Product

Folder

Order

Now

Support &

Community

Tools &

Software

Technical

Documents

Reference

Design

TPS92601-Q1, TPS92602-Q1

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

TPS9260x-Q1 Single- and Dual-Channel Automotive Headlight LED Driver

1 Features

3 Description

•

•

The TPS9260x-Q1 family of devices is a singlechannel and dual-channel high-side-current LED

driver. With full protection and diagnostics, this family

of devices is dedicated for and ideally suited to

automotive front lighting. The base of each

independent driver is a peak-current-mode boost

controller. Each controller has two independent

feedback loops, a current-feedback loop with a highside current-sensing shunt and a voltage-feedback

loop with an external resistor-divider network. The

controller delivers a constant output voltage or a

constant output current. The connected load

determines whether the device regulates a constant

output current (if the circuit reaches the current setpoint earlier than voltage set-point) or a constant

output voltage (if the circuit reaches the voltage setpoint is reached first, for example, in an open-load

condition).

1

•

•

•

•

•

•

•

•

•

•

•

Qualified for Automotive Applications

AEC-Q100 Qualified With the Following Results:

– Device Temperature Grade 1: –40°C to 125°C

Ambient Operating Temperature

– Device HBM ESD Classification Level 2

– Device CDM ESD Classification Level C4B

Input Voltage: 4 V–40 V (45 V Abs. Max.)

Output Voltage: 4 V–75 V (80 V Abs. Max.)

Fixed-Frequency Current-Mode Controller With

Integrated Slope Compensation

Two Regulation Loops, Constant-Current Output

and Constant-Voltage Output of Each Channel

High-Side Current Sense:

– 150-mV or 300-mV Sense Voltage (EEPROM

Option)

– ±6-mV Offset (Achieving Approx. 4% or 2%

LED Current Accuracy)

Output Voltage Sense, Internal Voltage

Reference: 2.2 V ±5%

Integrated Low-Side NMOS-FET Driver: Peak

Gate-Drive Current Typ. 0.7 A

Frequency Synchronization

Both PWM Dimming and Analog Dimming

Diagnostic:

– High-Side Current (LED Current) Available as

Analog Output

– Open-LED and Short-to-GND Detection

– Shorted Output Protection

Internal Under- and Overvoltage Lockout

2 Applications

•

•

Each controller supports all typical topologies such as

boost, boost-to-battery, SEPIC, or flyback.

Uses of the high-side PMOS FET driver are for PWM

dimming of the LED string and for cutoff in case of an

external short circuit to GND to protect the circuit.

Device Information(1)

PART NUMBER

SENSE-VOLTAGE

RANGE

CHANNELS

TPS92601-Q1,

TPS92601B-Q1

15 mV–150 mV

1

TPS92601A-Q1(2)

30 mV–300 mV

1

TPS92602-Q1,

TPS92602B-Q1

15 mV–150 mV

2

TPS92602A-Q1(2)

30 mV–300 mV

2

(1) For all available packages, see the orderable addendum at

the end of the datasheet.

(2) Device is available as a preview only.

Automotive Headlight LED Driver

High-Brightness LED Applications

Figure 1. Typical Schematic

VBAT

VBAT

Part of

TPS92602-Q1

VIN

RT

DIAG1

GDRV1

COMP1

ISNS1

DIAG2

GDRV2

COMP2

ISNS2

ICTRL1

PWIN1

VCC

ISP1

ISN1

VOUT1

PWMO1

OVFB1

PGND1

Part of

TPS92602-Q1

CHANNEL

2

ICTRL2

PWIN2

ISP2

ISN2

VOUT2

PWMO2

OVFB2

PGND2

AGND

CHANNEL

1

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. UNLESS OTHERWISE NOTED, this document contains PRODUCTION

DATA.

�TPS92601-Q1, TPS92602-Q1

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

4

6.1

6.2

6.3

6.4

6.5

6.6

4

4

5

5

5

8

Absolute Maximum Ratings ......................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Typical Characteristics ..............................................

Detailed Description ............................................ 10

7.1 Overview ................................................................. 10

7.2 Functional Block Diagram ....................................... 10

7.3 Feature Description................................................. 11

7.4 Device Functional Modes........................................ 16

8

Application and Implementation ........................ 18

8.1 Application Information............................................ 18

8.2 Typical Applications ................................................ 18

9 Power Supply Recommendations...................... 34

10 Layout................................................................... 34

10.1 Layout Guidelines ................................................. 34

10.2 Layout Example .................................................... 35

11 Device and Documentation Support ................. 36

11.1

11.2

11.3

11.4

Related Links ........................................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

36

36

36

36

12 Mechanical, Packaging, and Orderable

Information ........................................................... 36

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision D (January 2015) to Revision E

Page

•

Changed Device Information table ........................................................................................................................................ 1

•

Changed the pinout diagrams ................................................................................................................................................ 3

•

Changed VCC to VCC throughout the data sheet. .................................................................................................................. 4

Changes from Revision C (September 2014) to Revision D

Page

•

Changed the device status for the TPS92601-Q1 from Product Preview to Production Data ............................................... 1

•

Added single-channel in addition to the dual-channel text throughout the data sheet .......................................................... 1

•

Changed the Handling Ratings table to ESD Ratings and moved the storage temperature to the Absolute Maximum

Ratings table .......................................................................................................................................................................... 4

•

Updated the units of the Q(GS) equation (Equation 37) ...................................................................................................... 24

•

Updated the units of the Q(GS) equation (Equation 71) and the resulting values ............................................................... 31

•

Updated the rDS(on) values as a result of Equation 72........................................................................................................... 31

Changes from Revision B (August 2014) to Revision C

•

Page

Changed the package type for the TPS92601-Q1 and TPS92601A-Q1................................................................................ 3

Changes from Revision A (April 2014) to Revision B

Page

•

Added a column to the Device Comparison table ................................................................................................................. 1

•

Changed Device Information table ........................................................................................................................................ 1

•

Changed pinout diagram and combined Pin Function tables................................................................................................. 3

Changes from Original (March 2014) to Revision A

•

2

Page

Added all new content following the first page ....................................................................................................................... 3

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

�TPS92601-Q1, TPS92602-Q1

www.ti.com

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

5 Pin Configuration and Functions

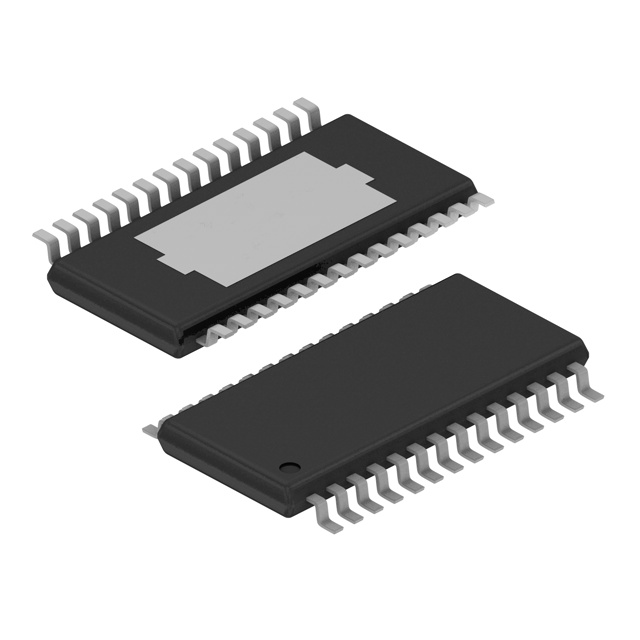

TPS92602x-Q1 PWP PowerPAD™ Package

28-Pin HTSSOP With Exposed Thermal Pad

Top View

TPS92601x-Q1 PWP PowerPAD Package

20-Pin HTSSOP Package With Exposed Thermal Pad

Top View

ICTRL1

1

28

PWMO1

COMP1

2

27

VOUT1

OVFB1

3

26

RT

4

25

DIAG1

5

24

PGND1

GND

6

23

ISNS1

PWMIN1

7

22

GDRV1

ICTRL1

1

20

PWMO1

ISN1

COMP1

2

19

VOUT1

ISP1

OVFB1

3

18

ISN1

RT

4

17

ISP1

DIAG1

5

16

PGND1

GND

6

15

ISNS1

PWMIN1

7

14

GDRV1

VIN

8

13

VCC

NC

9

12

NC

NC

10

11

NC

Thermal

Thermal

VIN

8

21

VCC

PWMIN2

9

20

GDRV2

Pad

OVFB2

10

19

ISNS2

ICTRL2

11

18

PGND2

COMP2

12

17

ISP2

DIAG2

13

16

ISN2

PWMO2

14

15

VOUT2

Pad

Not to scale

NC – No internal connection

Not to scale

NC – No internal connection

Pin Functions

PIN

TPS92601-Q1

TPS92601A-Q1

TPS92601B-Q1

20 PINS

TPS92602-Q1

TPS92602A-Q1

TPS92602B-Q1

28 PINS

COMP1

2

2

O

Compensation network (channel 1)

