Product

Folder

Order

Now

Support &

Community

Tools &

Software

Technical

Documents

TLV755P

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

TLV755P 500mA、

、低 IQ、小型低压降稳压器

1 特性

•

•

•

1

•

•

•

•

•

•

•

3 说明

输入电压范围:1.45V 至 5.5V

低 IQ:25µA(典型值)

低压降:

– 在 500mA 下为 238mV(最大值)(VOUT 为

3.3V)

输出精度:1%(85°C 时达到最大)

内置软启动功能,具有单调 VOUT上升

折返电流限制

有源输出放电

高 PSRR:100kHz 时为 46dB

与 1µF 陶瓷输出电容器搭配使用时可保持稳定

封装:

– 2.9mm × 1.6mm SOT-23-5

– 1mm x 1mm X2SON-4

– 2mm × 2mm WSON-6

2 应用

•

•

•

•

•

•

•

机顶盒、电视和游戏机

便携式和电池供电类设备

台式机、笔记本和超级本

平板电脑和遥控器

白色家电和电器

电网基础设施和保护继电器

摄像头模块和图像传感器

TLV755P 是一款超小型低静态电流、低压差稳压器

(LDO),可提供 500mA 拉电流,具有良好的线路和负

载瞬态性能。TLV755P 经过优化,支持 1.45V 至

5.5V 的输入电压 范围, 因此适用于各种应用。为最大

程度地降低成本和解决方案尺寸,该器件可在 0.6V 至

5V 范围内提供固定输出电压,以支持现代微控制器

(MCU) 更低的内核电压。此外,TLV755P 具备带有使

能功能的低 IQ,从而可将待机功耗降至最低。该器件

具有 内部软启动功能,旨在降低浪涌电流,因此可为

负载提供受控电压并在启动过程中最大程度地降低输入

电压压降。关断时,该器件可主动降低输出以快速释放

输出并确保已知的启动状态。

TLV755P 在与支持小尺寸总体解决方案的小型陶瓷输

出电容器搭配使用时,可保持稳定。高精度带隙与误差

放大器支持 1% 的典型精度。所有器件版本均具有集

成的热关断保护、电流限制和低压锁定 (UVLO) 功能。

TLV755P 具有内部折返电流限制,有助于在发生短路

时减少热耗散。

器件信息(1)

器件型号

封装

TLV755P

封装尺寸(标称值)

X2SON (4)

1.00mm x 1.00mm

SOT-23 (5)

2.90mm × 1.60mm

SON (6)

2.00mm × 2.00mm

(1) 如需了解所有可用封装,请参阅数据表末尾的可订购产品附

录。

典型应用

启动波形

7

EN

ON

OFF

GND

VIN

VEN

IOUT

6

150

5

125

4

100

3

75

2

50

1

25

COUT

0

Output Current (mA)

TLV755P

CIN

175

VOUT

OUT

Voltage (V)

IN

0

0

0.2

0.4

0.6

0.8

1

1.2

Time (ms)

1.4

1.6

1.8

2

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

English Data Sheet: SBVS320

�TLV755P

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

www.ti.com.cn

目录

1

2

3

4

5

6

7

特性 ..........................................................................

应用 ..........................................................................

说明 ..........................................................................

修订历史记录 ...........................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

4

6.1

6.2

6.3

6.4

6.5

6.6

4

4

4

4

5

7

Absolute Maximum Ratings ......................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information .................................................

Electrical Characteristics...........................................

Typical Characteristics ..............................................

Detailed Description ............................................ 12

7.1 Overview ................................................................. 12

7.2 Functional Block Diagram ....................................... 12

7.3 Feature Description................................................. 12

7.4 Device Functional Modes........................................ 14

8

Application and Implementation ........................ 15

8.1 Application Information............................................ 15

8.2 Typical Application ................................................. 19

9 Power Supply Recommendations...................... 20

10 Layout................................................................... 21

10.1 Layout Guidelines ................................................. 21

10.2 Layout Examples................................................... 21

11 器件和文档支持 ..................................................... 22

11.1

11.2

11.3

11.4

11.5

11.6

器件支持................................................................

接收文档更新通知 .................................................

社区资源................................................................

商标 .......................................................................

静电放电警告.........................................................

术语表 ...................................................................

22

22

22

22

22

22

12 机械、封装和可订购信息 ....................................... 22

4 修订历史记录

Changes from Original (November 2017) to Revision A

Page

•

已发布至生产 .......................................................................................................................................................................... 1

2

Copyright © 2017–2018, Texas Instruments Incorporated

�TLV755P

www.ti.com.cn

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

5 Pin Configuration and Functions

DQN Package

4-Pin X2SON

Top View

OUT

1

DBV Package

5-Pin SOT-23

Top View

4

IN

5

GND

2

3

IN

1

GND

2

EN

3

EN

Not to scale

5

OUT

4

NC

Not to scale

DRV Package

6-Pin WSON With Exposed Thermal Pad

Top View

OUT

1

NC

GND

6

IN

2 Thermal 5

Pad

NC

3

EN

4

Not to scale

NC = no internal connection.

Pin Functions

PIN

NAME

I/O

DESCRIPTION

DQN

DBV

DRV

EN

3

3

4

I

GND

2

2

3

—

IN

4

1

6

I

NC

—

4

2, 5

—

No internal connection.

OUT

1

5

1

O

Regulated output voltage pin. A capacitor with a value of 1 µF or larger

is required from this pin to ground (1). See the Input and Output

Capacitor Selection section for more information.

Pad

—

Pad

—

Connect the thermal pad to a large-area ground plane.

The thermal pad is internally connected to GND.

Thermal pad

(1)

Enable pin. Drive EN greater than VHI to turn on the regulator.

Drive EN less than VLO to place the LDO into shutdown mode.

Ground pin.

Input pin. A capacitor with a value of 1 µF or larger is required from

this pin to ground (1). See the Input and Output Capacitor Selection

section for more information.

The nominal input and output capacitance must be greater than 0.47 µF; throughout this document the nominal derating on these

capacitors is 50%. Make sure that the effective capacitance at the pin is greater than 0.47 µF.

Copyright © 2017–2018, Texas Instruments Incorporated

3

�TLV755P

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

www.ti.com.cn

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted) (1)

MIN

MAX

UNIT

Supply voltage, VIN

-0.3

6.0

V

Enable voltage, VEN

-0.3

6.0

V

Output voltage, VOUT

-0.3

VIN + 0.3 (2)

V

Operating junction temperature range, TJ

-40

150

°C

Storage temperature, Tstg

-65

150

°C

(1)

(2)

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

The absolute maximum rating is VIN + 0.3 V or 6.0 V, whichever is smaller

6.2 ESD Ratings

VALUE

V(ESD)

(1)

(2)

Electrostatic discharge

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001 (1)

±1000

Charged-device model (CDM), per JEDEC specification JESD22C101 (2)

±500

UNIT

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process. Manufacturing with

less than 500-V HBM is possible with the necessary precautions.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process. Manufacturing with

less than 250-V CDM is possible with the necessary precautions.

