LM3207

www.ti.com

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

LM3207 650mA Miniature, Adjustable, Step-Down DC-DC Converter for RF Power

Amplifiers with Integrated Vref LDO

Check for Samples: LM3207

FEATURES

•

•

•

•

1

•

•

2

•

•

•

•

•

2MHz (typ.) PWM Switching Frequency

Operates from a single Li-Ion cell (2.7V to

5.5V)

Variable Output Voltage (0.8V to 3.6V)

650mA Maximum load capability

High Efficiency (95% Typ at 3.9VIN, 3.4VOUT at

400mA) from internal synchronous

rectification

Integrated Vref LDO

Regulated LDO Output up to 10mA max

Fast 3uS Vref LDO On/Off Time

9-pin micro SMD Package

Current Overload Protection

Thermal Overload Protection

APPLICATIONS

•

•

•

•

Cellular Phones

Hand-Held Radios

RF PC Cards

Battery Powered RF Devices

DESCRIPTION

The LM3207 is a DC-DC converter optimized for powering WCDMA / CDMA RF power amplifiers (PAs) from a

single Lithium-Ion cell; however they may be used in many other applications. It steps down an input voltage

from 2.7V to 5.5V to a variable output voltage from 0.8V(typ.) to 3.6V(typ.). Output voltage is set using a VCON

analog input for controlling power levels and efficiency of the RF PA.

The LM3207 also provides a regulated reference voltage(Vref) required by linear RF power amplifiers through an

integrated LDO that has a maximum Iref up to 10 mA. See Ordering Information table on page 2 for Voltage

Options.

The LM3207 is available in a 9-pin lead free micro SMD package. High switching frequency (2MHz) allows use of

surface-mount components. Only four small external surface-mount components are required, an inductor and

three ceramic capacitors.

Typical Application

Vin

2.7V to 5.5V

VOUT

3.3 PH

PVIN

EN

0.8V to 3.6V

SW

FB

10 PF

VCON

4.7 PF

LM3207

LDO OUT

ENLDO

SGND

LDO

PGND

100 nF

Figure 1. LM3207 Typical Application

1

2

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

All trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2006–2007, Texas Instruments Incorporated

�LM3207

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

www.ti.com

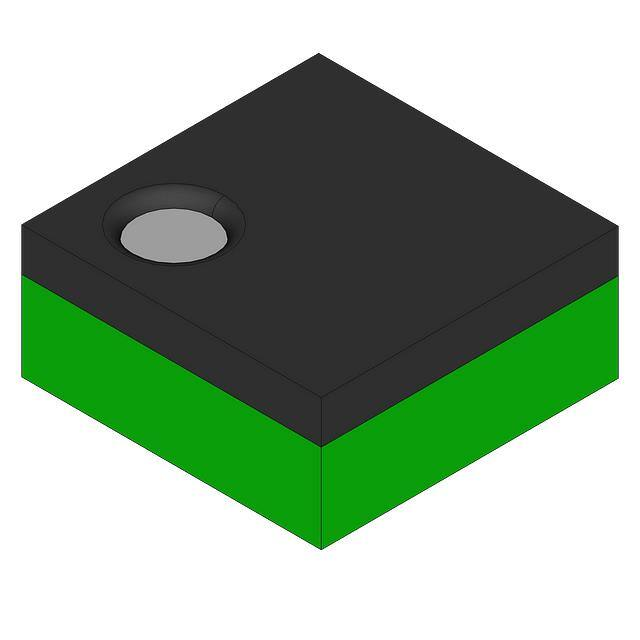

Connection Diagrams

SW

PVIN

A1

A2

A3

PGND

EN LDO

B1

EN

B2

B3

SGND

C1

C2

C3

LDO

FB

A

1

XVS/Device #

Vcon

Top View

Package Mark - Top View

9–Bump Thin Micro SMD Package, Large Bump NS Package Number TLA09TTA

(1)

Table 1. Pin Descriptions

Pin #

Name

A1

PVIN

B1

ENLDO

Description

Power Supply Voltage Input.

LDO Enable Input. Set this digital input high to turn on LDO (ENpin must also be set high). For shutdown, set

low.

C1

FB

C2

VCON

Feedback Analog Input. Connect to the output at the output filter capacitor.

Voltage Control Analog input. VCON controls VOUT in PWM mode.

C3

LDO

LDO Output Voltage.

B3

SGND

Analog and Control Ground.

A3

PGND

Power Ground.

A2

SW

Switch node connection to the internal PFET switch and NFET synchronous rectifier. Connect to an inductor

with a saturation current rating that exceeds the maximum Switch Peak Current Limit specification of the

LM3207.

B2

EN

PWM enable Input. Set this digital input high for normal operation. For shutdown, set low.

