�������

�

� �

� �� �

� ���� ��

��������

SWRS025C − APRIL 2004 − REVISED JULY 2007

D Hot Plug Protection

D Quad 1.0 to 2.5 Gigabits Per Second (Gbps)

Serializer/Deserializer

D Independent Channel Operation

D 2.5-V Power Supply for Low Power

D

D

D

D

Operation

Selectable Signal Preemphasis for Serial

Output

Interfaces to Backplane, Copper Cables, or

Optical Converters

Lock Indication and Sync Mode for Fast

Initialization

18-Bit Parallel Buses for Flexible Interface

Applications

D On-Chip PLL Provides Clock Synthesis

D

D

D

D

D

D

From Low-Speed Reference

Receiver Differential Input Thresholds

200 mV Min

Rated for Industrial Temperature Range

Typical Power: 1700 mW at 2.5 Gbps

Ideal for High-Speed Backplane

Interconnect and Point-to-Point Data Link

Internal Passive Receive Equalization

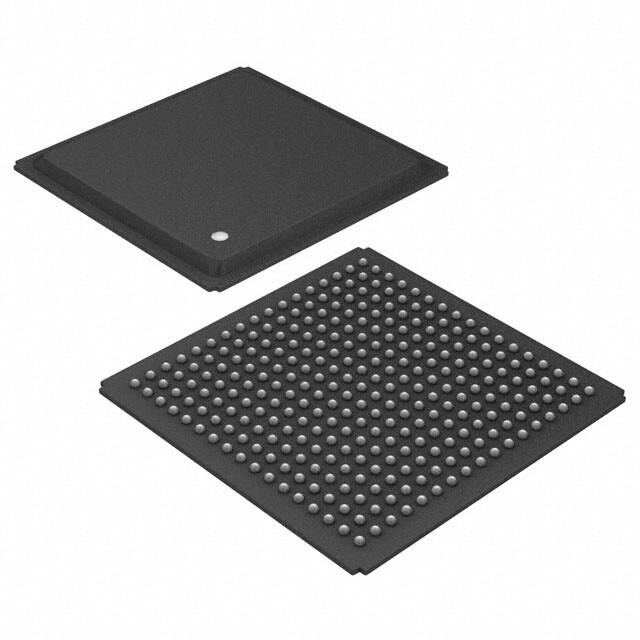

Small Footprint 19 mm x 19 mm, 289-Ball

PBGA Package

description

The TLK4250 device is a four-channel, multi-gigabit transceiver used in high-speed bidirectional point-to-point

data transmission systems. The four channels in the transceiver are configured as four separate links. The

transceiver supports an effective serial interface speed of 1.0 Gbps to 2.5 Gbps per channel, providing up to

2.25 Gbps of data bandwidth per channel.

The primary application of the transceiver is to provide high-speed I/O data channels for point-to-point baseband

data transmission over controlled impedance media of approximately 50 Ω. The transmission media can be a

printed-circuit board, copper cables, or fiber-optic cable. The maximum rate and distance of data transfer

depend on the attenuation characteristics of the media and the noise coupling to the environment.

The transceiver can also replace parallel data transmission architectures by providing a reduction in the number

of traces, connector pins, and transmit/receive pins. Parallel data loaded into the transmitter is delivered to the

receiver over a serial channel, which can be a coaxial copper cable, a controlled impedance backplane, or an

optical link. The data is then reconstructed into its original parallel format. It offers significant power and cost

savings over current solutions, as well as scalability for higher data rate in the future.

The transceiver performs the data parallel-to-serial and serial-to-parallel conversions. The clock extraction

functions as a physical layer interface device. The serial transceiver interface operates at a maximum data rate

of 2.5 Gbps. Each transmitter latches 18-bit parallel data at a rate based on the supplied reference clock

(GTx_CLK). The 18-bit parallel data is internally encoded into 20 bits by framing the 18-bit data with start and

stop bits. The resulting 20-bit frame is then transmitted differentially at 20 times the reference clock (GTx_CLK)

rate.

The receiver section performs the serial-to-parallel conversion on the input data, synchronizing the resulting

20-bit wide parallel data to the recovered clock (Rx_CLK). It then extracts the 18 bits of data from the 20-bit wide

data resulting in 18 bits of parallel data at the receive data terminals (RDx[0:17]). This results in an effective data

payload of 0.9 Gbps to 2.25 Gbps (18 bits data x GTx_CLK frequency) per channel.

The transceiver provides an internal loopback capability for self-test purposes. Serial data from the serializer

is passed directly to the deserializer, allowing the protocol device a functional self-check of the physical

interface.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PowerPAD is a trademark of Texas Instruments.

Copyright 2004 − 2007, Texas Instruments Incorporated

���� ����� �

�

����!"#���� �� $%!!&�� #� �� �%�'�$#���� (#�&

�!�(%$�� $����!" �� ��&$���$#����� �&! �)& �&!"� �� �&*#� ����!%"&���

��#�(#!( +#!!#��,

�!�(%$���� �!�$&����- (�&� ��� �&$&��#!�', ��$'%(&

�&����- �� #'' �#!#"&�&!�

WWW.TI.COM

1

��������

�

� �

� �� �

� ���� ��

��������

SWRS025C − APRIL 2004 − REVISED JULY 2007

The transceiver is designed to be hot plug capable. An on-chip power-on reset circuit holds the Rx_CLK low

during power up. This circuit also places the parallel side output signal terminals, DOUTTxP and DOUTTxN,

into a high-impedance state during power up.