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN

VIN

Input voltage

VOUT

VEN

NOM

MAX

UNIT

1.45

5.5

V

Output voltage

0.6

5.0

V

Enable voltage

0

5.5

V

IOUT

Output current

0

500

mA

CIN

Input capacitor

1

COUT

Output capacitor

1

fEN

Enable toggle frequency

TJ

Junction temperature

μF

–40

200

μF

10

kHz

125

°C

6.4 Thermal Information

TLV755

THERMAL METRIC (1)

DQN (X2SON) DBV (SOT-235)

DRV (SON)

4 PINS

5 PINS

6 PINS

UNIT

RθJA

Junction-to-ambient thermal resistance

168.4

231.1

100.2

°C/W

RθJC(top)

Junction-to-case (top) thermal resistance

139.1

118.4

108.5

°C/W

RθJB

Junction-to-board thermal resistance

101.4

64.4

64.3

°C/W

ψJT

Junction-to-top characterization parameter

5.6

28.4

10.4

°C/W

ψJB

Junction-to-board characterization parameter

101.7

63.8

64.8

°C/W

RθJC(bot)

Junction-to-case (bottom) thermal resistance

88.4

N/A

34.7

°C/W

(1)

4

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

Copyright © 2017–2018, Texas Instruments Incorporated

�TLV755P

www.ti.com.cn

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

6.5 Electrical Characteristics

at operating temperature range (TJ = –40°C to 125°C), VIN = VOUT(NOM) + 0.5 V or 2.0 V (whichever is greater), IOUT = 1 mA,

VEN = VIN, and CIN = COUT = 1 μF, unless otherwise noted. All typical values at TJ = 25°C.

PARAMETER

VIN

Input voltage

VOUT

Output voltage

TEST CONDITIONS

-40°C ≤ TJ ≤ +85°C, DBV and DRV package

VOUT ≥ 1.0 V, DQN package

Output accuracy

-40°C ≤ TJ ≤ +85°C; 0.6 V ≤ VOUT < 1.0 V

VOUT ≥ 1 V

0.6 V ≤ VOUT < 1 V

(ΔVOUT)

Line regulation

ΔVIN

VOUT + 0.5 V ≤ VIN ≤ 5.5 V, VOUT > 1.5 V

ΔVOUT/

ΔIOUT

0.1 mA ≤

IOUT ≤ 500

mA

Load regulation

Ground current

-1.2%

1.2%

-10

10

-1.5%

1.5%

-15

15

2

0.044

14

25

40

Short circuit current limit

VOUT = 0 V

IOUT =

500mA,

-40°C ≤ TJ

≤ +85°C

Dropout voltage

IOUT =

500mA,

-40°C ≤ TJ

≤ +125°C

0.1

1

VOUT = VOUT - 0.2 V, VOUT ≤ 1.5V

560

720

865

VOUT = 0.9 x VOUT, 1.5V < VOUT ≤ 4.5V

560

720

865

355

675

1080

0.8 V ≤ VOUT < 1.0V

600

930

1.0 V ≤ VOUT < 1.2 V

550

780

1.2 V ≤ VOUT < 1.5 V

500

630

1.5 V ≤ VOUT < 1.8 V

350

400

1.8 V ≤ VOUT < 2.5 V

325

380

2.5 V ≤ VOUT < 3.3 V

250

300

3.3 V ≤ VOUT < 5.0 V

150

1140

0.8 V ≤ VOUT < 1.0 V

985

1.0 V ≤ VOUT < 1.2 V

825

1.2 V ≤ VOUT < 1.5 V

665

1.5 V ≤ VOUT < 1.8 V

425

1.8 V ≤ VOUT < 2.5 V

400

2.5 V ≤ VOUT < 3.3 V

325

52

f = 100 kHz, VIN = VOUT + 1 V, IOUT = 50 mA

46

f = 1 MHz, VIN = VOUT + 1 V, IOUT = 50 mA

52

BW = 10 Hz to 100 kHz; VOUT = 1.2 V, IOUT = 500

mA

VUVLO

Undervoltage lockout

VIN rising

VUVLO,HY Undervoltage lockout

hysteresis

ST

VIN falling

Startup time

EN pin high voltage (enabled)

Copyright © 2017–2018, Texas Instruments Incorporated

µA

mA

mV

238

f = 1 kHz, VIN = VOUT + 1 V, IOUT = 50 mA

Output noise voltage

VHI

215

0.6 V ≤ VOUT < 0.8 V

VN

µA

mA

0.6 V ≤ VOUT < 0.8 V

3.3 V ≤ VOUT < 5.0 V

tSTR

31

33

ISC

mV

V/A

-40°C ≤ TJ ≤ +125°C, IOUT = 0 mA

Output current limit

mV

mV

-40°C ≤ TJ ≤ +85°C, IOUT = 0 mA

ICL

Power-supply rejection ratio

V

5.0

DRV package

VIN =

VOUT+

VDO(MAX) +

0.25 V

PSRR

V

1%

0.060

UNIT

5.5

0.6

0.036

VEN ≤ 0.4 V, 1.4 V ≤ VIN ≤ 5.5 V, -40°C ≤ TJ ≤

+125°C

VDO

MAX

-1%

DBV package

Shutdown current

ISHDN

TYP

DQN package

TJ = 25°C, IOUT = 0 mA

IGND

MIN

1.45

dB

71.5

1.21

1

1.3

µVRMS

1.44

V

40

mV

550

µs

V

5

�TLV755P

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

www.ti.com.cn

Electrical Characteristics (continued)

at operating temperature range (TJ = –40°C to 125°C), VIN = VOUT(NOM) + 0.5 V or 2.0 V (whichever is greater), IOUT = 1 mA,

VEN = VIN, and CIN = COUT = 1 μF, unless otherwise noted. All typical values at TJ = 25°C.