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

2

Submit Documentation Feedback

Copyright © 2006–2007, Texas Instruments Incorporated

Product Folder Links: LM3207

�LM3207

www.ti.com

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

Absolute Maximum Ratings

(1) (2)

PVIN to SGND

−0.2V to +6.0V

PGND to SGND

−0.2V to +0.2V

EN, FB, VCON, ENLDO, LDO

(SGND −0.2V)

to (VDD +0.2V)

w/6.0V max

SW

(PGND −0.2V)

to (PVIN +0.2V)

w/6.0V max

PVIN

−0.2V to +0.2V

Continuous Power Dissipation

(3)

Internally Limited

Junction Temperature (TJ-MAX)

+150°C

Storage Temperature Range

−65°C to +150°C

Maximum Lead Temperature

(Soldering, 10 sec)

+260°C

(1)

(2)

(3)

Absolute Maximum Ratings indicate limits beyond which damage to the component may occur. Operating Ratings are conditions under

which operation of the device is guaranteed. Operating Ratings do not imply guaranteed performance limits. For guaranteed

performance limits and associated test conditions, see the Electrical Characteristics tables.

All voltages are with respect to the potential at the GND pins. The LM3207 is designed for mobile phone applications where turn-on after

power-up is controlled by the system controller and where requirements for a small package size overrule increased die size for internal

Under Voltage Lock-Out (UVLO) circuitry. Thus, it should be kept in shutdown by holding the EN pin low until the input voltage exceeds

2.7V.

Internal thermal shutdown circuitry protects the device from permanent damage. Thermal shutdown engages at TJ = 150°C (typ.) and

disengages at TJ = 130°C (typ.).

Operating Ratings

(1) (2)

Input Voltage Range

2.7V to 5.5V

Recommended Load Current

0mA to 650mA

Junction Temperature (TJ) Range

−30°C to +125°C

Ambient Temperature (TA) Range

−30°C to +85°C

(3)

(1)

(2)

(3)

Absolute Maximum Ratings indicate limits beyond which damage to the component may occur. Operating Ratings are conditions under

which operation of the device is guaranteed. Operating Ratings do not imply guaranteed performance limits. For guaranteed

performance limits and associated test conditions, see the Electrical Characteristics tables.

All voltages are with respect to the potential at the GND pins. The LM3207 is designed for mobile phone applications where turn-on after

power-up is controlled by the system controller and where requirements for a small package size overrule increased die size for internal

Under Voltage Lock-Out (UVLO) circuitry. Thus, it should be kept in shutdown by holding the EN pin low until the input voltage exceeds

2.7V.

In applications where high power dissipation and/or poor package thermal resistance is present, the maximum ambient temperature may

have to be de-rated. Maximum ambient temperature (TA-MAX) is dependent on the maximum operating junction temperature (TJ-MAX-OP =

125°C), the maximum power dissipation of the device in the application (PD-MAX), and the junction-to ambient thermal resistance of the

part/package in the application (θJA), as given by the following equation: TA-MAX = TJ-MAX-OP – (θJA × PD-MAX).

Thermal Properties

Junction-to-Ambient Thermal

100°C/W

Resistance (θJA), TLA09 Package

(1)

(1)

Junction-to-ambient thermal resistance (θJA) is taken from thermal measurements, performed under the conditions and guidelines set

forth in the JEDEC standard JESD51-7.

Submit Documentation Feedback

Copyright © 2006–2007, Texas Instruments Incorporated

Product Folder Links: LM3207

3

�LM3207

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

Electrical Characteristics

www.ti.com

(1) (2) (3)

Limits in standard typeface are for TA = TJ = 25°C. Limits in boldface type apply over the full operating ambient temperature

range (−30°C ≤ TA = TJ ≤ +85°C). Unless otherwise noted, all specifications apply to all LM3207 LDO options with: PVIN = VIN

= ENLDO = EN = 3.6V.

Symbol

Parameter

Conditions

Min

Typ

Max

Units

+2.6

%

LDO

VLDO

LDO Output Voltage

Iout = 0 mA

VLDO,MIN

Minimum LDO Output Voltage

Iout = 10mA, PVIN = 3V

ISC

Short circuit current(DC)

VLDO = 0

IPUT

Pull-up current (transient)

VLDO = VLDO(nom)/2, PVIN = 3V

IPD

DC Pull-down current (DC)

VLDO = PVIN, ENLDO = 0

IPDT

Pull-down current (transient)

VLDO = 1.44V, PVIN = 3V

IQ_LDO + PWM

DC Bias current into PVIN

VCON = 2V, FB = 0V, No Switching,

ENLDO = EN = 3.6V (5)

IPIN,ENLDO

LDO Pin pull down current

(4)

-2.6

%

50

mA

150

mA

-50

mA

-200

mA

1.2

1.6

mA

5

10

uA

(4)

Switcher

VFB,

MIN

Feedback Voltage at minimum

setting

VCON = 0.32V

0.75

0.8

0.85

V

VFB,

MAX

Feedback Voltage at maximum

setting

VCON = 1.44V, PVIN = 4.2V

3.537

3.6

3.683

V

ISHDN

Shutdown supply current

EN = ENLDO= SW = VCON = 0V,

0.01

2

µA

IQ_PWM

DC bias current into PVIN

VCON = 2V, FB = 0V, ENLDO = 0V ,

EN = 3.6V, No Switching (5)

1.1

1.6

mA

RDSON(P)

Pin-pin resistance for PFET

ISW = 200mA

RDSON(N)

Pin-pin resistance for NFET

(6)

140

ISW = - 200mA

(7)

300

200

230

415

485

mΩ

mΩ

ILIM,PFET

Switch peak current limit

935

1100

1200

mA

FOSC

Internal oscillator frequency

1.7

2

2.3

MHz

VIH,EN

Logic high input threshold

(PWM, LDO)

