Please note that Cypress is an Infineon Technologies Company.

The document following this cover page is marked as “Cypress” document as this is the

company that originally developed the product. Please note that Infineon will continue

to offer the product to new and existing customers as part of the Infineon product

portfolio.

Continuity of document content

The fact that Infineon offers the following product as part of the Infineon product

portfolio does not lead to any changes to this document. Future revisions will occur

when appropriate, and any changes will be set out on the document history page.

Continuity of ordering part numbers

Infineon continues to support existing part numbers. Please continue to use the

ordering part numbers listed in the datasheet for ordering.

www.infineon.com

�CYW20737

Single-Chip Bluetooth Low Energy-Only

System-On-Chip

The Cypress CYW20737 is an advanced Bluetooth low energy SoC that supports wireless charging profile, includes advanced security

features and introduces new software support for NFC pairing via a tag. The CYW20737 is designed to support the entire spectrum

of Bluetooth Smart use cases for the medical, home automation, accessory, sensor, Internet Of Things, and wearable market

segments.

The CYW20737 radio has been designed to provide low power, low cost, and robust communications for applications operating in the

globally available 2.4 GHz unlicensed Industrial, Scientific, and Medical (ISM) band.

The single-chip Bluetooth low energy SoC is a monolithic component implemented in a standard digital CMOS process and requires

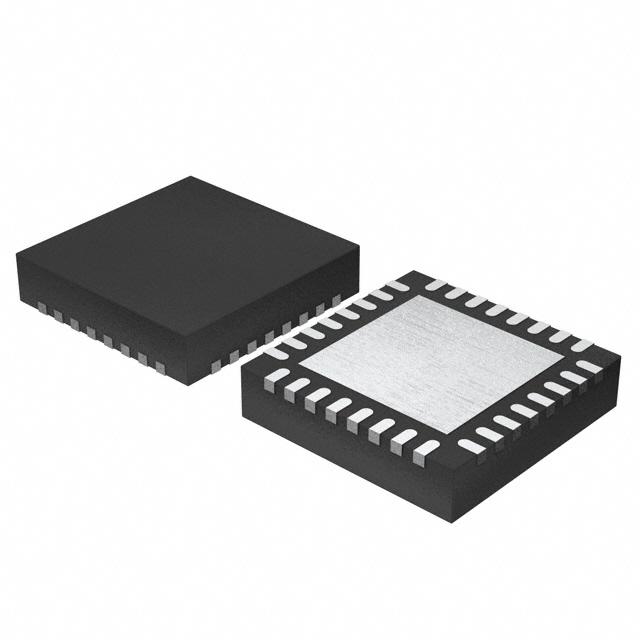

minimal external components to make a fully compliant Bluetooth device. The CYW20737 is available in a 32-pin, 5 mm × 5 mm 32QFN package as well as BGA SIP. CYW20737 is supported in WICED SDK 2.x.

Features

■

AirFuel wireless charging profile.

■

■

Support for RSA encryption/decryption and key exchange

mechanisms (up to 4 kbit)

Serial Communications interface (compatible with Philips®

I2C slaves)

■

Programmable output power control

■

Support for X.509 certificate exchange

■

Integrated ARM® Cortex™-M3 based microprocessor core

■

Support for NFC tag-based "tap-to-pair"

■

Automation Profile

■

Support for Bluetooth Smart Based Audio via Apple LEA

Spec.

■

Support for secure OTA

Bluetooth low energy (BLE)-compliant

■

On-chip power-on reset (POR)

■

Infrared modulator

■

Support for EEPROM and serial flash interfaces

■

Supports Adaptive Frequency Hopping

■

Integrated low-dropout regulator (LDO)

■

Excellent receiver sensitivity

■

On-chip software controlled power management unit

■

10-bit auxiliary ADC with nine analog channels

■

Package type:

■

■

On-chip support for serial peripheral interface (master and

slave modes)

❐

32-pin 32-QFN package (5 mm × 5 mm)

■

RoHS compliant

Applications

The following profiles are supported1 in ROM:

■

Battery status

■

Proximity

■

Blood pressure monitor

■

Thermometer

■

Find me

■

Weight scale

■

Heart rate monitor

■

Time

■

Location

Additional profiles that can be supported from RAM include:

■

Blood glucose monitor

■

Temperature alarm

1.Full qualification and use of these profiles may require FW updates from Broadcom. Some of these profiles are under development/approval at the Bluetooth SIG and

conformity with the final approved version is pending. Contact your supplier for updates and the latest list of profiles.

Cypress Semiconductor Corporation

Document Number: 002-16365 Rev. *D

•

198 Champion Court

•

San Jose, CA 95134-1709

•

408-943-2600

Revised June 8, 2020

�PRELIMINARY

CYW20737

Figure 1. Functional Block Diagram

Muxed on GPIO

RTS_N

RX TX CTS_N

UART_TXD

SCL/

SCK

SDA/

MISO

MOSI

UART_RXD

1.2V VDD_CORE

1.2V

28 ADC Inputs

Serial

control/SPI

Master

Interface

(SC is I2C compatible)

1.2V VDD_CORE

Domain

WDT

Test

UART

Processing Unit

(Arm - CM3)

Periph

UART

320K

ROM

60K

RAM

VSS, VDDO,

VDDC

1.2V

POR

CT ﺨ

ADC

1.2V

LDO

1.425V to 3.6V

3.6 V

MIA

POR

System Bus

32 kHz

LPCLK

Peripheral Interface

Block

hclk

(24 MHz to 1 MHz)

Volt. Trans

I/O Ring Control

Registers

1.62V to 3.6V

VDD_IO Domain

I/O Ring Bus

RF Control and

Data

2.4 GHz

Radio

Bluetooth

Baseband

Core

GPIO

Control/

Status

Registers

IR

Mod

SPI

M/S

PMU

24

MHz

RF I/O

WAKE

40 GPIO

T/R

Switch

Frequency

Synthesizer

IR I/O

8 x 20 Scan 6 Quadrature

Matrix

Inputs (3 pair) +

High Current

Driver Controls

Power

32 kHz LPCLK

128 kHz

LPO

AutoCal

9 ADC

Inputs

1.2V VDD_RF Domain

128 kHz

LPCLK

PWM

24 MHz

Ref Xtal

1.62V to 3.6V

VDD_IO

÷4

32 kHz Xtal

(optional)

