TPS546D24A

TPS546D24A

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER

2020

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

www.ti.com

TPS546D24A 2.95-V to 16-V, 40-A, Up to 4× Stackable, PMBus® Buck Converter

1 Features

3 Description

•

The TPS546D24A is a highly integrated, non-isolated

DC/DC converter capable of high frequency operation

and 40-A current output from a 7-mm × 5-mm

package. Two, three, and four TPS546D24A devices

can be interconnected to provide up to 160 A on a

single output. The device has an option to overdrive

the internal 5-V LDO with an external 5-V supply via

the VDD5 pin to improve efficiency and reduce power

dissipation of the converter.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Split rail support: 2.95-V to 16-V PVIN; 2.95-V to

18-V AVIN (4-VIN VDD5 for switching)

Integrated 4.5-mΩ/0.9-mΩ MOSFETs

Average current mode control with selectable

internal compensation

2×, 3×, 4× stackable with current sharing up to 160

A, supporting a single address per output

Selectable 0.5-V to 5.5-V output via pin strap or

0.25-V to 5.5-V using PMBus VOUT_COMMAND

Extensive PMBus command set with telemetry for

VOUT, IOUT and internal die temperature

Differential remote sensing with internal FB divider

for < 1% VOUT error –40°C to +150°C TJ

AVS and margining capabilities through PMBus

MSEL pins pin programming PMBus defaults

12 Selectable switching frequencies from 225 kHz

to 1.5 MHz (8 pin-strap options)

Frequency sync in/sync out

Supports prebiased output

Supports strongly coupled inductor

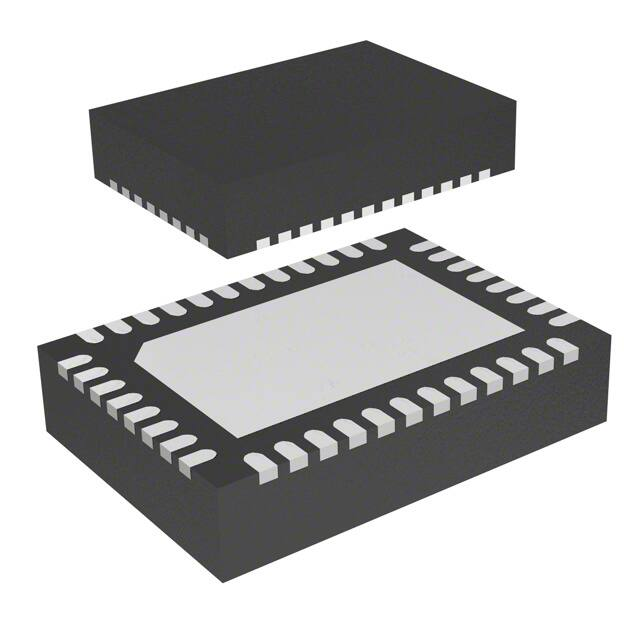

7-mm × 5-mm × 1.5-mm, 40-pin QFN,

pitch = 0.5 mm

Create a Custom Design Using the TPS546D24A

With WEBENCH® Power Designer

The TPS546D24A uses a proprietary fixed-frequency

current-mode control with input feedforward and

selectable internal compensation components for

minimal size and stability over a wide range of output

capacitances.

The PMBus interface with 1-MHz clock support gives

a convenient, standardized digital interface for

converter configuration as well as monitoring of key

parameters including output voltage, output current,

and internal die temperature. Response to fault

conditions can be set to restart, latch off, or ignore,

depending on system requirements. Back-channel

communication between stacked devices enables all

TPS546D24A converters powering a single output rail

to share a single address to simplify system software/

firmware design. Key parameters including output

voltage, switching frequency, soft-start time, and

overcurrent fault limits can also be configured through

BOM selection without PMBus communication to

support program free power-up.

2 Applications

•

•

•

•

Data center switches, rack servers

Active antenna system, remote radio and

baseband unit

Automated test equipment, CT, PET, and MRI

ASIC, SoC, FPGA, DSP core, and I/O voltage

Device Information

PART NUMBER (1)

TPS546D24A

(1)

PACKAGE

BODY SIZE (NOM)

LQFN-CLIP (40)

7.00 mm × 5.00 mm

For all available packages, see the orderable addendum at

the end of the data sheet.

DRTN

MSEL1

PVIN

AVIN

BP1V5

EN/UVLO

PGD/RST_B

VIN

VOSNS

GOSNS/SLAVE

BOOT

TPS546D24A

MSEL2

To Loop Slaves

SMB_ALRT

PMB_CLK

PMB_DATA

BCX_DAT

BCX_CLK

VDD5

SYNC

AGND

VSHARE

ADRSEL

VSEL

VOUT

SW

PGND

To PMBus

Simplified Application

An©IMPORTANT

NOTICEIncorporated

at the end of this data sheet addresses availability, warranty, changes, use in

safety-critical

applications,

Copyright

2020 Texas Instruments

Submit

Document

Feedback

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Product Folder Links: TPS546D24A

1

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

Table of Contents

1 Features............................................................................1

2 Applications..................................................................... 1

3 Description.......................................................................1

4 Revision History.............................................................. 2

5 Pin Configuration and Functions...................................3

6 Specifications.................................................................. 6

6.1 Absolute Maximum Ratings ....................................... 6

6.2 ESD Ratings .............................................................. 6

6.3 Recommended Operating Conditions ........................6

6.4 Thermal Information ...................................................6

6.5 Electrical Characteristics ............................................7

6.6 Typical Characteristics.............................................. 15

7 Detailed Description......................................................19

7.1 Overview................................................................... 19

7.2 Functional Block Diagram......................................... 19

7.3 Feature Description...................................................20

7.4 Device Functional Modes..........................................34

7.5 Programming............................................................ 36

7.6 Register Maps...........................................................47

8 Application and Implementation................................ 149

8.1 Application Information........................................... 149

8.2 Typical Application.................................................. 149

8.3 Two-Phase Application........................................... 159

8.4 Four-Phase Application...........................................164

9 Power Supply Recommendations..............................165

10 Layout.........................................................................166

10.1 Layout Guidelines................................................. 166

10.2 Layout Example.................................................... 167

10.3 Mounting and Thermal Profile Recommendation..167

11 Device and Documentation Support........................169

11.1 Device Support......................................................169

11.2 Receiving Notification of Documentation Updates 169

11.3 Support Resources............................................... 169

11.4 Trademarks........................................................... 169

11.5 Electrostatic Discharge Caution............................ 170

11.6 Glossary................................................................ 170

12 Mechanical, Packaging, and Orderable

Information.................................................................. 171

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision * (December 2019) to Revision A (November 2020)

Page

• Updated the numbering format for tables, figures and cross-references throughout the document. .................1

2

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

5 Pin Configuration and Functions

Figure 5-1. 40-Pin LQFN-CLIP With Exposed Thermal Pad RVF Package (Top View)

Table 5-1. Pin Functions

PIN

NO.

NAME

I/O

DESCRIPTION

1

PGD/RST_B

I/O

Open-drain power good or (21h) VOUT_COMMAND RESET#. As determined by user-programmable

RESET# bit in (EDh) MFR_SPECIFIC_29 (MISC_OPTIONS). The default pin function is an open-drain

power-good indicator. When configured as RESET#, an internal pullup can be enabled or disabled by the

PULLUP# bit in (EDh) MFR_SPECIFIC_29 (MISC_OPTIONS).

2

PMB_DATA

I/O

PMBus DATA pin. See Current PMBus Specifications.

3

PMB_CLK

I

PMBus CLK pin. See Current PMBus Specifications.

4

BP1V5

O

Output of the 1.5-V internal regulator. This regulator powers the digital circuitry and should be bypassed

with a minimum of 1 µF to DRTN with an X5R or better ceramic capacitor rated for a minimum of 6 V.

BP1V5 is not designed to power external circuit.

5

DRTN

—

Digital bypass return for bypass capacitor for BP1V5. Internally connected to AGND. Do not connect to

PGND or AGND.

6

SMB_ALRT

O

SMBus alert pin. See SMBus specification.

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

3

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

Table 5-1. Pin Functions (continued)

PIN

I/O

DESCRIPTION

BOOT

I

Bootstrap pin for the internal flying high side driver. Connect a typical 100-nF X5R or better ceramic

capacitor rated for a minimum of 10 V from this pin to SW. To reduce the voltage spike at SW, an optional

BOOT resistor of up to 8 Ω can be placed in series with the BOOT capacitor to slow down turn-on of the

high-side FET.