1.2

VIL,EN

Logic low input threshold

(PWM, LDO)

IPIN,EN

PWM Pin pull down current

Gain

VCON to VOUT Gain

0.32V ≤ VCON ≤ 1.44V

ICON

VCON pin leakage current

VCON = 1.0V

(1)

(2)

(3)

(4)

(5)

(6)

(7)

4

V

0.5

5

10

2.5

V

µA

V/V

±1

µA

All voltages are with respect to the potential at the GND pins. The LM3207 is designed for mobile phone applications where turn-on after

power-up is controlled by the system controller and where requirements for a small package size overrule increased die size for internal

Under Voltage Lock-Out (UVLO) circuitry. Thus, it should be kept in shutdown by holding the EN pin low until the input voltage exceeds

2.7V.

Min and Max limits are guaranteed by design, test, or statistical analysis. Typical numbers are not guaranteed, but do represent the

most likely norm. Due to the pulsed nature of the testing TA = TJ for the electrical characteristics table.

The parameters in the electrical characteristics table are tested under open loop conditions at PVIN = 3.6V. For performance over the

input voltage range and closed loop results refer to the datasheet curves.

Transient Pull-up current (IPUT) and Transient Pull-down Current (IPDT) will be tested which are inversely proportional to charge and

discharge times tLDO, ON and tLDO, OFF respectively.

IQ specified here is when the part is operating at 100% duty cycle.

Shutdown current includes leakage current of PFET.

Current limit is built-in, fixed, and not adjustable. Refer to datasheet curves for closed loop data and its variation with regards to supply

voltage and temperature. Electrical Characteristic table reflects open loop data (FB = 0V and current drawn from SW pin ramped up until

cycle by cycle limit is activated). Closed loop current limit is the peak inductor current measured in the application circuit by increasing

output current until output voltage drops by 10%.

Submit Documentation Feedback

Copyright © 2006–2007, Texas Instruments Incorporated

Product Folder Links: LM3207

�LM3207

www.ti.com

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

System Characteristics

The following spec table entries are guaranteed by design providing the component values in the typical application circuit are

used (L = 3.0µH, (DCR = 0.12Ω, FDK MIPW3226D3R0M);

CIN = 10µF, (6.3V, 0805, TDK C2012X5R0J106K); COUT = 4.7µF, (6.3V, 0603, TDK C1608X5R0J475M); CLDO = 100nF, (10V,

0402, TDK C1005X5R1A104KT) (or 220nF, (6.3V, 0402, TDK C1005X5R0J224KT))) . These parameters are not

guaranteed by production testing. Min and Max values are specified over the VIN range = 2.7V to 5.5V and over the

ambient temp range TA = −30°C to 85°C unless otherwise specified. Typical values are specified at PVIN = EN = 3.6V and TA

= 25°C unless otherwise specified.

Symbol

Parameter

Conditions

Min

Typ

Max

Units

PSRR

Power Supply Rejection

Ratio

Offset Freq = 1Khz, Cout = 100nF,

Iout = 1mA, PVin = Vout(nom) + 0.5V

50

dB

VLDO(NOISE)

Output Noise Voltage

BW = 10Hz to 100Khz, Iout = 1mA

30

uVrms

tLDO, ON

Time to reach 90% of

VLDO(nom) after ENLDO

signal goes high.

CLDO = 100nF, PWM mode assumed to be

fully functional before ENLDO goes high.

PVin = 3V, RLOAD = 562 Ω (1)

3

uS

CLDO = 220nF, PWM mode assumed to be

fully functional before ENLDO goes high.

PVin = 3V, RLOAD = 562 Ω (1)

5

uS

CLDO = 100nF, PVin = 3V, Iout = 0mA

3

CLDO = 220nF, PVin = 3V, Iout = 0mA

5

LDO

tLDO, OFF

Time to reach 10% of

VLDO(nom) after ENLDO

signal goes low.

(1)

uS

(1)

Switcher

TRESPONSE (Rise

time)

Time for VOUT to rise from

0.8V to 3.6V

PVIN = 4.2V, COUT = 4.7uF, L = 3.0uH,

RLOAD = 5.5Ω

20

30

µs

TRESPONSE (Fall

time)

Time for VOUT to fall from

3.6V to 0.8V

PVIN = 4.2V, COUT = 4.7uF, L = 3.0uH,

RLOAD = 10Ω

20

30

µs

CCON

VCON input capacitance

VCON = 1V,

Test frequency = 100 kHz

20

pF

VCON Linearity

Linearity in control

range 0.32V to 1.44V

PVIN = 3.9V, Monotonic in nature

+3

%

T_ON

Turn on time

(time for output to reach

3.6V from Enable low to

high transition)

EN = Low to High, PVIN = 4.2V,

VO = 3.6V, COUT = 4.7µF,

IOUT ≤ 1mA

70

100

µs

Efficiency

(L = 3.0µH, DCR ≤

100mΩ)

PVIN = 3.6V, VOUT = 0.8V, IOUT = 90mA

81

%

PVIN = 3.9V, VOUT = 3.4V, IOUT = 400mA

95

%

VO_ripple

Ripple voltage, PWM

mode

PVIN = 3V to 4.5V, VOUT = 0.8V,

IOUT = 10mA to 400mA, (2)

10

mVp-p

Line_tr

Line transient response

PVIN = 600mV perturbance,

TRISE = TFALL = 10µs, VOUT = 0.8V,

IOUT = 100mA

50

mV

PVIN = 3.1/3.6/4.5V, VOUT = 0.8V,

transients up to 100mA,

TRISE = TFALL = 10µs

50

mV

η

Load_tr

(1)

(2)

Load transient response

-3

Transient Pull-up current (IPUT) and Transient Pull-down Current (IPDT) will be tested which are inversely proportional to charge and

discharge times tLDO, ON and tLDO, OFF respectively.