COMP2

—

12

O

Compensation network (channel 2)

DIAG1

5

5

O

Diagnostic pin (open, short, LED current) (channel 1)

DIAG2

—

13

O

Diagnostic pin (open, short, LED current) (channel 2)

GDRV1

14

22

O

Gate driver NMOS-FET (channel 1)

GDRV2

—

20

O

Gate driver NMOS-FET (channel 2)

GND

6

6

—

Ground

ICTRL1

1

1

I

LED current-control pin, analog dimming (channel 1)

ICTRL2

—

11

I

LED current control pin, analog dimming (channel 2)

ISN1

18

26

I

Current-sense input – negative (channel 1)

ISN2

—

16

I

Current-sense input – negative (channel 2)

ISNS1

15

23

I

Overcurrent sense input (channel 1)

ISNS2

—

19

I

Overcurrent sense input (channel 2)

ISP1

17

25

I

Current-sense input – positive (channel 1)

ISP2

—

17

I

Current-sense input – positive (channel 2)

—

—

NAME

I/O

DESCRIPTION

9

NC

10

11

No internal connection

12

OVFB1

3

3

I

Voltage-feedback input (channel 1)

OVFB2

—

10

I

Voltage feedback input (channel 2)

PGND1

16

24

—

Power ground (channel 1)

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

Submit Documentation Feedback

3

�TPS92601-Q1, TPS92602-Q1

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

www.ti.com

Pin Functions (continued)

PIN

TPS92601-Q1

TPS92601A-Q1

TPS92601B-Q1

20 PINS

TPS92602-Q1

TPS92602A-Q1

TPS92602B-Q1

28 PINS

PGND2

—

18

—

PWMIN1

7

7

I

PWM input and channel enable or disable function (channel 1)

PWMIN2

—

9

I

PWM input and channel enable or disable function (channel 2)

PWMO1

20

28

O

PWM PMOS-FET driver output (channel 1)

PWMO2

—

14

O

PWM PMOS-FET driver output (channel 2)

RT

4

4

I

Oscillator pin and pin for external sync. frequency

VCC

13

21

O

Gate-drive supply voltage (external decoupling capacitor)

NAME

I/O

DESCRIPTION

Power ground (channel 2)

VIN

8

8

I

Supply voltage

VOUT1

19

27

I

Connect to boost output voltage (channel 1)

VOUT2

—

15

I

Connect to boost output voltage (channel 2)

Thermal pad

—

Solder to achieve appropriate power dissipation. Connect to PGND.

6 Specifications

6.1 Absolute Maximum Ratings (1) (2) (3)

over operating free-air temperature (unless otherwise noted)

MIN

Supply voltage

VIN, PWMINx (4)

MAX

–0.3

(4)

UNIT

40

V

Output voltage

VOUTx, ISPx, ISNx, PWMOx

–0.3

80

V

Differential voltage

(VOUTx – PWMOx) (4)

–0.3

8.8

V

Grounds

PGNDx (4)

–0.3

0.3

V

GDRVx, ISNSx

Other pins

VCC current

(4)

–0.3

8.8

V

OVFBx (4)

–0.3

80

V

VCC

–0.3

8.8

V

ICTRLx, COMPx, RT, DIAGx (4)

–0.3

3.6

V

220

mA

Junction temperature, TJ

–40

150

°C

Storage temperature, Tstg

–55

150

°C

(1)

(2)

(3)

(4)

Gate-driver supply

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, and do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods my affect device reliability.

The algebraic convention, whereby the most-negative value is a minimum and the most-positive value is a maximum.

All voltages are with respect to ground (GND pin), unless otherwise specified.

For the TPS9602-Q1 device, x = 1 or 2. For the TPS9601-Q1 device, x is blank.

6.2 ESD Ratings

VALUE

Human-body model (HBM), per AEC Q100-002

(1)

±2000

Other pins

V(ESD)

(1)

4

Electrostatic discharge

Charged-device model (CDM), per

AEC Q100-011

UNIT

±500

Corner pins (1, 14, 15, 28 for

TPS92602x-Q1; 1, 10, 11, 20 for

TPS92601x-Q1)

V

±750

AEC Q100-002 indicates HBM stressing is done in accordance with the ANSI/ESDA/JEDEC JS-001 specification.

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

�TPS92601-Q1, TPS92602-Q1

www.ti.com

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

6.3 Recommended Operating Conditions

over operating free-air temperature (unless otherwise noted)

Supply voltage

MIN

MAX

VIN (first connection to battery, full functionality)

6

26

V

VIN (battery voltage during cranking profile, full functionality)

4

26

V

26

40

V

4

75

V

VIN

Output sense

VOUTx, ISPx, ISNx (1)

PWMINx: enable and disable functionality

PWMIN

Other pins

(1)

UNIT

0

40

V

PWMINx: PWM functionality (1)

0

7

V

ISNSx, OVFBx (1)

0

8

V

VCC

3

8

V

ICTRLx, RT (1)

0

3.3

V

100

mA

Gate-driver supply current, VCC (2)

TA

Ambient temperature range

–40

125

°C

TJ

Junction temperature range

–40

150

°C

(1)

(2)

For the TPS9602-Q1 device, x = 1 or 2. For the TPS9601-Q1 device, x is blank.

Note available current for low-side gate drivers to drive the external BOOST FETs

6.4 Thermal Information

THERMAL METRIC

(1)

TPS92601-Q1

TPS92602-Q1

PWP (HTSSOP)

PWP (HTSSOP)

20 PINS

28 PINS

UNIT

RθJA

Junction-to-ambient thermal resistance

37

37.2

°C/W

RθJC(top)

Junction-to-case (top) thermal resistance

23.4

19.3

°C/W

RθJB

Junction-to-board thermal resistance

17.7

16.7

°C/W

ψJT

Junction-to-top characterization parameter

0.9

0.8

°C/W

ψJB

Junction-to-board characterization parameter

17.5

16.5

°C/W

RθJC(bot)

Junction-to-case (bottom) thermal resistance

0.9

2.6

°C/W

(1)

For more information about traditional and new thermal metrics, seeSemiconductor and IC Package Thermal Metrics application report,

SPRA953.

6.5 Electrical Characteristics

TJ = –40°C to 150°C, VVDD = 12 VDC, over recommended operating conditions (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

INPUT SUPPLY

V(VIN_norm)

V(VIN_crank)

Input voltage range

Normal mode after initial start-up, VIN rising

6

40

Normal mode after initial start-up, VIN falling

4

40

V

V(UVLO)

Undervoltage lockout

PWM1 = PWM2 = High, VIN falling,f(PWMOx) <

V(VOUTx) – 2 V

3.72

4

V

V(UVsh)

Undervoltage shutdown

PWM1 = PWM2 = High, VIN falling, quiescent

current < 2 µA

2.8

3.5

V

V(OVSH)

Overvoltage shutdown

PWM1 = PWM2 = High, VIN falling, V(PWMOx) =

V(VOUTx), V(GRDVx) = 0

40

40.7

V

SUPPLY CURRENT

I(stby)

Shutdown current

VIN = 12 V, PWMIN1 and PWMIN2 = low for >

t(CH_OFF),

TA = 25°C

2

VIN = 12 V, PWMIN1 and PWMIN2 = low for >

t(CH_OFF),

TA = 125°C

3

t(CH_OFF)

Channel OFF timer

PWMINx = low

t(CH_ON)

Channel ON timer

PWMINx = high, VCC = 5.5 V

Inom

Normal-mode current in OVP loop

VIN = 12 V, PWMINx = high

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

µA

9.5

14

8

18

ms

1

ms

12

mA

Submit Documentation Feedback

5

�TPS92601-Q1, TPS92602-Q1

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

www.ti.com

Electrical Characteristics (continued)

TJ = –40°C to 150°C, VVDD = 12 VDC, over recommended operating conditions (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

5.5

6.6

MAX

UNIT

GATE DRIVER SUPPLY VCC

V(VCC)

Output voltage

VIN > 6 V

V(VCC_dr)

Drop-out voltage

4 V < VIN < 8 V, I(VCC) < 50 mA

C(VCC)

VCC buffer capacitance

I(VCC)

Output current (only for internal usage)

I(VCC_LIM)