The transceiver uses a 2.5-V supply. The I/O section is 3-V compatible. With the 2.5-V supply, the transceiver

is power efficient, consuming less than 1700 mW typically. The transceiver is characterized for operation from

−40°C to 85°C.

AVAILABLE OPTIONS

PACKAGE

TA

−40°C to 85°C

PLASTIC BALL GRID ARRAY

(PBGA)

SYMBOL

TLK4250IGPV

TLK4250IZPV

ECAT

NOTE: For the most current package and ordering information, see the Package Option

Addendum at the end of this document, or see the TI website at www.ti.com.

2

WWW.TI.COM

��������

�

� �

� �� �

� ���� ��

��������

SWRS025C − APRIL 2004 − REVISED JULY 2007

17

A

B

TDB1

TDB0

C

D

E

DOUTTB

DOUTTB

PREEMP

P

N

HB

F

G

H

J

K

DINRBP

DINRBN

RDB0

GND

TDC0

L

M

N

DOUTTC

DOUTTC

PREEMP

P

N

HC

P

R

T

U

DINRCP

DINRCN

RDC0

RDC1

17

16

TDB4

TDB2

GNDA

GNDA

VDDAB

GNDA

GNDA

RDB1

VDD

TDC1

GNDA

GNDA

VDDAC

GNDA

GNDA

RDC2

RDC4

16

15

TDB5

TDB3

GND

RDB3

VDDAB

RDB2

GND

VDD

GND

VDD

GND

TDC2

VDDAC

VDD

GND

RDC3

RDC5

15

14

TDB7

TDB6

VDD

RB_CLK

RDB7

RDB4

RDB5

RDB6

GND

TDC5

TDC6

TDC7

TDC4

TDC3

GND

RDC6

RDC7

14

13

TDB8

GND

RDB17

RDB13

RDB10

RDB9

RDB8

VDD

TDC9

TDC10

TDC11

TDC14

VDD

RDC8

RC_CLK

13

TDC12

TDC13

TDC16

GND

RDC10

RDC9

12

GND

RDC13

RDC11

11

GTB_

GTC_

CLK

CLK

LOOPEN

12

TDB9

TDB10

VDD

SYNCB

RDB16

RDB14

RDB12

RDB11

VDD

TDC8

C

TESTEN

11

TDB11

TDB13

GND

VDD

LOCKBB

RDB15

GND

GND

GND

GND

GND

TDC15

VDD

C

10

TDB12

GND

LOOPEN

ENABLE

TESTEN

B

B

B

TDB17

GND

VDD

TDB15

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

TDC17

SYNCC

RDC17

RDC14

GND

RDC12

10

LOCKBC

GND

RDC16

RDC15

VDD

9

TDD5

TDD1

TDD0

8

GND

GNDA

ENABLE

9

TDB14

TDB16

GND

C

8

GTD_

RDA0

RDA1

VDD

RDA6

RDA8

RDA11

GND

GND

GND

GND

GND

TDD8

VDD

CLK

DOUTTD

7

DINRAN

GNDA

GND

RDA5

RDA9

RDA12

GND

GND

GND

GND

GND

TDD12

TDD9

TDD6

7

P

6

DINRAP

GNDA

RDA2

RDA4

RDA10

RDA14

PREEMP

VDDAA

5

VDDAA

RDA7

RDA13

ENABLE

A

D

DOUTTD

TDD17

LOCKB

ENABLE

A

A

TDD15

GNDA

RDA3

RA_CLK

RDA17

SYNCA

SYNCD

VDD

TDD2

GNDA

6

TDD16

TDD11

TDD4

VDDAD

5

VDDAD

LOOPEN

RDD17

LOCKBD

TDD14

TDD3

VDD

GNDA

DINRDP

4

VDD

GND

GND

GNDA

DINRDN

3

D

A

DOUTTA

3

TDD7

HD

TDA17

VDD

N

TDD10

N

LOOPEN

DOUTTA

TDD13

PREEMP

GND

RDA16

HA

4

TESTEN

RDA15

TESTEN

GNDA

GND

VDD

GND

VDD

GND

TDA15

RDD16

RDD15

GND

P

D

GTA_

2

TDA0

TDA2

TDA3

TDA6

TDA10

TDA13

GND

TDA16

RDD14

RDD13

RDD10

RDD8

RDD6

RDD3

RDD2

RDD0

2

1

CLK

1

TDA1

TDA4

TDA5

TDA7

TDA8

TDA9

TDA11

TDA12

TDA14

RDD12

RDD11

RDD9

RD_CLK

RDD7

RDD5

RDD4

RDD1

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

U

WWW.TI.COM

3

��������

�

� �

� �� �

� ���� ��

��������

SWRS025C − APRIL 2004 − REVISED JULY 2007

functional block diagram

A detailed block diagram of each channel is shown below. Channels A, B, C, and D are identical and are

configured as four separate links.