Page 2 of 2

�CYW20737

Contents

1. Functional Description ..................................... 4

1.1

Bluetooth Baseband Core ................................... 4

1.1.1 Frequency Hopping Generator ................ 4

1.1.2 E0 Encryption .......................................... 4

1.1.3 Link Control Layer ................................... 4

1.1.4 Adaptive Frequency Hopping .................. 4

1.1.5 Bluetooth Low Energy Profiles ................ 4

1.1.6 Test Mode Support .................................. 5

1.14.1 RF Power Management ..........................16

1.14.2 Host Controller Power Management ......16

1.14.3 BBC Power Management .......................16

2. Pin Assignments............................................. 17

2.1

Pin Descriptions .................................................17

2.2

GPIO Pin Multiplexing ........................................21

2.3

Ball Maps ...........................................................22

1.2

Infrared Modulator ............................................... 5

1.3

Security ............................................................... 5

3.1

Electrical Characteristics ....................................23

1.4

Support for NFC Tag Based Pairing ................... 6

3.2

RF Specifications ...............................................26

1.5

Bluetooth Smart Audio ........................................ 6

3.3

1.6

ADC Port ............................................................. 7

Timing and AC Characteristics ...........................28

3.3.1 UART Timing ..........................................28

1.7

Serial Peripheral Interface ................................... 8

3.3.2 SPI Timing ..............................................29

1.8

Microprocessor Unit ............................................ 9

1.8.1 EEPROM Interface .................................. 9

1.8.2 Serial Flash Interface ............................... 9

1.8.3 Internal Reset ........................................ 10

1.8.4 External Reset ....................................... 10

3.3.3 Serial Control Interface Timing ...............30

1.9

Integrated Radio Transceiver ............................ 11

1.9.1 Transmitter Path .................................... 11

1.9.2 Receiver Path ........................................ 11

1.9.3 Local Oscillator ...................................... 11

1.9.4 Calibration ............................................. 11

1.9.5 Internal LDO Regulator .......................... 11

1.10 Peripheral Transport Unit .................................. 12

1.10.1 Serial Communications Interface ........... 12

1.10.2 UART Interface ...................................... 12

1.11 Clock Frequencies ............................................ 12

1.11.1 Crystal Oscillator ................................... 12

1.12 GPIO Port .......................................................... 14

3. Specifications ................................................. 23

3.4

ESD Test Models ...............................................31

3.4.1 Human-Body Model (HBM) –

ANSI/ESDA/JEDEC JS-001-2012 ..........31

3.4.2 Machine Model (MM) – JEDEC

ESD22-A115C 31

3.4.3 Charged-Device Model (CDM) JEDEC JESD22-C101E .........................31

3.4.4 Results Summary ...................................31

4. Mechanical Information.................................. 32

4.1

Tape Reel and Packaging Specifications ...........33

5. Ordering Information...................................... 34

6. Additional Information ................................... 34

6.1

Acronyms and Abbreviations .............................34

6.2

IoT Resources ....................................................35

1.13 PWM ................................................................. 14

Document History Page ................................................. 36

1.14 Power Management Unit ................................... 16

Sales, Solutions, and Legal Information ...................... 37

Document Number: 002-16365 Rev. *D

Page 3 of 37

�CYW20737

1. Functional Description

1.1 Bluetooth Baseband Core

The Bluetooth Baseband Core (BBC) implements all of the time-critical functions required for high performance Bluetooth operation.

The BBC manages the buffering, segmentation, and data routing for all connections. It also buffers data that passes through it, handles

data flow control, schedules ACL TX/RX transactions, monitors Bluetooth slot usage, optimally segments and packages data into

baseband packets, manages connection status indicators, and composes and decodes HCI packets. In addition to these functions, it

independently handles HCI event types and HCI command types.

The following transmit and receive functions are also implemented in the BBC hardware to increase TX/RX data reliability and security

before sending over the air:

■

Receive Functions: symbol timing recovery, data deframing, forward error correction (FEC), header error control (HEC), cyclic

redundancy check (CRC), data decryption, and data dewhitening.

■

Transmit Functions: data framing, FEC generation, HEC generation, CRC generation, link key generation, data encryption, and

data whitening.

1.1.1 Frequency Hopping Generator

The frequency hopping sequence generator selects the correct hopping channel number depending on the link controller state,

Bluetooth clock, and device address.

1.1.2 E0 Encryption

The encryption key and the encryption engine are implemented using dedicated hardware to reduce software complexity and provide

minimal processor intervention.

1.1.3 Link Control Layer

The link control layer is part of the Bluetooth link control functions that are implemented in dedicated logic in the Link Control Unit

(LCU). This layer consists of the Command Controller, which takes software commands, and other controllers that are activated or

configured by the Command Controller to perform the link control tasks. Each task performs a different Bluetooth link controller state.

STANDBY and CONNECTION are the two major states. In addition, there are five substates: page, page scan, inquiry, and inquiry

scan.

1.1.4 Adaptive Frequency Hopping

The CYW20737 gathers link quality statistics on a channel-by-channel basis to facilitate channel assessment and channel map

selection. The link quality is determined by using both RF and baseband signal processing to provide a more accurate frequency hop

map.

1.1.5 Bluetooth Low Energy Profiles

The CYW20737 supports Bluetooth low energy, including the following profiles that are supported2 in ROM:

■

Battery status

■

Blood pressure monitor

■

Find me

■

Heart rate monitor

■

Proximity

■

Thermometer

■

Weight scale

■

Time

■

AirFuel wireless charging

2. Full qualification and use of these profiles may require FW updates from Broadcom. Some of these profiles are under development/approval at

the Bluetooth SIG and conformity with the final approved version is pending. Contact your supplier for updates and the latest list of profiles.

Document Number: 002-16365 Rev. *D

Page 4 of 37

�CYW20737

■

Automation profile

■

Support for secure OTA

The following additional profiles can be supported2 from RAM:

■

Blood glucose monitor

■

Temperature alarm

■

Location

■

Custom profile

1.1.6 Test Mode Support

The CYW20737 fully supports Bluetooth Test mode, as described in the Bluetooth low energy specification.

1.2 Infrared Modulator

The CYW20737 includes hardware support for infrared TX. The hardware can transmit both modulated and unmodulated waveforms.