Ripple voltage should measured at COUT electrode on good layout PC board and under condition using suggested inductors and

capacitors.

Submit Documentation Feedback

Copyright © 2006–2007, Texas Instruments Incorporated

Product Folder Links: LM3207

5

�LM3207

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

www.ti.com

Typical Performance Characteristics

(Circuit in Figure 3, See Operation Description Section),

PVIN = EN = 3.6V, L = 3.0µH, (DCR = 0.12Ω, FDK MIPW3226D3R0M); CIN = 10µF, (6.3V, 0805, TDK C2012X5R0J106K);

COUT = 4.7µF, (6.3V, 0603, TDK C1608X5R0J475M), CLDO = 100nF, 10V, (0402, TDK C1005X5R1A104KT) (or 220nF, (6.3V,

0402, TDK C1005X5R0J224KT)) can be used. TA = 25°C unless otherwise specified.

LDO Typical Performance Curves (2.875 Option)

LDO Voltage

vs

Load Current

(CLDO = 100nF)

LDO Dropout Voltage

vs

Load Current

(CLDO = 100nF), (1)

LDO Short Circuit Current

vs

Voltage

(VIN = 3.0V, CLDO = 100nF)

LDO Output Noise Density

(ILOAD = 1mA, CLDO = 100nF and 220nF)

LDO Power Supply Rejection Ratio

(VIN = Vout(nom) + 0.5V, CLDO = 100nF)

LDO Turn On Time

vs

VIN

(CLDO = 100nF)

50

RIPPLE REJECTION (dB)

40

ILOAD = 1mA

30

20

10

0

-10

-20

-30

-40

-50

100

1k

10k

100k

1M

FREQUENCY (Hz)

(1)

6

Dropout voltage is the voltage difference between the input and the output at which the output voltage drops to 100 mV below its

nominal value.

Submit Documentation Feedback

Copyright © 2006–2007, Texas Instruments Incorporated

Product Folder Links: LM3207

�LM3207

www.ti.com

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

LDO Typical Performance Curves (2.875 Option) (continued)

LDO Turn Off Time

vs

VIN

(CLDO = 100nF)

LDO Line Transient Response

(VIN = 3.0V to 3.6V, ILOAD = 10mA, CLDO = 100nF)

IL = 0 mA

1.4

TA = 25°C

TOFF (Ps)

1.2

TA = -30°C

1.0

TA = 85°C

0.8

0.6

3.0

3.5

4.0

4.5

5.0

5.5

PVIN (V)

LDO Load Transient Repsonse

(VIN= 3.2V, VOUT = 0.8V, CLDO = 100nF)

(VIN

LDO VLDO Out

vs

Temperature

= 3.6V,CLDO = 100nF)

Submit Documentation Feedback

Copyright © 2006–2007, Texas Instruments Incorporated

Product Folder Links: LM3207

7

�LM3207

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

www.ti.com

LDO Typical Performance Curves (2.53 Option)

LDO Voltage

vs

Load Current

(CLDO = 100nF)

LDO Dropout Voltage

vs

Load Current

(CLDO = 100nF), (1)

2.53

VLDO OUT (V)

VIN = 5.5V

DROPOUT VOLTAGE (mV)

VIN = 3.6V

VIN = 4.2V

2.52

VIN = 3.0V

VIN = 3.2V

2.51

0

5

10

15

20

0

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

-120

-130

-140

-150

-160

-170

-180

-190

-200

TA = -30°C

TA = 85°C

TA = 25°C

0

2

4

6

8

10

LOAD CURRENT (mA)

LDO LOAD CURRENT (mA)

LDO Short Circuit Current

vs

Voltage

(VIN = 3.0V, CLDO = 100nF)

LDO Power Supply Rejection Ratio

(VIN = Vout(nom) + 0.5V, CLDO = 100nF)

10

60

0

RIPPLE REJECTION (dB)

TA = 25°C

50

ISC (mA)

40

TA = 85°C

30

TA = -30°C

20

10

0

0.0

8

-20

-30

-40

-50

-60

-70

0.5

1.0

1.5

2.0

2.5

3.0

1

10

100

1000

FREQUENCY (kHz)

VLDO (V)

(1)

ILOAD = 1 mA

-10

Dropout voltage is the voltage difference between the input and the output at which the output voltage drops to 100 mV below its

nominal value.

