MASTER I2C ELECTRICAL CHARACTERISTICS (MOD_SCL AND MOD_SDA)

VOL

Low level output voltage

VIL

Low level input voltage

VIH

High level input voltage

Cb (1)

I2C bus capacitive load

IOL = 3 mA

1.6 kΩ pull-up resistor max

HOST-SIDE I2C ELECTRICAL CHARACTERISTICS (PROTOCOL_SEL = FLOAT/HIGH)

VIH

Input high level voltage

SDA (CTRL2) and SCL (CTRL1)

VIL

Input low level voltage

SDA (CTRL2) and SCL (CTRL1)

CIN (1)

Input pin capacitance

SDA (CTRL2) and SCL (CTRL1)

VOL

Low level output voltage

SDA (CTRL2) or SCL (CTRL1), IOL =

3 mA

IL

IL Leakage current

SDA (CTRL2) or SCL (CTRL1), VIN

= VDD2

Cb (1)

I2C bus capacitive load

0.7 ×

VDD2

0.5

HOST-SIDE SPI ELECTRICAL CHARACTERISTICS (PROTOCOL_SEL = GND)

VIH

Input high level voltage

SCK (CTRL1), SS_N (CTRL2), and

MOSI (CTRL3)

VIL

Input low level voltage

SCK (CTRL1), SS_N (CTRL2), and

MOSI (CTRL3)

CIN (1)

Input pin capacitance

SCK (CTRL1), SS_N (CTRL2), and

MOSI (CTRL3)

VOH

High level output voltage

MISO (CTRL4) pin, IOH = –4 mA

VOL

Low level output voltage

MISO (CTRL4) pin, IOL = 4 mA

GND

0.4

V

MOSI (CTRL3)

–220

–170

µA

–1

1

IL

Leakage current

SCK (CTRL1), SS_N (CTRL2), and

MISO (CTRL4)

CMISO (1)

MISO output capacitive load

MISO (CTRL4) pin

(1)

8

0.7 ×

VDD2

V

0.5

0.3 ×

VDD2

V

1

pF

0.7 ×

VDD2

V

50

pF

These parameters are not production tested.

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

7.6 Timing Requirements

MIN

NOM

MAX

UNIT

GENERAL TIMING REQUIREMENTS

TPOR

Internal power-on reset (PoR) time

Time between stable VDD1 power

supply (VDD1 ≥ 3.3V - 5%) and deassertion of internal PoR. The portside and host-side control interfaces

(I2C and/or SPI) are not operational

during this time.

30

60

ms

10

MHz

HOST-SIDE SPI TIMING REQUIREMENTS (PROTOCOL_SEL = GND) (1) (2)

fSPI

0.1

tHI-SCK

0.4 ÷ fSPI

ns

tLO-SCK

0.4 ÷ fSPI

ns

tHD-MOSI

1

ns

tSU-MOSI

1

ns

tHD-SSN

4

ns

tSU-SSN

1.2

ns

tOFF-SSN

For writes and local FPC402 register

reads

1

For consecutive downstream

(remote) register reads on the same

port, assuming 400-KHz I2C

170

For consecutive downstream

(remote) register reads on the same

port, assuming 100-KHz I2C

620

μs

tODZ-MISO

MISO (CTRL4) driven-to-TRI_STATE

time

32

ns

tOZD-MISO

MISO (CTRL4) TRI_STATE-to-driven

time

10

ns

tOD

MISO (CTRL4) output delay time

15

ns

HOST-SIDE I2C TIMING REQUIREMENTS (PROTOCOL_SEL = FLOAT OR

HIGH)(2) (3) (4)

fSCL

Host-side I2C clock frequency

(CTRL1) in I2C mode

100

tBUF

Bus free time between STOP and

START condition

0.5

μs

tHD-STA

Hold time after (repeated) START

condition. After this period, the first

clock is generated.

0.3

μs

tSU-STA

Repeated START condition setup

time

0.3

μs

tSU-STO

STOP condition setup time

0.3

μs

tHD-DAT

SDA (CTRL2) hold time

tSU-DAT

SDA (CTRL2) setup time

After this period, the first clock can

be generated by the master.

SCL (CTRL1) clock low time

tHIGH

SCL (CTRL1) clock high time

tR

SDA (CTRL2) rise time, read

kHz

32

ns

Applies to standard-mode I2C, 100

kHz

250

ns

Applies to fast-mode I2C, 400 kHz

100

ns

50

ns

0.5

μs

0.3

μs

Applies to fast-mode plus I2C, 1000

kHz

tLOW

1000

Applies to standard-mode I2C, 100

kHz

Applies to fast-mode I2C, 400 kHz

20

1000

ns

300

ns

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

9

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

MIN

tF

(1)

(2)

(3)

(4)

SDA (CTRL2) fall time, read

MAX

UNIT

Applies to fast-mode plus I2C, 1000

kHz

NOM

120

ns

Applies to standard-mode I2C, 100

kHz

300

ns

Applies to fast-mode I2C, 400 kHz

4.4

300

ns

Applies to fast-mode plus I2C, 1000

kHz

4.4

120

ns

UNIT

SPI operation is available TPOR milliseconds after VDD1 power up, provided EN = high or float and VDD2 is stable.

These parameters are not production tested.

I2C operation is available TPOR milliseconds after VDD1 power up, provided EN = high or float and VDD2 is stable.