PARAMETER

VLO

EN pin low voltage (enabled)

IEN

Enable pin current

TSD

Thermal shutdown

RPULLDO

Pulldown resistance

WN

6

TEST CONDITIONS

MIN

TYP

MAX

0.3

EN = 5.5V

10

Shutdown, temperature increasing

165

Reset, temperature decreasing

155

VIN = 5.5V

120

UNIT

V

nA

°C

Ω

版权 © 2017–2018, Texas Instruments Incorporated

�TLV755P

www.ti.com.cn

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

6.6 Typical Characteristics

at operating temperature TJ = 25°C, VIN = VOUT(NOM) + 0.5 V or 1.45 V (whichever is greater), IOUT = 1 mA, VEN = VIN, and CIN

= COUT = 1 µF (unless otherwise noted)

100

Power Supply Rejection Ratio (dB)

Power Supply Rejection Ratio (dB)

100

80

60

40

20

0

10

IOUT = 10 mA

IOUT = 50 mA

IOUT = 100 mA

IOUT = 500 mA

100

1k

10k

100k

Frequency (Hz)

1M

80

60

40

VIN

3.8 V

4V

4.3 V

4.5 V

5V

20

0

10

10M

100

VIN = 4.3 V, VOUT = 3.3 V, COUT = 1 µF

图 1. PSRR vs Frequency and IOUT

Noise (PV/—Hz)

Power Supply Rejection Ratio (dB)

40

2

1

0.5

COUT = 1 PF

COUT = 10 PF

COUT = 22 PF

COUT = 100 PF

100

1k

10k

100k

Frequency (Hz)

1M

10M

0.2

0.1

0.05

0.02

0.01

0.005

0.002

0.001

10

VIN = 4.3 V, VOUT = 3.3 V, IOUT = 500 mA

100

1k

10k

100k

Frequency (Hz)

1M

10M

图 4. Output Spectral Noise Density vs

Frequency and COUT

10

5

220

200

2

1

0.5

Output Noise Voltage (PVRMS)

Noise (PV/—Hz)

COUT

1 PF, 143 PVRMS

10 PF, 150 PVRMS

22 PF, 149 PVRMS

100 PF, 146 PVRMS

VOUT = 3.3 V, VRMS BW = 10 Hz to 100 kHz

图 3. PSRR vs Frequency and COUT

0.2

0.1

0.05

0.002

0.001

10

10M

图 2. PSRR vs Frequency and VIN

60

0.02

0.01

0.005

1M

10

5

80

0

10

10k

100k

Frequency (Hz)

VOUT = 3.3 V, COUT = 1 µF, IOUT = 500 mA

100

20

1k

IOUT

10 mA, 140 PVRMS

50 mA, 142 PVRMS

100 mA, 142 PVRMS

500 mA, 143 PVRMS

100

1k

10k

100k

Frequency (Hz)

160

140

120

100

80

60

1M

10M

VOUT = 3.3 V, IOUT = 500 mA, COUT = 1 µF, VRMS BW = 10 Hz to

100 kHz

图 5. Output Spectral Noise Density vs

Frequency and IOUT

版权 © 2017–2018, Texas Instruments Incorporated

180

40

0.5

1

1.5

2

2.5

3

3.5

Output Voltage (V)

4

4.5

5

IOUT = 500 mA, COUT = 1 µF, VRMS BW = 10 Hz to 100 kHz

图 6. Output Noise Voltage vs VOUT

7

�TLV755P

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

www.ti.com.cn

Typical Characteristics (接

接下页)

at operating temperature TJ = 25°C, VIN = VOUT(NOM) + 0.5 V or 1.45 V (whichever is greater), IOUT = 1 mA, VEN = VIN, and CIN

= COUT = 1 µF (unless otherwise noted)

3.328

VIN

VOUT

3.312

3

3.304

2

3.296

1

3.288

0

0

20

Time (ms)

3.35

480

3.325

400

3.3

320

3.275

240

3.25

160

3.225

80

0

0

VOUT = 3.3 V, COUT = 1 µF, VIN slew rate = 1 V/µs

40

图 7. Line Transient

图 8. 3.3-V, 1-mA to 500-mA Load Transient

6

VIN

VOUT

5

VIN

VOUT

5

4

4

Voltage (V)

Voltage (V)

80 120 160 200 240 280 320 360 400 440 480

Time (Ps)

VIN = 5 V, VOUT = 3.3 V, COUT = 1 µF, IOUT slew rate = 1 A/µs

6

3

3

2

2

1

1

0

0

0

0.5

1

1.5

2

2.5

3

Time (ms)

3.5

4

4.5

5

0

1

2

图 9. VIN = VEN Power-Up

175

10

6

150

5

5

125

4

100

3

75

2

50

1

25

-25

0

-30

VEN

0

0.2

0.4

0.6

0.8

1

1.2

Time (ms)

1.4

1.6

4

5

6

Time (ms)

7

8

IOUT

1.8

2

Output Voltage (mV)

VIN

Output Current (mA)

Voltage (V)

VOUT

3

9

10

图 10. VIN = VEN Shutdown

7

0

560

3.2

3.28

50

40

Output Voltage (V)

4

640

VOUT

IOUT

3.375

3.32

Output Voltage (V)

Input Voltage (V)

5

3.4

Output Current (A)

6

-40°C

0°C

25°C

85°C

125°C

0

-5

-10

-15

-20

0

50

100

150

200 250 300 350

Output Current (mA)

400

450

500

VIN = 5 V, IOUT = 100 mA, VEN slew rate = 1 V/µs, VOUT = 3.3 V

图 11. EN Startup

8

图 12. Load Regulation vs IOUT

版权 © 2017–2018, Texas Instruments Incorporated

�TLV755P

www.ti.com.cn

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

Typical Characteristics (接

接下页)

at operating temperature TJ = 25°C, VIN = VOUT(NOM) + 0.5 V or 1.45 V (whichever is greater), IOUT = 1 mA, VEN = VIN, and CIN

= COUT = 1 µF (unless otherwise noted)

200

200

-40qC

0qC

25qC

-40qC

0qC

25qC

160

150

Dropout Voltage (mV)

Dropout Voltage (mV)

175

85qC

125qC

125

100

75

50

85qC

125qC

120

80

40

25

0

0

0

50

100

150

200 250 300 350

Output Current (mA)

400

450

500

0

图 13. 3.3-V Dropout Voltage vs IOUT

100

-40qC

0qC

25qC

85qC

125qC

-40qC

0qC

0.75

400

450

500

25qC

85qC

125qC

0.5

Accuracy (%)

0.5

0.25

0

-0.25

0.25

0

-0.25

-0.5

-0.5

-0.75

-0.75

-1

3.5

-1

3.75

4

4.25

4.5

4.75

Input Voltage (V)

5

5.25

5.5

5

5.1

VOUT = 3.3 V, IOUT = 1 mA

600

500

400

300

-40°C

0°C

25°C

85°C

125°C

200

100

0

150

200 250 300 350

Output Current (mA)