For modulated waveforms, hardware inserts the desired carrier frequency into all IR transmissions. IR TX can be sourced from

firmware-supplied descriptors, a programmable bit, or the peripheral UART transmitter.

If descriptors are used, they include IR on/off state and the duration between 1–32767 µsec. The CYW20737 IR TX firmware driver

inserts this information in a hardware FIFO and makes sure that all descriptors are played out without a glitch due to underrun (see

Figure 2).

Figure 2. Infrared TX

1.3 Security

CYW20737 provides elaborate mechanisms for implementing security and authentication schemes using:

■

RSA (Public Key Cryptography)

■

X.509 (excluding parsing)

■

Hash functions: MD5, SHA-1, SHA-224, SHA-256, SHA-384, SHA-512

■ Message authentication code: HMAC MD5, HMAC SHA-1

Note: Details on how to use this functionality via SDK are available in application notes on this topic.

Document Number: 002-16365 Rev. *D

Page 5 of 37

�CYW20737

1.4 Support for NFC Tag Based Pairing

CYW20737 provides support for "ease of pairing" and "secure key exchange" use cases using passive tags. Active tags can be used

with the chip for OOB pairing. In a typical use case, the BCM20203 (NFC tag) can be used to provide "tap to pair" functionality for

easy pairing.

Note: Details on how to use this functionality via SDK are available in application notes on this topic.

1.5 Bluetooth Smart Audio

CYW20737 supports using the BLE link for audio streaming. This functionality can be used for audio applications in toys, wearable,

and HID devices, as well as in hearing aids.

Note: Details on how to use this functionality via SDK are available in application notes on this topic.

Document Number: 002-16365 Rev. *D

Page 6 of 37

�CYW20737

1.6 ADC Port

The CYW20737 contains a 16-bit ADC (effective number of bits is 10).

Additionally:

■

■

There are 9 analog input channels in the 32-pin package

The following GPIOs can be used as ADC inputs:

P0

❐ P1

❐ P8/P33 (select only one)

❐ P11

❐ P12

❐ P13/P28 (select only one)

❐ P14/P38 (select only one)

❐ P15

❐ P32

❐

■

The conversion time is 10 μs.

■

There is a built-in reference with supply- or bandgap-based reference modes.

■

The maximum conversion rate is 187 kHz.

■

There is a rail-to-rail input swing.

The ADC consists of an analog ADC core that performs the actual analog-to-digital conversion and digital hardware that processes

the output of the ADC core into valid ADC output samples. Directed by the firmware, the digital hardware also controls the input

multiplexers that select the ADC input signal Vinp and the ADC reference signals Vref.

The ADC input range is selectable by firmware control:

■

When an input range of 0–3.6V is used, the input impedance is 3 MΩ.

■

When an input range of 0–2.4V is used, the input impedance is 1.84 MΩ.

■

When an input range of 0–1.2V is used, the input impedance is 680 kΩ.

ADC modes are defined in Table 1.

Table 1. ADC Modes

Mode

ENOB (Typical)

Latency[1] (μs)

Maximum Sampling Rate (kHz)

0

13

5.859

171

1

12.6

11.7

85

2

12

46.875

21

3

11.5

93.75

11

4

10

187

5

Note

1. Settling time after switching channels.

Document Number: 002-16365 Rev. *D

Page 7 of 37

�CYW20737

1.7 Serial Peripheral Interface

The CYW20737 has two independent SPI interfaces. One is a master-only interface and the other can be either a master or a slave.

Each interface has a 16-byte transmit buffer and a 16-byte receive buffer. To support more flexibility for user applications, the

CYW20737 has optional I/O ports that can be configured individually and separately for each functional pin as shown in Table 2,

Table 3, and Table 4. The CYW20737 acts as an SPI master device that supports 1.8V or 3.3V SPI slaves. The CYW20737 can also

act as an SPI slave device that supports a 1.8V or 3.3V SPI master.

Table 2. CYW20737 First SPI Set (Master Mode)

Pin Name

Configured Pin Name

SPI_CLK

SPI_MISO[2]

SPI_MOSI

SPI_CS[3]

SCL

SDA

–

–

–

–

–

–

–

–

P32

P33[4]

Note

2. SPIFFY1 MISO should always be P32. Boot ROM does not configure any others.

3. Any GPIO can be used as SPI_CS when SPI 1 is in master mode, and when the SPI slave is not a serial flash.

4. P33 is always SPI_CS when a serial flash is used for non-volatile storage.

Table 3. CYW20737 Second SPI Set (Master Mode)

Pin Name

Configured Pin Name

SPI_CLK

P3

SPI_MOSI

P0

SPI_CS[5]

SPI_MISO

P1

–

–

P4

P25

–

P24

P27

–

–

Note

5. Any GPIO can be used as SPI_CS when SPI is in master mode.

Table 4. CYW20737 Second SPI Set (Slave Mode)

Pin Name

Configured Pin Name

SPI_CLK

SPI_MOSI

SPI_MISO

SPI_CS

P3

P0

P1

P2

–

P27

–

–

P24

P33

P25

P26

–

–

–

P32

Document Number: 002-16365 Rev. *D

Page 8 of 37

�CYW20737

1.8 Microprocessor Unit

The CYW20737 microprocessor unit (µPU) executes software from the link control (LC) layer up to the application layer components.

The microprocessor is based on an ARM® Cortex™ M3, 32-bit RISC processor with embedded ICE-RT debug and JTAG interface

units. The µPU has 320 KB of ROM for program storage and boot-up, 60 KB of RAM for scratch-pad data, and patch RAM code. The

SoC has a total storage of 380 KB, including RAM and ROM.

The internal boot ROM provides power-on reset flexibility, which enables the same device to be used in different HID applications with

an external serial EEPROM or with an external serial flash memory. At power-up, the lowest layer of the protocol stack is executed

from the internal ROM memory.

External patches may be applied to the ROM-based firmware to provide flexibility for bug fixes and feature additions. The device can

also support the integration of user applications.

1.8.1 EEPROM Interface

The CYW20737 provides a Serial Control master interface. Serial Control is programmed by the CPU to generate four types of bus

transfers: read-only, write-only, combined read/write, and combined write/read. Serial Control supports both low-speed and fast mode

devices. Serial Control is compatible with an NXP® I2C slave device, except that master arbitration (multiple I2C masters contending

for the bus) is not supported.