Current limit

2.2

VCC shorted to ground

150

Gate-source voltage to switch on boost NMOS

FET. Depends on VCC

5.5

10

7.4

V

400

mV

20

µF

80

mA

220

mA

7.4

V

GATE DRIVER – LOW-SIDE BOOST NMOS-FET

VGS(NMOS)

NMOS gate-source voltage

6.6

D(MAX)

Maximum duty cycle

tr(NMOS)

Gate driver rising

VCC = 6.6 V, no load

22

tf(NMOS)

Gate driver falling

VCC = 6 V, no load

8.5

rDS(on)(Source,Nmos)

Gate driver resistance, sourcing

VCC = 6.6 V, 100-mA load

2.5

4

Ω

rDS(on)(Sink,Nmos)

Gate driver resistance, sinking

VCC = 6.6 V, 100-mA load

2.5

4

Ω

100

115

mV

65

µA

93.8%

ns

ns

CURRENT LIMIT – NMOS FET

V(ISNSx)

Voltage limit threshold across sensecurrent resistor

t(ISNSx)

Leading edge blanking

I(ISNSx)

Current on ISNSx

A(PS)

VC current-mode gain (ΔVvc / ΔVsns)

83

200

40

50

ns

4

V/V

150

mA

GATE DRIVER – HIGH-SIDE PWM PMOS-FET

I(PWMOx_Source)

Peak source current

V(OUT) – V(PWMOx) = 6.5 V, V(OUT) = 40 V

I(PWMOx_Sink)

Peak sink current

V(OUT) – V(PWMOx) = 0 V, V(OUT) = 40 V

V(PWMOx)

Output voltage

VGS(PMOS)

PMOS gate-source voltage

PWMx = high, V(OUT) = 40 V

VGS(NMOS)

NMOS gate-source voltage

Sufficient gate-source voltage to switch on the

NMOS FET; this depends on VCC.

tr(PMOS)

HS gate driver rising

No load

1

µs

tf(PMOS)

HS gate driver falling

No load

3

µs

f(PWMIN)

Dimming frequency

See PWM dimming section

2

kHz

V(thLOW)

Logic low

Switch off PMOS dimming FET (low below)

V(thHIGH)

Logic high

Switch on PMOS dimming FET (high above)

R(PWMIN_pd)

Pulldown resistance at PWMINx pin

10

4

mA

75

V

6

6.9

8

V

5.5

6.6

7.4

V

PWM DIMMING

0.2

0.8

V

150

kΩ

2

90

V

120

PWMIN to LED turnoff time

80

ns

PWMIN to LED turnon time

60

ns

INTERNAL PLL OSCILLATOR

f(OSC)

Oscillator range

RT: 20-kΩ resistor. See Equation 2 and Figure 4

for f(OSC) vs RT

100

600

–20%

20%

100

kHz

Δf(OSC)

Oscillator accuracy

f(EXT)

Ext. synchronization

600

kHz

t(CLKpw)

Minimum clock input pulse duration

70

ns

V(RTthLO)

RT low voltage

0.8

V

V(RTthHI)

RT high voltage

t(RTdelay)

RT rising edge to GDRV1 rising edge

t(PLLlock)

PLL lock-in time

6

Submit Documentation Feedback

2

V

35

200

ns

µs

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

�TPS92601-Q1, TPS92602-Q1

www.ti.com

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

Electrical Characteristics (continued)

TJ = –40°C to 150°C, VVDD = 12 VDC, over recommended operating conditions (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

HIGH-SIDE CURRENT-SENSE ERROR AMPLIFIER VFBx < 2.1 V

V(SPSN,Com)

V(SPSN_Diff)

Common-mode voltage ISPx, ISNx

Full-scale sense voltage ISPx – ISNx

4

74

4 V < V(SPSN_Com) < 75 V, VFBx < 2.1 V,

TPS92601-Q1, TPS92602-Q1,TPS92601B-Q1,

TPS92602B-Q1

150

4 V < V(SPSN_Com) < 75 V, VFBx < 2.1 V,

TPS92601A-Q1, TPS92602A-Q1

300

mV

V(SPSN_AC)

Sense-voltage accuracy

Common-mode voltage 4 V to 75 V

I(BIAS_SPSN)

Input bias current ISPx, ISNx

4 V < V(SPSN_Com) < 75 V, V(SPSN_Diff) = 150 mV

100

135

Input offset current ISPx, ISNx

TPS92601-1, TPS92602-Q1, TPS92601B-Q1,

TPS92602B-Q1, 4 V < V(SPSN_Com) < 75 V,

V(SPSN_Diff) = 150 mV

TPS92601A-Q1, TPS92602A-Q1, 4 V <

V(SPSN_Com) < 75 V, V(SPSN_Diff) = 300 mV

175

200

I(offset_SPSN)

gMC

–6

mV

µA

µA

TPS92601-Q1, TPS92602-Q1, TPS92601B-Q1,

TPS92602B-Q1

HS current-sense gain

6

40

Forward transconductance

A(HSCS)

V

TPS92601A-Q1, TPS92602A-Q1

1

mS

5

V/V

2.5

V/V

CURRENT CONTROL ICTRL – ANALOG DIMMING FOR ALL PARAMETERS: VFBx < 2.1 V

I(DIM_LIN)

K(DIMfactor)

Linear analog dimming range

Dimming factor, V(ICTRL) / V(SNSPx)

10%

9.7

10

10.3

TPS92601-Q1, TPS92602-Q1, TPS92601B-Q1,

TPS92602B-Q1, TA = 125ºC (1)

9.5

10

10.5

4.85

5

5.15

4.75

5

5.25

TPS92601A-Q1, TPS92602A-Q1, TA = 25ºC

(1)

TPS92601A-Q1, TPS92602A-Q1, TA = 125ºC (1)

V(ICTRLx)

Adjustable voltage range

R(ICTRLpd)

Pulldown resistance at ICTRLx pin

100%

TPS92601-Q1, TPS92602-Q1, TPS92601B-Q1,

TPS92602B-Q1, TA = 25ºC (1)

See Figure 13

0

0.75

1

1.5

V

1.2

MΩ

ERROR AMPLIFIER - REFERENCE VOLTAGE

V(VFB)

Voltage feedback

ΔV(VFB)

Voltage FB accuracy

I(BIAS)

Input bias current

g(Mv)

Forward transconductance

2.2

–5%

V

5%

VFB = 2.2 V

500

nA

1

mS

3.5

ms

INTERNAL SOFT-START

t(softstart)

Soft-start time, internal soft-start

COMP 0 V to 1.5 V

DIAGNOSIS – DIAGx PIN

V(OPLED)

V(DIAG_OP)

V(SHLED)

Open LED failure

TPS92601-Q1, TPS92602-Q1, TPS92601B-Q1,

TPS92602B-Q1

10

TPS92601A-Q1, TPS92602A-Q1

20

Low-level voltage, DIAGx pin

DIAGx pin pulled low, I(DIAGx) = 100 µA

Shorted LED failure

TPS92601-Q1, TPS92602-Q1, TPS92601B-Q1,

TPS92602B-Q1

225

TPS92601A-Q1, TPS92602A-Q1

450

0.15

V(DIAG_SH)

High-level voltage, DIAGx pin

V(ILED1)

V(ILED2)

Range for tracking LED current on DIAGx

pin

Voltage range on DIAGx pin (VIN > 6 V)

V(DIAG_AC)

Offset of DIAG output buffer

At input of DIAG buffer

12.5

Factor V(DIAG) / V(SPSN)

Within linear analog dimming range and DIAG

tracking range. Exclusive offset V(DIAG_AC),

TPS92601-Q1, TPS92602-Q1, TPS92601B-Q1,

TPS92602B-Q1

Within linear analog dimming range and DIAG

tracking range. Exclusive offset V(DIAG_AC),

TPS92601A-Q1, TPS92602A-Q1

6.25

K(DIAG_factor)

(1)

mV

DIAGx pin pulled high, I(DIAGx) = 100 µA

V

mV

3

3.47

0.2

2.85

0.2

2.85

–12

12

V

V

mV

Within linear analog dimming range (10%–100%). Exclusive offset V(SPSN_AC) = 6 mV

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

Submit Documentation Feedback

7

�TPS92601-Q1, TPS92602-Q1

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

www.ti.com

Electrical Characteristics (continued)

TJ = –40°C to 150°C, VVDD = 12 VDC, over recommended operating conditions (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

COMPENSATION NETWORK – COMPx PIN

V(COMPx)

Compensation-network output-pin voltage

0

3.3

V

THERMAL SHUTDOWN

T(SD)

Thermal shutdown

T(HYS)

Hysteresis

165

°C

20

°C

6.6 Typical Characteristics

Load is eight LEDs per channel at 500 mA, –40ºC ≤ TA ≤ 125ºC, –40ºC ≤ TJ ≤ 150ºC, C(COMP) = 0.22 µF, unless otherwise

noted.