These specifications support I2C Rev 6 specifications

7.7 Switching Characteristics

over operating free-air temperature range (unless otherwise noted)

MIN

TYP

MAX

Applies to standard-mode I2C, 100

kHz

66

83

100

Applies to fast-mode I2C, 400 kHz

264

332

400

DOWNSTREAM MASTER I2C SWITCHING CHARACTERISTICS

fSCL

SCL clock frequency

tLOW-SCL

SCL clock pulse width low period

kHz

1.3

μs

0.6

μs

20

μs

tHIGH-SCL

SCL clock pulse width high period

tBUF

Time bus free before new

transmission starts

tHD-STA

Hold time START operation

0.6

μs

0.6

μs

0

μs

0

μs

tSU-STA

Setup time START operation

tHD-DAT

Data hold time

tSU-DAT

Data setup time

tR

SCL and SDA rise time

tF

SCL and SDA fall time

tSU-STO

STOP condition setup time

tSP-I2C (1)

Pulse width of spikes that are

suppressed by FPC402 input filter

(1)

10

Between STOP and START and

between ACK and RESTART

100-KHz operation. From VIL (Max)

– 0.15 V to VIH (Min) + 0.15 V.

300

100-KHz operation. From VIL (Max)

– 0.15 V to VIH (Min) + 0.15 V.

300

100-KHz operation. From VIH (Min) +

0.15 V to VIL (Max) – 0.15 V.

300

400-KHz operation. From VIH (Min) +

0.15 V to VIL (Max) – 0.15 V.

300

ns

ns

0.6

0

μs

50

ns

These parameters are not production tested.

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

7.8 Typical Characteristics

8

31

VDD2 = 1.8 V

VDD2 = 2.5 V

VDD2 = 3.3 V

30.5

7

30

29.5

29

5

IDD (mA)

IDD (mA)

6

4

28

27.5

3

27

2

26.5

VDD2 = 1.8 V

VDD2 = 2.5 V

VDD2 = 3.3 V

1

0

-50

0

50

Temperature (qC)

26

25.5

-50

100

D003

Figure 7-1. Static IDD1 vs. Ambient Temperature

0

50

100

Temperature (qC)

D004

Figure 7-2. Dynamic IDD1 vs. Ambient Temperature

0.4

0.2

VDD2 = 1.8 V

VDD2 = 2.5 V

VDD2 = 3.3 V

0.35

0.18

0.16

0.3

0.14

0.25

IDD (mA)

IDD (mA)

28.5

0.2

0.15

0.12

0.1

0.08

0.06

0.1

0.04

0.05

0

-50

VDD2 = 1.8 V

VDD2 = 2.5 V

VDD2 = 3.3 V

0.02

0

50

Temperature (qC)

100

0

-50

Figure 7-3. Static IDD2 vs. Ambient Temperature

0

50

Temperature (qC)

D001

100

D002

Figure 7-4. Dynamic IDD2 vs. Ambient Temperature

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

11

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

8 Detailed Description

8.1 Overview

The FPC402 is designed to interface with four ports and aggregate the I2C and low-speed control and status

signals associated with these ports into a single host-side interface (I2C or SPI). Multiple FPC402s can be

combined to support up to 56 total ports, all of which are controlled via the same host-side interface. This greatly

reduces the number of signals which route to the host controller, saving valuable I/O resources, board routing

space, and bill of materials (BOM) cost.

Functionally, the FPC402 is organized as shown in Section 8.2. Two types of host-side control interfaces are

supported (I2C and SPI) for controlling and monitoring the downstream ports. The FPC402 has two special

outputs per downstream port (OUT_C and OUT_D) which can be used to drive port status LEDs.

8.2 Functional Block Diagram

FPC402

Host Controller

Management

I/F

(I2C, SPI)

GPIO

Common Control Logic

CTRL[4:1]

PROTOCOL_SEL

HOST_INT_N

GPIO[3:0]

SPI_LED_SYNC

EN

TEST_N

CAPL

VDD1

VDD2

Host Control

Interface

Common Port

Control Registers

GPIO control

I2C Master

Data pre-fetch

from modules

Ports[3:0]

Port-Specific Control Logic

Low-speed Output

Control

Low-Speed Input

Status and

Interrupt

Generator

I2C Master

LED Control

OUT_A[3:0]

OUT_B[3:0]

Port Inputs

IN_A[3:0]

IN_B[3:0]

Port Outputs

IN_C[3:0]

MOD_SCL[3:0]

MOD_SDA[3:0]

OUT_C[3:0]

OUT_D[3:0]

Port I2C

Slave

LEDs

Copyright © 2017, Texas Instruments Incorporated

12

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

8.3 Feature Description

The features of the FPC402 quad port controller include:

• Host-Side Control Interface

• LED Control

• Low-Speed Output Signal Control

• Low-Speed Input Status and Interrupt Generation

• Downstream (Port-Side) I2C Master

• Data Prefetch From Modules

• Scheduled Write

• Protocol Timeouts

• General-Purpose Inputs and Outputs

• Hot-Plug Support

8.3.1 Host-Side Control Interface

The FPC402 has a single host-side interface which can be configured as one of two available protocols,

depending on the pin strap value of the PROTOCOL_SEL pin:

• Inter-Integrated Circuit (I2C) up to 1-MHz Fast-mode Plus

• Serial Peripheral Interface (SPI) up to 10 MHz

These represent the two functional modes of operation for which the FPC402 can be configured. Refer to

Section 8.4 for more details.

8.3.2 LED Control

The FPC402 uses two sets of outputs, OUT_C[3:0] and OUT_D[3:0], to drive LEDs associated with the ports

under its control. Most SFP and QSFP applications use one yellow and one green LED per port to indicate

different link status such as link up, link down, and other link states.

LEDs must be connected to the FPC402 in an active-low fashion as shown in Figure 8-1 below. When the

OUT_C or OUT_D pin drives a low voltage (VOL), the LED is illuminated. When the OUT_C or OUT_D pin drives

a high voltage (VOH), the LED is off. Bi-color LEDs can be connected in a similar fashion, and each LED must

have its own current-limiting resistor. The current-limiting resistor value is selected by choosing the desired

maximum current through the LED and the corresponding voltage drop from the LED's current vs. voltage plot.