LOOPENx

DOUTTxP

18-Bit

Register

TDx[0:17]

DOUTTxN

18

Start/Stop

Encoder

20

Parallel to

Serial

Bit

Clock

PREEMPHx

Multiplying

Clock

Synthesizer

GTx_CLK

Controls:

PLL, Bias,

Rx, Tx

TESTENx

ENABLEx

Bit

Clock

Interpolator and

Clock Recovery

MUX

Recovered

Clock

LOCKBx

RDx[0:17]

18-Bit

Register

Rx_CLK

18

Start/Stop

Decoder

20

Serial to

Parallel

MUX

DINRxP

DINRxN

4

WWW.TI.COM

��������

�

� �

� �� �

� ���� ��

��������

SWRS025C − APRIL 2004 − REVISED JULY 2007

Terminal Functions

TERMINAL

NAME

NO.

DINRAP

DINRAN

A6

A7

DINRBP

DINRBN

F17

G17

DINRCP

DINRCN

P17

R17

DINRDP

DINRDN

U4

U3

DOUTTAP

DOUTTAN

A3

A4

DOUTTBP

DOUTTBN

C17

D17

DOUTTCP

DOUTTCN

L17

M17

DOUTTDP

DOUTTDN

U7

U6

ENABLEA

H5

ENABLEB

E10

ENABLEC

M9

ENABLED

J6

GTA_CLK

E2

GTB_CLK

B13

GTC_CLK

K13

GTD_CLK

P8

SYNCA

F4

SYNCB

D12

SYNCC

N10

SYNCD

K5

LOOPENA

H4

LOOPENB

D10

LOOPENC

P12

LOOPEND

M4

LOCKBA

G5

LOCKBB

E11

LOCKBC

N9

LOCKBD

L4

PREEMPHA

A5

PREEMPHB

E17

PREEMPHC

N17

PREEMPHD

U5

TYPE

Input

DESCRIPTION

Serial receive inputs. DINRxP and DINRxN together are the differential serial

inputs that interface from a copper or an optical I/F module.

Output

(high-z

power up)

Serial transmit outputs. DOUTTxP and DOUTTxN are differential serial outputs

that interface to copper or an optical I/F module. These terminals transmit NRZ

data at a rate of 20 times the GTx_CLK value. DOUTTxP and DOUTTxN are

put in a high-impedance state when LOOPENx is high and are active when

LOOPENx is low. During power-on reset these terminals are high impedance.

Input

(w/pullup)

Device enable. When this terminal is held low, the device is placed in

power-down mode. When asserted high while the device is in power-down

mode, the transceiver goes into power-on reset before beginning normal

operation.

Input

Reference clock. GTx_CLK is a continuous external input clock that

synchronizes the transmitter interface TDx. The frequency range of GTx_CLK

is 50 MHz to 125 MHz.

The transmitter uses the rising edge of this clock to register the 18-bit input

data (TDx) for serialization.

Input

(w/pulldown)

Fast synchronization. When asserted high, the transmitter substitutes the

18-bit pattern 111111111000000000 so that when the start/stop bits are framed

around the data, the receiver can immediately detect the proper deserialization

boundary. This is typically used during initialization of the serial link.

Input

(w/pulldown)

Loop enable. When LOOPENx is active high, the internal loop-back path is

activated. The transmitted serial data is directly routed internally to the inputs

of the receiver. This provides a self-test capability with the protocol device. The

DOUTTxP and DOUTTxN outputs are held in a high-impedance state during

the loop-back test. LOOPENx is held low during standard operational state

with external serial outputs and inputs active.

Output

Receiver lock. When this signal is asserted low, it indicates that the receiver

has acquired bit synchronization on the data stream and has located the

start/stop bits so that the deserialized data presented on the parallel receive

bus is properly received.

Input

Preemphasis. When asserted, the serial transmit outputs have extra output

swings on the first bit of any run length of save value bits. If the run length of

output bits is one, then that bit has larger output swings.

WWW.TI.COM

5

��������

�

� �

� �� �

� ���� ��

��������

SWRS025C − APRIL 2004 − REVISED JULY 2007

Terminal Functions (Continued)

TERMINAL

NAME

NO.

RDA[0:17]

A8, B8, C6, C4, D6, D7, D8,

D5, E8, E7, E6, F8, F7, E5,

F6, G6, F5, E4

RDB[0:17]

H17, H16, F15, D15, F14,

G14, H14, E14, H13, G13,

F13, H12, G12, E13, F12,

F11, E12, D13

RDC[0:17]

T17, U17, T16, T15, U16,

U15, T14, U14, T13, U12,

T12, U11, U10, T11, R10,

T9, R9, P10

RDD[0:17]

U2, U1, T2, R2, T1, R1, P2,

P1, N2, M1, M2, L1, K1, L2,

K2, K3, J3, K4

RA_CLK

D4

RB_CLK

D14

RC_CLK

U13

RD_CLK

N1

TDA[0:17]

A2, A1, B2, C2, B1, C1, D2,

D1, E1, F1, F2, G1, H1, G2,

J1, H3, J2, J4

TDB[0:17]