510

100

CH1

508

98

CH2

96

LED Current (mA)

Boost Efficiency (%)

506

94

92

90

504

502

500

498

496

494

88

492

490

86

8

10

12

14

16

18

V(VIN) Voltage (V)

20

8

10

14

16

18

V(VIN) Voltage (V)

Figure 2. Boost Efficiency vs Input Voltage

20

C002

Figure 3. Line Regulation

700

600

600

500

Output Current (mA)

Switching Frequency (kHZ)

12

C001

500

400

300

200

CH1

CH2

400

300

200

100

100

0

0

0

20

40

60

80

100

R(RT) Resistance (kŸ)

120

140

0

20

40

60

80

Dimming Duty Cycle (%)

C003

100

C004

f(PWM) = 200 Hz

Figure 4. Switching Frequency vs R(RT) Resistance

8

Submit Documentation Feedback

Figure 5. I(OUT) vs PWM Dimming Duty Cycle

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

�TPS92601-Q1, TPS92602-Q1

www.ti.com

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

Typical Characteristics (continued)

Load is eight LEDs per channel at 500 mA, –40ºC ≤ TA ≤ 125ºC, –40ºC ≤ TJ ≤ 150ºC, C(COMP) = 0.22 µF, unless otherwise

noted.

3000

180

160

2500

120

V(DIAGx) (mV)

ISP t ISN (mV)

140

100

80

60

2000

1500

1000

40

500

20

0

0

0

500

1000

1500

2000

V(ICTRLx) (mV)

0

2500

100

503

603

502

Output Current (mA)

601

597

595

593

591

589

200

250

C006

Figure 7. V(DIAGx) vs V(ISPx – ISNx)

605

599

150

ISP t ISN (mV)

Figure 6. Analog Dimming: Differential Sense Voltage,

V(ISPx – ISNx) vs V(ICTRLx)

Switching Frequency (kHZ)

50

C005

CH1

CH2

501

500

499

498

497

496

587

585

495

±40 ±25 ±10

5

20

35

50

65

80

Ambient Temperature (ƒC)

95

110 125

±40 ±25 ±10

5

20

35

50

65

80

95

110 125

Ambient Temperature (ƒC)

C007

C008

R(RT) = 20 kΩ

Figure 8. Switching Frequency vs Ambient Temperature

Figure 9. V(ISPx – ISNx) vs Ambient Temperature

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

Submit Documentation Feedback

9

�TPS92601-Q1, TPS92602-Q1

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

www.ti.com

7 Detailed Description

7.1 Overview

The TPS92602y-Q1 device is a dual-channel LED driver. The base of each independent driver is a peak-currentmode boost controller. The two boost controllers operate 180° out-of-phase in order to reduce ripple currents and

radiation.

Each controller is independently configurable to regulate the output current (the typical case for driving LEDs) or

to regulate the output voltage. Depending on the chosen configuration for each channel, one loop is active while

the other loop only acts in case of a failure condition. In a constant-current application, the inactive voltage loop

sets the maximum output-voltage limit (and hence becomes active in case of output overvoltage due to an open

LED). In constant-voltage applications, the inactive current loop sets the maximum output current limit (and

hence becomes active in case of output overcurrent because of an LED short to ground).

The TPS92601y-Q1 device is a single-channel version of the TPS92602y-Q1 device. Both devices have the

same functions.

7.2 Functional Block Diagram

V(BAT)

L

VIN

TPS9260x-Q1

LDO

VDD

LDO

VCC

Int. FET

C

D

LED

VCC

Int. FET

CVCC

Voltage

Monitor

TJ

Shutdown

ISP

+

UVLO

±

VDD

Shutdown

Logic

VOUT

DIAG

Osc

or

PLL

ROSC

VCC

CLRZ

CLRZ

D

CLK

QZ

Q

VDD

Slope

Compensation

CP

±

±

VDD

VDD

VDD

C Z RZ

VDD

PWMIN

PWMO

MP

Overcurrent

Detect

GDRV

ISNS

+

+

+

COMP

VDD

1

CLRZ

&

RT

RLED_SNS

ISN

Softstart

RSNS

100 mV

ROVFB_B

OVFB

±

+

±

+

+

2.2 V

ROVFB_A

0.75 V

ICTRL

PGND

GND

Figure 10. Block Diagram, TPS9260xy-Q1 in Boost-To-Battery Configuration

10

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

�TPS92601-Q1, TPS92602-Q1

www.ti.com

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

Functional Block Diagram (continued)

TPS9260x-Q1

VBAT

TPS9260x-Q1

VBAT

TPS9260x-Q1

VBAT

TPS9260x-Q1

VBAT

TPS9260x-Q1

VBAT

VCC

VCC

VCC

VCC

VCC

BOOST-TO-BATTERY

SEPIC

BOOST

FLYBACK

BUCK-TO-BATTERY

Note: The SEPIC and flyback topologies require two extra diodes per channel for start-up, because the minimum common-mode voltage of the current-regulation amplifier is 4 V.

Figure 11. Supported Topologies per Channel

7.3 Feature Description

7.3.1 Fixed-Frequency PWM Control

Each boost controller uses an adjustable fixed-frequency peak-current-mode control. In a constant-current

application, the device senses the output current across an external shunt resistor at the ISPx and ISNx pins,

amplifies and level-shifts it to ground-reference, and compares it to the voltage applied on the ICTRLx pin by the

primary error amplifier, which drives the COMPx pin. In a constant-voltage application, the device compares the

output voltage through external resistors on the OVFBx pin to an internal 2.2-V voltage reference by a secondary

error amplifier, which drives the COMPx pin. Depending on the chosen application, only one of the error

amplifiers is active.

An internal oscillator initiates the turnon of the external boost-power NMOS switch. The device compares the

error-amplifier output to the switch current sensed on the ISNSx pin. When the power-switch current reaches the

level set by the COMPx voltage, the power NMOS switch turns off. The COMPx pin voltage increases and

decreases as the output current increases and decreases. The device implements a current limit by clamping the

COMPx pin voltage to a maximum level.

7.3.2 Slope-Compensation Output Current

Each controller adds a compensating ramp to the switch-current signal. This slope compensation prevents subharmonic oscillations. The available peak inductor current remains constant over the full duty-cycle range.

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

Submit Documentation Feedback

11

�TPS92601-Q1, TPS92602-Q1

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

www.ti.com

Feature Description (continued)

7.3.3 Boost-Current Limit

Each controller achieves peak-current-mode control using a comparator that monitors the current through the

external boost FET at the ISNSx pin by comparing it with the voltage on the COMPx pin. A redundant currentlimit comparator, which compares the voltage on the ISNSx pin with a typical 100-mV reference voltage, limits

the current through the external boost FET. If the voltage on the ISNSx pin exceeds this typical 100-mV

threshold, the on-cycle of the respective boost controller immediately terminates. The current-limit comparator

has a lead-edge blanking time to avoid any unwanted triggering of the current limit during switch-on of the

external boost FET. One can set the current-limit level with an external resistor, as calculated with the following

equation.

100 mV

I (Lim) =

R (LIM)

(1)

7.3.4 Oscillator and PLL

The switching frequency is adjustable over a range from 100 kHz to 600 kHz by placing a resistor on the RT pin.

The RT pin voltage is typically 0.5 V and must have a resistor to ground to set the switching frequency. To

determine the timing resistance for a given switching frequency, use Equation 2 or the curve in Figure 4. To

reduce the solution size one would typically set the switching frequency as high as possible, but give

consideration to tradeoffs of the supply efficiency, maximum input voltage, and minimum controllable on-time.

12.5 MHz ´ 1 kW

R RT [kW] =

f (OSC) [MHz]

(2)

One can also use the RT pin to synchronize the controllers to an external system clock, over a range from 100

kHz to 600 kHz. Apply a square wave to the RT pin to use this synchronization feature. The square wave must

transition lower than 0.8 V and higher than 2 V on the RT pin and have an on-time greater than 70 ns and an off

time greater than 70 ns. The synchronization frequency range is 100 kHz to 600 kHz. The rising edge of GDRV1

is synchronized to the falling edge of the RT pin signal.

Leaving the RT pin open or shorted to ground with no external system clock signal is present disables both boost

controllers, and both PWM dimming FETs switch off. In order to recover from this global failure state, (for

example, after the failure condition on the RT pin has been removed) there must be one global disable-andenable cycle (active shutdown by pulling both PWMINx pins low for t > t(CH_OFF), and setting one or both PWMINx

pins high for t > t(CH_ON)).