The sum of forward voltage drop of the LED, the voltage drop across the series resistor, and the maximum VOL

(0.5-V maximum for currents between 2 and 18 mA) is equal to the LED supply voltage. Note that OUT_C and

OUT_D are tri-stated while the device is held in reset (during POR or while the EN pin is low), and are enabled

during normal operation and drive a high voltage by default.

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

13

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

3.3V

VDD1

OUT_D[3:0]

OUT_C[3:0]

MOD_SDA[3:0]

MOD_SCL[3:0]

IN_C[3:0]

OUT_B[3:0]

IN_B[3:0]

OUT_A[3:0]

3.3V

IN_A[3:0]

FPC402

Tx_Fault[3:0]

Tx_Disable[3:0]

Mod_ABS[3:0]

RS[3:0]

Rx_LOS[3:0]

Mod_SCL[3:0]

Mod_SDA[3:0]

SFP_Port[3:0]

3.3V

LED_GRN[3:0]

Anode

Cathode

3.3V

LED_YLW[3:0]

Anode

Cathode

Copyright © 2017, Texas Instruments Incorporated

Figure 8-1. Example Connection Between OUT_C/OUT_D and Active-Low LEDs

Each port controlled by the FPC402 has a set of registers that allow the user to configure each LED into one of

the following states:

• ON

• OFF

• PWM (ON with programmable intensity)

• BLINK (with programmable blink duty cycle, frequency, and ON intensity)

LED blinking is configured by setting an on and an off time. Each of these times is configured separately and

have a minimum value of 2.5 ms and a maximum value of 637.5 ms for a maximum blinking period of 1.275

seconds. The pulse width modulation (PWM) duty cycle has 256 settings where 0 is completely off, and 255 is

maximum brightness. Note that the PWM is 0 by default and must be configured for the LEDs to be visible in

BLINK or PWM modes.

LED blinking can be synchronized across all four ports controlled by the FPC402, and the blinking can be

synchronized across all ports in the system. For SPI, cross-device synchronization uses the SPI_LED_SYNC

pin. One device is configured to forward its internal LED clock to this pin, and all other devices are configured to

receive an external LED clock on this pin. For I2C, the first device in the CTRL4 to CTRL3 pin daisy chain is

configured to output the internal LED clock to the CTLR4 pin. All other devices are configured to receive an

external LED clock from the CTRL3 pin and to output the clock to the CTRL4 pin.

In some applications, it may be desirable to control more than two LEDs per port. In cases where the additional

LEDs are relatively static in nature and blinking is not required, the GPIO and OUT_B pins of the FPC402 can be

allocated for driving these LEDs in an active-low configuration. OUT_C and OUT_D must be connected to LEDs

14

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

requiring blinking, dimming, or both, and up to two additional LEDs can be controlled per port from the GPIO and

OUT_B pins. OUT_B is optionally used to drive RS0/RS1 in SFP ports or LPMode in QSFP ports. These module

pins are often not used in a system and are instead pulled to 3.3 V (SFP) or GND (QSFP). The module

functionality affected by these pins is anyway controllable through software. Figure 8-2 shows an example of

how up to four LEDs can be controlled per port.

3.3 V

IN_A[3:0]

OUT_A[3:0]

IN_B[3:0]

IN_C[3:0]

MOD_SCL[3:0]

MOD_SDA[3:0]

OUT_B[3:0]

OUT_C[3:0]

OUT_D[3:0]

GPIO[3:0]

VDD1

FPC402

3.3V

Tx_Fault[3:0]

Tx_Disable[3:0]

Mod_ABS[3:0]

RS[3:0]

Rx_LOS[3:0]

Mod_SCL[3:0]

Mod_SDA[3:0]

SFP_Port[3:0]

Non-blinking

LED Port

status

3.3 V

LED_RED[3:0]

Anode

Cathode

Anode

Cathode

Anode

Cathode

Anode

Cathode

3.3 V

Port

activity

LEDs

LED_GRN[3:0]

3.3 V

Non-blinking

LED Port

status

LED_YLW[3:0]

3.3 V

LED_BLU[3:0]

Copyright © 2017, Texas Instruments Incorporated

Figure 8-2. Example Configuration for Driving Four LEDs Per Port

8.3.3 Low-Speed Output Signal Control

The FPC402 has two general-purpose outputs per port which can be used to drive the low-speed inputs to the

module. The host controller can change the state of these outputs for each port individually, for all ports

connected to a given FPC402 device simultaneously, or for all ports in the system simultaneously.

There are two configuration registers for these outputs. One register configures the enable state of the OUT_A

and OUT_B pins for every port, and by default both OUT_A and OUT_B pins are disabled (tri-stated). The

second register controls the output value for all OUT_A and OUT_B pins, where OUT_A has default value of 1

and OUT_B has a default value of 0. The output values must be configured before the outputs are enabled. If a

default value is desired during boot up before these pins are enabled, a 10-kΩ pullup or pulldown resistor is

recommended (note that SFP and QSFP modules have internal pullup and pulldowns on certain inputs). Note

that if the VDD1 rail does not have power and there is an externally powered pullup resistor connected to an

output pin, the output pin will be pulled low until VDD1 is supplied.

Table 8-1 provides an example signal connection. OUT_A and OUT_B are not restricted to this port pin

assignment, and they can be used to drive any 3.3-V signal required for the application, provided the IOH and IOL

limits are met.