The EEPROM can contain customer application configuration information including application code, configuration data, patches,

pairing information, BD_ADDR, baud rate, SDP service record, and file system information used for code.

Native support for the Microchip® 24LC128, Microchip 24AA128, and ST Micro® M24128-BR is included.

1.8.2 Serial Flash Interface

The CYW20737 includes an SPI master controller that can be used to access serial flash memory. The SPI master contains an AHB

slave interface, transmit and receive FIFOs, and the SPI core PHY logic.

Devices natively supported include the following:

■

Atmel® AT25BCM512B

■

MXIC® MX25V512ZUI-20G

Other (larger) serial flash parts from MXIC, Numonyx, and Adesto with commands identical to these parts here are also supported.

Document Number: 002-16365 Rev. *D

Page 9 of 37

�CYW20737

1.8.3 Internal Reset

Figure 3. Internal Reset Timing

VDDO POR delay

~ 2 ms

VDDO

VDDO POR threshold

VDDO POR

VDDC POR threshold

VDDC

VDDC POR delay

~ 2 ms

VDDC POR

Crystal

warm‐up

delay:

~ 5 ms

Baseband Reset

Start reading EEPROM and

firmware boot

Crystal Enable

1.8.4 External Reset

The CYW20737 has an integrated power-on reset circuit that completely resets all circuits to a known power-on state. An external

active low reset signal, RESET_N, can be used to put the CYW20737 in the reset state. The RESET_N pin has an internal pull-up

resistor and, in most applications, it does not require that anything be connected to it. RESET_N should only be released after the

VDDO supply voltage level has been stabilized.

Figure 4. External Reset Timing

Pulse width

>20 µs

RESET_N

Crystal

warm‐up

delay:

~ 5 ms

Baseband Reset

Start reading EEPROM and

firmware boot

Crystal Enable

Document Number: 002-16365 Rev. *D

Page 10 of 37

�CYW20737

1.9 Integrated Radio Transceiver

The CYW20737 has an integrated radio transceiver that is optimized for 2.4 GHz Bluetooth wireless systems. It has been designed

to provide low power, low cost, and robust communications for applications operating in the globally available 2.4 GHz unlicensed

ISM band. It is fully compliant with Bluetooth Radio Specification 4.1 and meets or exceeds the requirements to provide the highest

communication link quality of service.

1.9.1 Transmitter Path

The CYW20737 features a fully integrated transmitter. The baseband transmit data is GFSK modulated in the 2.4 GHz ISM band.

Digital Modulator

The digital modulator performs the data modulation and filtering required for the GFSK signal. The fully digital modulator minimizes

any frequency drift or anomalies in the modulation characteristics of the transmitted signal.

Power Amplifier

The CYW20737 has an integrated power amplifier (PA) that can transmit up to +4 dBm for class 2 operation.

1.9.2 Receiver Path

The receiver path uses a low IF scheme to downconvert the received signal for demodulation in the digital demodulator and bit

synchronizer. The receiver path provides a high degree of linearity, an extended dynamic range, and high-order, on-chip channel

filtering to ensure reliable operation in the noisy 2.4 GHz ISM band. The front-end topology, which has built-in out-of-band attenuation,

enables the CYW20737 to be used in most applications without off-chip filtering.

Digital Demodulator and Bit Synchronizer

The digital demodulator and bit synchronizer take the low-IF received signal and perform an optimal frequency tracking and bit

synchronization algorithm.

Receiver Signal Strength Indicator

The radio portion of the CYW20737 provides a receiver signal strength indicator (RSSI) to the baseband. This enables the controller

to take part in a Bluetooth power-controlled link by providing a metric of its own receiver signal strength to determine whether the

transmitter should increase or decrease its output power.

1.9.3 Local Oscillator

The local oscillator (LO) provides fast frequency hopping (1600 hops/second) across the 79 maximum available channels. The

CYW20737 uses an internal loop filter.

1.9.4 Calibration

The CYW20737 radio transceiver features a self-contained automated calibration scheme. No user interaction is required during

normal operation or during manufacturing to provide optimal performance. Calibration compensates for filter, matching network, and

amplifier gain and phase characteristics to yield radio performance within 2% of what is optimal. Calibration takes process and

temperature variations into account, and it takes place transparently during normal operation and hop setting times.

1.9.5 Internal LDO Regulator

The CYW20737 has an integrated 1.2V LDO regulator that provides power to the digital and RF circuits. The 1.2V LDO regulator

operates from a 1.425V to 3.63V input supply with a 30 mA maximum load current.

Note: Always place the decoupling capacitors near the pins as closely together as possible.

Document Number: 002-16365 Rev. *D

Page 11 of 37

�CYW20737

1.10 Peripheral Transport Unit

1.10.1 Serial Communications Interface

The CYW20737 provides a 2-pin master Serial Control interface, which can be used to retrieve configuration information from an

external EEPROM or to communicate with peripherals such as track-ball or touch-pad modules, and motion tracking ICs used in

mouse devices. The Serial Control interface is compatible with I2C slave devices. The Serial Control does not support multimaster

capability or flexible wait-state insertion by either master or slave devices.

The following transfer clock rates are supported by the Serial Control:

■

100 kHz

■

400 kHz

■

800 kHz (not a standard I2C-compatible speed.)

■

1 MHz (Compatibility with high-speed I2C-compatible devices is not guaranteed.)

The following transfer types are supported by the Serial Control:

■

Read (Up to 16 bytes can be read.)

■

Write (Up to 16 bytes can be written.)

■

Read-then-Write (Up to 16 bytes can be read and up to 16 bytes can be written.)

■

Write-then-Read (Up to 16 bytes can be written and up to 16 bytes can be read.)

Hardware controls the transfers, requiring minimal firmware setup and supervision.

The clock pin (SCL) and data pin (SDA) are both open-drain I/O pins. Pull-up resistors external to the CYW20737 are required on

both the SCL and SDA pins for proper operation.

1.10.2 UART Interface

The UART is a standard 2-wire interface (RX and TX) and has adjustable baud rates from 9600 bps to 1.5 kbps. The baud rate can

be selected via a vendor-specific UART HCI command. The interface supports the Bluetooth 3.0 UART HCI (H4) specification. The

default baud rate for H4 is 115.2 kbaud.

Both high and low baud rates can be supported by running the UART clock at 24 MHz.

The CYW20737 UART operates correctly with the host UART as long as the combined baud rate error of the two devices is within ±5%.