7.3.5 Control Loop Compensation

Modeling of the TPS9260xy-Q1 control loop is like that for any current-mode controller. Using a first-order

approximation, one can model the uncompensated loop as a single pole created by the output capacitor and, in

the boost and buck-boost topologies, a right half-plane zero created by the inductor, where both have a

dependence on the dynamic resistance of the LED string. There is also in the model a high-frequency pole

which, however, is near the switching frequency and plays no part in the compensation design process.

Therefore, the loop analysis neglects this high-frequency pole. Because TI recommends ceramic capacitors for

use with LED drivers due to long lifetimes and high ripple-current rating, one can also neglect the ESR of the

output capacitor in the loop analysis. Finally, there is a dc gain of the uncompensated loop which depends on

internal controller gains and the external sensing network. A boost regulator serves as an example case. See the

Detailed Design Procedure section for compensation of all topologies.

Equation 3 gives the whole-loop gain for a boost regulator.

æ

s( j) ö æ

s( j)

ç1 +

÷ ´ çç 1 w

w

ezc ø è

ezrhp

è

Tu = Tuo ´

æ

ö

s( j)

ç1 +

÷

ç

÷

w

ep0 ø

è

ö

÷

÷

ø

(3)

Equation 4 approximates the output pole (ωep0).

12

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

�TPS92601-Q1, TPS92602-Q1

www.ti.com

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

Feature Description (continued)

wep0 =

2

r(D) ´ Co

where

•

•

r(D): LED and R(ILED_SNS) dynamic resistance

CO: Output capacitor

(4)

Use Equation 5 to calculate the right half-plane zero (ωezrhp).

wezrhp =

r(D) ´ D' 2

L1

(5)

Use Equation 6 to calculate the output capacitor and ESR zero (ωezc).

1

wezc =

resr ´ Co

(6)

The EA transfer function with compensation capacitor and resistor of the system is described in Equation 7 is

shown in Equation 7.

s( j) ö

æ

ç 1 + wez1 ÷

è

ø

Tuo = Adc ´

æ

s( j) ö æ

s( j) ö

ç1 +

÷ ´ ç1 +

÷

wep1 ø è

wep2 ø

è

where

Adc is the error-amplifier (EA) dc gain

(7)

Use Equation 8 to calculate the EA output with compensation capacitor pole (ωep1).

1

wep1 =

R (o) ´ Cz

where

R(o) is the EA output impendence

(8)

The EA higher frequency pole (ωep2 to filter the high-frequency noise, which is higher than whole-loop bandwidth)

is shown in Equation 9.

1

wep2 =

R z ´ Cp

(9)

The EA output ESR zero (ωez1) is shown in Equation 10.

1

wez1 =

R z ´ Cz

(10)

Compensator design should give adequate phase margin (above 45°) at the crossover frequency. A simple

compensator using a single capacitor at the COMP pin adds a dominant pole to the system, which ensures

adequate phase margin if placed low enough. At high duty cycles, the RHP zero places extreme limits on the

achievable bandwidth with this type of compensation. However, because an LED driver is essentially free of

output transients (except catastrophic failures, open or short), the dominant pole approach, even with reduced

bandwidth, is usually the best approach.

7.3.6 LED Open-Circuit Detection

An open LED in any channel interrupts the current flow of that channel. If the LED current in the sensing circuit

falls below the defined threshold thOLED, then the device pulls the DIAGx pin of the affected channel low (for

example, for use as an interrupt to a microcontroller). The output-voltage regulation is with respect to the set

point of the voltage-control loop (resistor divider network on the OVFBx pin). Removal of the failure releases the

DIAGx pin automatically.

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

Submit Documentation Feedback

13

�TPS92601-Q1, TPS92602-Q1

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

www.ti.com

Feature Description (continued)

7.3.7 Output Short-Circuit and Overcurrent Detection

In case of an external short circuit of a boost output supply line to GND, the respective boost controller of the

affected channel is no longer able to limit the current through the control loop. This is because of the conductive

path from the supply voltage to the shorted output through the inductor and the boost diode.

To protect the external components from excessive currents, the controller of the affected channel interrupts the

path to its output by switching off the high-side PWM-dimming PMOS-FET. The interruption occurs as soon as

the high-side current-sense amplifier detects a common-mode voltage below 4 V, or when the voltage on the

VOUTx pin is below 4 V, or once the high-side current-sense amplifier hits the shorted-output detection threshold

V(OPLED). The protection of each channel operates in this way, independently of the other channel (see statediagram in Figure 14). The device pulls the DIAGx pin of the affected channel high, and the controller of the

affected channel remains in this channel-fail state. In order to reset the controller of the affected channel (for

example, after removal of a short circuit) there must be one disable-and-enable cycle for the affected channel by

pulling the PWMINx pin low for t > t(CH_OFF), and setting it high for t > t(CH_ON).

7.3.8 Measuring LED Current During a Non-Failure Condition

In regular operation mode, one can measure the actual output current of the controller with an external

microcontroller by sensing the voltage at the DIAGx pin. The DIAGx pin voltage between 0.2 V and 2.85 V

represents in a linear relation the output current measured by the current-sense block across the external shunt

resistor. Parameter DIAGfactor gives the scale factor of typically 12.5 (the TPS92601y-Q1 or TPS92602y-Q1

device with 150-mV full-scale current-sense voltage) or 6.25 (the TPS92601A-Q1 or TPS92602A-Q1 device with

300-mV full-scale current-sense voltage). Figure 12 gives the relation between the DIAGx pin voltage and the

current-sense voltage.

VDIAGx

Short Circuit or

Overcurrent Detected

HIGH, 3 V < VDIAG < 3.465 V

Default Working Point

0.2 V to 2.85 V

for VIN > 6 V

Normal Operation

LOW, 0 V < VDIAG < 0.15 V

TPS92601-Q1, TPS92602-Q1: 20 mV*

TPS92601A-Q1, TPS92602A-Q1: 40 mV*

Open LED Detected

225 mV*

450 mV*

150 mV*

300 mV*

VISPx_ISNx

* Approximate voltages

Figure 12. DIAGx Pin Function

When the device is in global shutdown mode (when both PWMINx pins go low for t > t(CH_OFF)), both DIAGx pins

are low.

14

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

�TPS92601-Q1, TPS92602-Q1

www.ti.com

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

Feature Description (continued)

7.3.9 LED Dimming Options

The device offers two different approaches to regulate and control the brightness and the color of the LEDs:

analog dimming and PWM dimming.

7.3.9.1 Analog Dimming

An analog voltage applied to the ICTRLx pin allows changing the output current for each channel on the fly from

10%–100% of full-scale. Typically, this approach is used to:

• Reduce the default current in a narrow range to adjust to different binning classes of the LEDs

• Reduce the current at high temperatures (protect LEDs from overtemperature)

• Reduce the current at low input voltages (for example, cranking-pulse breakdown of the supply)

Implementing this analog dimming function is possible with an analog approach (discrete resistor and NTC

network) or with a more-flexible approach by using a microcontroller. Internally clamping the maximum voltage

on the ICTRLx pin at 1.5 V simplifies the analog implementation. So applying any higher voltage has no effect on

the output current (which remains at its current set point at 100% of full scale, that is, 150 mV or 300 mV drop at

the external current shunt resistor).

V(ISPx_ISNx)

TPS92601A-Q1, TPS92601-Q1,

TPS92602A-Q1, TPS92602-Q1,

300 mV

150 mV

Linear Analog Dimming

Region

10%–100%

30 mV

15 mV

0 mV

0 mV

150 mV

1.5 V

V(ICTRLx)

Figure 13. Analog Dimming – ICTRLx Pin

7.3.9.2 PWM Dimming

To change the brightness of an LED string by a certain magnitude without affecting the lighting-color of the LED,

it is necessary to use PWM dimming topology. Turning the LEDs ON and OFF at a certain frequency with a

certain duty cycle reduces the brightness without changing the LED current (so not affecting the color).

The integrated high-side PMOS-FET gate driver turns the LED string ON and OFF following the supplied signal

frequency and duty cycle on the PWMIN pin. During the OFF time of the FET, the device stops the internal

control loop by disconnecting the loop internally and then stores the value of the compensation network. This

technique allows fastest recovery of the regulator with the following ON time, as the control loop restarts from the

point at which it stopped. The average LED current during ON time is almost the same as the LED current with

no PWM dimming (duty cycle 100%). For very low duty cycles, the time required by the controller to ramp up the

inductor current form 0 A becomes more significant relative to the overall ON time, leading to lower average

current. So for very low duty cycles, the relation between average current and duty cycle is no longer linear.