Submit Documentation Feedback

Copyright © 2006–2007, Texas Instruments Incorporated

Product Folder Links: LM3207

�LM3207

www.ti.com

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

LDO Typical Performance Curves (2.53 Option) (continued)

LDO Turn On Time

vs

VIN

(CLDO = 100nF)

LDO Turn Off Time

vs

VIN

(CLDO = 100nF)

1.6

1.2

ILOAD = 5 mA

ILOAD = 0 mA

1.1

1.4

TA = 85°C

TA = 25°C

1.0

1.2

0.9

TOFF (Ps)

TON (Ps)

TA = -30°C

0.8

0.7

TA = -30°C

1.0

0.8

TA = 85°C

0.6

0.6

TA = 25°C

0.5

0.4

0.4

3.0

3.5

4.0

4.5

5.0

5.5

3.0

3.5

4.0

4.5

5.0

5.5

PVIN (V)

PVIN (V)

(VIN

2.536

LDO VLDO Out

vs

Temperature

= 3.6V,CLDO = 100nF)

ILOAD = 0 mA

ILOAD = 5 mA

ILOAD = 1 mA

VLDO OUT (V)

2.534 ILOAD =

10 mA

2.532

2.530

2.528

VIN = 3.6V

2.526

-40

-20

0

20

40

60

80

100

TEMPERATURE (°C)

Submit Documentation Feedback

Copyright © 2006–2007, Texas Instruments Incorporated

Product Folder Links: LM3207

9

�LM3207

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

www.ti.com

SWITCHER Typical Performance Curves

Quiescent Current

vs

Supply Voltage

(VCON = 2V, FB = 0V, No Switching, LDO Disabled)

Quiescent Current

vs

Supply Voltage

(VCON = 2V, FB = 0V, No Switching, LDO Enabled)

Shutdown Current

vs

Temperature

(VCON = 0V, EN = 0V)

Switching Frequency

vs

Temperature

(VOUT = 1.3V, IOUT = 200mA)

SWITCHING FREQUENCY VARIATION (%)

4.0

3.0

VIN = 5.5V

2.0

VIN = 4.2V

1.0

0.0

-1.0

VIN = 3.6V

-2.0

VIN = 2.7V

-3.0

-4.0

-40

-20

0

20

40

60

80

100

AMBIENT TEMPERATURE (oC)

Output Voltage Regulation(%)

vs

Output Load

(VOUT = 1.5V)

(VIN

Output Voltage

vs

Temperature

= 3.6V, VOUT = 0.8V)

-0.30

-0.25

REGULATION (%)

-0.20

VIN = 3.6V

-0.15

-0.10

VIN = 2.7V

-0.05

-0.00

-0.05

-0.10

VIN = 5.5V

-0.15

VIN = 4.5V

-0.20

-0.25

-0.30

0

100

200

300

400

500

600

700

OUTPUT LOAD (mA)

10

Submit Documentation Feedback

Copyright © 2006–2007, Texas Instruments Incorporated

Product Folder Links: LM3207

�LM3207

www.ti.com

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

SWITCHER Typical Performance Curves (continued)

(VIN

Output Voltage

vs

Temperature

= 3.6V, VOUT = 3.4V)

Open/Closed Loop Current Limit

vs

Temperature

(PWM Mode)

VCON Voltage

vs

Output Voltage

(VIN = 4.2V, RLOAD = 8Ω)

Efficiency

vs

Output Voltage

(VIN = 3.9V)

Efficiency

vs

Output Current

(VOUT = 0.8V)

Efficiency

vs

Output Current

(VOUT = 3.4V)

Submit Documentation Feedback

Copyright © 2006–2007, Texas Instruments Incorporated

Product Folder Links: LM3207

11

�LM3207

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

www.ti.com

SWITCHER Typical Performance Curves (continued)

Load Transient Response

(VOUT = 0.8V)

Load Transient Response

(VIN = 4.2V, VOUT = 3.4V)

Startup

(VIN = 3.6V, VOUT = 1.3V, RLOAD = 1kΩ)

Startup

(VIN = 4.2V, VOUT = 3.4V, RLOAD = 5kΩ)

Shutdown Response

(VIN = 4.2V, VOUT = 3.4V, RLOAD = 10Ω)

Line Transient Reponse

(VIN = 3.0V to 3.6V, IOUT = 100mA)

VSW

5V/DIV

VIN = 4.2V

VOUT

VOUT = 3.4V

RL = 10:

2V/DIV

IL

500 mA/DIV

2V/DIV

EN

40 Ps/DIV

(VIN

VCON Voltage Response

= 4.2V, VCON = 0.32V/1.44V, RLOAD = 10Ω)

VSW

VCON and Load Transient

(VIN = 4.2V, VCON = 0.32V/1.44V, RLOAD = 15Ω/8Ω)

2V/DIV

2V/DIV

VSW

3.6V

VOUT

VIN = 4.2V

VCON = 0.32/1.44V

RL = 10:

3.6V

VOUT

0.8V

VIN = 4.2V

VCON = 0.32/1.44V

RL = 15:/8:

1.44V

VCON

0.32V

1.44V

VCON

40 Ps/DIV

12

0.8V

0.32V

40 Ps/DIV

Submit Documentation Feedback

Copyright © 2006–2007, Texas Instruments Incorporated

Product Folder Links: LM3207

�LM3207

www.ti.com

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

SWITCHER Typical Performance Curves (continued)