B17, A17, B16, B15, A16,

A15, B14, A14, A13, A12,

B12, A11, A10, B11, A9,

C10, B9, D9

TDC[0:17]

K17, K16, M15, P14, N14,

K14, L14, M14, K12, L13,

M13, N13, L12, M12, P13,

M11, N12, M10

TDD[0:17]

U8, T8, R6, P4, P5, R8, P7,

P6, M8, N7, N6, N5, M7, M6,

N4, L6, M5, K6

TESTENA

H6

TESTENB

F10

TESTENC

P11

TESTEND

M3

TYPE

DESCRIPTION

Output (hi-z

on power up)

Receive data bus. These outputs carry 18-bit parallel data output from the

transceiver to the protocol device, synchronized to Rx_CLK. The data is

valid on the rising edge of Rx_CLK as shown in Figure 7. These terminals

are high-impedance during power-on reset.

Output (low

on power up)

Recovered clock. Output clock that is synchronized to RDx. Rx_CLK is the

recovered serial data rate clock divided by 20. Rx_CLK is held low during

power-on reset.

Input

Transmit data bus. These inputs carry the 18-bit parallel data output from a

protocol device to the transceiver for encoding, serialization, and

transmission. This 18-bit parallel data is clocked into the transceiver on the

rising edge of GTx_CLK as shown in Figure 6.

Input

(w/pulldown)

Test mode enable. This terminal must be left unconnected or tied low.

POWER

VDD

VDDAA

6

C8, C12, C14, D3, D11, F3,

F9, G4, H15, J12, J13, J16,

K15, L5, N3, N8, N11, P15,

R4, R13, U9

Supply

Digital logic power. Provides power for all digital circuitry and digital I/O

buffers.

Supply

Analog power. VDDAx provides a supply reference for the high-speed

receiver and transmitter analog circuits.

B5, C5

VDDAB

E15, E16

VDDAC

N15, N16

VDDAD

R5, T5

WWW.TI.COM

��������

�

� �

� �� �

� ���� ��

��������

SWRS025C − APRIL 2004 − REVISED JULY 2007

Terminal Functions (Continued)

TERMINAL

NAME

TYPE

NO.

DESCRIPTION

GROUND

GNDA

GND

B3, B4, B6, B7, C16, D16,

F16, G16, L16, M16, P16,

R16, T3, T4, T6, T7

Ground

Analog ground. GNDA provides a ground reference for the high-speed

receiver and transmitter analog circuits.

B10, C3, C7, C9, C11, C13,

C15, E3, E9, G3, G7, G8,

G9, G10, G11, G15, H2, H7,

H8, H9, H10, H11, J5, J7, J8,

J9, J10, J11, J14, J15, J17,

K7, K8, K9, K10, K11, L3, L7,

L8, L9, L10, L11, L15, P3,

P9, R3, R7, R11, R12, R14,

R15, T10

Ground

Digital logic ground. Provides a ground for the logic circuits and digital I/O

buffers.

transmit interface

The transmitter portion registers valid incoming 18-bit-wide data (TDx[0:17]) on the rising edge of GTx_CLK.

The data is then framed with start and stop bits, serialized, and transmitted sequentially over the differential

high-speed I/O channel. The clock multiplier multiplies the reference clock (GTx_CLK) by a factor of 10, creating

a bit clock. This internal bit clock is fed to the parallel-to-serial shift register, which transmits data on both the

rising and falling edges of the bit clock providing a serial data rate that is 20 times the reference clock. Data is

transmitted LSB (TDx0) first.

transmit data bus

The transmit bus interface accepts 18-bit-wide, single-ended, TTL parallel data at the TDx[0:17] terminals. Data

is valid on the rising edge of GTx_CLK. The GTx_CLK is used as the word clock. The data and clock signals

must be properly aligned as shown in Figure 1. Detailed timing information can be found in the TTL input

electrical characteristics table.

GTx_CLK

TDXn

tsu

th

Figure 1. Transmit Timing Waveform

transmission latency

The data transmission latency of the transceiver is defined as the delay from the initial 18-bit word on the parallel

transmit interface to the serial transmission of the start bit of the 20-bit frame containing the 18-bit word. The

transmit latency is fixed once the link is established. However, due to silicon process variations and

implementation variables, such as supply voltage and temperature, the exact delay varies slightly. Figure 2

illustrates the timing relationship between the transmit data bus, GTx_CLK, and the serial transmit terminals.

WWW.TI.COM

7

��������

�

� �

� �� �

� ���� ��

��������

SWRS025C − APRIL 2004 − REVISED JULY 2007

Transmitted 20-Bit Frame

DOUTTxP,

DOUTTxN

td(Tx latency)

TDx[0:17]

18-Bit Word to Transmit

GTx_CLK

Figure 2. Transmitter Latency

start/stop framing logic

All true serial interfaces require a method of encoding to ensure minimum transition density so that the receiving

PLL has a minimal number of transitions in which to stay locked onto the data stream. The signal encoding also

provides a mechanism for the receiver to identify the word boundary for correct deserialization. The TLK4250

transceiver wraps a start bit (1) and a stop bit (0) around the 18-bit data payload as shown in Figure 3. This is

transparent to the user, as the transceiver internally adds the framing bits to the data such that the user reads

and writes actual 18-bit data.