Table 8-1. Example Connections for Low-Speed FPC402 Outputs to SFP/QSFP ports

PIN NAME

OUT_A

EXAMPLE CONNECTION

SFP

QSFP

Tx_Disable

ResetL

COMMENT

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

15

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

Table 8-1. Example Connections for Low-Speed FPC402 Outputs to SFP/QSFP ports (continued)

EXAMPLE CONNECTION

PIN NAME

OUT_B

SFP

QSFP

RS0 and RS1

LPMode

COMMENT

RS0 and RS1 will both be driven to the same

level.

8.3.4 Low-Speed Input Status and Interrupt Generation

The FPC402 has three general-purpose inputs per port which can be used to monitor the low-speed outputs

from the module. The host controller can monitor the status of these signals for each port by reading the

appropriate registers in the FPC402. In addition, the FPC402 can be configured to generate an interrupt to the

host through the HOST_INT_N signal whenever one or more of the low-speed input signals change state. The

interrupt can be configured to trigger on the falling edge, the rising edge, or both the falling and rising edges. A

single register stores flags for which inputs and edges are responsible for the trigger.

The recommended signal connection is as follows. IN_A, IN_B, and IN_C are not restricted to this port pin

assignment, and in fact they can be used to monitor the status of any low-speed 3.3-V signal required for the

application.

Table 8-2. Example Connections for Low-Speed FPC402 Inputs to SFP/QSFP ports

PIN NAME

EXAMPLE CONNECTION

SFP

COMMENT

QSFP

IN_A

Tx_Fault

IntL

IN_B

Mod_ABS

ModPrsL

IN_C

Rx_LOS

—

This pin is unused in QSFP applications, or it

can be utilized as a general-purpose input.

The events which trigger an active-low interrupt on the HOST_INT_N pin are user-configurable. The

HOST_INT_N pins from multiple FPC402 devices can be connected together in a wired-or fashion. Interrupt

generation can be configured as follows:

Table 8-3. Host-Side Interrupt Options

INTERRUPT-TRIGGERING

EVENT

Rising edge

Falling edge

Rising or falling edge

(1)

16

PIN(S) MONITORED

EXAMPLE APPLICATION(1)

IN_A

Indicates deassertion of port-side interrupt (Tx_Fault or IntL).

IN_B

Indicates that a module has been removed.

IN_C

Indicates loss of optical signal (Rx_LOS) for SFP applications.

IN_A, IN_B, or IN_C

Indicates deassertion of port-side interrupt, removal of module, or

loss of optical signal (Rx_LOS).

IN_A

Indicates assertion of port-side interrupt (Tx_Fault or IntL).

IN_B

Indicates that a module has been inserted.

IN_C

Indicates presence of optical signal (Rx_LOS) for SFP applications.

IN_A, IN_B, or IN_C

Indicates assertion of port-side interrupt, insertion of module, or

presence of optical signal (Rx_LOS).

IN_A

Indicates assertion or deassertion of port-side interrupt (Tx_Fault or

IntL).

IN_B

Indicates that a module has been inserted/removed.

IN_C

Indicates presence or absence of optical signal (Rx_LOS) for SFP

applications.

IN_A, IN_B, or IN_C

Indicates assertion or deassertion of port-side interrupt, the insertion

or removal of module, or the presence or absence of optical signal

(Rx_LOS).

Example applications assume that IN_A, IN_B, and IN_C are connected to the downstream ports as per the example connection table,

Table 8-2.

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

The FPC402 is also able to generate an interrupt based on prefetched data. This is known as a data-driven

interrupt. The FPC402 monitors up to four bytes within the prefetched range for each port. For each of the bytes,

the register offset address is programmed to a local FPC402 register as well as the enable bit fields which will

trigger the interrupt. When one of the enabled bits of the four monitored bytes changes state from a 0 to a 1 and

stays a 1 for two consecutive periodic prefetch cycles (0→1→1), the interrupt is generated and the periodic

prefetch operation is halted. The FPC402 has four port-specific registers which contain the sampled data from

the bytes being monitored after the interrupt is triggered. To clear the interrupt, the sampled data register of the

trigger source byte is read. The periodic prefetch must be restarted after the interrupt is cleared with an I2C

command. Because it takes two periodic prefetch cycles to trigger this interrupt, it may take up to 10 ms for the

host to see the trigger after the monitored bit field of the downstream module changes for the fastest periodic

prefetch setting.

The FPC402 also has the ability to generate an interrupt if there is a mishap in the downstream I2C bus. The

SDA bus and the SCL bus each have timers that will trigger an interrupt if they are held in a low state too long

due to excessive clock stretching or a port error. Once the interrupt is triggered, it is cleared by issuing a port

reset on the relevant port. These interrupts are known as SCL Stuck and SDA Stuck interrupts and can be

configured individually for each port. By default, the SCL Stuck interrupt will trigger after the SCL bus is held low

for 35 ms (typical). This value is configurable individually by port. The SDA Stuck interrupt will trigger after the

SDA is held low for 1 s (typical). The user may issue a port reset sequence (9 consecutive SCL clock cycles with

the last being an I2C stop condition) or module reset to restore the module to a known state.

When a host-side interrupt is triggered, the host must determine the source and cause of the interrupt. The

recommended procedure for identifying the source and cause of an interrupt is as follows:

1. Read the FPC402 aggregated port interrupt flags of the first FPC402 instance to see which, if any,

downstream port triggered the interrupt.

2. If this instance of the FPC402 has any aggregated port interrupts flagged, read all of the status registers to

determine the source of the interrupt and clear it. If an SCL Stuck or SDA Stuck interrupt is triggered, a port

reset must be issued and the periodic prefetch must be restarted. The host may also perform other

housekeeping activities based on the interrupt, such as change the state of the LEDs after a module is no

longer present.