1.11 Clock Frequencies

The CYW20737 is set with crystal frequency of 24 MHz.

1.11.1 Crystal Oscillator

The crystal oscillator requires a crystal with an accuracy of ±20 ppm as defined by the Bluetooth specification. Two external load

capacitors in the range of 5 pF to 30 pF (see Figure 5) are required to work with the crystal oscillator. The selection of the load

capacitors is crystal-dependent. Table 5 shows the recommended crystal specifications.

Figure 5. Recommended Oscillator Configuration—12 pF Load Crystal

22 pF

XIN

Crystal

XOUT

20 pF

Table 5 shows the recommended crystal specifications.

Document Number: 002-16365 Rev. *D

Page 12 of 37

�CYW20737

Table 5. Reference Crystal Electrical Specifications

Parameter

Conditions

Minimum

Typical

24.000

Maximum

–

Unit

Nominal frequency

–

–

Oscillation mode

–

Fundamental

MHz

Frequency tolerance

@25°C

–

±10

–

ppm

Tolerance stability over temp

@0°C to +70°C

–

±10

–

ppm

–

Equivalent series resistance

–

–

–

50

Load capacitance

–

–

12

–

pF

Operating temperature range

–

0

–

+70

°C

Storage temperature range

–

–40

–

+125

°C

Drive level

–

–

–

200

μW

Aging

–

–

–

±10

ppm/year

Shunt capacitance

–

–

–

2

pF

Peripheral Block

The peripheral blocks of the CYW20737 all run from a single 128 kHz low-power RC oscillator. The oscillator can be turned on at the

request of any of the peripherals. If the peripheral is not enabled, it shall not assert its clock request line.

The keyboard scanner is a special case, in that it may drop its clock request line even when enabled, and then reassert the clock

request line if a keypress is detected.

32 kHz Crystal Oscillator

Figure 6 shows the 32 kHz crystal (XTAL) oscillator with external components and Table 6 lists the oscillator’s

characteristics. It is a standard Pierce oscillator using a comparator with hysteresis on the output to create a singleended digital output. The hysteresis was added to eliminate any chatter when the input is around the threshold of the

comparator and is ~100 mV. This circuit can be operated with a 32 kHz or 32.768 kHz crystal oscillator or be driven with

a clock input at similar frequency. The default component values are: R1 = 10 MΩ, C1 = C2 = ~10 pF. The values of C1

and C2 are used to fine-tune the oscillator.

Figure 6. 32 kHz Oscillator Block Diagram

C2

R1

32.768 kHz

XTAL

C1

Document Number: 002-16365 Rev. *D

Page 13 of 37

�CYW20737

Table 6. XTAL Oscillator Characteristics

Parameter

Symbol

Conditions

Minimum

Typical

Maximum

Unit

Output frequency

Foscout

–

–

32.768

–

kHz

Frequency

tolerance

–

Crystal dependent

–

100

–

ppm

Start-up time

Tstartup

–

–

–

500

ms

XTAL drive level

Pdrv

For crystal selection

0.5

–

–

μW

XTAL series resistance

Rseries

For crystal selection

–

–

70

kΩ

XTAL shunt capacitance

Cshunt

For crystal selection

–

–

1.3

pF

1.12 GPIO Port

The CYW20737 has 14 general-purpose I/Os (GPIOs) in the 32-pin package. All GPIOs support programmable pull-up and pull-down

resistors, and all support a 2 mA drive strength except P26, P27, and P28, which provide a 16 mA drive strength at 3.3V supply.

The following GPIOs are available:

■

P0–P4

■

P8/P33 (Dual bonded, only one of two is available.)

■

P11/P27 (Dual bonded, only one of two is available.)

■

P12/P26 (Dual bonded, only one of two is available.)

■

P13/P28 (Dual bonded, only one of two is available.)

■

P14/P38 (Dual bonded, only one of two is available.)

■

P15

■

P24

■

P25

■

P32

For a description of all GPIOs, see Table 8. “GPIO Pin Descriptions[6]”.

1.13 PWM

The CYW20737 has four internal PWM channels. The PWM module is described as follows:

■

■

PWM0–3

The following GPIOs can be mapped as PWMs:

P26

❐ P27

❐ P14/P28 (Dual bonded, only one of two is available.)

❐ P13

❐

■

Each of the PWM channels, PWM0–3, contains the following registers:

10-bit initial value register (read/write)

❐ 10-bit toggle register (read/write)

❐ 10-bit PWM counter value register (read)

❐

■

The PWM configuration register is shared among PWM0–3 (read/write). This 12-bit register is used:

To configure each PWM channel.

❐ To select the clock of each PWM channel.

❐ To change the phase of each PWM channel.

❐

Document Number: 002-16365 Rev. *D

Page 14 of 37

�CYW20737

Figure 7 shows the structure of one PWM channel.

Figure 7. PWM Channel Block Diagram

pwm_cfg_adr register

pwm#_init_val_adr register

pwm#_togg_val_adr register

enable

clk_sel

o_flip

10

10

pwm#_cntr_adr

10

cntr value is CM3 readable

pwm_out

Example: PWM cntr w/ pwm#_init_val = 0 (dashed line)

PWM cntr w/ pwm#_init_val = x (solid line)

10'H3FF

pwm_togg_val_adr

10'Hx

10'H000

pwm_out

Document Number: 002-16365 Rev. *D

Page 15 of 37

�CYW20737

1.14 Power Management Unit

The Power Management Unit (PMU) provides power management features that can be invoked by software through power

management registers or packet-handling in the baseband core.

1.14.1 RF Power Management

The BBC generates power-down control signals for the transmit path, receive path, PLL, and power amplifier to the 2.4 GHz transceiver, which then processes the power-down functions accordingly.

1.14.2 Host Controller Power Management

Power is automatically managed by the firmware based on input device activity. As a power-saving task, the firmware controls the

disabling of the on-chip regulator when in deep sleep mode.

1.14.3 BBC Power Management

There are several low-power operations for the BBC:

■

Physical layer packet handling turns RF on and off dynamically within packet TX and RX.

■

Bluetooth-specified low-power connection mode. While in these low-power connection modes, the CYW20737 runs on the Low

Power Oscillator and wakes up after a predefined time period.