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

Submit Documentation Feedback

15

�TPS92601-Q1, TPS92602-Q1

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

www.ti.com

Feature Description (continued)

One must maintain a minimum on-time in order for PWM dimming to operate in the linear region of its transfer

function. Because of disabling the controller during dimming, the PWM pulse must be long enough that the

energy intercepted from the input is greater than or equal to the energy being put into the LEDs. For boost and

boost-to-battery topologies, the minimum ON time (in seconds) for which the PWM dimming operates in the

linear region is:

2 ´ I(LED) ´ V(out) ´ L

t(PWMON _ MIN) =

V(IN)2

(11)

To ensure that the applied dimming-pulse duration matches with the effective dimming-pulse duration, TI

recommends synchronizing the dimming pulses with the switching clock of the boost converter. Choose the

external inductor and output capacitors according to the requirements for the minimum duty cycle.

7.4 Device Functional Modes

7.4.1 Undervoltage and Overvoltage Shutdown

During normal operation (6 V < V(VIN) < 40 V), when the supply voltage at the VIN pin drops below 4 V during

cranking, each boost controller is disabled (when previously in normal operation). As long as the battery voltage

stays above 3.5 V, both PWM dimming FETs are still controllable through the PWMINx pins, and the VCC

regulator is still active. The supply voltage recovering above 4 V re-enables each boost controller (which was

working normally before the supply voltage drop). When supply voltage at the VIN pin drops below 3.5 V, the

device enters standby due to battery undervoltage. From standby mode, re-enabling the device can only occur

when the supply voltage is above 6 V and one or both PWMINx pins are high for t > t(CH_ON)). See the state

diagram in Figure 14. When the supply voltage at the VIN pin goes above 40 V during load-dump, the device

disables both boost controllers due to battery overvoltage, and switches both PWM dimming FETs off. The VCC

regulator is still active. Once the battery voltage is below 40 V, the device recovers from this global failure state

after a global disable-and-enable cycle (active shutdown by pulling both PWMINx pins low for t > t(CH_OFF), and

setting one or both PWMINx pins high for t > t(CH_ON)). See the state diagram in Figure 14.

7.4.2 Overtemperature Shutdown

When the junction temperature rises above 165ºC, both boost controllers are disabled due to junction

overtemperature, and both PWM dimming FETs are switched off. Once the junction temperature is below 145ºC,

the device recovers from this global failure state or a global disable-and-enable cycle (active shutdown by pulling

both PWMINx pins low for t > t(CH_OFF), and setting one or both PWMINx pins high for t > t(CH_ON)). See the state

diagram in Figure 14.

7.4.3 Device State Diagram

Figure 14 shows the state diagram of the device, with a short description of the device behavior in each state.

16

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

�TPS92601-Q1, TPS92602-Q1

www.ti.com

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

Device Functional Modes (continued)

Main State Machine

V(VIN) > 6 V AND

Wakeup

Standby

V(VCC) disabled

Both boost controllers

disabled

Both PWM dimming

FETs switched off

Both DIAGx pins low

VIN > 40 V OR

Missing Clock OR

TJ > 165°C

Active

V(VCC) enabled

One or both channels

active (see Active

Sub-State Machine)

Global Failure

VCC enabled

Both boost controllers

disabled

Both PWM dimming

FETs switched off

DIAG1 and 2 pins low

PowerOnReset OR

PowerDown

WakeUp =

.(V

(PWMIN1) = 1 for t > t(CH_ON) OR V(PWMIN2) = 1 for t > t(CH_ON))

PowerDown = .(V(PWMIN1) = 0 for t > t(CH_ON) AND V(PWMIN2) = 0 for t > t(CH_ON))

Missing Clock = RT terminal open AND no sync pulse (CH_ON)

PowerOnReset = V(VIN) < 3.5 V

Active Sub-State Machine

Each channel can independently follow this State Machine.

Low-Voltage

V(PWMINx) = 0 for t > t(CH_OFF)

Boost controller

disabled

PWM dimming FET

controllable through

PWMINx pin

DIAGx pin shows

measured current

Main State ≠ Active

3.5 V < V(VIN) < 4 V

V(VIN) > 6 V

V(VIN) > 6 V AND

V(PWMINx) = 1 for t > t(CH_ON)

OFF

ON

Boost controller

enabled

PWM dimming FET

controllable through

PWMINx terminal

DIAGx terminal shows

measured current

Boost controller

disabled

PWM dimming FET

switched off

DIAGx terminal low

V(PWMINx) = 0 for t > t(CH_OFF)

V(PWMINx) = 0 for t > t(CH_OFF)

Channelx Failure

Detected

Channel-Fail

Boost controller

disabled

PWM dimming FET

switched off

DIAGx terminal high

Channelx Failure Detected = (V (VOUTx) < 4 V OR V(SPSNx_Com) < 4V OR V(SPSNx_Diff) > th(SHOUT))

NOTE: In the case of an open LED on channel x, the DIAGx pin is low, but the boost controller and the PWM

dimming FET of channel x work normally. Hence, the behavior is as in the ON state or the low-voltage state.

Figure 14. Device State Diagram

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

Submit Documentation Feedback

17

�TPS92601-Q1, TPS92602-Q1

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

www.ti.com

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

8.1 Application Information

This section describes the application-level considerations when designing with the TPS9260xy-Q1 family of

devices. For corresponding calculations, see the following section.

8.2 Typical Applications

In an application directly connected to a battery, if the application is a passenger car, V(VIN) is from 9 V to 16 V,

and LED forward voltage is always higher than battery, then one can select the boost topology. If the LED

forward voltage is between 9 V and 16 V, boost-to-battery or single-ended primary-inductance converter (SEPIC)

topology is appropriate.

8.2.1 Boost Regulator With Separate or Paralleled Channels

A boost application is appropriate for a situation where V(VIN) is from 9 V to 16 V and LED forward voltage is

always higher than battery the battery voltage. One can use the boost-regulator topology with each channel

driving a separate LED string. For higher-current applications, connect both channels in parallel to drive a single

LED string. The per-channel design parameters and calculations are the same in either case.

18

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

�TPS92601-Q1, TPS92602-Q1

www.ti.com

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

Typical Applications (continued)

VBAT

CIN1

L1

VIN

Q1

D1

DIAG1

RSNS1

GDRV1

CO1

COMP1

ISNS1

RLIM1

CHANNEL

1

ICTRL1

PWIN1

ISP1

ISN1

VOUT1

PWMO1

OVFB1

PGND1

ROV1

ROV2

VCC

VBAT

RT

CIN2

TPS92602-Q1

L2

Q1

D2

DIAG2

RSNS2

GDRV2

COMP2

ISNS2

CO2

RLIM2

CHANNEL

2

ISP2

ISN2

VOUT2

PWMO2

OVFB2

PGND2

ICTRL2

PWIN2

ROV3

AGND

ROV4

Figure 15. Boost Regulator (VIN < VO) Simplified Schematic, Separate Channels

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

Submit Documentation Feedback

19

�TPS92601-Q1, TPS92602-Q1

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

www.ti.com

Typical Applications (continued)

VBAT

CIN1

L1

VIN

Q1

D1

DIAG1

RSNS1

GDRV1

CO1

COMP1

ISNS1

RLIM1

CHANNEL

1

ICTRL1

PWIN1

ISP1

ISN1

VOUT1

PWMO1

OVFB1

PGND1

ROV1

ROV2

VCC

VBAT

CIN2

TPS92602-Q1

RT

L2

Q1

D2

DIAG2

RSNS2

GDRV2

COMP2

ISNS2

CO2

RLIM2

CHANNEL

2

ISP2

ISN2

VOUT2

PWMO2

OVFB2

PGND2

ICTRL2

PWIN2

ROV3

AGND

ROV4

Figure 16. Boost Regulator (VIN < VO) Simplified Schematic, Paralleled Channels

20

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

�TPS92601-Q1, TPS92602-Q1

www.ti.com

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

Typical Applications (continued)