3. Repeat steps 1 and 2 for the next FPC402 instance, until the HOST_INT_N bus is cleared.

This procedure applies to every FPC402 device which is wire-or’ed to the host-side interrupt signal. The total

time required for the host to identify the source and cause of the interrupt for an implementation consisting of N

total FPC402s, where all N HOST_INT_N outputs are wire-or’ed together, is as follows:

Tinterrupt = Delay between the IN_* pin changing state and the corresponding FPC402 device triggering an

interrupt (50 µs maximum).

Tread = Time required to read a single register from N FPC402 devices.

For I2C mode, Tread = (9 × 4 × N)/FI2C, where FI2C is the SCL clock frequency.

For SPI mode, Tread = (29 × 2 × N)/FSPI + TOFF-SSN, where FSPI is the SCK clock frequency, and TOFF-SSN is the

SS_N off time.

Ttotal = Tinterrupt + 4 × Tread

Table 8-4 gives some examples of Ttotal for different I2C/SPI frequencies and different values of N.

Table 8-4. Example Calculations for Determining the Source and Cause of a Host-Side Interrupt

MODE

FI2C

FSPI

N

Tread (ms)

Ttotal (ms)

I2C

100 kHz

–

1

0.36

1.5

I2C

100 kHz

–

4

1.44

5.8

I2C

100 kHz

–

8

2.88

11.6

I2C

100 kHz

–

12

4.32

17.3

I2C

400 kHz

–

1

0.09

0.4

I2C

400 kHz

–

4

0.36

1.5

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

17

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

Table 8-4. Example Calculations for Determining the Source and Cause of a Host-Side Interrupt

(continued)

MODE

FI2C

FSPI

N

Tread (ms)

Ttotal (ms)

I2C

400 kHz

–

8

0.72

2.9

I2C

400 kHz

–

12

1.08

4.4

I2C

1000 kHz

–

1

0.0036

0.1

I2C

1000 kHz

–

4

0.144

0.6

I2C

1000 kHz

–

8

0.288

1.2

I2C

1000 kHz

–

12

0.432

1.8

SPI

–

1 MHz

1

0.06

0.3

SPI

–

1 MHz

4

0.23

1.0

SPI

–

1 MHz

8

0.47

1.9

SPI

–

1 MHz

12

0.70

2.8

SPI

–

10 MHz

1

0.01

0.1

SPI

–

10 MHz

4

0.02

0.1

SPI

–

10 MHz

8

0.05

0.2

SPI

–

10 MHz

12

0.07

0.3

Click here to request access to the FPC401 Programmer's Guide (SNLU221) for more details on how to

configure the interrupts.

8.3.5 Downstream (Port-Side) I2C Master

The FPC402 has four master I2C interfaces for managing up to four ports, referred to as downstream ports.

Each downstream I2C interface can be configured to operate with an SCL clock frequency between 100 kHz and

400 kHz (maximum). The downstream I2C master supports clock stretching.

The SFF-8472 and SFF-8431 specifications define up to two logical device addresses per SFP port: 0xA0 and

0xA2. The SFF-8436 specification defines one logical device address per QSFP port: 0xA0. Both 0xA0 and 0xA2

are directly addressable by the upstream host controller by default. The directly accessible addresses may be

modified through I2C writes to the FPC402 such that any valid I2C address is directly accessible. Refer to Table

8-6 (I2C) and Table 8-7 (SPI). The FPC402 uses this address mapping scheme to decode the port and device

address and perform a downstream I2C read or write operation. This is known as a remote access. Remote

accesses have the highest priority when accessing the downstream module. If there is an on-going periodic

prefetch or scheduled write, these operations will be stopped at the next byte boundary and the remote access

will be executed. The periodic prefetch or schedule write operation will be resumed after the remote access

finishes. Note that the periodic prefetch will begin from the starting register offset of the prefetch range rather

than where it left off during the interruption. If a remote access is attempted during an interrupt-driven prefetch,

the interrupt-driven prefetch will finish and the remote access is executed afterwards. If an autonomous access

(prefetch or scheduled write) occurs during a remote access, the autonomous access is executed after the

remote access is completed.

8.3.6 Data Prefetch From Modules

The FPC402 can be configured to prefetch data from each module of the downstream port. The prefetched data

is stored locally in the memory of the device, allowing any downstream read operations in the prefetch range to

be directly read from the FPC402 rather than waiting for the FPC402 to read from the downstream device

through I2C. The FPC402 can prefetch data from the ports on a one-time basis, a regular basis (periodic

prefetch), or upon the occurrence of certain events (interrupt-driven prefetch).

For periodic prefetching, the period is configured in steps of 5 ms from 0 to 1.275 s, where 0 is a one-time

prefetch. The prefetched range is determined by two settings, the prefetch length and the prefetch offset

address. The FPC402 will prefetch beginning at the offset address for a length of bytes between 1 and 32. The

target device is configured between downstream device 0 and device 1, and both of these device addresses are

fully configurable to any valid I2C address. By default, these addresses are 0xA0 and 0xA2 respectively. Once

18

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

configured, the start bit is set to begin periodic prefetching and the stop bit is set to stop prefetching. After a

prefetch is completed, the gate bit is set to 0, and any attempted read operation in the prefetched range will

return data from the FPC402's memory containing the last prefetched data. To modify the prefetched range or to

stop the FPC402 from returning the data from memory, the gate bit must be reset to 1. If the FPC402 receives a

NACK during a prefetch attempt, the gate bit will automatically be reset. Each port has its own gate bit and

separate memory and settings.