SW

I/O

Switched power output of the device. Connect the output averaging filter and bootstrap to this group of

pins.

PGND

—

Power stage ground return. These pins are internally connected to the thermal pad.

NO.

NAME

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

I

Input power to the power stage. Low-impedance bypassing of these pins to PGND is critical. PVIN to

PGND should be bypassed with X5R or better ceramic capacitors rated for at least 1.5x the maximum

PVIN voltage. In addition, a minimum of one 0402 2.2-nF - 10-nF X7R or better ceramic capacitance

rated for at least 1.5x the maximum PVIN voltage should placed as close to the PVIN and PGND pins or

under the PVIN pins to reduce the high-frequency bypass impedance.

22

23

PVIN

24

25

26

AVIN

I

Input power to the controller. Bypass with a minimum 1-µF X5R or better ceramic capacitor rated for at

least 1.5x the maximum AVIN voltage to AGND. If AVIN is connected to the same input as PVIN or

VDD5, a minimum 10-µs R-C filter between PVIN or VDD5 and AVIN is recommended to reduce

switching noise on AVIN.

27

EN/UVLO

I

Enable switching as the PMBus CONTROL pin. EN/UVLO can also be connected to a resistor divider to

program input voltage UVLO.

28

VDD5

O

Output of the 5-V internal regulator. This regulator powers the driver stage of the controller and should be

bypassed with a minimum of 4.7-µF X5R or better ceramic capacitor rated for a minimum of 10 V to

PGND at the thermal pad. Low impedance bypassing of this pin to PGND is critical.

29

MSEL2

I

Connect this pin to a resistor divider between BP1V5 and AGND for different options of soft-start time,

overcurrent fault limit,and multiphase information. See Programming MSEL2 or Programming MSEL2 for

a Slave Device (GOSNS Tied to BP1V5) for a Slave Device (GOSNS tied to BP1V5) if GOSNS is tied to

BP1V5.

30

VSEL

I

Connect this pin to a resistor divider between BP1V5 and AGND for different options of internal voltage

feedback divider and default output voltage. See Programming VSEL.

31

ADRSEL

I

Connect this pin to a resistor divider between BP1V5 and AGND for different options of PMBus

addresses and frequency sync (including determination of SYNC pin as SYNCIN or SYNCOUT

function).See Programming ADRSEL.

32

MSEL1

I

Connect this pin to a resistor divider between BP1V5and AGND for different options of switching

frequency and internal compensation parameters. See Programming MSEL1.

I

The positive input of the remote sense amplifier. For a stand-alone device or the loop master device in a

multi-phase configuration, connect VOSNS pin to the output voltage at the load. For the loop slave

device in a multi-phase configuration, the remote sense amplifier is not required for output voltage

sensing or regulation and this pin can be left floating. If used to monitor another voltage with the Phased

READ_VOUT command, VOSNS should be maintained between 0 V and 0.75 V with a 4.5 V, input current to PMB_DATA,

SMB_ALRT, BCX_DAT = 20 mA

0.4

V

IOH(PMBUS)

Output high level open drain

leakage current into

PMB_DATA, SMB_ALRT

Voltage on PMB_DATA, SMB_ALRT = 5.5 V

10

μA

IOL(PMBUS)

Output low level open drain

sinking current on

PMB_DATA, SMB_ALRT,

BCX_DAT

Voltage on PMB_DATA, SMB_ALRT, BCX_DAT =

0.4 V

20

fPMBUS_CLK

PMBus operating frequency

range

GOSNS = AGND

10

CPMBUS

PMBUS_CLK &

PMBUS_DATA pin input

capactiance(1)

Vpin = 0.1V to 1.35V

NWR_NVM

Number of NVM writeable

cycles(1)

–40°C to 150°C

tCLK_STCH(max)

Maximum Allowable Clock

Stretch(1)

(1)

(2)

(3)

(4)

(5)

14

1.35

V

0.8

mA

1000

kHz

5

pF

1000

cycle

6

ms

Specified by design. Not production tested.

The parameter covers 2.95 V to 18 V of AVIN.

The setting of TON_RISE and TOFF_FALL of 0 ms means the unit to bring its output voltage to the programmed regulation value of

down to 0 as quickly as possible, which results in an effective TON_RISE and TOFF_FALL time of 0.5 ms (fastest time supported).

The setting of TON_MAX_FAULT_LIMIT and TOFF_MAX_WARN_LIMIT of 0 means disabling TON_MAX_FAULT and

TOFF_MAX_WARN response and reporting completely.

Not production tested. Guaranteed by correlation. AVIN = PVIN = 12 V, VOUT = 1 V fsw = 325kHz L = 320nH

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

6.6 Typical Characteristics

105

105

100

100

95

95

Ambient Temperature (qC)

Ambient Temperature (qC)

V PIN = V AVIN = 12 V, T A = 25°C, f sw = 325 kHz (unless otherwise specified). Safe operating area curves were

measured using a Texas Instruments evaluation module (EVM).

90

85

80

75

70

65

60

55

50

10

Nat conv

100 LFM

200 LFM

400 LFM

15

20

90

85

80

75

70

65

60

55

25

30

35

Phase Current (A)

40

45

50

10

50

Nat conv

100 LFM

200 LFM

400 LFM

15

20

D001

25

30

35

Phase Current (A)

40

45

50

D002

VIN = 5 V

VOUT = 1 V

Snubber = 1 nF + 1 Ω

VIN = 5 V

VOUT = 1 V

Snubber = 1 nF + 1 Ω

fSW = 325 kHz

L = 300 nH

RBOOT = 0 Ω

fSW = 550 kHz

L = 300 nH

RBOOT = 0 Ω

Figure 6-2. TPS546D24A Safe Operating Area

105

105

100

100

95

95

Ambient Temperature (qC)

Ambient Temperature (qC)

Figure 6-1. TPS546D24A Safe Operating Area

90

85

80

75

70

65

60

55

50

10

Nat conv

100 LFM

200 LFM

400 LFM

15

20

90

85

80

75

70

65

60

55

25

30

35

Phase Current (A)

40

45

50

10

50

Nat conv

100 LFM

200 LFM

400 LFM

15

20

D003

25

30

35

Phase Current (A)

40

45

50

D004

VIN = 12 V

VOUT = 1 V

Snubber = 1 nF + 1Ω

VIN = 12 V

VOUT = 1 V

Snubber = 1 nF + 1 Ω

fSW = 325 kHz

L = 300 nH

RBOOT = 0 Ω

fSW = 550 kHz

L = 300 nH

RBOOT = 0 Ω

105

100

95

90

85

80

75

70

65

60

55

50

45

40

35

10

Nat conv

100 LFM

200 LFM

400 LFM

15

20

Figure 6-4. TPS546D24A Safe Operating Area

Ambient Temperature (qC)

Ambient Temperature (qC)

Figure 6-3. TPS546D24A Safe Operating Area

25

30

35

Phase Current (A)

40

45

50

105

100

95

90

85

80

75

70

65

60

55

50

45

40

35

10

D005

Nat conv

100 LFM

200 LFM

400 LFM

15

20

25

30

35

Phase Current (A)

40

45

50

D006

VIN = 12 V

VOUT = 3.3 V

Snubber = 1 nF + 1Ω

VIN = 12 V

VOUT = 3.3 V

Snubber = 1 nF + 1 Ω

fSW = 325 kHz

L = 300nH

RBOOT = 0 Ω

fSW = 550 kHz

L = 300 nH

RBOOT = 0 Ω

Figure 6-5. TPS546D24A Safe Operating Area

Figure 6-6. TPS546D24A Safe Operating Area

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

15

�TPS546D24A

www.ti.com

110

110

100

100

Ambient Temperature (qC)

Ambient Temperature (qC)

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

90

80

70

60

50

Nat conv

100 LFM

200 LFM

400 LFM

40

30

10

15

20

80

70

60

50

Nat conv

100 LFM

200 LFM

400 LFM

40

30

25

30

35

Phase Current (A)

40

45

20

10

50

15

20

D007

25

30

35

Phase Current (A)

40

45

50

D008

VIN = 12 V

VOUT = 5 V

Snubber = 1 nF + 1 Ω

VIN = 12 V

VOUT = 5 V

Snubber = 1 nF + 1 Ω

fSW = 325 kHz

L = 300 nH

RBOOT = 0 Ω

fSW = 550 kHz

L = 300 nH

RBOOT = 0 Ω

Figure 6-8. TPS546D24A Safe Operating Area

100

100

95

95

90

90

Efficiency (%)