20-Bit Frame

18-Bit Word

Stop

Bit

Start

Bit

TDx0

TDx1

...

TDx16

TDx17

Stop

Bit

Start

Bit

Figure 3. Serial Output Data Stream With Start and Stop Bit

parallel-to-serial

The parallel-to-serial shift register takes in the 20-bit-wide frame multiplexed from the framing logic and converts

it to a serial stream. The shift register is clocked on both the rising and falling edges of the internally generated

bit clock, which is 10 times the GTx_CLK input frequency. The LSB (TDx0) is first out after the start bit as shown

in Figure 3.

high-speed data output

The high-speed data output driver consists of a PECL-compatible differential pair that can be optimized for a

particular transmission line impedance and length. The line can be directly coupled or ac coupled. See Figure 10

and Figure 11 for termination details. No external pullup or pulldown resistors are required.

The transceiver provides a selectable signal preemphasis option for driving lossy media. When signal

preemphasis is enabled, the first bit of a run length of same-value bits (e.g., 111...) is driven to a larger output

swing, which precompensates for signal inter-symbol interference (ISI) in lossy media, such as copper cables

or printed circuit board traces.

8

WWW.TI.COM

��������

�

� �

� �� �

� ���� ��

��������

SWRS025C − APRIL 2004 − REVISED JULY 2007

receive interface

The receiver portion of the TLK4250 accepts 20-bit framed differential serial data. The interpolator and clock

recovery circuit locks to the data stream and extracts the bit rate clock. This recovered clock retimes the input

data stream. The serial data is then aligned to the 20-bit frame by finding the start and stop bits and the 18-bit

data is output on a 18-bit wide parallel bus synchronized to the extracted receive clock (Rx_CLK).

receive data bus

The receive bus interface drives 18-bit-wide, single-ended, TTL parallel data at the RDx[0:17] terminals. Data

is valid on the rising edge of Rx_CLK. The Rx_CLK is used as the recovered word clock. The data and clock

signals are aligned as shown in Figure 4. Detailed timing information can be found in the TTL output switching

characteristics table.

Rx_CLK

RDx[0:17]

tsu

th

Figure 4. Receive Timing Waveform

data reception latency

The serial-to-parallel data receive latency is the time from when the start bit arrives at the receiver until the output

of the aligned parallel word. The receive latency is fixed once the link is established. However, due to silicon

process variations and implementation variables, such as supply voltage and temperature, the exact delay

varies slightly. Figure 5 illustrates the timing relationship between the serial receive terminals, the recovered

word clock (Rx_CLK), and the receive data bus.

20-Bit Encoded Frame

DINTxP,

DINTxN

R(latency)

RDx[0:17]

18-Bit Decoded Word

Rx_CLK

Figure 5. Receiver Latency

serial-to-parallel

Serial data is received on the DINRxP and DINRxN terminals. The interpolator and clock recovery circuit locks

to the data stream if the clock to be recovered is within ±100 PPM of the internally generated bit rate clock. The

recovered clock retimes the input data stream. The serial data is then clocked into the serial-to-parallel shift

registers.

WWW.TI.COM

9

��������

�

� �

� �� �

� ���� ��

��������

SWRS025C − APRIL 2004 − REVISED JULY 2007

synchronization mode

The deserializer must synchronize to the serializer in order to receive valid data. Synchronization can be

accomplished in one of two ways.

rapid synchronization

The serializer has the capability to send specific SYNC patterns consisting of 9 ones and 9 zeros, switching at

the input clock rate. The transmission of SYNC patterns enables the deserializer to lock to the serializer signal

within a deterministic time frame. The transmission of SYNC patterns is selected via the SYNC input on the

serializer. On receiving a valid SYNC pulse (wider than 6 clock cycles), 1026 cycles of SYNC pattern are sent.

When the deserializer detects edge transitions at the serial input, it attempts to lock to the embedded clock

information. The deserializer LOCKBx output remains inactive while its clock/data recovery (CDR) locks to the

incoming data or SYNC patterns present on the serial input. When the deserializer locks to the serial data, the

LOCKBx output goes active. When LOCKBx is active, the deserializer outputs represent incoming serial data.

One approach is to tie the deserializer LOCKBx output directly to the SYNCx input of the transmitter. This

ensures that enough SYNC patterns are sent to achieve deserializer lock.

random lock synchronization

The deserializer can attain lock to a data stream without requiring the serializer to send special SYNC patterns.

This allows the transceiver to operate in open-loop applications. Equally important is the deserializer’s ability

to support hot insertion into a running backplane. In the open-loop or hot-insertion case, it is assumed the data

stream is essentially random. Therefore, because lock time varies due to data stream characteristics, the exact

lock time cannot be predicted. The primary constraint on the random lock time is the initial phase relation

between the incoming data and the GTx_CLK when the deserializer powers up.