For interrupt-driven prefetch, the interrupt event can be configured for either the rising- or falling-edge of one of

the IN_[A,B,C] input signals of a port. The prefetch range and target device address is configured similarly but

independently of the periodic prefetch settings. Interrupt-driven prefetch also has a gate bit and memory

independent of the periodic prefetch. Once an interrupt-driven prefetch occurs successfully, an interrupt is

triggered on the HOST_INT_N pin and the aggregated interrupt flag for that port will be set. For the interrupt to

be cleared and for another interrupt prefetch to occur, it must be re-armed with a register write. If the prefetch

attempt is NACK'd, the gate bit will not be set, the interrupt will not be generated, and the interrupt-driven

prefetch does not need to be re-armed. Note that the prefetched data from the interrupt-driven prefetch has

precedence over the data from a periodic prefetch if they have overlapping prefetch ranges. The FPC402 will

return data from the interrupt-driven prefetch even if the periodic prefetch data is more recent. When an

interrupt-driven prefetch occurs, TI recommends correcting this immediately by reading the prefetched data and

re-arming it.

Click here to request access to the FPC401 Programmer's Guide (SNLU221) for more details on how to

configure data prefetch.

8.3.7 Scheduled Write

The FPC402 has the ability to schedule a write operation on one or more downstream modules simultaneously

by writing to local FPC402 registers. This operation, known as a scheduled write, allows for quicker writing by

using the faster host-side I2C rate. The host-side I2C bus is not held while the write occurs in the downstream

I2C. This command may be broadcasted to all FPC402s to write to any combination of ports concurrently. The

downstream device address targeted by the scheduled write is configured between downstream device 0 and

device 1, and both of these device addresses are fully configurable to any valid I2C address. By default, these

addresses are 0xA0 and 0xA2, respectively.

Scheduled writes can be directed to an individual port (port scheduled write) or to a group of two or more ports

simultaneously (common scheduled write). The status of the port scheduled write or common scheduled write

may be checked in a local FPC402 register. This register will reflect if the operation completed successfully, or if

it was NACKed by the downstream module. The on-going scheduled write command must be completed before

the scheduled write settings for the target port are modified, or before a new command on the same port is

issued.

Scheduled write operations have a higher priority than periodic prefetch operations. This means that if a

schedule write is sent while a periodic prefetch is on-going, the periodic prefetch is stopped at the next byte

boundary and the scheduled write is executed. The periodic prefetch resumes on the next period. Note that it will

begin reading at the start of the prefetch range rather than where the scheduled write occurred.

Click here to request access to the FPC401 Programmer's Guide (SNLU221) for more details on how to

configure scheduled write.

8.3.8 Protocol Timeouts

The FPC402 has a watchdog timer to ensure that the I2C buses do not become permanently stuck. For

example, if the host is performing a remote access on a downstream module, the FPC402 will clock stretch the

host-side I2C while the downstream I2C transaction occurs. If the downstream module clock stretches for a very

long time or any other error occurs that prevents the transaction from finishing, the host-side I2C will not become

stuck. The watchdog timer is what prevents this from happening by setting a maximum time for the downstream

transaction to complete; and if it does not complete, the timer expires and the FPC402 will NACK the host to

terminate the transaction. By default, the timer is set to 3 ms and is programmable in steps of 1 ms up to 127

ms. This timer may also be disabled, but this is not recommended as the I2C bus may become permanently

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

19

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

stuck and a device reset will be necessary. Each port's I2C master also has a programmable watchdog timer

which operates similarly to the host-side I2C watchdog timer.

When the host attempts a remote access transaction through I2C, after the I2C device ID has been ACKed, the

FPC402 waits for the host to send a register offset address or a read/write command before downplaying it on

the downstream port I2C. If the host becomes busy with something else and does not finish the I2C transaction,

the FPC402 state machine will be stuck. There is a protocol timeout timer for each port to prevent this from

happening. If the host does not finish the I2C transaction within this timer, the FPC402 will timeout and return to

the idle state. This counter is 10 ms (typical) by default and is configurable in steps of 1 ms up to 255 ms.

Click here to request access to the FPC401 Programmer's Guide (SNLU221) for more details on how to

configure protocol timeouts.

8.3.9 General-Purpose Inputs and Outputs

The FPC402 has multiple general-purpose input and output pins which can be used to control auxiliary functions

on the board through the same host-side control interface which is used to manage the ports. The GPIO pins

can be configured as inputs or outputs through the FPC402 registers. One example use case for these GPIO

pins is to control a power switch (that is, TPS2556 or TSP2557) to enable or disable power to the modules to

manage power sequencing of the modules and prevent large inrush current at board power up.

A GPIO pin can be used with an external pullup resistor to drive low-voltage I/Os on other devices. When used in

this fashion, the GPIO would drive VOL when set to logic 0, and when set to high-impedance (tri-state), the pullup

resistor would pull the signal up to the appropriate I/O voltage. When using the GPIO pins for this purpose, it is

important to drive the GPIOs to logic 0 and high-impedance only. Do not drive the GPIO to logic 1 as it would risk

damaging the I/O of the connected device.

Figure 8-3 shows an example configuration for using the GPIOs to drive 1.2-V I/Os on another device.

1.2V

Low-I/O-Voltage

Device

FPC402

GPIO[3]

Input0

GPIO[2]

Input1

GPIO[1]

Input2

GPIO[0]

Input3

Copyright © 2017, Texas Instruments Incorporated

Figure 8-3. Example Use Of External Pullups to Drive Low-I/O-Voltage Devices From GPIOs

The GPIO pins have a driver impedance of 10 Ω (typical). This is lower than the typical characteristic impedance

of a transmission line and therefore may cause ringing due to the fast edge rate. The ringing duration is a

function of the transmission line length and will typically be less than 100 ns. The magnitude of the overshoot is

a function of the difference of driver impedance and impedance seen by the driver and may be as large as 5 V to

GND for a transmission line with a characteristic impedance of 60 Ω. If ringing is a concern, a series resistor may

be placed near the GPIO pin. A good rule of thumb for sizing the resistor is the difference of the transmission line

characteristic impedance minus the driver impedance. For example, in the case of a 60 Ω transmission line

impedance, a 50-Ω series resistor may be used to minimize ringing. Cases such as these may be simulated

using the provided FPC402 IBIS model.