Timed Current Limit Response

(VIN = 3.6V)

Output Voltage Ripple

(VOUT = 1.3V)

Output Voltage Ripple

(VOUT = 3.4V)

Output Voltage Ripple in Pulse Skip

(VIN = 3.64V, VOUT = 3.4V, RLOAD = 5Ω)

VSW

2V/DIV

VSW

VIN = 3.64V

2V/DIV

VOUT = 3.4V

RL = 5:

VIN = 4.2V

VOUT = 3.4V

IOUT = 200 mA

VOUT

10 mV/DIV

AC Coupled

VOUT

10 mV/DIV

AC Coupled

IL

500 mA/DIV

IL

500 mA/DIV

400 ns/DIV

400 ns/DIV

RDSON

vs

Temperature (microSMD)

(P-ch, ISW = 200mA)

RDSON

vs

Temperature (microSMD)

(N-ch, ISW = -200mA)

Submit Documentation Feedback

Copyright © 2006–2007, Texas Instruments Incorporated

Product Folder Links: LM3207

13

�LM3207

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

www.ti.com

SWITCHER Typical Performance Curves (continued)

EN High Threshold

vs

VIN

14

Submit Documentation Feedback

Copyright © 2006–2007, Texas Instruments Incorporated

Product Folder Links: LM3207

�LM3207

www.ti.com

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

Block Diagram

PVIN

CURRENT

SENSE

OSCILLATOR

ERROR AMPLIFIER

FB

~

PWM

COMP

MOSFET

CONTROL

LOGIC

VCON

SW

MAIN CONTROL

EN

SHUTDOWN

CONTROL

PGND

PVIN

Active Charge Control

Vref

LDO

LDO Control

(Over Current and Thermal

Protection)

ENLDO

Active Discharge Control

PGND

Figure 2. Functional Block Diagram

Operation Description

The LM3207 is a simple, step-down DC-DC converter with a VREF LDO optimized for powering RF power

amplifiers (PAs) in mobile phones, portable communicators, and similar battery powered RF devices. The DC-DC

converter is designed to allow the RF PA to operate at maximum efficiency over a wide range of power levels

from a single Lithium-Ion battery cell. The DC-DC is based on current-mode buck architecture, with synchronous

rectification for high efficiency. It is designed for a maximum load capability of 650mA in PWM mode.

Maximum load range may vary from this depending on input voltage, output voltage and the inductor chosen.

The device has two pin-selectable operating modes required for powering RF PAs in mobile phones and other

sophisticated portable devices. Fixed-frequency PWM operation offers regulated output at high efficiency while

minimizing interference with sensitive IF and data acquisition circuits. Shutdown mode turns the device off and

reduces battery consumption to 0.01uA (typ).

Submit Documentation Feedback

Copyright © 2006–2007, Texas Instruments Incorporated

Product Folder Links: LM3207

15

�LM3207

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

www.ti.com

Efficiency is typically around 95% for a 400mA load with 3.9VIN, 3.4VOUT. The output voltage is dynamically

programmable from 0.8V (typ) to 3.6V (typ) by adjusting the voltage on the control pin without the need for

external feedback resistors. This ensures longer battery life by being able to change the PA supply voltage

dynamically depending on its transmitting power.

Additional features include current overload protection, and thermal overload shutdown.

The LM3207 is constructed using a chip-scale 9-pin micro SMD package. This package offers the smallest

possible size, for space-critical applications such as cell phones, where board area is an important design

consideration. Use of a high switching frequency (2MHz) reduces the size of external components. As shown in

Figure 1, only four external power components are required for implementation. Use of a micro SMD package

requires special design considerations for implementation. (See Micro SMD Package Assembly and use in the

Applications Information section.) The fine bump-pitch requires careful board design and precision assembly

equipment. Use of this package is best suited for opaque-case applications, where its edges are not subject to

high-intensity ambient red or infrared light. Also, the system controller should set EN low during power-up and

other low supply voltage conditions. (See Shutdown Mode in the Device Information section.)

VIN

10 PF

TX_ON/OFF

EN

R

F

I

C

DAC

VCON

RF_ON/OFF

ENLDO

3.3 PH

PVIN

SW

FB

LM3207

VCC

4.7 PF

RFin

PA

VREF

LDO

100 nF

Figure 3. Typical Application Circuit

Circuit Operation (DC-DC Converter)

Referring to Figure 1 and Figure 2, the LM3207 operates as follows. During the first part of each switching cycle,

the control block in the LM3207 turns on the internal PFET (P-channel MOSFET) switch. This allows current to

flow from the input through the inductor to the output filter capacitor and load. The inductor limits the current to a

ramp with a slope of around (PVIN - VOUT) / L, by storing energy in a magnetic field. During the second part of

each cycle, the controller turns the PFET switch off, blocking current flow from the input, and then turns the

NFET (N-channel MOSFET) synchronous rectifier on. In response, the inductor’s magnetic field collapses,

generating a voltage that forces current from ground through the synchronous rectifier to the output filter

capacitor and load. As the stored energy is transferred back into the circuit and depleted, the inductor current

ramps down with a slope around VOUT / L. The output filter capacitor stores charge when the inductor current is

high, and releases it when low, smoothing the voltage across the load.