LED_B1

LED_B2

D7

J_B1

D1

D8

1

2

D9

1

2

D10

1

2

1

2

VBAT1

R1

464k

OVP1

B150-13-F

0.7V

D2

VBAT2

R2

464k

OVP2

R3

30.0k

White

GND

R4

30.0k

AGND

R5

0.15

AGND

U1

0.1uF

AGND

8

21

DIAG1 5

GND

R7

510

2

C5

0.22uF

C6

270pF

1

PWM1 7

AGND

AGND

LED_B1

VIN

VCC

DIAG1

GDRV1

COMP1

ISNS1

ISP1

ISN1

VOUT1

PWMO1

OVFB1

ICTRL1

PWMIN1

R8

10.0k

PGND1

DIAG2 13

R12

R11

20.0k

12

510

C8

0.22uF

C9

270pF

11

PWM2 9

AGND

AGND

AGND

DIAG2

GDRV2

COMP2

ISNS2

ISP2

ISN2

VOUT2

PWMO2

OVFB2

ICTRL2

PWMIN2

+5V

R13

10.0k

PGND2

4

White

MP_PMOS1

B150-13-F

0.7V

C1

C2

10uF

C3

0.1uF

White

White

RT

GND

PAD

GND

23

25

26

27

28

3 OVP1

24

GND

GND

10uF/50V

100V

J_VBAT1

L_B1

R9

VBAT1

10A

22u

R10

C7

19

J_VBAT2

L_B2

10

VBAT2

D5

10A

22u

D6

C10

10uF/50V

MN_POWER2

OVP2

R14

0.012

18

GND

R16

0.15

6

GND LED_B2

TPS92602-Q1

R15

20.0k

GND

D4

MN_POWER1

D3

10

20

17

16

15

14

10

C4

3.3uF/100V

R6

0.012

22

GND

R17

20.0k

C11

3.3u/100V

MP_PMOS2

R18

0

AGND

AGND

GND

AGND

J_B2

GND

D11

1

D12

2

White

1

D13

2

1

D14

2

White

1

White

2

White

GND

Figure 17. Boost Regulator (VIN < VO) Detailed Schematic

8.2.1.1 Design Requirements

For this boost regulator example, use the following as the design parameters.

Table 1. Design Parameters

DESIGN PARAMETER

EXAMPLE VALUE

Input voltage range

Connect to battery (6 V to 16 V)

Output current per channel (I(setting))

1A

Output voltage

30 V (9 white LEDs)

Input ripple voltage

400 mV

Output ripple current

±10%

Operating frequency

600 kHz

8.2.1.2 Detailed Design Procedure

To

•

•

•

•

•

•

begin the design process, one must decide on a few parameters. The designer must know the following:

Input voltage range

Output current per channel

Output voltage

Input ripple voltage

Output ripple current

Operating frequency

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

Submit Documentation Feedback

21

�TPS92601-Q1, TPS92602-Q1

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

www.ti.com

8.2.1.2.1 Switching Frequency

The RT pin resistor sets the switching frequency of the TPS92602y-Q1 device. Use Equation 2 to calculate the

required value for R17. The calculated value is 20.83 kΩ. Use the nearest standard value of 20 kΩ.

8.2.1.2.2 Maximum Output-Current Set Point

The constant output current of the TPS92602y-Q1 device is adjustable by using the external current-shunt

resistor. In the application circuit of Figure 17, R5 is the channel 1 current-shunt resistor, and R16 is the channel2 current shunt resistor. Equation 12 and Equation 13 calculate the resistors that determine maximum output

current.

R(sense) = VSPSN_Diff / I(setting)

R5 = R16 = 150 mV / 1 A = 0.15 Ω

(12)

(13)

8.2.1.2.3 Output Overvoltage-Protection Set Point

The output overvoltage protection threshold of the TPS92602y-Q1 device is externally adjustable using a resistor

divider network. In the application circuit of Figure 17, this divider network comprises R1 and R3 for channel1

and R2 and R4 for channel2. The following equation gives the relationship of the overvoltage-protection

threshold (V(OVPT)) to the resistor divider.

R1 / R3 = R2 / R4 = (V(OVPT) – V(VFB)) / V(VFB)

(14)

The load is nine white LEDs, the forward voltage is about 30 V. For an overvoltage protection margin of 20%,

V(OVPT) is: V(OVPT) = 30 × 1.2 = 36 V. So R1 / R3 = R2 / R4 = (36 – 2.2) / 2.2 = 15.36. Select R3 = R4 = 30 kΩ;

then R1 = R2 = 460 kΩ. Use the nearest standard value of 464 kΩ.

8.2.1.2.4 Duty Cycle Estimation

Estimate the duty cycle of the main switching MOSFET using Equation 15 and Equation 16.

V(OUT) - V(IN- max) + V(FD) 30 V - 16 V + DMIN 0.5 V

D (MIN) »

=

= 47.5%

V(OUT) + V(FD)

30 V + 0.5 V

where

D is the duty cycle in these and all following equations

V(OUT) - V(IN- min) + V(FD) 30 V - 6 V + 0.5 V

D (MAX) »

=

= 80.3%

V(OUT) + V(FD)

30 V + 0.5 V

(15)

(16)

Using an estimated forward drop of 0.5 V for a Schottky rectifier diode, the approximate duty cycle is 47.5%

(minimum) to 80.3% (maximum).

8.2.1.2.5 Inductor Selection

The peak-to-peak ripple is limited to 30% of the maximum output current.

I(OUT- max)

1

I(Lrip- max) = 0.3 ´

= 0.3 ´

= 0.571 A

1 - D (MIN)

1 - 0.475

(17)

Estimate the minimum inductor size using Equation 18.

V(IN- max)

1

16 V

1

L (MIN) >>

´ D (MIN) ´

=

´ 0.475 ´

= 22.1 mH

I(Lrip-max)

f (SW ) 0.571 A

600 kHz

(18)

Select the nearest standard inductor value of 22 µH. Estimate the ripple current using Equation 19.

V(IN)

1

16 V

1

I(RIPPLE) »

´ D (MIN) ´

=

´ 0.475 ´

= 0.575 A

L

f (SW ) 22 mH

600 kHz

(19)

I(RIPPLE-Vinmin) »

V(IN)

L

´ D (MIN) ´

1

f (SW )

6V

1

=

´ 0.475 ´

= 0.365 A

22 mH

600 kHz

(20)

The worst-case peak-to-peak ripple current occurs at 47.5% duty cycle and is estimated as 0.575 A. Equation 21

estimates the worst-case rms current through the inductor.

22

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

�TPS92601-Q1, TPS92602-Q1

www.ti.com

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

2

I(Lrms)

2

2

æ I(OUT- max) ö æ 1

æé 1

ùö

ö

= (I(L-avg) ) + ç ê ´ I(RIPPLE) ú ÷ » ç

÷ + ç ´ I(RIPPLE-Vinmin) ÷

ç

÷

ûø

ø

è ë12

è 1 - D (MAX) ø è 12

2

2

æ 1A ö æ 1

ö

= ç

+ ç ´ 0.365 A ÷ = 5.08 A rms

÷

è 1 - 0.803 ø è 12

ø

(21)

The worst-case rms inductor current is 5.08 A rms. Equation 22 estimates the peak inductor current.

I(OUT- max) 1

1

I(Lpeak) »

+ ´ I(RIPPLE- Vinmin) =

+ 0.5 ´ 0.365 = 5.26 A

1 - D (MAX) 2

1 - 0.083

(22)

Select a 22-µH inductor with a minimum rms current rating of 5.08 A and minimum saturation current rating of

5.26 A. The selection is a Wurth 74435572200 inductor (shielded-drum core, ferrite, 22 µH, 11 A, 0.0146 Ω,

SMD).

Equation 23 estimates the power dissipation of this inductor

P(L) » (I(Lrms) )2 ´ DCR

(23)

The Wurth 74435572200 inductor with 14.6-mΩ DCR dissipates 404 mW of power.

8.2.1.2.6 Rectifier Diode Selection

The circuit uses a low-forward-voltage-drop Schottky diode as a rectifier diode to reduce power dissipation and

improve efficiency. Use 80% derating for the diode on VOUTx to allow for for ringing on the switch node.

Equation 24 gives the rectifier-diode minimum reverse-breakdown voltage.

V(VOPT)

V(BR)(R- min) ³

= 1.25 ´ 36 V = 45 V

0.8

(24)

The diode must have a reverse-breakdown voltage greater than 45 V. Equation 25 and Equation 26 estimate the

rectifier diode peak and average currents.

I(D-avg) » I(OUT- max) = 1 A

(25)

I(D-peak) = I(L-peak) = 5.26 A

(26)

For this design, average current is 1 A and peak current is 5.26 A.

Equation 27 estimates the power dissipation in the diode.

P(D- max) » V(F) ´ I(OUT- max) = 0.5 V ´ 1 A = 0.5 W

(27)

For this design, the maximum power dissipation is estimated as 0.5 W. After reviewing 45-V and 60-V Schottky

diodes, the selection is the 30BQ060PbF diode, Schottky, 60 V, 3 A, SMC. This diode has a forward voltage drop

of 0.5 V at 1 A, so the conduction power dissipation is approximately 500 mW, less than half its rated power

dissipation.