The data contained in the data stream can also affect lock time. If a specific pattern is repetitive, the deserializer

could enter false lock—falsely recognizing the data pattern as the start/stop bits. This is referred to as repetitive

multitransition (RMT). This occurs when more than one low-high transition takes place per clock cycle over

multiple clock cycles. In the worst case, the deserializer could become locked to the data pattern rather than

the clock. Circuitry within the deserializer can detect that the possibility of false lock exists. On detection, the

circuitry prevents the LOCKBx from becoming active until the potential false-lock pattern changes. Notice that

the RMT pattern only affects the deserializer lock time, and once the deserializer is in lock, the RMT pattern does

not affect the deserializer state as long as the same data boundary happens each cycle. The deserializer does

not go into lock until it finds a unique data boundary that consists of four consecutive cycles of data boundary

(start/stop bits) at the same position.

The deserializer stays in lock until it cannot detect the same data boundary (start/stop bits) for four consecutive

cycles. Then the deserializer goes out of lock and hunts for the new data boundary (start/stop bits). In the event

of loss of synchronization, the LOCKBx terminal output goes inactive and the outputs (including Rx_CLK) enter

a high-impedance state. The user’s system must monitor the LOCKBx terminal in order to detect a loss of

synchronization. On detection of loss of lock, sending SYNC patterns for resynchronization is desirable if

reestablishing lock within a specific time is critical. However, the deserializer can lock to random data as

previously noted. LOCKBx is held inactive for at least nine cycles after loss of lock is detected.

recommended power-up sequence

When powering up the device, it is recommended to first set the ENABLEx terminal low. Set the ENABLEx

terminal to high once sufficient time has passed to allow the power supply to stabilize.

power-down mode

When the ENABLEx terminal is deasserted low, the transceiver goes into a power-down mode. In the

power-down mode, the serial transmit terminals (DOUTTxP, DOUTTxN) and the receive data bus terminals

(RDx[0:17]) go into a high-impedance state.

10

WWW.TI.COM

��������

�

� �

� �� �

� ���� ��

��������

SWRS025C − APRIL 2004 − REVISED JULY 2007

reference clock input

The reference clock (GTx_CLK) is an external input clock that synchronizes the transmitter interface. The

reference clock is then multiplied in frequency 10 times to produce the internal serialization bit clock. The internal

serialization bit clock is frequency locked to the reference clock and clocks out the serial transmit data on both

its rising and falling edges, providing a serial data rate that is 20 times the reference clock.

The receiver tracking logic uses clock phases from the internal PLL as it aligns the recovered clock phase with

the incoming serial data stream; therefore, the input reference clock (GTX_CLK) is needed even if the transmit

function of the TLK4250 is not being used. The receiver function has the ability to track an incoming serial data

stream that is within ±200 ppm of the data rate that is set by GTX_CLK. This allows the use of clock sources

with ±100 ppm frequency tolerance.

operating frequency range

The transceiver may operate at a serial data rate between 1.0 Gbps to 2.5 Gbps. GTx_CLK must be within

±100 PPM of the desired parallel data rate clock. Each individual channel may operate at a different rate.

testability

The transceiver has a comprehensive suite of built-in self-tests. The loopback function provides for at-speed

testing of the transmit/receive portions of the circuitry. The ENABLEx terminal allows for all circuitry to be

disabled so that a quiescent current test can be performed.

loop-back testing

The transceiver can provide a self-test function by enabling (LOOPENx) the internal loop-back path. Enabling

this terminal causes serial transmitted data to be routed internally to the receiver. The parallel data output can

be compared to the parallel input data for functional verification. (The external differential output is held in a

high-impedance state during the loop-back testing.)

power-on reset

On application of minimum valid power, the transceiver generates a power-on reset. During the power-on reset,

the RDx terminals are 3-stated and Rx_CLK is held low. The length of the power-on reset cycle depends on the

GTx_CLK frequency, but is less than 1 ms in duration.

WWW.TI.COM

11

��������

�

� �

� �� �

� ���� ��

��������

SWRS025C − APRIL 2004 − REVISED JULY 2007

absolute maximum ratings over operating free-air temperature (unless otherwise noted)†

Supply voltage, VDD (see Note 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . −0.3 V to 3 V

Voltage range at TDx, ENABLEx, GTx_CLK, LOOPENx, SYNCx, PREEMPHx . . . . . . . . . . . . . . . . −0.3 V to 4 V

Voltage range at any other terminal except above . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . −0.3 V to VDD + 0.3 V

Package power dissipation, PD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Dissipation Rating Table

Storage temperature, Tstg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . −65°C to 150°C

Electrostatic discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HBM: 2 kV

Characterized free-air operating temperature range, TA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . −40°C to 85°C

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260°C

† Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: All voltage values, except differential I/O bus voltages, are with respect to network ground.

Air Flow

0 m/s

0.5 m/s

1 m/s

2.5 m/s

TJA (C/W)

18.4

16.92

15.95

14.7

electrical characteristics over recommended operating conditions

PARAMETER

VDD

TA

ICC

PD

TEST CONDITION

Supply voltage

Operating free-air temperature

Supply current

MIN

TYP

MAX

2.3

2.5

2.7

V

85

°C

−40

VDD = 2.5 V, Rate = 1 Gbps, PRBS pattern

VDD = 2.5 V, Rate = 2.5 Gbps, PRBS pattern

UNIT

285

mA

680

Power dissipation

VDD = 2.5 V, Rate = 1 Gbps, PRBS pattern

VDD = 2.5 V, Rate = 2.5 Gbps, PRBS pattern

715

Shutdown current

VDD = 2.7 V, Rate = 2.5 Gbps, worst case pattern†

ENABLEx = 0, VDDA, VDD terminals, VDD = maximum

PLL start-up lock time

VDD, VDDA = 2.3 V, EN ↑ to PLL acquire

1700

mW

2920

µA

520

0.1

Data acquisition time

† Worst case pattern is a pattern that creates a maximum transition density on the serial transceiver.