400

450

500

GND Pin Current (PA)

700

100

5.4

5.5

图 16. 5.0-V Accuracy vs VIN (Line Regulation)

800

50

5.2

5.3

Input Voltage (V)

IOUT = 1 mA, VOUT = 5 V

图 15. 3.3-V Regulation vs VIN (Line Regulation)

GND Pin Current (ɥA)

200 250 300 350

Output Current (mA)

1

0.75

0

150

图 14. 5.0-V Dropout Voltage vs IOUT

1

Accuracy (%)

50

650

600

550

500

450

400

350

300

250

200

150

100

50

0

-40qC

0qC

25qC

85qC

125qC

0

1

2

3

4

Input Voltage (V)

5

6

VOUT = 3.3 V, IOUT = 1 mA

图 17. IGND vs IOUT

版权 © 2017–2018, Texas Instruments Incorporated

图 18. IGND vs VIN

9

�TLV755P

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

www.ti.com.cn

Typical Characteristics (接

接下页)

at operating temperature TJ = 25°C, VIN = VOUT(NOM) + 0.5 V or 1.45 V (whichever is greater), IOUT = 1 mA, VEN = VIN, and CIN

= COUT = 1 µF (unless otherwise noted)

350

300

-40qC

0qC

25qC

85qC

125qC

200

Shutdown Current (nA)

Quiescent Current (PA)

250

-40qC

0qC

25qC

85qC

125qC

300

150

100

50

250

200

150

100

50

0

0

0

1

2

3

4

Input Voltage (V)

5

6

0

1

2

VOUT = 3.3 V, IOUT = 0 mA

3

4

Input Voltage (V)

5

6

VEN = 0 V

图 19. IQ vs VIN

图 20. ISHDN vs VIN

180

800

160

Enable Threshold (mV)

Shutdown Current (nA)

750

140

120

100

80

60

40

700

650

600

550

20

EN Negative

0

-40

-20

0

20

40

60

80

Temperature (qC)

100

120

500

-50

140

-25

0

EN Positive

25

50

Temperature (qC)

75

100

125

VEN = 0 V

图 21. ISHDN vs Temperature

图 22. Enable Threshold vs Temperature

250

1.4

-40qC

0qC

25qC

85qC

125qC

1.36

UVLO Threshold (V)

Enable Current (PA)

200

150

100

1.32

1.28

1.24

50

UVLO Negative

0

0

1

2

3

4

Input Voltage (V)

5

6

1.2

-50

-25

0

UVLO Positive

25

50

Temperature (qC)

75

100

125

VEN = 5.5 V

图 23. IEN vs VIN

10

图 24. UVLO Threshold vs Temperature

版权 © 2017–2018, Texas Instruments Incorporated

�TLV755P

www.ti.com.cn

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

Typical Characteristics (接

接下页)

at operating temperature TJ = 25°C, VIN = VOUT(NOM) + 0.5 V or 1.45 V (whichever is greater), IOUT = 1 mA, VEN = VIN, and CIN

= COUT = 1 µF (unless otherwise noted)

600

3.5

-40qC

0qC

25qC

550

3

450

Output Voltage (mV)

Output Voltage (mV)

500

85qC

125qC

400

350

300

250

200

150

100

2.5

2

1.5

-40°C

0°C

25°C

85°C

125°C

1

0.5

50

0

0

0

1

2

3

Output Current (mA)

4

图 25. VOUT vs IOUT Pulldown Resistor

版权 © 2017–2018, Texas Instruments Incorporated

5

0

100

200

300

400

500

Output Current (mA)

600

700

800

图 26. 3.3-V Foldback Current Limit, VOUT vs IOUT

11

�TLV755P

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

www.ti.com.cn

7 Detailed Description

7.1 Overview

The TLV755P belongs to a family of next-generation, low-dropout regulators (LDOs). This device consumes low

quiescent current and delivers excellent line and load transient performance. The TLV755P is optimized for a

wide variety of applications by supporting an input voltage range from 1.45 V to 5.5 V. To minimize cost and

solution size, the device is offered in fixed output voltages ranging from 0.6 V to 5 V to support the lower core

voltages of modern microcontrollers (MCUs).

This regulator offers foldback current limit, shutdown, and thermal protection. The operating junction temperature

is –40°C to +125°C.

7.2 Functional Block Diagram

OUT

IN

Current

Limit

R1

±

+

Thermal

Shutdown

UVLO

120 Ÿ

R2

EN

Bandgap

GND

Logic

NOTE: R2 = 550 kΩ, R1 = adjustable.

7.3 Feature Description

7.3.1 Undervoltage Lockout (UVLO)

An undervoltage lockout (UVLO) circuit disables the output until the input voltage is greater than the rising UVLO

voltage (VUVLO). This circuit ensures that the device does not exhibit any unpredictable behavior when the supply

voltage is lower than the operational range of the internal circuitry. When VIN is less than VUVLO, the output is

connected to ground with a 120-Ω pulldown resistor.

7.3.2 Enable (EN)

The enable pin (EN) is active high. Enable the device by forcing the EN pin to exceed VHI. Turn off the device by

forcing the EN pin below VLO. If shutdown capability is not required, connect EN to IN.

The device has an internal pulldown that connects a 120-Ω resistor to ground when the device is disabled. The

discharge time after disabling depends on the output capacitance (COUT) and the load resistance (RL) in parallel

with the 120-Ω pulldown resistor. 公式 1 calculates the time constant τ:

120 · RL

t=

· COUT

120 + RL

(1)

12

版权 © 2017–2018, Texas Instruments Incorporated

�TLV755P

www.ti.com.cn

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

Feature Description (接

接下页)

The EN pin is independent of the input pin (IN), but if the EN pin is driven to a higher voltage than VIN, the

current into the EN pin increases. This effect is illustrated in 图 23. When the EN voltage is higher than the input

voltage there is an increased current flow into the EN pin. If this increased flow causes problems in the

application, sequence the EN pin after VIN is high, or to tie EN to VIN to prevent this flow increase from

happening. If EN is driven to a higher voltage than VIN, limit the frequency on EN to below 10 kHz.

7.3.3 Internal Foldback Current Limit

The TLV755P has an internal current limit that protects the regulator during fault conditions. The current limit is a

hybrid scheme with brick wall until the output voltage is less than 0.4 V × VOUT(NOM). When the voltage drops

below 0.4 V × VOUT(NOM), a foldback current limit is implemented that scales back the current as the output

voltage approaches GND. When the output shorts, the LDO supplies a typical current of ISC. The output voltage

is not regulated when the device is in current limit. In this condition, the output voltage is the product of the

regulated current and the load resistance. When the device output shorts, the PMOS pass transistor dissipates

power [(VIN – VOUT) × ISC] until thermal shutdown is triggered and the device turns off. After the device cools

down, the internal thermal shutdown circuit turns the device back on. If the fault condition continues, the device

cycles between current limit and thermal shutdown.