The output voltage is regulated by modulating the PFET switch on time to control the average current sent to the

load. The effect is identical to sending a duty-cycle modulated rectangular wave formed by the switch and

synchronous rectifier at SW to a low-pass filter formed by the inductor and output filter capacitor. The output

voltage is equal to the average voltage at the SW pin.

16

Submit Documentation Feedback

Copyright © 2006–2007, Texas Instruments Incorporated

Product Folder Links: LM3207

�LM3207

www.ti.com

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

PWM Operation

While in PWM (Pulse Width Modulation) mode, the output voltage is regulated by switching at a constant

frequency and then modulating the energy per cycle to control power to the load. Energy per cycle is set by

modulating the PFET switch on-time pulse width to control the peak inductor current. This is done by comparing

the signal from the current-sense amplifier with a slope compensated error signal from the voltage-feedback error

amplifier. At the beginning of each cycle, the clock turns on the PFET switch, causing the inductor current to

ramp up. When the current sense signal ramps past the error amplifier signal, the PWM comparator turns off the

PFET switch and turns on the NFET synchronous rectifier, ending the first part of the cycle. If an increase in load

pulls the output down, the error amplifier output increases, which allows the inductor current to ramp higher

before the comparator turns off the PFET. This increases the average current sent to the output and adjusts for

the increase in the load. Before appearing at the PWM comparator, a slope compensation ramp from the

oscillator is subtracted from the error signal for stability of the current feedback loop. The minimum on time of

PFET in PWM mode is 50ns (typ.)

Shutdown Mode

Setting the EN digital pin low (1.2V) enables normal operation.

EN should be set low to turn off the LM3207 during power-up and under voltage conditions when the power

supply is less than the 2.7V minimum operating voltage. The LM3207 is designed for compact portable

applications, such as mobile phones. In such applications, the system controller determines power supply

sequencing and requirements for small package size outweigh the additional size required for inclusion of UVLO

(Under Voltage Lock-Out) circuitry.

Internal Synchronous Rectification

While in PWM mode, the LM3207 uses an internal NFET as a synchronous rectifier to reduce rectifier forward

voltage drop and associated power loss. Synchronous rectification provides a significant improvement in

efficiency whenever the output voltage is relatively low compared to the voltage drop across and ordinary rectifier

diode.

The internal NFET synchronous rectifier is turned on during the inductor current down slope in the second part of

each cycle. The synchronous rectifier is turned off prior to the next cycle. The NFET is designed to conduct

through its intrinsic body diode during transient intervals before it turns on, eliminating the need for an external

diode.

Current Limiting

A current limit feature allows the LM3207 to protect itself and external components during overload conditions. In

PWM mode, a 1200mA (max.) cycle-by-cycle current limit is normally used. If an excessive load pulls the output

voltage down to approximately 0.375V, then the device switches to a timed current limit mode. In timed current

limit mode the internal PFET switch is turned off after the current comparator trips and the beginning of the next

cycle is inhibited for 3.5us to force the instantaneous inductor current to ramp down to a safe value. The

synchronous rectifier is off in timed current limit mode. Timed current limit prevents the loss of current control

evident in some products when the output voltage is pulled low in serious overload conditions.

Dynamically Adjustable Output Voltage

The LM3207 features dynamically adjustable output voltage to eliminate the need for external feedback resistors.

The output can be set from 0.8V(typ.) to 3.6V(typ.) by changing the voltage on the analog VCON pin. This feature

is useful in PA applications where peak power is needed only when the handset is far away from the base station

or when data is being transmitted. In other instances the transmitting power can be reduced. Hence the supply

voltage to the PA can be reduced, promoting longer battery life. See Setting the Output Voltage in the Application

Information section for further details.

Submit Documentation Feedback

Copyright © 2006–2007, Texas Instruments Incorporated

Product Folder Links: LM3207

17

�LM3207

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

www.ti.com

Thermal Overload Protection

The LM3207 has a thermal overload protection function that operates to protect itself from short-term misuse and

overload conditions. When the junction temperature exceeds 150°C, the device inhibits operation. The PFET and

NFET are turned off in PWM mode. The LDO is turned off as well. When the temperature drops below 130°C,

normal operation resumes. Prolonged operation in thermal overload conditions may damage the device and is

considered bad practice.

LDO Operation

An LDO is used to provide a regulated Vref supply to a RF PA with a fixed voltage. The LDO can be enabled

only after the PWM is running. The LDO will automatically be disabled whenever the EN or ENLDO is disabled.

Included in the LDO are active charge and discharge circuits to quickly move a 100nF capacitor to meet the 3us

timing requirements, or an 220nF capacitor to meet the 5us timing requirements. The charging and discharging

currents are controlled to minimize supply disturbances. The LM3207 was designed specifically to work with a

100nF or a 220nF ceramic capacitor and no bypass capacitor. See Ordering Information table on page 2 for

Voltage Options.

Application Information

SETTING THE DC-DC CONVERTER OUTPUT VOLTAGE

The LM3207 features a pin-controlled variable output voltage to eliminate the need for external feedback

resistors. It can be programmed for an output voltage from 0.8V (typ.) to 3.6V (typ.) by setting the voltage on the

VCON pin, as in the following formula:

VOUT = 2.5 x VCON

(2)

When VCON is between 0.32V and 1.44V, the output voltage will follow proportionally by 2.5 times of VCON.