Efficiency (%)

Figure 6-7. TPS546D24A Safe Operating Area

85

80

75

70

85

80

75

70

0.8V

1.0V

1.2V

3.3V

65

0.8V

1.0V

1.2V

3.3V

65

60

60

0

5

10

15

20

25

Load Current (A)

30

35

40

0

5

10

D009

15

20

25

Load Current (A)

30

35

40

D010

VIN = 5 V

L = 300 nH

Snubber = 1 nF + 1 Ω

VIN = 5 V

L = 300 nH

Snubber = 1 nF + 1 Ω

fSW = 325 kHz

RDCR = 0.15 mΩ

RBOOT = 0 Ω

fSW = 550 kHz

RDCR = 0.15 mΩ

RBOOT = 0 Ω

Figure 6-10. TPS546D24A Efficiency vs Output

Current

100

100

95

95

90

90

Efficiency (%)

Efficiency (%)

Figure 6-9. TPS546D24A Efficiency vs Output

Current

85

80

75

0.8V

1.0V

1.2V

3.3V

5.0V

70

65

85

80

75

0.8V

1.0V

1.2V

3.3V

5.0V

70

65

60

60

0

5

10

15

20

25

Load Current (A)

30

35

40

0

D011

VIN = 12 V

L = 300 nH

Snubber = 1 nF + 1 Ω

fSW = 325 kHz

RDCR = 0.15 mΩ

RBOOT = 0 Ω

Figure 6-11. TPS546D24A Efficiency vs Output

Current

16

90

5

10

15

20

25

Load Current (A)

30

35

40

D012

VIN = 12 V

L = 300 nH

Snubber = 1 nF + 1

Ω

fSW = 550 kHz

RDCR = 0.15 mΩ

RBOOT = 0 Ω

Figure 6-12. TPS546D24A Efficiency vs Output

Current

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

9

1.65

8.5

1.55

8

7.5

Rdson (m:)

Rdson (m:)

1.45

1.35

1.25

1.15

6

5.5

1.05

5

Vgate

3.0V

4.5V

0.95

0.85

-40

7

6.5

-20

0

20

40

60

80 100

Temperature (qC)

120

140

Vgate = 3.0V

Vgate = 4.5V

4.5

4

-40

160

-20

0

20

D013

Figure 6-13. Low-Side MOSFET On-Resistance (R

DS(on))

vs Junction Temperature

40

60

80 100

Temperature (qC)

120

140

160

D014

Figure 6-14. High-Side MOSFET On-Resistance (R

DS(on))

vs Junction Temperature

1.003

700

650

Switching Frequency (kHz)

VOSNS - GOSNS (V)

1.002

1.001

1

0.999

0.998

-20

0

20

40

60

80 100

Temperature (qC)

120

140

550

500

450

400

350

300

325kHz

550kHz

250

VOUT = 1.00V

0.997

-40

600

200

-40

160

-20

0

20

D015

40

60

80 100

Temperature (qC)

120

140

160

D016

VOUT_COMMAND = 1 V

Figure 6-15. Output Voltage vs Junction

Temperature

Figure 6-16. Switching Frequency

vs Junction Temperature

4.75

13.8

13.6

13.4

4.725

13

VDD5 (V)

IAVIN (mA)

13.2

12.8

12.6

4.7

12.4

4.675

12.2

12

11.8

-40

-20

0

20

40

60

80 100

Temperature (qC)

120

140

160

4.65

-40

D017

IVDD5 = 10 mA

Figure 6-17. Non-Switching Input Current (IAVIN)

vs Junction Temperature

-20

0

20

40

60

80 100

Temperature (qC)

120

140

160

D018

VPVIN = VAVIN= 12 V

Figure 6-18. VDD5 Voltage vs Junction

Temperature

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

17

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

2.9

1.55

2.85

PVIN_ON (V)

BP1V5 (V)

1.525

1.5

2.8

2.75

2.7

1.475

2.65

1.45

-40

-20

0

20

40

60

80 100

Temperature (qC)

IBP1V5 = 2 mA

120

140

2.6

-40

160

-20

0

20

D023

VPVIN = VAVIN= 12 V

40

60

80 100

Temperature (qC)

120

140

160

D019

(35h) VIN_ON = 2.75 V

Figure 6-19. BP1V5 Voltage vs Junction

Temperature

Figure 6-20. Turnon Voltage vs Junction

Temperature

2.65

1.1

2.6

EN/UVLO (V)

PVIN_OFF (V)

1.05

2.55

2.5

2.45

1

0.95

2.4

2.35

-40

ON

OFF

-20

0

20

40

60

80 100

Temperature (qC)

120

140

160

0.9

-40

D020

-20

0

20

40

60

80 100

Temperature (qC)

120

140

160

D021

Figure 6-22. EN/UVLO Thresholds vs Junction

Temperature

(36h) VIN_OFF = 2.5 V

Figure 6-21. Turnoff Voltage vs Junction

Temperature

18

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

7 Detailed Description

7.1 Overview

The TPS546D24A uses a fixed-frequency, proprietary current-mode control. The switching frequency can be

selected from pre-set values through pin-strapping and PMBus programming. The output voltage is sensed

through a true differential remote sense amplifier and internal resistor divider, then compared to an internal

voltage reference by an error amplifier. An internal oscillator initiates the turnon of the high-side power switch.

The error amplifier output is buffered and shared through VSHARE among stacked devices. This shared voltage

is compared to the sensed switch node current to drive a linear voltage ramp modulator with input voltage,

output voltage, and switching frequency feedforward to regulate the average switch-node current. As a

synchronous buck converter, the device normally works in continuous conduction mode (CCM) under all load

conditions. The compensation components are integrated into the TPS546D24A devices, and programmable

through the PMBus command (B1h) USER_DATA_01 (COMPENSATION_CONFIG) or with the external pin

MSEL1 to select pre-set values based on switching frequency and output LC filters.

7.2 Functional Block Diagram

SYNC

MSEL2

BP1V5

VDD5

EN/UVLO

Auto-detection/

Decoder

PMBus

(SS, OC, Phase

SYNC

Count)

_IN

SYNC_

OUT

AVIN PVIN

Linear

Regulators

UVLO

PLL

To

Infrastructure

BOOT

BP1V8

Oscillator

PVIN

MSEL1

PWM

Decoder

(Fsw, Comp)

On-Time

Generator

MSEL2/PMBus

Driver

Control

SW

Anti-CrossConduction

VDD5

Pre-Bias

VSEL

Decoder

(Vref, Divider

Ratio)

Soft-Start

DAC

PGND

Output Current

Sensing

AGND

IMON

To Infrastructure &

Selectable Divider Ratio

R1

VOSNS

VSHARE

Error Amplifier with

Internal Compensation

+

Fault

Management

VOUT/UV/OV VMON & OV/UV

Detection

R2

GOSNS/SLAVE

RESET Vout

Slave

Detection

ADC, PMBus Interface, Back Channel

Interface, Memory

Decoder

(Addr, PH Pos,

Det SYNC in/out)

PGD/RST_B

TMON

Die Temp

Sensing

SMB_ALRT

BCX_DAT

PMB_CLK

DRTN

ADRSEL

PMB_DATA

BCX_CLK

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

19

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

7.3 Feature Description

7.3.1 Average Current-Mode Control

The TPS546D24A device uses an average current-mode control architecture with independently programmable

current error integration and voltage error integration loops. This architecture provides similar performance to

peak current-mode control without restricting the minimum on-time or minimum-off time control, allowing the gain

selection of the current loop to effectively set the slope compensation. For help selecting compensation values,

customers can use the TPS546x24A Compensation and Pin-Strap Resistor Calculator design tool.