The CYW20737 automatically adjusts its power dissipation based on user activity. The following power modes are supported:

■

Active mode

■

Idle mode

■

Sleep mode

■

HIDOFF (Deep Sleep) mode

■

Timed Deep Sleep mode

The CYW20737 transitions to the next lower state after a programmable period of user inactivity. Busy mode is immediately entered

when user activity resumes.

In HIDOFF (Deep Sleep) mode, the CYW20737 baseband and core are powered off by disabling power to LDOOUT. The VDDO

domain remains powered up and will turn the remainder of the chip on when it detects user events. This mode minimizes chip power

consumption and is intended for long periods of inactivity.

Document Number: 002-16365 Rev. *D

Page 16 of 37

�CYW20737

2. Pin Assignments

2.1 Pin Descriptions

Table 7. Pin Descriptions

Pin Number

Pin Name

I/O

Power Domain

Description

Radio I/O

6

RF

I/O

VDD_RF

RF antenna port

I

VDD_RF

IFPLL power supply

RF Power Supplies

4

VDDIF

5

VDDFE

I

VDD_RF

RF front-end supply

7

VDDVCO

I

VDD_RF

VCO, LOGEN supply

8

VDDPLL

I

VDD_RF

RFPLL and crystal oscillator supply

11

VDDC

I

VDDC

Baseband core supply

28

VDDO

I

VDDO

I/O pad and core supply

14

VDDM

I

VDDM

I/O pad supply

Power Supplies

Clock Generator and Crystal Interface

9

XTALI

I

VDD_RF

Crystal oscillator input. See page 12 for options.

10

XTALO

O

VDD_RF

Crystal oscillator output.

1

XTALI32K

I

VDDO

Low-power oscillator (LPO) input is used.

Alternative Function:

32

XTALO32K

O

VDDO

■

P11

■

P27

Low-power oscillator (LPO) output.

Alternative Function:

■

P12

■

P26

Core

18

RESET_N

I/O PU

VDDO

Active-low system reset with open-drain output & internal

pull-up resistor

17

TMC

I

VDDO

Test mode control

High: test mode

Connect to GND if not used.

12

UART_RXD

I

VDDM

UART serial input – Serial data input for the HCI UART

interface. Leave unconnected if not used.

Alternative function:

13

UART_TXD

O, PU

VDDM

UART

■

■

Document Number: 002-16365 Rev. *D

GPIO3

UART serial output – Serial data output for the HCI UART

interface. Leave unconnected if not used.

Alternative Function:

GPIO2

Page 17 of 37

�CYW20737

Table 7. Pin Descriptions (Cont.)

Pin Number

Pin Name

I/O

Power Domain

Description

Serial Control

15

SDA

16

I/O, PU

SCL

I/O, PU

VDDM

VDDM

Data signal for an external I2C device.

Alternative function:

■

SPI_1: MOSI (master only)

■

GPIO0

■

CTS

Clock signal for an external I2C device.

Alternative function:

■

SPI_1: SPI_CLK (master only)

■

GPIO1

■

RTS

LDO Regulator Power Supplies

2

LDOIN

I

N/A

Battery input supply for the LDO

3

LDOOUT

O

N/A

LDO output

Table 8. GPIO Pin Descriptions[6]

Pin Number

19

20

21

22

23

Pin Name

P0

P1

P3

P2

P4

Default Di- After POR Power Domain

rection

State

Input

Input

Input

Input

Input

Input

floating

VDDO

Input

floating

VDDO

Input

floating

VDDO

Input

floating

VDDO

Input

floating

VDDO

Alternate Functions

GPIO: P0

PUART_TX (peripheral UART)

■ SPI_2: MOSI (master and slave)

■ ADC_IN29 (A/D converter input)

■ IR_RX/60 Hz_main

■ Not available during TMC=1

■

■

GPIO: P1

IR_TX

■ PUART_RTS (peripheral UART)

■ SPI_2: MISO (master and slave)

■ ADC_IN28 (A/D converter input)

■

■

GPIO: P3

SPI_2: SPI_CLK (master and slave)

■ Quadrature X1

■ PUART_CTS (peripheral UART)

■

■

GPIO: P2

SPI_2: SPI_MOSI (master only)

■ Quadrature X0

■ PUART_RX (peripheral UART)

■ SPI_2: SPI_CS (slave)

■

■

GPIO: P4

IR_TX

■ SPI_2: MOSI (master and slave)

■ Quadrature Y0

■ PUART_RX (peripheral UART)

■

■

Note

6. During power-on reset, all inputs are disabled.

Document Number: 002-16365 Rev. *D

Page 18 of 37

�CYW20737

Table 8. GPIO Pin Descriptions[6]

Pin Number

24

Pin Name

P8

P33

Default Di- After POR Power Domain

rection

State

Input

Input

Input

floating

VDDO

Input

floating

VDDO

Alternate Functions

GPIO: P8

~TX_PD (external T/R switch control)

■ ADC_IN27 (A/D converter input)

■

■

GPIO: P33

ACLK1 (auxiliary clock output)

■ SPI_2: MOSI (slave)

■ ADC_IN6 (A/D converter input)

■ QDX1 (quadrature X1)

■ PUART_RX (peripheral UART)

■

■

GPIO: P9

TX_PD

■ ADC_IN26

P9

■

■

GPIO: P10

PA_RAMP (power amplifier ramp)

■ ADC_IN25 (A/D converter input)

P10

■

■

1

P11

P27

32

P12

P26

29

P13

P28

Input

Input

Input

Input

Input

Input

Input

floating

VDDO

Input

floating

VDDO

Input

floating

VDDO

Input

floating

VDDO

Input

floating

VDDO

Input

floating

VDDO

GPIO: P11

ADC_IN24 (A/D converter input)

■ XTALI32K

■

■

GPIO: P27

QOC1 (quadrature output control)

■ SPI_2: MOSI (master and slave)

■ PWM1

■ Current: 16 mA

■

■

GPIO: P12

ADC_IN23 (A/D converter input)

■ XTALO32K

■

■

GPIO: P26

QOC0 (quadrature output control)

■ SPI_2: SPI_CS (slave)

■ SPI_1: MISO (master)

■ PWM0

■ Current: 16 mA

■

■

GPIO: P13

PWM3

■ ADC_IN22 (A/D converter input)

■

■

GPIO: P28

Q0C2 (quadrature output control)

■ ADC_IN11 (A/D converter input)