If VCON is over 1.44V (VOUT = 3.6V), sub-harmonic oscillation may occur because of insufficient slope

compensation. If VCON voltage is less than 0.32V (VOUT = 0.8V), the output voltage may not be regulated due to

the required on-time being less than the minimum on-time (50ns). The output voltage can go lower than 0.8V

providing a limited VIN range is used. Refer to datasheet curve (VCON Voltage vs Output Voltage) for details. This

curve is for a typical part and there could have part-to-part variation for output voltages less than 0.8V over the

limited VIN range.

LDO CAPACITOR SELECTION

The output capacitor should be connected between the LDO output and a good ground connection. This

capacitor must be selected within specified capacitance range and have sufficiently low ESR. The ESR of the

capacitor is generally a major factor in LDO stability. Refer to manufacturer ESR curves for more detail. Table 2

suggests acceptable capacitors and their suppliers.

Table 2. Suggested capacitors and their suppliers

Model

Vendor

C1005X5R1A104KT, 100nF, 10V

TDK

C1005X5R0J224KT, 220nF, 6.3V

TDK

INDUCTOR SELECTION

A 3.3µH inductor with saturation current rating over 1200mA and low inductance drop at the full DC bias

condition is recommended for almost all applications. The inductor’s DC resistance should be less than 0.2Ω for

good efficiency. For low dropout voltage, lower DCR inductors are advantageous. The lower limit of acceptable

inductance is 1.7µH at 1200mA over the operating temperature range. Full attention should be paid to this limit,

because some small inductors show large inductance drops at high DC bias. These can not be used with the

LM3207. Table 3 suggests some inductors and suppliers.

Table 3. Suggested inductors and their suppliers

Model

NR3015T3R3M

18

Size (WxLxH) [mm]

3.0 x 3.0 x 1.5

Submit Documentation Feedback

Vendor

Taiyo-Yuden

Copyright © 2006–2007, Texas Instruments Incorporated

Product Folder Links: LM3207

�LM3207

www.ti.com

SNVS400A – AUGUST 2006 – REVISED APRIL 2007

Table 3. Suggested inductors and their suppliers (continued)

Model

Size (WxLxH) [mm]

Vendor

DO3314-332MXC

3.3 x 3.3 x 1.4

Coilcraft

MIPW3226D3R0M

3.2 x 2.6 x 1.0

FDK

If a smaller inductance inductor is used in the application, the LM3207 may become unstable during line and load

transients and VCON transient response times may be affected. For low-cost applications, an unshielded bobbin

inductor is suggested. For noise critical applications, a toroidal or shielded-bobbin inductor is recommended. A

good practice is to layout the board with footprints accommodating both types for design flexibility. This allows

substitution of a low-noise toroidal inductor, in the event that noise from low-cost bobbin models is unacceptable.

Saturation occurs when the magnetic flux density from current through the windings of the inductor exceeds what

the inductor’s core material can support with a corresponding magnetic field. This can result in poor efficiency,

regulation errors or stress to DC-DC converter like the LM3207.

DC-DC CONVERTER CAPACITOR SELECTION

The LM3207 is designed with a ceramic capacitor for its input and output filters. Use a 10µF ceramic capacitor

for input and a 4.7µF ceramic capacitor for output. They should maintain at least 50% capacitance at DC bias

and temperature conditions. Ceramic capacitors types such as X5R, X7R are recommended for both filters.

These provide an optimal balance between small size, cost, reliability and performance for cell phones and

similar applications. Table 4 lists suggests acceptable part numbers and their suppliers. DC bias characteristics

of the capacitors must be considered when selecting the voltage rating and case size of the capacitor. If it is

necessary to choose a 0603-size capacitor for VIN, the operation of the LM3207should be carefully evaluated on

the system board. Output capacitors with smaller case sizes mitigate piezo electric vibrations when the output

voltage is stepped up and down at fast rates. However, they have a larger percentage drop in value with dc bias.

Use of multiple 2.2µF or 1µF capacitors in parallel may also be considered.

Table 4. Suggested capacitors and their suppliers

Model

Vendor

0805ZD475KA, 4.7µF, 10V

Taiyo-Yuden

C1608X5R0J475M, 4.7uF, 6.3V

TDK

C1608X5R0J106M, 10µF, 6.3V

TDK

C2012X5R0J106M, 10uF, 6.3V

TDK

C2012X5R1A475M, 4.7uF, 6.3V

TDK

The input filter capacitor supplies AC current drawn by the PFET switch of the LM3207 in the first part of each

cycle and reduces the voltage ripple imposed on the input power source. The output filter capacitor absorbs the

AC inductor current, helps maintain a steady output voltage during transient load changes and reduces output

voltage ripple. These capacitors must be selected with sufficient capacitance and sufficiently low ESR

(Equivalent Series Resistance) to perform these functions. The ESR of the filter capacitors is generally a factor in

voltage ripple.

EN PIN CONTROL

Drive the EN and ENLDO pins using the system controller to turn the LM3207 ON and OFF. Use a comparator,

Schmidt trigger or logic gate to drive the EN and ENLDO pins. Set EN high (>1.2V) for normal operation and low

(