The foldback current-limit circuit limits the current that is allowed through the device to current levels lower than

the minimum current limit at nominal VOUT current limit (ICL) during start up. See 图 26 for typical current limit

values. If the output is loaded by a constant-current load during start up, or if the output voltage is negative when

the device is enabled, then the load current demanded by the load may exceed the foldback current limit and the

device may not rise to the full output voltage. For constant-current loads, disable the output load until the output

has risen to the nominal voltage.

Excess inductance can cause the current limit to oscillate. Minimize the inductance to keep the current limit from

oscillating during a fault condition.

7.3.4 Thermal Shutdown

Thermal shutdown protection disables the output when the junction temperature rises to approximately 165°C.

Disabling the device eliminates the power dissipated by the device, allowing the device to cool. When the

junction temperature cools to approximately 155°C, the output circuitry is enabled again. Depending on power

dissipation, thermal resistance, and ambient temperature, the thermal protection circuit may cycle on and off.

This cycling limits regulator dissipation that protects the circuit from damage as a result of overheating.

Activating the thermal shutdown feature usually indicates excessive power dissipation as a result of the product

of the (VIN – VOUT) voltage and the load current. For reliable operation, limit junction temperature to a maximum

of 125°C. To estimate the margin of safety in a complete design, increase the ambient temperature until the

thermal protection is triggered; use worst-case loads and signal conditions.

The internal protection circuitry protects against overload conditions but is not intended to be activated in normal

operation. Continuously running the device into thermal shutdown degrades device reliability.

版权 © 2017–2018, Texas Instruments Incorporated

13

�TLV755P

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

www.ti.com.cn

7.4 Device Functional Modes

表 1 lists a comparison between the normal, dropout, and disabled modes of operation.

表 1. Device Functional Modes Comparison

PARAMETER

OPERATING MODE

(1)

(2)

VIN

EN

IOUT

TJ

Normal (1)

VIN > VOUT(NOM) + VDO

VEN > VHI

IOUT < ICL

TJ < TSD

Dropout (1)

VIN < VOUT(NOM) + VDO

VEN > VHI

—

TJ < TSD

Disabled (2)

VIN < VUVLO

VEN < VLO

—

TJ > TSD

All table conditions must be met.

The device is disabled when any condition is met.

7.4.1 Normal Operation

The device regulates to the nominal output voltage when all of the following conditions are met.

• The input voltage is greater than the nominal output voltage plus the dropout voltage (VOUT(NOM) + VDO)

• The enable voltage has previously exceeded the enable rising threshold voltage and has not decreased

below the enable falling threshold

• The output current is less than the current limit (IOUT < ICL)

• The device junction temperature is less than the thermal shutdown temperature (TJ < TSD)

7.4.2 Dropout Operation

If the input voltage is lower than the nominal output voltage plus the specified dropout voltage, but all other

conditions are met for normal operation, the device operates in dropout. In this mode, the output voltage tracks

the input voltage. During this mode, the transient performance of the device degrades because the pass device

is in a triode state and no longer controls the output voltage of the LDO. Line or load transients in dropout can

result in large output-voltage deviations.

When the device is in a steady dropout state (defined as when the device is in dropout, VIN < VOUT(NOM) + VDO,

right after being in a normal regulation state, but not during startup), the pass-FET is driven as hard as possible

when the control loop is out of balance. During the normal time required for the device to regain regulation, VIN ≥

VOUT(NOM) + VDO, VOUT can overshoot VOUT(NOM) during fast transients.

7.4.3 Disabled

The output is shut down by forcing the enable pin below VLO. When disabled, the pass device is turned off,

internal circuits are shut down, and the output voltage is actively discharged to ground by an internal switch from

the output to ground. The active pulldown is on when sufficient input voltage is provided.

14

版权 © 2017–2018, Texas Instruments Incorporated

�TLV755P

www.ti.com.cn

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

8 Application and Implementation

注

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

8.1 Application Information

8.1.1 Input and Output Capacitor Selection

The TLV755P requires an output capacitance of 0.47 µF or larger for stability. Use X5R- and X7R-type ceramic

capacitors because these capacitors have minimal variation in capacitance value and equivalent series

resistance (ESR) over temperature. When selecting a capacitor for a specific application, consider the DC bias

characteristics for the capacitor. Higher output voltages cause a significant derating of the capacitor. As a

general rule, ceramic capacitors must be derated by 50%. For best performance, TI recommends a maximum

output capacitance value of 200 µF.

Place a 1 µF or greater capacitor on the input pin of the LDO. Some input supplies have a high impedance.

Placing a capacitor on the input supply reduces the input impedance. The input capacitor counteracts reactive

input sources and improves transient response and PSRR. If the input supply has a high impedance over a large

range of frequencies, several input capacitors are used in parallel to lower the impedance over frequency. Use a

higher-value capacitor if large, fast, rise-time load transients are expected, or if the device is located several

inches from the input power source.

8.1.2 Dropout Voltage

The TLV755P uses a PMOS pass transistor to achieve low dropout. When (VIN – VOUT) is less than the dropout

voltage (VDO), the PMOS pass device is in the linear region of operation and the input-to-output resistance is the

RDS(ON) of the PMOS pass element. VDO scales linearly with the output current because the PMOS device

functions like a resistor in dropout mode. As with any linear regulator, PSRR and transient response degrade as

(VIN – VOUT) approaches dropout operation. See 图 13 and 图 14 for typical dropout values.

8.1.3 Exiting Dropout

Some applications have transients that place the LDO into dropout, such as slower ramps on VIN during start-up.

As with other LDOs, the output may overshoot on recovery from these conditions. A ramping input supply causes

an LDO to overshoot on start-up when the slew rate and voltage levels are in the correct range; see 图 27. Use

an enable signal to avoid this condition.

版权 © 2017–2018, Texas Instruments Incorporated

15

�TLV755P

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

www.ti.com.cn

Application Information (接

接下页)

Input Voltage

Response time for

LDO to get back into

regulation.

Load current discharges

output voltage.

VIN = VOUT(nom) + VDO

Voltage

Output Voltage

Dropout

VOUT = VIN - VDO

Output Voltage in

normal regulation.