■ PWM2

■ LED1

■ IR_TX

■ Current: 16 mA

■

■

Note

6. During power-on reset, all inputs are disabled.

Document Number: 002-16365 Rev. *D

Page 19 of 37

�CYW20737

Table 8. GPIO Pin Descriptions[6]

Pin Number

30

Pin Name

P14

P38

31

27

26

25

P15

P24

P25

P32

Default Di- After POR Power Domain

rection

State

Input

Input

Input

Input

Input

Input

Input

floating

VDDO

Input

floating

VDDO

Input

floating

VDDO

Input

floating

VDDO

Input

floating

VDDO

Input

floating

VDDO

Alternate Functions

GPIO: P14

PWM2

■ ADC_IN21 (A/D converter input)

■

■

GPIO: P38

IR_TX

■ SPI_2: MOSI (master and slave)

■ ADC_IN1 (A/D converter input)

■

■

GPIO: P15

SWDIO

■ IR_RX/60 Hz_main

■ ADC_IN20 (A/D converter input)

■

■

GPIO: P24

PUART_TX (peripheral UART)

■ SPI_2: SPI_CLK (master and slave)

■ SPI_1: MISO (master)

■

■

GPIO: P25

SPI_2: MISO (master and slave)

■ PUART_RX (peripheral UART)

■

■

GPIO: P32

ACLK0 (auxiliary clock output)

■ PUART_TX (peripheral UART)

■ SPI_2: SPI_CS (slave)

■ ADC_IN7 (A/D converter input)

■ SPI_1: MISO (master)

■

■

Note

6. During power-on reset, all inputs are disabled.

Document Number: 002-16365 Rev. *D

Page 20 of 37

�CYW20705

2.2 GPIO Pin Multiplexing

Table 9 provides GPIO pin multiplexing information.

Table 9. GPIO Pin Multiplexing

Alternate Functions

1

GPIO Pin

2

Input/

Output

3

4

5

Outputs

6

7

Inputs

P0

–

PUART_TX

SPI_2: MOSI(master)

–

ADC_IN29

IR_RX/60 Hz_main SPI_2: MOSI (slave)

P1

IR_TX

PUART_RTS

SPI_2: MISO (slave)

–

ADC_IN28

–

SPI_2: MISO (master)

P2

–

SPI_2: MOSI(master) –

–

QDX0

PUART_RX

SPI_2: SPI_CS (slave)

P3

–

–

SPI_2: SPI_CLK

(master)

–

QDX1

PUART_CTS

SPI_2: SPI_CLK

(slave)

P4

IR_TX

–

SPI_2: MOSI (master)

–

QDY0

PUART_RX

SPI_2: MOSI (slave)

P8/

–

~TX_PD

–

–

ADC_IN27

–

–

P33[7]

ACLK1

–

–

SPI_2: MOSI (slave)

ADC_IN6

QDX1

PUART_RX

P9

–

TX_PD

–

–

ADC_IN26

–

–

P10/

–

PA_RAMP

–

–

ADC_IN25

–

–

P11/

–

–

–

–

ADC_IN24

–

–

P27/

xtal32i[8]

–

QOC1

SPI_2: MOSI (master)

SPI_2: MOSI (slave)

–

–

–

P12/

–

–

–

–

ADC_IN23

–

–

P26[9]

–

QOC0

–

SPI_2: SPI_CS (slave)

SPI_1: MISO (master)

–

–

P13/

–

PWM3

–

–

ADC_IN22

–

–

P28[10]

–

QOC2

–

–

ADC_IN11

–

–

P14/

–

PWM2

–

–

ADC_IN21

–

–

P38

IR_TX

–

SPI_2: MOSI (master)

SPI_2: MOSI (slave)

ADC_IN1

–

–

P15

–

SWDIO

–

IR_RX/ 60 Hz_main

ADC_IN20

SWDIO

–

P24

–

PUART_TX

–

SPI_2: SPI_CLK (slave) SPI_1: MISO

–

–

P25

–

SPI_2: MISO (slave)

–

PUART_RX

SPI_2: MISO (master)

–

–

P32

ACLK0

PUART_TX

–

SPI_2: SPI_CS (slave)

ADC_IN7

QDX0

SPI_1: MISO

Notes

7. If dual-bonded, then use one of P8 or P33.

8. If quad-bonded, then use only one of P10, P11, or P27. P27 can source/sink 16 mA.

9. If dual-bonded, then use one of P12 or P26. P27 can source/sink 16 mA

10. If dual-bonded, use one of P13 or P28. P28 can source/sink 16 mA.

Document Number: 002-16365 Rev. *D

Page 21 of 37

�CYW20737

2.3 Ball Maps

P12/P26/XO32

P15

P14/P38

P13/P28

VDDO

P24

P25

P32

Figure 8. 32-pin QFN Ball Map

32

31

30

29

28

27

26

25

LDO_OUT

3

22

P2

VDDIF

4

21

P3

VDDFE

5

20

P1

RF

6

19

P0

VDDVCO

7

18

RST_N

VDDPLL

8

17

TMC

9

10

11

12

13

14

15

16

SCL

P4

SDA

23

VDDM

2

UART_TXD

LDO_IN

UART_RXD

P8/P33

VDDC

24

XTALO

1

XTALI

P11/P27/XIN32

Document Number: 002-16365 Rev. *D

Page 22 of 37

�CYW20737

3. Specifications

3.1 Electrical Characteristics

Table 10 shows the maximum electrical rating for voltages referenced to VDD pin.

Table 10. Maximum Electrical Rating

Rating

DC supply voltage for RF domain

DC supply voltage for core domain

DC supply voltage for VDDM domain (UART/I2C)

DC supply voltage for VDDO domain

DC supply voltage for VR3V

DC supply voltage for VDDFE

Voltage on input or output pin

Operating ambient temperature range

Storage temperature range

Symbol

–

–

–

–

–

–

–

Topr

Tstg

Value

1.4

1.4

3.8

3.8

3.8

1.4

VSS – 0.3 to VDD + 0.3

–30 to +85

–40 to +125

Unit

V

V

V

V

V

V

V

°C

°C

Table 11 shows the power supply characteristics for the range TJ = 0 to 125°C.