8.2.1.2.7 Output Capacitor Selection

Assume a maximum LED current ripple of 0.1 × I(LED). Also, assume that the dynamic impedance of the chosen

LED is 0.2 Ω (1.8 Ω total for the nine-LED string). The total output-voltage ripple calculation is then as per

Equation 28.

V(VOUT-ripple) = 0.1 A ´ 1.8 W = 180 mV

(28)

Assuming a ripple contribution of 95% from bulk capacitance, Equation 29 calculates the output capacitor.

I(OUT) ´ D

æ 1 A ´ 0.803 ö

1

1

C (OUT) =

´

=ç

= 7.83 mF

÷´

V(VOUT-ripple) ´ 0.95 f (SW ) è 180 mV ´ 0.95 ø 600 kHz

ESR =

V(VOUT-ripple)

I(L-peak)

=

9 mV

= 1.71 mW

5.26 A

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

(29)

(30)

Submit Documentation Feedback

23

�TPS92601-Q1, TPS92602-Q1

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

www.ti.com

Use three 3.3-μF capacitors in parallel to achieve the minimum output capacitance of 10 μF. Ensure that the

chosen capacitors meet the minimum bulk capacitance requirement at the operating voltage.

8.2.1.2.8 Input Capacitor Selection

Because a boost converter has continuous input current, the input capacitor senses only the inductor ripple

current. Equation 31 and Equation 32 calculate the input capacitor values.

I(L-RIPPLE)

0.575 A

C (IN) =

=

= 4 mF

4 ´ v (IN-RIPPLE) ´ f (SW ) 4 ´ 60 mV ´ 600 kHz

(31)

ESR =

V(VIN-RIPPLE)

I(L-RIPPLE)

=

60 mV

= 52 mW

2 ´ 0.575 A

(32)

For this design, to meet a maximum input ripple of 60 mV requires a minimum 4-µF input capacitor with ESR

less than 52 mΩ. Select a 10-µF X7R ceramic capacitor.

8.2.1.2.9 Current Sense and Current Limit

The maximum allowable current sense resistor value is limited by R(ISNSx). Equation 33 gives this limitation.

V(SNS)

100 mV

R (ISNSx) =

=

= 14.62 mW

1.3 ´ I(L-peak) 1.3 ´ 5.26 A

(33)

Select a 15-mΩ resistor.

8.2.1.2.10 Switching MOSFET Selection

The TPS92602y-Q1 device drives a ground-referenced N-channel FET. The breakdown voltage is the output

voltage plus any voltage spike, with 30% added for a safety margin as shown in Equation 34.

V(BD-MOS- min) ³ V(VOPT) ´ 1.3 = 1.3 ´ 36 V = 46.8 V

(34)

Select an N-channel FET with breakdown voltage of 50 V.

Estimate the rDS(on) and gate charge based on the desired efficiency target.

æ1 ö

æ 1

ö

P(DISS-total) » P(OUT) ´ ç - 1÷ = 30 V ´ 1 A ´ ç

- 1÷ = 1.578 W

è 0.95 ø

èh ø

(35)

For a target of 95% efficiency with a 16-V input voltage at 1 A, maximum power dissipation is limited to 1.578 W.

The main power-dissipating devices are the MOSFET, inductor, diode, current-sense resistor and the integrated

circuit, the TPS92602y-Q1 device.

P(FET) < P(DISS-total) - P(L) - P(D) - P(RSNS) - V(IN- max) ´ I(VDD)

(36)

This assumption leaves 740 mW of power dissipation for the MOSFET. Allowing half for conduction and half for

switching losses, we can determine a target rDS(on) and Q(GS) for the MOSFET by Equation 37 and Equation 38.

3 ´ P(FET) ´ I(DRIVE)

3 ´ 0.5 W ´ 0.7 A

Q (GS) <

=

= 29.2 nC

2 ´ V(OUT) ´ I(OUT) ´ f (SW ) 2 ´ 30 V ´ 1 A ´ 600 kHz

(37)

Calculate a target MOSFET gate-to-source charge of less than 29.2 nC to limit the switching losses to less than

250 mW.

P(FET)

0.5 W

rDS(on) <

=

= 12 mW

2

2

2 ´ I(RMS) ´ D 2 ´ (5.08 A) ´ 0.803

(

)

(38)

Selecting a target MOSFET rDS(on) of 12 mΩ limits the conduction losses to less than 250 mW.

24

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

�TPS92601-Q1, TPS92602-Q1

www.ti.com

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

8.2.1.2.11 Loop Compensation

The COMP pin on the TPS92602y-Q1 device is for external compensation, allowing optimization of the loop

response for each application. The COMP pin is the output of the internal transconductance amplifier. External

resistor R7, along with ceramic capacitors C5 and C6 (see Figure 17 ), connect to the COMP pin to provide

poles and zero. The poles and zero, along with the inherent pole and zero in a peak-current-mode control boost

converter, determine the closed-loop frequency response. Thhis connection is important to converter stability and

transient response. The first step is to calculate the pole and the right half-plane zero of the peak-current-mode

boost converter by Equation 39 and Equation 40. To make the loop stable, the loop must have sufficient phase

margin at the crossover frequency where the loop gain is 1. To avoid the effect of the right half-plane zero on

loop stability, choose a crossover frequency less than 1/5 of f(ZRHP).

I(OUT)

1

f (p) =

=

2p ´ V(OUT) ´ C(OUT) 2p ´ R (OUT) ´ C(OUT)

where

•

•

C(OUT) is the bulk output capacitance calculated previously

R(OUT) is the effective output impedance

(39)

2

f (ZRHP) =

R (OUT) =

V(OUT) ´ (1 - D)

2p ´ L ´ I(OUT)

(40)

(R (LED) + R (SENSE) ) ´ V(LED)

(R (LED) + R (SENSE) ) ´ I(LED) + V(LED)

where

R(LED) is the dynamic impedance of the LED string in ohms at the operating current

(41)

The loop compensation consists of a series resistor and capacitor (R(COMP) and C(COMP)) from COMP to SGND.

R(COMP) sets the crossover frequency and C(COMP) sets the zero frequency of the integrator. For optimum

performance, use the following equations:

gM(COMP) = 1000

R (COMP) =

C (COMP) =

(42)

f (ZRHP) ´ R (ISNSx)

5 ´ f (p) ´ (1 - D(MAX) ) ´ R (SENSE) ´ 5 ´ GM(COMP)

(43)

1

2p ´ R (COMP) ´ 5 ´ f (p)

where

f(p) is the pole frequency of the power stage calculated by Equation 39

(44)

An output capacitor that is an electrolytic capacitor which has large ESR requires a capacitor to cancel the zero

of the output capacitor. Equation 45 calculates the value of this capacitor.

C (OUT) ´ R (ESR)

C6 =

R (COMP)

(45)

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

Submit Documentation Feedback

25

�TPS92601-Q1, TPS92602-Q1

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

www.ti.com

8.2.1.3 Application Curves

26

Figure 18. PWM Dimming at 200 Hz, 5% Duty Cycle

Figure 19. PWM Dimming at 200 Hz, 50% Duty Cycle

Figure 20. PWM Dimming at 200 Hz, 95% Duty Cycle

Figure 21. Switching and LED Current Ripple

When I(OUT) = 1 A

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

�TPS92601-Q1, TPS92602-Q1

www.ti.com

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

8.2.2 Boost-to-Battery Regulator

When the LED forward voltage is between 9 V and 16 V, an appropriate selection is boost-to-battery topology,

which can share the same layout and components as the boost topology, with just a different way to connect

load.

VBAT

CIN1

L1

CO1

VIN

Q1

D1

DIAG1

RSNS1

GDRV1

COMP1

ISNS1

RLIM1

CHANNEL

1

ICTRL1

PWIN1

ISP1

ISN1

VOUT1

PWMO1

OVFB1

PGND1

ROV1

ROV2

VCC

VBAT

RT

TPS92602-Q1

L2

CIN2

CO2

Q1

D2

DIAG2

RSNS2

GDRV2

COMP2

ISNS2

RLIM2

CHANNEL

2

ICTRL2

AGND

PWIN2

ISP2

ISN2

VOUT2

PWMO2

OVFB2

PGND2

ROV3

ROV4

Figure 22. Boost-to-Battery Regulator Simplified Schematic

Copyright © 2014–2018, Texas Instruments Incorporated

Product Folder Links: TPS92601-Q1 TPS92602-Q1

Submit Documentation Feedback

27

�TPS92601-Q1, TPS92602-Q1

SLUSBP5E – MARCH 2014 – REVISED JULY 2018

www.ti.com

D7

D8

1

LED_B1

LED_B2

J_B1

2

1

D10

1

White

White

D1

D9