Voltage Feed Forward and Frequency Setting

Voltage Feed Forward

Switching Frequency

Remote Sense with Internal

Resistor Divider

Voltage Regulation Error Amplifier w/

Internal Type-II Compensator

VO_SNS

Unity Gain

Remote

Sense Amp

Voltage Error

Amp

Sensed

GMV

VOUT

+

-

g VOUT err

+

VREF

GND_SNS

+

High-Bandwidth

Average Current Mode

Control Amplifier w/

Internal Compensation

Icntrl

+

GMI

g IL err

-

RVV

I_SNS

CZV

CPV

RVI

Current Error

Amp

CZI

S

Q

R

Q

PWM

Vcntrl

TON

Generator

CPI

Start

High-Frequency, Low Jitter

On-Time Modulator

Common Internal Ground for Regulation

PLL Synchronizable

PWM_CLK_EDGE

VSHARE

Regulation & Current Share Loop for

Stackability

Figure 7-1. Average Current Mode Control Block Diagram

7.3.1.1 On-Time Modulator

The input voltage feedforward modulator converts the integrated current error signal, ILerr, into an inductor ontime that provides a controlled volt-second balance across the inductor over each full switching period that

simplifies the current error integration loop design. The modulator produces a full-cycle averaged small signal

Vcntrl to dIL/dt transfer function given by Equation 1:

dIL

dt

dVcntrl

VIN

1

u

Vramp L

5.5

L

(1)

Thus the inductor current modulator gain is given by Equation 2:

dIL

¦

dVcntrl

VIN

1

u

Vramp L u ¦

5.5

Lu¦

(2)

This natural integration 1/f function allows the current loop to be compensated by the mid-band gain of the error

current integrator.

20

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

7.3.1.2 Current Error Integrator

The current error integrator adjusts the modulator control voltage to match the sensed inductor current, Isns, to

the current voltage at the VSHARE pin. The integrator is tuned through the GMI, RVI, CZI, CPI, and CZI_MUL

parameters in (B1h) USER_DATA_01 (COMPENSATION_CONFIG). Thanks to the natural integration of the 1/f

function of the current control gain, the bandwidth of the current control loop can be adjusted with the mid-band

gain of the integrator, GMI × RVI.

The current loop crossover occurs at the frequency when the full loop gain is equal to 1 according to Equation 3:

ILOOP ¦ u

VPVIN

1

u CSA u

Vramp

1.7 u S u ¦ u /

1

(3)

Solving for the mid-band gain of the current loop, you find Equation 4:

ILOOPMB

GMI u RVI

Vramp

u

VPVIN

1.7

u L u S u ¦coi

CSA

(4)

While Nyquist Theorem suggests that a bandwidth of ½ fSW is possible, inductor tolerances and phase delays in

the current sense, modulator, and H-bridge power FETs make f SW/4 a more practical target, which simplifies the

target current loop midband gain to achieve a current loop bandwidth of fSW/4 to Equation 5:

ILOOPMB

GMI u RVI

Vramp

u

VPVIN

¦

1.7

u L u S u sw

CSA

4

1.7 u S

4 u 5.5 u 6.155 u 10

3

u / u ¦sw

u / u ¦sw

(5)

An integrator from DC to the low-frequency zero, RVI × CZI, compensates for the valley voltage of the modulator

ramp and the nominal offset of the output voltage. A high-frequency filter pole, RVI × CPI between half the

switching frequency and the switching frequency reduces high-frequency noise from VSHARE and minimizes

pulse-width jitter.

To avoid loop interactions, the integrating zero frequency should be below the voltage loop cross-over frequency,

while the high-frequency pole should be between ½ the switching frequency and the switching frequency to limit

high-frequency noise and jitter in the current loop without imposing additional phase loss in the voltage loop.

The closed loop average current mode control allows the current sense amplifier, on-time modulator, H-bridge

power FETs, and inductor to operate as a transconductance amplifier with forward gain of 1/CSA or 162.5 A/V

with a bandwidth equal to Fcoi.

7.3.1.3 Voltage Error Integrator

The voltage error integrator regulates the output voltage by adjusting the current control voltage, VSHARE,

similar to any current mode control architecture. A transconductance amplifier compares the sense feedback

voltage to a programmed reference voltage to set the current control voltage VSHARE to maintain the desired

output voltage. While a regulated current source feeding an output capacitance provides a natural, stable

integrator, mid-band gain is often desired to improve the loop bandwidth and transient response.

With a transconductance set by the current sense gain, the voltage loop cross-over occurs when the full loop

gain equal 1 according to Equation 6.

VOUT _ SCALE _ LOOP u VLOOP ¦ u

1

u ZOUT ¦

CSA

1

(6)

To prevent the current integration loop bandwdith from negatively impacting the phase margin of the voltage

loop, the voltage loop should have a target bandwidth of Fcoi / 2.5. With a current mode loop of f SW/4, the

voltage loop mid-band gain should be Equation 7:

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

21

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

VLOOPMB

GMV u RVV

1

u

VOUT _ SCALE _ LOOP

CSA

·

§f

ZOUT ¨ SW ¸

© 10 ¹

(7)

An integrator pole is necessary to maintain accurate DC regulation, and the zero-frequency set by RVV × CZV

should be set below the lowest cross-over frequency with the largest output capacitor intended to be supported

at the output, but not more than 1/2 the target voltage loop crossover frequency fcov.

A high frequency noise pole, intended to keep switching noise out of the current loop should also be employed,

with a high-frequency pole set by RVV × CPV should be set between fsw/4 and fsw.

For pin programmed options of compensation components, see Table 7-9.

For PMBus programming of compensation values, see (B1h) USER_DATA_01 (COMPENSATION_CONFIG).

7.3.2 Linear Regulators

The TPS546D24A devices have three internal linear regulators receiving power from AVIN and providing

suitable bias (1.5 V, 1.8 V, and 5 V) for the internal circuitry of the device. External bypass pins for VDD5 and

BP1V5 must be bypassed to their respective grounds for the converter to function properly. BP1V5 requires a

minimum of 1 μF of capacitance connected to DRTN. VDD5 requires a minimum 4.7 μF of capacitance

connected to PGND. Once AVIN, 1.5-V, 1.8-V, and 5-V reach their respective UVLOs, the device initiates a

power-on reset, after which the device can be communicated with through PMBus for configuration and users

can store defaults to the NVM.

The VDD5 has internally-fixed undervoltage lockout of 3.9 V (typ.) to enable power-stage conversion. The VDD5

regulator can also be fed by external supply to reduce internal power dissipation and improve efficiency by

eliminating the loss in the internal LDO, or to allow operation with AVIN less than 4 V. The external supply should

be higher voltage than the LDO regulation voltage programmed by (B5h) USER_DATA_05

(POWER_STAGE_CONFIG).

Place bypass capacitors as close as possible to the device pins, with a minimum return loop back to their

respective ground. Keep the return loop away from fast switching voltage and main current path — see Layout

for details. Poor bypassing can degrade the performance of the regulator.

The use of the internal regulators to power other circuits is not recommended because the loads placed on the

regulators might adversely affect operation of the controller.

7.3.3 AVIN and PVIN Pins

The device allows for a variety of applications by using the AVIN and PVIN pins together or separately. The AVIN

pin voltage supplies the internal control circuits of the device. The PVIN pin voltage provides the input voltage to

the switching power stage. When connected to a single supply, the input voltage for AVIN and PVIN can range

from 4 V to 16 V. If the PVIN is connected to separate supply from AVIN, the PVIN voltage can be 2.95 V to 16 V,

and AVIN has to meet 4-V minimum and 18-V maximum to drive the control and driver. If AVIN is connected to

the same supply as PVIN or VDD5, TI recommends a minimum 10-µs R-C filter with a 1-Ω to 10-Ω resistor and

AVIN bypass capacitor between AVIN and PVIN to reduce PVIN switching noise on the AVIN input.

22

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

2.95 V ± 16 V

PVIN

VDD5

PGND

4.25 V ± 18 V

AVIN

AGND

Figure 7-2. TPS546D24A Separate PVIN and AVIN connections

2.95 V ± 16 V

PVIN

VDD5

PGND

4 V ± 5.25 V

AVIN

AGND

Figure 7-3. TPS546D24A Separate PVIN and AVIN connections with VDD5

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

23

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

2.95 V ± 16 V

4.75 V ± 5.25 V

PVIN

VDD5

PGND

2.95 V ± 18 V

or PVIN

AVIN

AGND

Figure 7-4. TPS546D24A Separate PVIN, AVIN, and VDD5 Connections

7.3.4 Input Undervoltage Lockout (UVLO)

The TPS546D24A provides four independent UVLO functions for the broadest range of flexibility in start-up

control. While only the fixed AVIN UVLO is required to enable PMBus connectivity as well as VOUT and

TEMPERATURE monitoring, all four UVLO functions must be met before switching can be enabled.

7.3.4.1 Fixed AVIN UVLO

The TPS546D24A has internally fixed UVLO of 2.5 V (typical) on AVIN to enable the digital core and initiate

power on reset, including pin detection. The off-threshold on AVIN is 2.3 V (typ).

7.3.4.2 Fixed VDD5 UVLO

The TPS546D24A has an internally-fixed UVLO of 3.9 V (typ) on VDD5 to enable drivers and output voltage

conversion. The off-threshold on VDD5 is 3.5 V.