Time

图 27. Startup Into Dropout

Line transients out of dropout can also cause overshoot on the output of the regulator. These overshoots are

caused by the error amplifier having to drive the gate capacitance of the pass element and bring the gate back to

the correct voltage for proper regulation. 图 28 illustrates what is happening internally with the gate voltage and

how overshoot can be caused during operation. When the LDO is placed in dropout, the gate voltage (VGS) is

pulled all the way down to ground to give the pass device the lowest on-resistance as possible. However, if a line

transient occurs while the device is in dropout, the loop is not in regulation and can cause the output to

overshoot until the loop responds and the output current pulls the output voltage back down into regulation. If

these transients are not acceptable, then continue to add input capacitance in the system until the transient is

slow enough to reduce the overshoot.

16

版权 © 2017–2018, Texas Instruments Incorporated

�TLV755P

www.ti.com.cn

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

Application Information (接

接下页)

Transient response

time of the LDO

Input Voltage

Load current

discharges

output

voltage

VDO

Voltage

Output Voltage

Output Voltage in

normal regulation

Dropout

VOUT = VIN - VDO

VGS voltage

(pass device

fully off)

Input Voltage

VGS voltage for

normal operation

VGS voltage for

normal operation

Gate Voltage

VGS voltage in

dropout (pass device

fully on)

Time

图 28. Line Transients From Dropout

8.1.4 Reverse Current

As with most LDOs, excessive reverse current can damage this device.

Reverse current flows through the body diode on the pass element instead of the normal conducting channel. At

high magnitudes, this current flow degrades the long-term reliability of the device, as a result of one of the

following conditions:

• Degradation caused by electromigration

• Excessive heat dissipation

• Potential for a latch-up condition

Conditions where reverse current can occur are outlined in this section, all of which can exceed the absolute

maximum rating of VOUT > VIN + 0.3 V:

• If the device has a large COUT and the input supply collapses with little or no load current

• The output is biased when the input supply is not established

• The output is biased above the input supply

版权 © 2017–2018, Texas Instruments Incorporated

17

�TLV755P

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

www.ti.com.cn

Application Information (接

接下页)

If reverse current flow is expected in the application, external protection must be used to protect the device. 图

29 shows one approach of protecting the device.

Schottky Diode

IN

CIN

Internal Body Diode

Device

OUT

COUT

GND

图 29. Example Circuit for Reverse Current Protection Using a Schottky Diode

8.1.5 Power Dissipation (PD)

Circuit reliability demands that proper consideration be given to device power dissipation, location of the circuit

on the printed circuit board (PCB), and correct sizing of the thermal plane. The PCB area around the regulator

must be as free of other heat-generating devices as possible that cause added thermal stresses.

As a first-order approximation, power dissipation in the regulator depends on the input-to-output voltage

difference and load conditions. Use 公式 2 to approximate PD:

PD = (VIN – VOUT) × IOUT

(2)

Power dissipation must be minimized to achieve greater efficiency. This minimizing process is achieved by

selecting the correct system voltage rails. Proper selection helps obtain the minimum input-to-output voltage

differential. The low dropout of the device allows for maximum efficiency across a wide range of output voltages.

The main heat-conduction path for the device is through the thermal pad on the package. As such, the thermal

pad must be soldered to a copper pad area under the device. This pad area contains an array of plated vias that

conduct heat to inner plane areas or to a bottom-side copper plane.

The maximum allowable junction temperature (TJ) determines the maximum power dissipation for the device.

According to 公式 3, power dissipation and junction temperature are most often related by the junction-toambient thermal resistance (RθJA) of the combined PCB, device package, and the temperature of the ambient air

(TA).

TJ = TA + RθJA × PD

(3)

Unfortunately, this thermal resistance (RθJA) is dependent on the heat-spreading capability built into the particular

PCB design, and therefore varies according to the total copper area, copper weight, and location of the planes.

The RθJA value is only used as a relative measure of package thermal performance. RθJA is the sum of the

package junction-to-case (bottom) thermal resistance (RθJCbot) plus the thermal resistance contribution by the

PCB copper.

18

版权 © 2017–2018, Texas Instruments Incorporated

�TLV755P

www.ti.com.cn

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

Application Information (接

接下页)

8.1.5.1 Estimating Junction Temperature

The JEDEC standard recommends the use of psi (Ψ) thermal metrics to estimate the junction temperatures of

the LDO when in-circuit on a typical PCB board application. These metrics are not thermal resistances, but offer

practical and relative means of estimating junction temperatures. These psi metrics are independent of the

copper-spreading area. The key thermal metrics (ΨJT and ΨJB) are used in accordance with 公式 4 and are

described in the table.

YJT: TJ = TT + YJT ´ PD

YJB: TJ = TB + YJB ´ PD

where:

•

•

•

PD is the power dissipated as shown in 公式 2

TT is the temperature at the center-top of the device package

TB is the PCB surface temperature measured 1 mm from the device package and centered on the package

edge

(4)

8.2 Typical Application

IN

OUT

1 …F

DC/DC

Converter

1 …F

TLV755P

EN

Load

GND

ON

OFF

图 30. TLV755P Typical Application

8.2.1 Design Requirements

表 2 lists the design requirements for this application.

表 2. Design Parameters

PARAMETER

DESIGN REQUIREMENT

Input voltage

4.3 V

Output voltage

3.3 V

Input current

500 mA (maximum)

Output load

250-mA DC

Maximum ambient temperature

70°C

版权 © 2017–2018, Texas Instruments Incorporated

19

�TLV755P

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

www.ti.com.cn

8.2.2 Detailed Design Procedure

8.2.2.1 Input Current

During normal operation, the input current to the LDO is approximately equal to the output current of the LDO.

During startup, the input current is higher as a result of the inrush current charging the output capacitor. Use 公式

5 to calculate the current through the input.

VOUT(t)

COUT ´ dVOUT(t)

IOUT(t) =

+

RLOAD

dt

where:

•

•

•

VOUT(t) is the instantaneous output voltage of the turn-on ramp

dVOUT(t) / dt is the slope of the VOUT ramp

RLOAD is the resistive load impedance

(5)

8.2.2.2 Thermal Dissipation

The junction temperature can be determined using the junction-to-ambient thermal resistance (RθJA) and the total

power dissipation (PD). Use 公式 6 to calculate the power dissipation. Multiply PD by RθJA as 公式 7 shows and

add the ambient temperature (TA) to calculate the junction temperature (TJ).

PD = (IGND+ IOUT) × (VIN – VOUT)

TJ = RθJA × PD + TA

(6)

(7)

Calculate the maximum ambient temperature as 公式 8 shows if the (TJ(MAX)) value does not exceed 125°C. 公式

9 calculates the maximum ambient temperature with a value of 99.95°C.