8.3.10 Hot-Plug Support

The FPC402 has features which enable it to support hot-plug applications.

• Power-on-reset (PoR). The FPC402 is automatically held in reset until TPOR milliseconds have elapsed after

VDD1 power supply is stable. The host-side control interface (I2C or SPI) must not be used prior to the

20

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

�FPC402

www.ti.com

•

•

•

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

completion of the PoR. Likewise, the port-side I2C interfaces are not exercised prior to the completion of the

PoR.

Enable pin (EN). When this pin is low, the FPC402 is held in reset. The host must hold this pin low until the

host-side control interface (I2C or SPI) is fully connected and stable. This pin has a weak pullup such that it

can be left floating for applications which do not require hot-plug or manual enable control.

Host-side I2C false START / false STOP tolerance. The FPC402 is designed to ignore false START and

STOP conditions on the host-side I2C control interface.

Port-side glitch suppression. The FPC402 is designed to suppress glitches from the port-side module lasting

less than 30 µs (typical). This applies to all IN_* pins.

8.4 Device Functional Modes

The FPC402 has a single host-side control interface which can be configured as one of two available protocols,

depending on the pin strap value of the PROTOCOL_SEL pin:

• Inter-Integrated Circuit (I2C) up to 1-MHz Fast-mode Plus

• Serial Peripheral Interface (SPI) up to 10 MHz

Depending on which functional mode is selected (SPI or I2C), the CTRL[4:1] pins will assume the corresponding

behavior.

Table 8-5. Host-Side Control Interface Options

HOST-SIDE

INTERFACE

PROTOCOL_SEL

CTRL4

CTRL3

I2C

Float or High

ADDR_DONE_N

SET_ADDR_N

SDA

SCL

SPI

GND

MISO

MOSI

SS_N

SCK

CTRL2

CTRL1

8.4.1 I2C Host-Side Control Interface

If I2C is used as the host-side communication protocol, the maximum number of FPC402 devices which can

share a single I2C bus is 14. This allows for controlling up to 56 downstream ports through a single I2C bus.

I2C is an addressed interface. To reduce pin count and simplify integration, the FPC402 has an auto-addressing

scheme whereby all FPC402s in a system will take on a unique address without requiring dedicated address

pins. This is accomplished by connecting one CTRL4 (ADDR_DONE_N) pin of a FPC402 device to the

subsequent CTRL3 (SET_ADDR_N) pin of another FPC402 device. The first FPC402 will connect CTRL3

(SET_ADDR_N) to GND, and the final FPC402 will connect CTRL4 (ADDR_DONE_N) to GND, as shown in

Figure 8-4.

Host Controller

(CPLD/FPGA/CPU)

Float

VDD Host

Instance 1

FPC402

Float

Instance 2

FPC402

Instance 3

FPC402

Float

Float

Instance N

FPC402

PROTOCOL_SEL

PROTOCOL_SEL

PROTOCOL_SEL

PROTOCOL_SEL

SET_ADDR_N

(CTRL3)

(CTRL4)

ADDR_DONE_N

SET_ADDR_N

(CTRL4)

(CTRL3)

ADDR_DONE_N

SET_ADDR_N

(CTRL4)

(CTRL3)

ADDR_DONE_N

SET_ADDR_N

(CTRL3)

(CTRL4)

ADDR_DONE_N

(CTRL1)

SCL

(CTRL2)

SDA

(CTRL1)

SCL

(CTRL2)

SDA

(CTRL1)

SCL

(CTRL2)

SDA

(CTRL1)

SCL

(CTRL2)

SDA

SCL

SDA

Copyright © 2017, Texas Instruments Incorporated

Figure 8-4. FPC402 Connection Diagram for Unique Addressing in I2C Mode

For I2C host-side control interface implementations, the host controller must first configure each FPC402 device

to have a unique address. The CTRL3 (SET_ADDR_N) pin is internally pulled to high logic (regardless of the EN

pin status) and the FPC402 device will not respond to any I2C transactions until this pin is pulled low. Once it is

driven to low logic, the device will respond to the default I2C 8-bit address (0x1E). A single I2C write to the

FPC402 will reassign a new I2C address, and once this is done, the FPC402 will drive low logic with the CTRL4

pin (ADDR_DONE_N) which allows the next FPC402 in the daisy chain to be programmed using the default

address. Until this address reassignment happens, the CTRL4 (ADDR_DONE_N) pin is high-Z.

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

21

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

This scheme allows each FPC402 to take a unique I2C address without any contention on the bus. The

addresses may be programmed in any order except for the default 8-bit address (0x1E) which must be assigned

to the last device in the daisy chain, or else two FPC402s will respond to 0x1E and bus contention will occur.

The state of the CTRL3 (SET_ADDR_N) pin does not matter after the address is reprogrammed (this pin is then

used to transfer the LED clock for blinking synchronization). Once the new address is programmed, it becomes

fixed and may no longer be changed by a new register write. Only power cycling the device or toggling the EN

pin will restore the device to the default reprogrammable address.