7.3.4.3 Programmable PVIN UVLO

Two PMBus commands ((35h) VIN_ON and (36h) VIN_OFF) allow the user to set PVIN voltage turnon and

turnoff thresholds independently, with 0.25-V resolution from 2.75 V to 15.75 V (6-bit) for (35h) VIN_ON and from

2.5 V to 15.5 V (6-bit) for (36h) VIN_OFF.

Note

If (36h) VIN_OFF is programmed higher than (35h) VIN_ON, the TPS546D24A rapidly switches

between enabled and disabled while PVIN remains below (36h) VIN_OFF. Propagation delays

between enable and disable can result in the converter starting (61h) TON_RISE and (65h)

TOFF_FALL in such conditions.

7.3.4.4 EN/UVLO Pin

The TPS546D24A also offers a precise threshold and hysteresis current source on the EN/UVLO pin so that it

can be used to program an additional UVLO to any external voltage greater than 1.05 V (typ.), including AVIN,

PVIN, or VDD5. For an added level of flexibility, the EN/UVLO pin can be disabled or its logic inverted through

the PMBUS Command (02h) ON_OFF_CONFIG, which allows the pin to be connected to AGND to ensure the

output is not enabled until PMBus programming has been completed.

24

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

PVIN

Ihys

EN/UVLO

CNTRL

AGND

Figure 7-5. TPS546D24A UVLO Voltage Divider

7.3.5 Start-Up and Shutdown

The start-up and shutdown of the device is controlled by several PMBus programmable values including:

•

•

•

•

•

•

(01h) OPERATION

(02h) ON_OFF_CONFIG

(60h) TON_DELAY

(61h) TON_RISE

(64h) TOFF_DELAY

(65h) TOFF_FALL

With the default (02h) ON_OFF_CONFIG settings, the timing is as shown in Figure 7-6. See the Supported

PMBus Commands for full details on the implementation.

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

25

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

CNTRL

VDD5_OK

PVIN_OK

VOUT

TON_DELAY

TON_RISE

TOFF_DELAY

TOFF_FALL

Figure 7-6. TPS546D24A Start-up and Shutdown

Note

The TPS546D24A requires time between the AVIN and VDD5 reaching their UVLO levels for pindetection and PMBus Communication and valid sensing of EN/UVLO and PVIN_OK. Once AVIN and

VDD5 exceed their lower UVLO thresholds (2.9-V typ.), the TPS546D24A starts its power-on-reset,

self-calibration, and pin-detection. This time delay, t delay(uvlo_PMBus) (6 ms typ.) must be complete

before PVIN_OK or EN/UVLO sensing is enabled.

If VDD5PS_ON, PVIN_OK, and EN/UVLO are above their thresholds before the end of tdelay(uvlo_PMBus),

(60h) TON_DELAY will start after tdelay(uvlo_PMBus) completes.

If VDD5 PS_ON, PVIN_OK, or EN/UVLO are below their thresholds when t delay(uvlo_PMBus) completes,

(60h) TON_DELAY will start when VDD5_OK, PVIN_OK, and EN/UVLO are all above their thresholds.

7.3.6 Differential Sense Amplifier and Feedback Divider

The TPS546D24A includes a fully integrated, internal, precision feedback divider and remote sense. Using both

the selectable feedback divider and precision adjustable reference, output voltages up to 6.0 V can be obtained.

The feedback divider can be programmed to divider ratios of 1:1, 1:2, 1:4, or 1:8 using the (29h)

VOUT_SCALE_LOOP command.

The recommended operating range of (21h) VOUT_COMMAND is dependent upon the feedback divider ratio

configured (29h) VOUT_SCALE_LOOP as follows:

Table 7-1. (29h) VOUT_SCALE_LOOP and (21h)

VOUT_COMMAND Recommended Range

RECOMMENDED VOUT

RANGE (V)

1

0.25 to 0.75

0.5

0.5 to 1.5

0.25

1 to 3

0.125

2 to 6

Setting (21h) VOUT_COMMAND lower than the recommended range can negatively affect VOUT regulation

accuracy while setting (21h) VOUT_COMMAND above the recommended range can limit the actual output

voltage achieved.

26

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

Note

If the regulation output voltage is limited by the recommended range of the current (29h)

VOUT_SCALE_LOOP value, VOUT can be below the intended (43h) VOUT_UV_WARN_LIMIT or

(44h) VOUT_UV_FAULT_LIMIT without triggering their respective warning or faults due to the limited

range of the reference voltage.

7.3.7 Set Output Voltage and Adaptive Voltage Scaling (AVS)

The initial output voltage can be set by the VSEL pin at AVIN power up. As part of power-on reset (POR), the

VSEL pin senses both the resistance from the VSEL pin to AGND and the divider ratio of the VSEL pin between

B1V5 and AGND. These values program (29h) VOUT_SCALE_LOOP, (21h) VOUT_COMMAND, (2Bh)

VOUT_MIN, and (24h) VOUT_MAX and select the appropriate settings for the internal feedback divider and

precision adjustable reference voltage. Once the TPS546D24A completes its POR and enables PMBus

communication, these initial values can be changed through PMBus communication.

•

•

•

•

•

•

•

•

(20h) VOUT_MODE

(21h) VOUT_COMMAND

(29h) VOUT_SCALE_LOOP

(22h) VOUT_TRIM

(25h) VOUT_MARGIN_HIGH

(26h) VOUT_MARGIN_LOW

(01h) OPERATION

(02h) ON_OFF_CONFIG

The output voltage can be programmed through PMBus and its value is related to the following registers:

•

•

•

•

•

•

(24h) VOUT_MAX

(2Bh) VOUT_MIN

(40h) VOUT_OV_FAULT_LIMIT

(42h) VOUT_OV_WARN_LIMIT

(43h) VOUT_UV_WARN_LIMIT

(44h) VOUT_UV_FAULT_LIMIT

The TPS546D24A defaults to the relative format for the following, but can be changed to use absolute format

through the PMBus command (20h) VOUT_MODE:

•

•

•

•

•

•

(25h) VOUT_MARGIN_HIGH

(26h) VOUT_MARGIN_LOW

(40h) VOUT_OV_FAULT_LIMIT

(42h) VOUT_OV_WARN_LIMIT

(43h) VOUT_UV_WARN_LIMIT

(44h) VOUT_UV_FAULT_LIMIT

Refer to the detailed description of (20h) VOUT_MODE for details.

7.3.7.1 Reset Output Voltage

The (21h) VOUT_COMMAND value and the corresponding output voltage can be reset to the last selected

power-on reset value set by VSEL or EEPROM as selected in the (EEh) MFR_SPECIFIC_30

(PIN_DETECT_OVERRIDE) command when the PGD/RST_B pin function is set to RESET# in the (EDh)

MFR_SPECIFIC_29 (MISC_OPTIONS) PMBus command. To reset (21h) VOUT_COMMAND to its last PowerOn Reset value, when the RESET# optional function is enabled, assert the PGD/RST_B pin low externally.

While RESET# is asserted low, (21h) VOUT_COMMAND values received through PMBus is ACKed but no

change in (21h) VOUT_COMMAND is made. When RESET# is selected in (EDh) MFR_SPECIFIC_29

(MISC_OPTIONS), an internal pullup on the PGD/RST_B pin can be selected by the PULLUP# bit in the same

PMBus command to eliminate the need for an external pullup with the RESET# function.

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

27

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

PGD/

RST_B

Boot VOUT (VSEL or NVM)

Pre-AVS VOUT

VOUT

Slew Rate set by

VOUT_TRANSITION_RATE

AVS by

VOUT_COMMAND

RST_B Response Delay

Figure 7-7. TPS546D24A Output Voltage Reset

7.3.7.2 Soft Start

To control the inrush current needed to charge the output capacitor bank during start-up, the TPS546D24A

implements a soft-start time programmed by the (61h) TON_RISE command. When the device is enabled, the

reference voltage ramps from 0 V to the final level defined by the following at a slew rate defined by the (61h)

TON_RISE command:

•

•

•

•

•

•

(21h) VOUT_COMMAND

(29h) VOUT_SCALE_LOOP

(22h) VOUT_TRIM

(25h) VOUT_MARGIN_HIGH

(26h) VOUT_MARGIN_LOW

(01h) OPERATION

The TPS546D24A devices support several soft-start times from 0 ms to 31.75 ms in 250-µs steps (7 bits)

selected by the (61h) TON_RISE command. The tON_RISE time is selectable by pin-strapping through the MSEL2

pin (eight options), PMBus programming, or both.