TA(MAX) = TJ(MAX) – RθJA × PD

TA(MAX) = 125°C – 100.2°C/W × (4.3 V – 3.3 V) × (0.25 A) = 99.95°C

(8)

(9)

8.2.3 Application Curve

Power Supply Rejection Ratio (dB)

100

80

60

40

20

0

10

IOUT = 10 mA

IOUT = 50 mA

IOUT = 100 mA

IOUT = 500 mA

100

1k

10k

100k

Frequency (Hz)

1M

10M

VIN = 4.3 V, VOUT = 3.3 V

图 31. PSRR vs Frequency (4.3 V to 3.3 V)

9 Power Supply Recommendations

Connect a low output impedance power supply directly to the IN pin of the TLV755P. If the input source is

reactive, consider using multiple input capacitors in parallel with the 1-µF input capacitor to lower the input supply

impedance over frequency.

20

版权 © 2017–2018, Texas Instruments Incorporated

�TLV755P

www.ti.com.cn

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

10 Layout

10.1 Layout Guidelines

•

•

•

Place input and output capacitors as close as possible to the device.

Use copper planes for device connections to optimize thermal performance.

Place thermal vias around the device to distribute the heat.

10.2 Layout Examples

OUT

IN

1

4

COUT

CIN

EN

3

2

GND PLANE

Represents via used for application

specific connections

图 32. Layout Example for the DQN Package

VOUT

VIN

1

CIN

5

COUT

2

3

4

EN

GND PLANE

Represents via used for

application specific connections

图 33. Layout Example for the DBV Package

VIN

VOUT

COUT

1

6

2

5

3

4

CIN

EN

GND PLANE

Represents via used for

application specific connections

图 34. Layout Example for the DRV Package

版权 © 2017–2018, Texas Instruments Incorporated

21

�TLV755P

ZHCSI89A – NOVEMBER 2017 – REVISED MAY 2018

www.ti.com.cn

11 器件和文档支持

11.1 器件支持

11.1.1 器件命名规则

表 3. 器件命名规则 (1) (2)

(1)

(2)

产品

VOUT

TLV755xx(x)Pyyyz

xx(x) 为标称输出电压。对于分辨率为 100mV 的输出电压,订货编号中使用两位数字;否则,使用三位数

字(例如,28 = 2.8V;125 = 1.25V)。

P 表示有源输出放电功能。TLV755P 系列的所有产品在器件处于禁用状态时都可以对输出进行主动放电。

yyy 为封装标识符。

z 为封装数量。R 表示卷(3000 片),T 表示带(250 片)。

要获得最新的封装和订货信息,请参阅本文档末尾的封装选项附录,或者访问器件产品文件夹(www.ti.com.cn)。

可提供 0.6V 至 5V 范围内的输出电压(以 50mV 为单位增加)。有关器件的详细信息和供货情况,请联系制造商。

11.2 接收文档更新通知

要接收文档更新通知,请导航至 TI.com.cn 上的器件产品文件夹。单击右上角的通知我 进行注册,即可每周接收产

品信息更改摘要。有关更改的详细信息,请查看任何已修订文档中包含的修订历史记录。

11.3 社区资源

下列链接提供到 TI 社区资源的连接。链接的内容由各个分销商“按照原样”提供。这些内容并不构成 TI 技术规范,

并且不一定反映 TI 的观点;请参阅 TI 的 《使用条款》。

TI E2E™ 在线社区 TI 的工程师对工程师 (E2E) 社区。此社区的创建目的在于促进工程师之间的协作。在

e2e.ti.com 中,您可以咨询问题、分享知识、拓展思路并与同行工程师一道帮助解决问题。

设计支持

TI 参考设计支持 可帮助您快速查找有帮助的 E2E 论坛、设计支持工具以及技术支持的联系信息。

11.4 商标

E2E is a trademark of Texas Instruments.

All other trademarks are the property of their respective owners.

11.5 静电放电警告

ESD 可能会损坏该集成电路。德州仪器 (TI) 建议通过适当的预防措施处理所有集成电路。如果不遵守正确的处理措施和安装程序 , 可

能会损坏集成电路。

ESD 的损坏小至导致微小的性能降级 , 大至整个器件故障。 精密的集成电路可能更容易受到损坏 , 这是因为非常细微的参数更改都可

能会导致器件与其发布的规格不相符。

11.6 术语表

SLYZ022 — TI 术语表。

这份术语表列出并解释术语、缩写和定义。

12 机械、封装和可订购信息

以下页面包含机械、封装和可订购信息。这些信息是指定器件的最新可用数据。数据如有变更,恕不另行通知,且

不会对此文档进行修订。如需获取此数据表的浏览器版本,请参阅左侧的导航栏。

22

版权 © 2017–2018, Texas Instruments Incorporated

�PACKAGE OPTION ADDENDUM

www.ti.com

10-Dec-2020

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

MSL Peak Temp

Op Temp (°C)

Device Marking

(3)

(4/5)

(6)

TLV75507PDQNR

ACTIVE

X2SON

DQN

4

3000

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

KD

TLV75507PDQNT

ACTIVE

X2SON

DQN

4

250

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

KD

TLV75509PDBVR

ACTIVE

SOT-23

DBV

5

3000

RoHS & Green

Level-1-260C-UNLIM

-40 to 125

1HAF

TLV75509PDQNR

ACTIVE

X2SON

DQN

4

3000

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

AX

TLV75509PDQNT

ACTIVE

X2SON

DQN

4

250

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

AX

TLV75509PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1HDH

TLV75510PDBVR

ACTIVE

SOT-23

DBV

5

3000

RoHS & Green

NIPDAU | SN

Level-1-260C-UNLIM

-40 to 125

1FPF

TLV75510PDQNR

ACTIVE

X2SON

DQN

4

3000

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

KE

TLV75510PDQNT

ACTIVE

X2SON

DQN

4

250

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

KE

TLV75510PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1GUH

TLV75511PDQNR

ACTIVE

X2SON

DQN

4

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

E8

TLV75512PDBVR

ACTIVE

SOT-23

DBV

5

3000

RoHS & Green

NIPDAU | SN

Level-1-260C-UNLIM

-40 to 125

1FQF

TLV75512PDQNR

ACTIVE

X2SON

DQN

4

3000

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

AG

TLV75512PDQNT

ACTIVE

X2SON

DQN

4

250

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

AG

TLV75512PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1GVH

TLV75515PDBVR

ACTIVE

SOT-23

DBV

5

3000

RoHS & Green

NIPDAU | SN

Level-1-260C-UNLIM

-40 to 125

1FRF

TLV75515PDQNR

ACTIVE

X2SON

DQN

4

3000

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

KF

TLV75515PDQNT

ACTIVE

X2SON

DQN

4

250

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

KF

TLV75515PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1GWH

TLV755185PDQNR

ACTIVE

X2SON

DQN

4

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

EZ

NIPDAU | SN

Addendum-Page 1

Samples

�PACKAGE OPTION ADDENDUM

www.ti.com

Orderable Device

10-Dec-2020

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

NIPDAU | SN

MSL Peak Temp

Op Temp (°C)