0.4

1024

ms

bits

reference clock (GTx_CLK) timing requirements over recommended operating conditions (unless

otherwise noted)

PARAMETER

Rω

Frequency

TEST CONDITIONS

TYP

MAX

TYP−0.01%

50

TYP+0.01%

Maximum data rate

TYP−0.01%

125

TYP+0.01%

50%

60%

Frequency tolerance

−100

Duty cycle

40%

Jitter

12

MIN

Minimum data rate

Peak-to-peak

WWW.TI.COM

100

40

UNIT

MHz

ppm

ps

��������

�

� �

� �� �

� ���� ��

��������

SWRS025C − APRIL 2004 − REVISED JULY 2007

TTL input electrical characteristics over recommended operating conditions (unless otherwise

noted)

TTL Signals: TDx0 ... TDx17, GTx_CLK, LOOPENx, SYNCx, PREEMPHx

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

2

UNIT

VIH

VIL

High-level input voltage

See Figure 6

Low-level input voltage

See Figure 6

3.6

V

0.8

V

IIH

IIL

High-level input current

Low-level input current

VDD = Max, VIN = 2 V

VDD = Max, VIN = 0.4 V

40

µA

CIN

Input capacitance

0.8 V to 2 V

tr

tf

GTx_CLK, TDx rise time

0.8 V to 2 V, C = 5 pF, see Figure 6

1

ns

GTx_CLK, TDx fall time

2 V to 0.8 V, C = 5 pF, see Figure 6

1

ns

tsu

th

TDx setup to ↑ GTx_CLK

See Figure 6

1.5

ns

TDx hold to ↑ GTx_CLK

See Figure 6

0.4

ns

µA

−40

4

pF

3.6 V

2V

GTx_CLK

0.8 V

0V

tr

tf

3.6 V

2V

TDx[0:17]

0.8 V

0V

tsu

tf

tr

th

Figure 6. TTL Data Input Valid Levels for AC Measurements

WWW.TI.COM

13

��������

�

� �

� �� �

� ���� ��

��������

SWRS025C − APRIL 2004 − REVISED JULY 2007

TTL output switching characteristics over recommended operating conditions (unless otherwise

noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

2.1

2.3

GND

0.25

MAX

UNIT

VOH

VOL

High-level output voltage

Low-level output voltage

IOH= −1 mA, VDD = minimum

IOL= 1 mA, VDD = minimum

tr(slew)

tf(slew)

Magnitude of Rx_CLK, RDx slew rate (rising)

0.8 V to 2 V, C = 5 pF, see Figure 7

0.5

V/ns

Magnitude of Rx_CLK, RDx slew rate (falling)

0.8 V to 2 V, C = 5 pF, see Figure 7

0.5

V/ns

tsu

th

RDx setup to ↑ Rx_CLK

RDx hold to ↑ Rx_CLK

V

0.5

V

50% voltage swing, GTx_CLK = 50 MHz,

see Figure 7

8

ns

50% voltage swing, GTx_CLK = 125 MHz,

see Figure 7

3

ns

50% voltage swing, GTx_CLK = 50 MHz,

see Figure 7

8

ns

50% voltage swing, GTx_CLK = 125 MHz,

see Figure 7

3

ns

2V

Rx_CLK

0.8 V

0V

tr(slew)

tf(slew)

2V

RDx[0:17]

0.8 V

0V

tr(slew)

tsu

tf(slew)

th

Figure 7. TTL Data Output Valid Levels for AC Measurements

14

WWW.TI.COM

��������

�

� �

� �� �

� ���� ��

��������

SWRS025C − APRIL 2004 − REVISED JULY 2007

transmitter/receiver characteristics

PARAMETER

TEST CONDITION

MIN

TYP

MAX

UNIT

DC-coupled. Preemphasis = high, see Figure 8

750

1000

1375

DC-coupled. Preemphasis = low, see Figure 8

650

950

1300

DC-coupled. Preemphasis = high, see Figure 8

1500

2000

2750

DC-coupled. Preemphasis = low, see Figure 8

1000

1500

2600

DC-coupled. See Figure 8

500

750

1100

mV

DC-coupled. See Figure 8

1000

1500

2200

mV

1000

1250

1400

mV

VOD(p)

VOD(p) = |VTXP − VTXN|,

Preemphasis VOD

VOD(pp−p)

Differential, peakĆto-peak output

voltage with preemphasis

VOD(d)

VD(d) = |VTXP − VTXN|,

De-emphasis VOD

VOD(pp−d)

Differential, peak-to-peak output

voltage with deemphasis

V(cmt)