During soft start, when the PWM pulse width is shorter than the minimum controllable on-time, pulse skipping

can be seen and the output can show larger ripple voltage than normal operation.

7.3.8 Prebiased Output Start-Up

The TPS546D24A limits current from being discharged from a pre-biased output voltage during start-up by

preventing the low-side FET from forcing the SW node low until after the first PWM pulse turns on the high-side

FET. Once VOSNS voltage exceeds the increasing reference voltage and high-side SW pulses start, the

TPS546D24A limits the synchronous rectification during each SW period with a narrow on-time. The maximum

low-side MOSFET on-time slowly increases on a cycle-by-cycle basis until 128 switch periods have elapsed and

the synchronous rectifier runs fully complementary to the high-side MOSFET. This limits the sinking of current

from a pre-biased output, and ensures the output voltage start-up and ramp-to regulation sequences are

monotonically increasing.

In the event of a pre-biased output voltage greater than (40h) VOUT_OV_FAULT_LIMIT, the TPS546D24A

responds as soon as it completes POR and VDD5 is greater than its own 3.9-V UVLO, even if conversion is

disabled by EN/UVLO or the PMBus (01h) OPERATION command.

7.3.9 Soft Stop and (65h) TOFF_FALL Command

When enabled by (02h) ON_OFF_CONFIG or (01h) OPERATION, the TPS546D24A implements (65h)

TOFF_FALL command to force a controlled decrease of the output voltage from regulation to 0. There can be

negative inductor current forced during the (65h) TOFF_FALL time to discharge the output voltage. The setting

of (65h) TOFF_FALL of 0 ms means the unit to bring its output voltage down to 0 as quickly as possible, which

results in an effective (65h) TOFF_FALL time of 0.5 ms. When disabled in the (02h) ON_OFF_CONFIG for the

turnoff controlled by EN/UVLO pin or bit 6 of (01h) OPERATION if the regulator is turned off by (01h)

28

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

OPERATION command, both high-side and low-side FET drivers are turned off immediately and the output

voltage slew rate is controlled by the discharge from the external load.

This feature is disabled for EN/UVLO in (02h) ON_OFF_CONFIG by default.

7.3.10 Power Good (PGOOD)

When conversion is enabled and t ON_RISE complete, if the output voltage remains between (43h)

VOUT_UV_WARN_LIMIT and (42h) VOUT_OV_WARN_LIMIT, the PGOOD open-drain output is released and

allowed to rise to an externally supplied logic level. Upon any fault condition with a shutdown response, the

PGOOD open-drain output is asserted, forcing PGOOD low by default. See Table 7-4 for the possible sources to

pull down the PGOOD pin.

The PGOOD signal can be connected to the EN/UVLO pin of another device to provide additional controlled

turnon and turnoff sequencing.

7.3.11 Set Switching Frequency

An internal oscillator generates a 225-kHz to 1.5-MHz clock for PWM switching with 16 discrete programmable

options. The switching frequency is selectable by pin-strapping through the resistor divider of MSEL1 (8 options),

PMBus programming (16 options), or both, using the (33h) FREQUENCY_SWITCH command, listed in Table

7-2.

Table 7-2. Oscillator fSW Options

AVAILABLE fSW OPTIONS (kHz)

fSW PIN-STRAPPING OPTIONS (kHz)

225

275

275

325

325

375

450

450

550

550

650

650

750

900

900

1100

1100

1300

1500

1500

7.3.12 Frequency Synchronization

The oscillator can be synchronized to external clock (SYNC IN) or output a clock to synchronize other devices

(SYNC out) on the SYNC pin. To support phase shifted clock for both multi-rail interleaving and multi-phase

operation, the internal oscillator can be phase-shifted from the SYNC pin by 0, 90, 120, 180, 240, or 270

degrees for 1, 2, 3, or 4 phase operation. The SYNC IN or SYNC OUT function, and phase position of single

phase or stand-alone devices can be selected by pin-strapping through resistor divider on at the ADRSEL pin, or

by the resistor from the MSEL2 pin to AGND for multi-phase slave devices.

In single output multi-phase stack configurations, the SYNC phase offset is programmed along with device count

and phase position using the MSEL2 pin. Slave devices in multi-phase stacks are always configured as

SYNC_IN while the master device can be configured for auto-detect, SYNC_IN, or SYNC_OUT through the

resistor divider on the ADRSEL pin.

Table 7-3. Pin Programmed Phase Positions through ADRSEL Resistor Divider (Single Phase StandAlone)

RDIV CODE

PHASE POSITION (DEGREE)

SYNC IN/OUT

Open (No resistor to BP1V5)

0

Auto-detect In/Out

0, 1

0

In

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

29

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

Table 7-3. Pin Programmed Phase Positions through ADRSEL Resistor Divider (Single Phase StandAlone) (continued)

RDIV CODE

PHASE POSITION (DEGREE)

SYNC IN/OUT

2, 3

90

In

4, 5

120

In

6, 7

180

In

8, 9

240

In

10,11

270

In

12, 13

0

Out

14, 15

180

Out

After initial power up and pin detection, if SYNC IN/OUT is set as auto-detection configuration, the TPS546D24A

senses the SYNC pin to determine if there is any external SYNC clock. Switching or a consistent pullup on the

SYNC pin sets the device for SYNC_IN while a consistent pulldown on SYNC sets the device for SYNC_OUT.

The TPS546D24A devices programmed to be loop slaves are always programmed to be SYNC IN.

When configured for SYNC_IN, if SYNC input pulses are missed for two cycles, or the oscillator frequency drops

below 50% of the free-running switching frequency, the device determines that SYNC clock is lost. If the

TPS546D24A is part of a multi-phase stack, the converter shuts down and remains disabled until a SYNC signal

is reestablished to prevent damage due to the loss of synchronization. Single phase stand-alone devices

continues to operate at approximately 50% of the nominal frequency.

7.3.13 Loop Slave Detection

The GOSNS/SLAVE pin voltage is detected at power up. When it is pulled high to BP1V5, the device is

recognized as loop slave. When the GOSNS/SLAVE pin is connected to the Output Ground, the TPS546D24A is

configured as a loop master.

7.3.14 Current Sensing and Sharing

Both high-side and low-side FET use a SenseFET architecture for current sensing to achieve accurate and

temperature compensated current monitoring. This SenseFET architecture uses the parasitic resistance of the

FETs to achieve lossless current sense with no external components.

When multiple (2×, 3×, or 4×) devices operate in multi-phase application, all devices share the same internal

control voltage through VSHARE pin. The sensed current in each phase is regulated by the VSHARE voltage by

internal transconductance amplifier, to achieve loop compensation and current balancing between different

phases. The amplifier output voltage is compared with an internal PWM ramp to generate the PWM pulse.

7.3.15 Telemetry

The telemetry sub-system in the controller core supports direct measurements of input voltage, output voltage,

output current, and die temperature. The ADC supports internal rolling window averaging with rolling windows up

to 16 previous measurements for accurate measurements of these key system parameters. Each ADC

conversion requires less than 500 µs, allowing each telemetry value to be updated within 2 ms.

The current sense telemetry, which senses the low-side FET current at the start and end of each low-side FET

on-time and averages the two measurements to monitor the average inductor current over-report current if the

inductor current is non-linear during the low-side FET on-time, such as when the inductor is operating above its

saturation current.

7.3.16 Overcurrent Protection

Both low-side overcurrent (OC) and high-side short circuit protection are implemented.

The low-side overcurrent fault and warning thresholds are programmed through PMBus and sensed across

cycle-by-cycle average current through the low-side MOSFET and compared to the set warning or fault threshold

while High-side pulses are terminated on a cycle-by-cycle basis, if the peak current through the high-side

MOSFET exceeds the 1.5× the programmed low-side threshold.

30

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

When either a low-side overcurrent or high-side short circuit threshold is exceeded during a switching cycle, an

OCP fault counter is incremented. If no overcurrent condition is detected in a switching cycle, the counter is

decremented. If the counter exceeds the delay selected by the (47h) IOUT_OC_FAULT_RESPONSE PMBus

value (default = 3) overcurrent fault condition is declared and the output shuts down. Restart and timing is also

defined as part of (47h) IOUT_OC_FAULT_RESPONSE.

The output OC fault thresholds and fault response are set through PMBUS. The OC fault response can be set to

shutdown, restart, or ignore.