Device Marking

(3)

(4/5)

(6)

TLV75518PDBVR

ACTIVE

SOT-23

DBV

5

3000

RoHS & Green

Level-1-260C-UNLIM

-40 to 125

1FSF

TLV75518PDQNR

ACTIVE

X2SON

DQN

4

3000

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

AI

TLV75518PDQNT

ACTIVE

X2SON

DQN

4

250

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

AI

TLV75518PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1GXH

TLV75519PDBVR

ACTIVE

SOT-23

DBV

5

3000

RoHS & Green

NIPDAU | SN

Level-1-260C-UNLIM

-40 to 125

1HBF

TLV75519PDQNR

ACTIVE

X2SON

DQN

4

3000

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

B5

TLV75519PDQNT

ACTIVE

X2SON

DQN

4

250

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

B5

TLV75519PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1HEH

TLV75525PDBVR

ACTIVE

SOT-23

DBV

5

3000

RoHS & Green

NIPDAU | SN

Level-1-260C-UNLIM

-40 to 125

1FTF

TLV75525PDQNR

ACTIVE

X2SON

DQN

4

3000

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

AJ

TLV75525PDQNT

ACTIVE

X2SON

DQN

4

250

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

AJ

TLV75525PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1GZH

TLV75528PDBVR

ACTIVE

SOT-23

DBV

5

3000

RoHS & Green

NIPDAU | SN

Level-1-260C-UNLIM

-40 to 125

1FUF

TLV75528PDQNR

ACTIVE

X2SON

DQN

4

3000

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

KG

TLV75528PDQNT

ACTIVE

X2SON

DQN

4

250

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

KG

TLV75528PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1H1H

TLV75529PDBVR

ACTIVE

SOT-23

DBV

5

3000

RoHS & Green

NIPDAU | SN

Level-1-260C-UNLIM

-40 to 125

1HCF

TLV75529PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1HFH

TLV75530PDBVR

ACTIVE

SOT-23

DBV

5

3000

RoHS & Green

NIPDAU | SN

Level-1-260C-UNLIM

-40 to 125

1FVF

TLV75530PDQNR

ACTIVE

X2SON

DQN

4

3000

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

KI

TLV75530PDQNT

ACTIVE

X2SON

DQN

4

250

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

KI

Addendum-Page 2

Samples

�PACKAGE OPTION ADDENDUM

www.ti.com

Orderable Device

10-Dec-2020

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

MSL Peak Temp

Op Temp (°C)

Device Marking

(3)

(4/5)

(6)

TLV75530PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1H2H

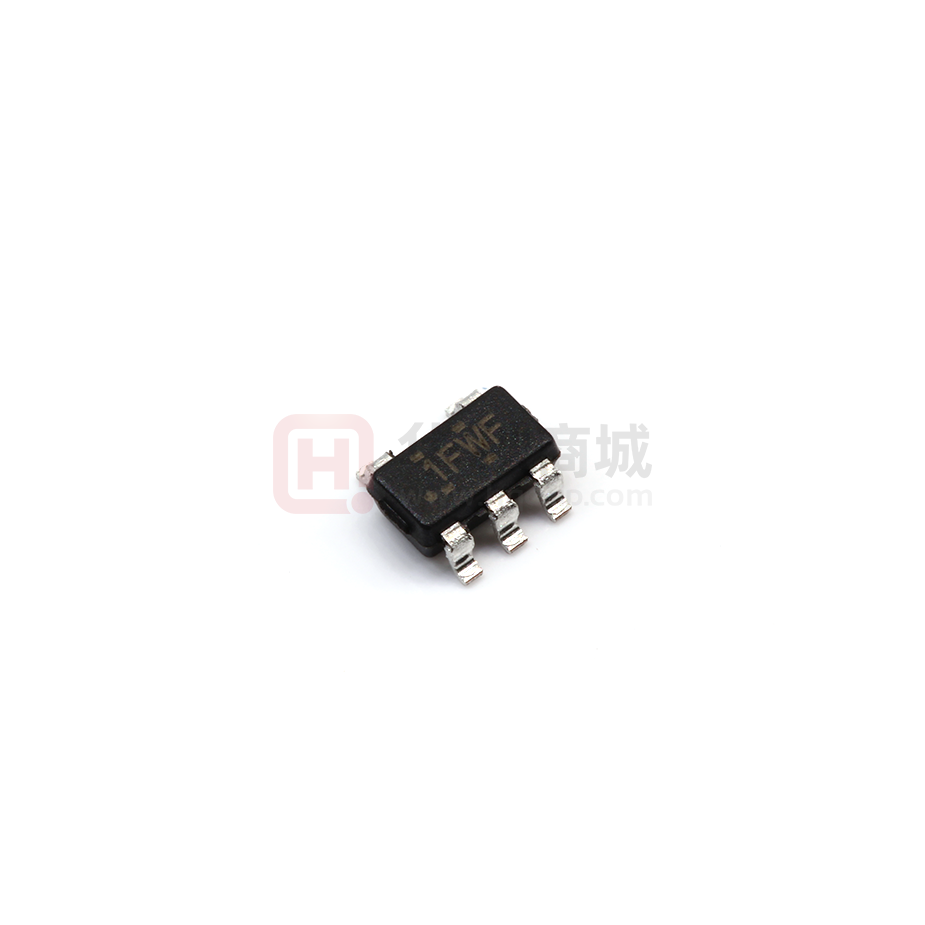

TLV75533PDBVR

ACTIVE

SOT-23

DBV

5

3000

RoHS & Green

NIPDAU | SN

Level-1-260C-UNLIM

-40 to 125

1FWF

TLV75533PDQNR

ACTIVE

X2SON

DQN

4

3000

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

AN

TLV75533PDQNT

ACTIVE

X2SON

DQN

4

250

RoHS & Green NIPDAU | NIPDAUAG

Level-1-260C-UNLIM

-40 to 125

AN

TLV75533PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

Level-1-260C-UNLIM

-40 to 125

1H3H

NIPDAU

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of