Transmit termination voltage range,

(VTXP + VTXN)/2

VID

Receiver input voltage differential

VID= |RXP – RXN|

200

Vcmr

Receiver common-mode voltage

range, (VRXP + VRXN)/2

1000

VDD−350

mV

−10

10

µA

2

pF

Iin

Cin

tr, tf

Receiver input leakage

RL = 50 Ω, CL = 5 pF, see Figure 9

Serial transmit data total jitter

(peak-to-peak)

Differential output jitter, random + deterministic,

223 − 1 PRBS pattern at 2.5 Gbps

Receive jitter tolerance

Total input jitter, PRBS pattern, permitted eye

closure at zero crossing

100

150

ps

0.15

UI

0.5

UI

At 1.0 Gbps

Tlatency

TX latency

Rlatency

RX latency

mV

mV

Receiver input capacitance

Differential output signal rise and

fall time (20% to 80%)

mV

Bit

times

At 2.5 Gbps

At 1.0 Gbps

Bit

times

At 2.5 Gbps

VOD(p)

VOD(d)

VOD(pp-d)

V(cmt)

VOD(pp-p)

tf

tr

VOD(d)

Bit

Time

Bit

Time

VOD(p)

Figure 8. Differential and Common-Mode Output Voltage Definitions

WWW.TI.COM

15

��������

�

� �

� �� �

� ���� ��

��������

SWRS025C − APRIL 2004 − REVISED JULY 2007

80%

DOUTTxP

50%

20%

tr

tf

80%

50%

20%

DOUTTxN

tf

tr

+V

80%

V(cmt)

DOUTTxP−DOUTTxN

20%

−V

tr

tf

Figure 9. Rise and Fall Time Definitions

TXP

RXP

VDD

ZO

ZO

5 kΩ

ZO

7.5 kΩ

ZO

TXN

Transmitter

+

_

GND

RXN

Media

Receiver

Figure 10. High-Speed I/O Directly Coupled Mode

TXP

RXP

VDD

ZO

ZO

5 kΩ

ZO

7.5 kΩ

ZO

TXN

Transmitter

GND

RXN

Media

Receiver

Figure 11. High-Speed I/O AC-Coupled Mode

16

WWW.TI.COM

+

_

��������

�

� �

� �� �

� ���� ��

��������

SWRS025C − APRIL 2004 − REVISED JULY 2007

AC-coupling is only recommended if the parallel TX data stream is encoded to achieve a dc-balanced data

stream. Otherwise, the ac capacitors can induce common-mode voltage drift due to the dc-unbalanced data

stream.

WWW.TI.COM

17

�PACKAGE OPTION ADDENDUM

www.ti.com

5-Jun-2016

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

Lead/Ball Finish

MSL Peak Temp

(2)

(6)

(3)

TLK4250GPV

PREVIEW

BGA

GPV

289

TBD

Call TI

Call TI

TLK4250IGPV

OBSOLETE

BGA

GPV

289

TBD

Call TI

Call TI

TLK4250IZPV

LIFEBUY

BGA

ZPV

289

TBD

Call TI

Call TI

Op Temp (°C)

Device Marking

(4/5)

-40 to 85

TLK4250I

-40 to 85

TLK4250I

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

(6)

Lead/Ball Finish - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead/Ball Finish values may wrap to two lines if the finish

value exceeds the maximum column width.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

Addendum-Page 1

Samples

�PACKAGE OPTION ADDENDUM

www.ti.com

5-Jun-2016

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

Addendum-Page 2

�MECHANICAL DATA

MPBG233 – FEBRUARY 2002

GPV (S–PBGA–N289)

PLASTIC BALL GRID ARRAY

19,20

SQ

18,80

16,00 TYP

1,00

U

T

R

P

1,00

N

M

L

K

J

H

G

F

E

D

A1 Corner

C

B

A

3

1

2

5

4

7

6

9

8

11

10

13

12

15

14

17

16

Bottom View

2,00 MAX

Seating Plane

0,60

0,40

0,10

0,50

0,30

0,15

4204203/A 02/2002

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

POST OFFICE BOX 655303

• DALLAS, TEXAS 75265

1

��IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products

Applications

Audio

www.ti.com/audio

Automotive and Transportation

www.ti.com/automotive

Amplifiers

amplifier.ti.com

Communications and Telecom

www.ti.com/communications

Data Converters

dataconverter.ti.com

Computers and Peripherals

www.ti.com/computers

DLP® Products

www.dlp.com

Consumer Electronics

www.ti.com/consumer-apps

DSP

dsp.ti.com

Energy and Lighting

www.ti.com/energy

Clocks and Timers

www.ti.com/clocks

Industrial

www.ti.com/industrial

Interface

interface.ti.com

Medical

www.ti.com/medical

Logic

logic.ti.com

Security

www.ti.com/security

Power Mgmt

power.ti.com

Space, Avionics and Defense

www.ti.com/space-avionics-defense

Microcontrollers

microcontroller.ti.com

Video and Imaging

www.ti.com/video

RFID

www.ti-rfid.com

OMAP Applications Processors

www.ti.com/omap

TI E2E Community

e2e.ti.com

Wireless Connectivity

www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2016, Texas Instruments Incorporated