7.3.17 Overvoltage/Undervoltage Protection

The voltage on VOSNS pin is monitored to provide output voltage overvoltage (OV) and undervoltage (UV)

protection. When VOSNS voltage is higher than OV fault threshold, OV fault is declared and the low-side FET is

turned on to discharge the output voltage and eliminate the OV condition. The low-side FET remains on until the

VOSNS voltage is discharged to 200 mV divide by the internal feedback divider as programmed by (29h)

VOUT_SCALE_LOOP. Once the output voltage is discharged, the output is disabled and the converter times out

and restarts according to the (41h) VOUT_OV_FAULT_RESPONSE PMBus command. When VOSNS voltage is

lower than UV fault threshold, UV fault is declared. After an initial delay programmed by the (45h)

VOUT_UV_FAULT_RESPONSE PMBus command, the output is disabled and the converter times out and

restarts according to the (45h) VOUT_UV_FAULT_RESPONSE PMBus command.

The output UV/OV fault thresholds and fault response are set through PMBUS. The UV/OV fault response can

be set to shutdown, restart, or continue operating without interruption.

7.3.18 Overtemperature Management

There are two schemes of overtemperature protections in the TPS546D24A device:

1. On-chip die temperature sensor for monitoring and overtemperature protection (OTP)

2. The bandgap based thermal shutdown (TSD) protection. TSD provides OT fail-safe protection in the event of

a failure of the temperature telemetry system, but can be disabled through (50h) OT_FAULT_RESPONSE for

high temperature testing

The overtemperature protection (OTP) threshold is set through PMBus and compares the (8Dh)

READ_TEMPERATURE_1 telemetry to the (51h) OT_WARN_LIMIT and (4Fh) OT_FAULT_LIMIT. The

overtemperature (OT) fault response can be set to shutdown, restart, or continue operating without interruption.

7.3.19 Fault Management

For the response on OC fault, OT fault, and thermal shutdown for multi-phase stack, the shutdown response has

the highest priority, followed by restart response. Continue operating without interruption response has the

lowest priority.

When multiple faults occur in rapid succession, it is possible for the first fault to occur to mask the second fault. If

the first fault to be detected is configured to continue operating without interruption, and the second fault is

configured to shutdown and restart, the second fault will shutdown but can fail to restart as programmed.

Table 7-4. Fault Protection Summary

FAULT OR

WARNING

Internal OT fault

Internal OT warning

FAULT RESPONSE

SETTING

FET BEHAVIOR

(4Fh)

OT_FAULT_LIMIT

Shutdown

Both FETs off

Restart

Both FETs off, restart

Ignore

FETS still controlled by PWM

(51h)

OT_WARN_LIMIT

Shutdown or restart

on Fault

FETS still controlled by PWM

PROGRAMMING

ACTIVE DURING t

ON_RISE

Yes

SMB_ALRT

MASKABLE

Y

Y

PGOOD LOGIC

Low

High

Yes

Y

Y

Yes

Y

Y

Yes

Y

Y

High

Ignore fault

TSD

Low Side OC fault

Threshold fixed

internally

(46h)

IOUT_OC_FAULT_LI

MIT

Shutdown

Both FETs off

Restart

Both FETs off, restart

Ignore

FETS still controlled by PWM

Shutdown

3 PWM counts, then both FETs off

Restart

3 PWM counts, then both FETs

off, restart after [DELAY]*tON_RISE

Ignore

FETS still controlled by PWM

Low

High

Low

High

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

31

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

Table 7-4. Fault Protection Summary (continued)

FAULT OR

WARNING

Low Side OC

warning

PROGRAMMING

(4Ah)

IOUT_OC_WARN_LI

MIT

Negative OC fault

(lower priority than

OVF)

N/A

High side OC fault

(46h)

IOUT_OC_FAULT_LI

MIT

FAULT RESPONSE

SETTING

Shutdown or restart

on Fault

FET BEHAVIOR

MASKABLE

PGOOD LOGIC

Yes

Y

Y

High

Yes

Y

Y

Yes

Y

Y

Ignore fault

Enable

Turn off LS FET

Disable

FETS still controlled by PWM

Shutdown

3 cycles of pulse-by-pulse current

limiting followed by both FETs off

Restart

3 cycles of pulse-by-pulse current

limiting followed by both FETs off,

restart after [DELAY]*tON_RISE

Ignore

FETS still controlled by PWM

LS FET latched ON or turned on

till VOUTreaches 200mV/

VOUT_SCALE_LOOP; HS FET

OFF

Restart

LS FET latched ON or turned on

till VOUTreaches 200mV/

VOUT_SCALE_LOOP; HS FET

OFF, restart after [DELAY] * t

Ignore

FETS still controlled by PWM

Shutdown

LS FET latched ON or turned on

till VOUTreaches 200mV/

VOUT_SCALE_LOOP; HS FET

OFF

Restart

LS FET latched ON or turned on

till VOUTreaches 200mV/

VOUT_SCALE_LOOP; HS FET

OFF, restart after [DELAY]*t

Ignore

FETS still controlled by PWM

(42h)

VOUT_OV_WARN_L

IMIT

Shutdown or restart

on Fault

FETS still controlled by PWM

(44h)

VOUT_UV_FAULT_L

IMIT

Shutdown

Both FETs off

Restart

Both FETs off , restart after

[DELAY]*tON_RISE

Ignore

FETS still controlled by PWM

(43h)

VOUT_UV_WARN_L

IMIT

Shutdown or restart

on Fault

FETS still controlled by PWM

(62h)

TON_MAX_FAULT_L

IMIT

Shutdown

Both FETs off

Restart

Both FETs off, restart after

[DELAY]*tON_RISE

Ignore

FETS still controlled by PWM

PVin UVLO

(35h) VIN_ON, (36h)

VIN_OFF

Shutdown

Both FETs off

PVIN OV FAULT

(55h)

VIN_OV_FAULT_LIM

IT

Shutdown

Both FETs off

Restart

Both FETs off, restart

(40h)

VOUT_OV_FAULT_L

IMIT

SMB_ALRT

ON_RISE

FETS still controlled by PWM

Shutdown

Vout OV fault

ACTIVE DURING t

Low

High

Low

High

No

Y

Y

Low

ON_RISE

VOUT OVF fix

(40h)

VOUT_OV_FAULT_L

IMIT

High

Yes

Y

Y

Low

ON_RISE

Vout OV warning

Vout UV fault

Vout UV warning

tON MAX rault

High

No

Y

Y

No

Y

Y

High

Ignore Fault

Low

High

No

Y

Y

Yes

Y

Y

Low

Ignore fault

Ignore

FETS still controlled by PWM

BCX_fault

N/A

N/A

FETS still controlled by PWM

Pin_Strap_NonConv

erge

N/A

VSEL

Both FETs off, pull low VSHARE

MSEL1

MSEL2

Low

High

Yes

Y

Y

Low

Yes

Y

Y

Yes

Y

Y

High

No (active before t

ON_RISE)

N

N/A

Low

Yes

N

N/A

High

Low

High

ADRSEL

SYNC_Fault

SYNC_High/Low

32

N/A

N/A

Loop master or

stand-alone device

FETS still controlled by PWM

Slave device

Both FETs off, pull low VSHARE

Loop master or

stand-alone device

FETS still controlled by PWM

Slave device

Both FETs off, pull low VSHARE

Low

Yes

Submit Document Feedback

N

N/A

High

Low

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

7.3.20 Back-Channel communication

To allow multiple devices with a shared output to communicate through a single PMBus address and single

PMBus slave, the TPS546D24A uses a back-channel communication implemented through BCX_CLK and

BCX_DAT pins. During POR, all of the devices connected to VSHARE must also be connected to BCX_CLK and

BCX_DAT and have appropriate (ECh) MFR_SPECIFIC_28 (STACK_CONFIG) settings. Any programming error

among the devices of a stack will result in a POR fault and prevent enabling of conversion.

During POR, the loop master reads the programmed values from the loop slaves to ensure all expected slaves

are present and correctly phase-shifted. Then, the Master will load critical operating parameters such as the

following to the slave devices to ensure correct operation of the STACK:

•

•

•

•

(B1h) USER_DATA_01 (COMPENSATION_CONFIG)

(33h) FREQUENCY_SWITCH

(61h) TON_RISE

(21h) VOUT_COMMAND

During operation, the master device receives and responds to all PMBus communication, and slave devices do

not need to be connected to the PMBus. If the master receives commands that require updates to the PMBus

registers of the slave, the master relays these commands to the slaves. Additionally, the master periodically polls

slave devices for status and telemetry information to maintain an accurate record of the telemetry and STATUS

information for the full stack of devices.