The I2C address space for FPC402 applications is designed such that each FPC402, each port being controlled,

and each logical device address within each port is accessible to the host controller through a unique I2C

address. All FPC402 devices will also respond to 8-bit I2C address 0x02. This allows the host controller to

broadcast write to all FPC402 devices simultaneously. For a system with up to 14 FPC402 devices on a single

I2C bus, the full 8-bit I2C address map is shown in Table 8-6.

Table 8-6. I2C 8-Bit Address Map

PORT 0

PORT 1

PORT 2

PORT 3

FPC402

INSTANCE

NUMBER

FPC402 SELFADDRESS

DEVICE 0

DEFAULT

= 0xA0(1)

DEVICE 1

DEFAULT

= 0xA2(1)

DEVICE 0

DEFAULT

= 0xA0(1)

DEVICE 1

DEFAULT

= 0xA2(1)

DEVICE 0

DEFAULT

= 0xA0(1)

DEVICE 1

DEFAULT

= 0xA2(1)

DEVICE 0

DEFAULT

= 0xA0(1)

DEVICE 1

DEFAULT

= 0xA2(1)

ALL

0x02

–

–

–

–

–

–

–

–

0

0x04

0x20

0x22

0x24

0x26

0x28

0x2A

0x2C

0x2E

1

0x06

0x30

0x32

0x34

0x36

0x38

0x3A

0x3C

0x3E

2

0x08

0x40

0x42

0x44

0x46

0x48

0x4A

0x4C

0x4E

3

0x0A

0x50

0x52

0x54

0x56

0x58

0x5A

0x5C

0x5E

4

0x0C

0x60

0x62

0x64

0x66

0x68

0x6A

0x6C

0x6E

5

0x0E

0x70

0x72

0x74

0x76

0x78

0x7A

0x7C

0x7E

6

0x10

0x80

0x82

0x84

0x86

0x88

0x8A

0x8C

0x8E

7

0x12

0x90

0x92

0x94

0x96

0x98

0x9A

0x9C

0x9E

8

0x14

0xA0

0xA2

0xA4

0xA6

0xA8

0xAA

0xAC

0xAE

9

0x16

0xB0

0xB2

0xB4

0xB6

0xB8

0xBA

0xBC

0xBE

10

0x18

0xC0

0xC2

0xC4

0xC6

0xC8

0xCA

0xCC

0xCE

11

0x1A

0xD0

0xD2

0xD4

0xD6

0xD8

0xDA

0xDC

0xDE

12

0x1C

0xE0

0xE2

0xE4

0xE6

0xE8

0xEA

0xEC

0xEE

13

0x1E

0xF0

0xF2

0xF4

0xF6

0xF8

0xFA

0xFC

0xFE

(1)

Device addresses are programmable. By default, the device 0 address is 0xA0 and the device 1 address is 0xA2. Click here to request

access to the FPC401 Programmer's Guide (SNLU221) for more details.

The timing specification for an I2C transaction is described in Figure 8-5.

tf

SDA

(CTRL2)

VIH

VIL

tr

30%

tHD-STA

SCL

(CTRL1)

ttBUFt

tHD-DAT

70%

VIH

tHIGH

t

tSU-DAT

tSU-STA

tHD-STA

tSU-STO

70%

30%

VIL

START

t1 / fSCLt

tLOW

REPEATED

START

STOP

START

Copyright © 2017, Texas Instruments Incorporated

Figure 8-5. I2C Timing Diagram

8.4.2 SPI Host-Side Control Interface

If SPI is used as the host-side communication protocol, the maximum number of FPC402 devices which can

share a single SPI bus is technically unlimited. The read and write latency from/to the downstream ports will

increase as the length of the SPI chain increases.

22

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: FPC402

�FPC402

www.ti.com

SNLS582C – JUNE 2017 – REVISED SEPTEMBER 2020

SPI does not require each FPC402 to have an address. The FPC402 devices are connected in a daisy-chain

fashion as shown in Figure 8-6. The first FPC402 will connect CTRL3 (MOSI) to the MOSI signal of the host

controller. CTRL4 (MISO) on the first FPC402 will connect to the subsequent CTRL3 (MOSI) signal of another

FPC402, and continues until the final CTRL4 (MISO) signal connects back to the MISO signal of the host

controller. All FPC402 devices will connect CTRL1 (SCK) and CTRL2 (SS_N) to the same SCK and SS_N pin on

the host controller. For LED blink synchronization across multiple FPC402 devices, the SPI_LED_SYNC pin

must be connected across all FPC402 devices in SPI mode. This is not necessary in I2C mode.

Each FPC402 device in the SPI chain will capture and act upon the command in its shift register when SS_N

transitions from low (0) to high (1). The MOSI input is ignored and the MISO output is high impedance whenever

SS_N is deasserted high.

The prior SPI command, address, and data are shifted out on MISO as the current SPI command, address, and

data are shifted in on MOSI. In all SPI transactions, the MISO output signal is enabled asynchronously whenever

SS_N is asserted low.

MISO

Instance 1

Instance 2

Instance 3

FPC402

FPC402

FPC402

FPC402

PROTOCOL_SEL

PROTOCOL_SEL

PROTOCOL_SEL

PROTOCOL_SEL

Host Controller

(CPLD/FPGA/CPU)

MOSI

SPI_LED_SYNC

MISO

(CTRL4)

MOSI

(CTRL3)

(CTRL1)

SCK

(CTRL2)

SS_N

SPI_LED_SYNC

MISO

(CTRL4)

MOSI

(CTRL3)

(CTRL1)

SCK

(CTRL2)

SS_N

Instance N

SPI_LED_SYNC

SPI_LED_SYNC

MISO

(CTRL4)

MOSI

(CTRL3)

(CTRL1)

SCK

MOSI

(CTRL3)

(CTRL1)