Most PMBus communication should be directed to all phases by leaving the (04h) PHASE PMBus command at

its Power On Reset default value of FFh. If a specific device must be communicated with, the (04h) PHASE

command can be changed to address a specific device within the stack, as set by the order value of the (37h)

INTERLEAVE command programmed during POR.

When commands are directed to individual slaves, write commands are queued by the master to be sent to the

slaves through the BCX if other BCX communication is in progress. Queued write commands are written to the

slaves in the order the master receives them. To avoid unnecessary delays on the PMBus and excessive clock

stretching, read transactions targeting individual slaves are not queued, and will be processed as soon as the

BCX bus is available. As a result, it is possible for a read command targeting an individual slave immediately

following a write command can be processed before the preceding write command. To ensure accurate readback, users must allow a minimum of 4 ms between writing a value to an individual slave and reading that same

value back from the same slave.

7.3.21 Switching Node (SW)

The SW pin connects to the switching node of the power conversion stage. It acts as the return path for the

highside gate driver. When configured as a synchronous buck stage, the voltage swing on SW normally

traverses from below ground to well above the input voltage. Parasitic inductance in the high-side FET and the

output capacitance (COSS) of both power FETs form a resonant circuit that can produce high frequency (> 100

MHz) ringing on this node. The voltage peak of this ringing, if not controlled, can be significantly higher than the

input voltage. Ensure that the peak ringing amplitude does not exceed the absolute maximum rating limit for the

pin.

In many cases, a series resistor and capacitor snubber network connected from the switching node to PGND

can be helpful in damping the ringing and decreasing the peak amplitude. Provide provisions for snubber

network components in the layout of the printed circuit board. If testing reveals that the ringing amplitude at the

SW pin exceeds the limit, then include snubber components.

7.3.22 PMBus General Description

Timing and electrical characteristics of the PMBus interface specification can be found in the PMB Power

Management Protocol Specification, Part 1, revision 1.3 available at http://pmbus.org. The TPS546D24A device

supports both the 100-kHz, 400-kHz, and 1-MHz bus timing requirements.

The TPS546D24A uses clock stretching during PMBus communication, but only stretches the clock during

specific bits of the transaction.

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

33

�TPS546D24A

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

•

•

•

•

•

www.ti.com

The TPS546D24A does not stretch the clock during the address byte of any transaction.

The TPS546D24A can stretch the clock between bit 0 of the command byte and its ACK response.

The TPS546D24A stretches the clock after bit 0 of the read address of a read transaction.

The TPS546D24A stretches the clock between bit 0 of the last byte of data and its ACK response

The TPS546D24A can stretch the clock between bit 1 and bit zero of every fourth byte of data for blocks with

more than four bytes of data.

Communication over the PMBus interface can either support the packet error checking (PEC) scheme or not. If

the master supplies clock (CLK) pulses for the PEC byte, PEC is used. If the CLK pulses are not present before

a STOP, the PEC is not used. If PEC will always be used, consider enabling Require PEC in (EDh)

MFR_SPECIFIC_29 (MISC_OPTIONS) to configure the TPS546D24A to reject any write transaction that does

not include CLK pulses for a PEC byte.

The device supports a subset of the commands in the PMBus 1.3 Power Management Protocol Specification.

See Supported PMBus Commands for more information

The TPS546D24A also supports the SMB_ALERT response protocol. The SMB_ALERT response protocol is a

mechanism by which the TPS546D24A can alert the bus master that it has experienced an alert and has

important information for the host. The host should process this event and simultaneously accesses all slaves on

the bus that support the protocol through the alert response address. All slaves that are asserting SMB_ALERT

should acknowledge this request with their PMBus Address. The host performs a modified receive byte

operation to get the address of the slave. At this point, the master can use the PMBus status commands to query

the slave that caused the alert. For more information on the SMBus alert response protocol, see the system

management bus (SMBus) specification. Persistent faults associated with status registers other than (7Eh)

STATUS_CML will reassert SMB_ALERT after responding to the host alert response address.

The TPS546D24A contains non-volatile memory that is used to store configuration settings and scale factors.

The settings programmed into the device are not automatically saved into this non-volatile memory. The (15h)

STORE_USER_ALL command must be used to commit the current PMBus settings to non-volatile memory as

device defaults. The settings that are capable of being stored in non-volatile memory are noted in their detailed

descriptions.

All pin programmable values can be committed to non-volatile memory. The POR default selection between pin

programmable values and non-volatile memory can be selected by the manufacturer specific (EEh)

MFR_SPECIFIC_30 (PIN_DETECT_OVERRIDE) command.

7.3.23 PMBus Address

The PMBus specification requires that each device connected to the PMBus have a unique address on the bus.

The TPS546D24A PMBus address is determined by the value of the resistor connected between ADRSEL and

AGND and is programmable over the range from 0x10 – 0x2F, providing 32 unique PMBus addresses.

7.3.24 PMBus Connections

The TPS546D24A supports the 100-kHz, 400-kHz, and 1-MHz bus speeds. Connection for the PMBus interface

must follow the high power DC specifications given in section 3.1.3 in the SMBus specification V2.0 for the 400kHz bus speed or the low power DC specifications in section 3.1.2. The complete SMBus specification is

available from the SMBus web site, smiforum.org

The PMBus interface pins: PMB_CLK, PMB_DATA, and SMB_ALRT require external pullup resistors to a 1.8-V

to 5.5-V termination. Pullup resistors should be sized to meet the minimize rise-time required for the desired

PMBus clock speed but should not source more current than the lowest rated CLK, DATA, or SMB_ALRT pin on

the bus when the bus voltage is forced to 0.4 V. The TPS546D24A supports a minimum of 20 mA of sink current

on PMB_CLK, PMB_DATA, and SMB_ALRT.

7.4 Device Functional Modes

7.4.1 Programming Mode

The TPS546D24A devices can operate in programming mode when AVIN and VDD5 are powered above their

lower UVLO but VDD5 and PVIN are not powered above their UVLO to enable conversion. In programing mode,

34

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS546D24A

�TPS546D24A

www.ti.com

SLUSDN0A – DECEMBER 2019 – REVISED NOVEMBER 2020

the TPS546D24A accepts and respond to PMBus commands but does not enable switching or conversion.

While PMBus commands can be accepted and processed with VDD5 lower than 3 V, NVM programming through

the (15h) STORE_USER_ALL command must not be used when VDD5 is less than 3 V.

Programming mode allows the TPS546D24A to complete POR and to be configured through PMBus from a 3.3V supply without PVIN present.

7.4.2 StandAlone/Master/Slave Mode Pin Connections

The TPS546D24A can be programmed as a Stand-Alone device (Single Output, Single Phase) Master device of

a single-output multi-phase stack of devices, or a Slave device to a master of a mult-phase stack. The details of

the recommended pin connects for each configuration is given in Table 7-5.

Table 7-5. Stand-Alone/Master/Slave pin connections

PIN

STAND ALONE

MASTER

SLAVE

GOSNS

Ground at Output Regulation Point

Ground at Output Regulation Point

BP1V5

VOSNS

Vout at Output Regulation Point

Vout at Output Regulation Point

Float or connect to divider for other

voltage to be monitored

EN/UVLO

Enable/Control or Resistor Divider

from PVIN

Enable/Control or Resistor Divider

from PVIN

Connect to EN/UVLO of the Master

MSEL1

Programming MSEL1

Programming MSEL1

Short to PGND (Thermal Pad)

Programming MSEL2

Programming MSEL2 for a Slave

Device (GOSNS Tied to BP1V5)

MSEL2

Programming MSEL2

VSEL

Programming VSEL

Programming VSEL

Short to PGND (Thermal Pad)

ADRSEL

Programming ADRSEL

Programming ADRSEL

Short to PGND (Thermal Pad)

VSHARE

Float or Bypass to AGND with

capacitor

Connect to VSHARE of the Slave

Connect to VSHARE of the Master

SYNC

Float or External Sync

External Sync or Slave SYNC

Connect to SYNC of the Master

PMB_CLK

Connect to System PMBus or PGND

(Thermal Pad) if not used

Connect to System PMBus or PGND

(Thermal Pad) if not used

Short to PGND (Thermal Pad)

PMB_DATA

Connect to System PMBus or PGND

(Thermal Pad) if not used

Connect to System PMBus or PGND

(Thermal Pad) if not used

Short to PGND (Thermal Pad)