Table 11. Power Supply

Minimum[11]

Typical

1.14

1.2

1.14

1.2

1.62

–

1.62

–

1.425

–

1.14

1.2[12]

Parameter

DC supply voltage for RF

DC supply voltage for Core

DC supply voltage for VDDM (UART/I2C)

DC supply voltage for VDDO

DC supply voltage for LDOIN

DC supply voltage for VDDFE

Maximum[11]

1.26

1.26

3.63

3.63

3.63

1.26

Unit

V

V

V

V

V

V

Notes

11. Overall performance degrades beyond minimum and maximum supply voltages.

12. 1.2V for Class 2 output with internal VREG.

Table 12 shows the digital level characteristics for (VSS = 0V).

Table 12. LDO Regulator Electrical Specifications

Parameter

Conditions

Min

Typ

Max

Unit

Input voltage range

–

1.425

–

3.63

V

Default output voltage

–

–

1.2

–

V

Output voltage

Range

0.8

–

1.4

V

Step size

–

40 or 80

–

mV

Accuracy at any step

–5

–

+5

%

Load current

–

–

–

30

mA

Line regulation

Vin from 1.425 to 3.63V, Iload = 30 mA

–0.2

–

0.2

%VO/V

Load regulation

Iload from 1 µA to 30 mA, Vin = 3.3V, Bonding R = 0.3Ω –

0.1

0.2

%VO/mA

Quiescent current

No load @Vin = 3.3V

*Current limit enabled

–

6

–

µA

Power-down current

Vin = 3.3V, worst@70°C

–

5

200

nA

Table 13 shows the specifications for the ADC characteristics.

Document Number: 002-16365 Rev. *D

Page 23 of 37

�CYW20737

Table 13. ADC Specifications

Parameter

Symbol

Conditions

Min

Typ

Max

Unit

Number of Input channels –

–

–

9

–

–

Channel switching rate

–

–

–

133.33

kch/s

fch

Input signal range

Vinp

–

0

–

3.63

V

Reference settling time

–

Changing refsel

7.5

–

–

s

Input resistance

Rinp

Effective, single ended

–

500

–

k

Input capacitance

Cinp

–

–

–

5

pF

Conversion rate

fC

–

5.859

–

187

kHz

Conversion time

TC

–

5.35

–

170.7

s

Resolution

R

–

–

16

–

bits

Effective number of bits

–

In specified performance range

–

See

Table 1

–

Absolute voltage

measurement error

–

Using on-chip ADC firmware driver

–

±2

–

%

Current

I

Iavdd1p2 + Iavdd3p3

–

–

1

mA

Power

P

–

–

1.5

–

mW

Leakage current

Ileakage

T = 25°C

–

–

100

nA

Power-up time

Tpowerup

–

–

–

200

µs

Integral nonlinearity

INL

In guaranteed performance range

–1

–

1

LSB[13]

In guaranteed performance range

–1

–

1

LSB[13]

Differential nonlinearity[13] DNL

Note

13. LSBs are expressed at the 10-bit level.

Table 14 shows the specifications for the digital voltage levels.

Table 14. Digital Levels[14]

Characteristics

Symbol

Min

Typ

Max

Unit

Input low voltage

VIL

–

Input high voltage

VIH

Input low voltage (VDDO = 1.62V)

VIL

Input high voltage (VDDO = 1.62V)

Output low voltage[15]

VOH

VDDO – 0.4

–

–

V

CIN

–

0.12

–

pF

Output high

voltage[15]

Input capacitance (VDDMEM domain)

–

0.4

V

0.75 × VDDO –

–

V

–

–

0.4

V

VIH

1.2

–

–

V

VOL

–

–

0.4

V

Notes

14. This table is also applicable to VDDMEM domain.

15. At the specified drive current for the pad.

Document Number: 002-16365 Rev. *D

Page 24 of 37

�CYW20737

Table 15 shows the specifications for current consumption.

Table 15. Current Consumption [16]

Operational Mode

Conditions

Typ

Max

Unit

Receive

Receiver and baseband are both operating, 100% ON.

9.8

10.0

mA

Transmit

Transmitter and baseband are both operating, 100% ON.

9.1

9.3

mA

Sleep

Internal LPO is in use.

12.0

13.0

μA

–

0.65

–

Note

16. Currents measured between power terminals (Vdd) using 90% efficient DC-DC converter at 3V.

Table 16. Power Supply Current Consumption

Power Supply

VDDC

Advertisement Rates

20 ms

Typ

1.96

Max

Unit

mA

100 ms

500 ms

1s

Document Number: 002-16365 Rev. *D

Page 25 of 37

�CYW20737

3.2 RF Specifications

Table 17. Receiver RF Specifications

Parameter

Receiver

Mode and Conditions

Min

Typ

Max

Unit

Section[17]

Frequency range

–

RX sensitivity (standard)

0.1%BER, 1 Mbps

RX sensitivity (low current)

2402

–

2480

MHz

–

–94

–

dBm

–

–91.5

–

dBm

Input IP3

–

–16

–

–

dBm

Maximum input

–

–10

–

–

dBm

C/I cochannel

0.1%BER

–

–

21

dB

C/I 1 MHz adjacent channel

0.1%BER

–

–

15

dB

C/I 2 MHz adjacent channel

0.1%BER

–

–

–17

dB

Interference Performance[17],[18]

C/I 3 MHz adjacent channel

0.1%BER

–

–

–27

dB

C/I image channel

0.1%BER

–

–

–9.0

dB

C/I 1 MHz adjacent to image channel

0.1%BER

–

–

–15

dB

Out-of-Band Blocking Performance (CW)

[17],[18]

30 MHz to 2000 MHz

0.1%BER[19]

–

–30.0

–

dBm

2003 MHz to 2399 MHz

0.1%BER[20]

–

–35

–

dBm

2484 MHz to 2997 MHz

0.1%BER[20]

–

–35

–

dBm

3000 MHz to 12.75 GHz

0.1%BER[21]

–

–30.0

–

dBm

30 MHz to 1 GHz

–

–

–

–57.0

dBm

1 GHz to 12.75 GHz

–

–

–

–55.0

dBm

Spurious Emissions

Notes

17. 30.8% PER

18. Desired signal is 3 dB above the reference sensitivity level (defined as –70 dBm)

19. Measurement resolution is 10 MHz.

20. Measurement resolution is 3 MHz.

21. Measurement resolution is 25 MHz.

Document Number: 002-16365 Rev. *D

Page 26 of 37

�CYW20737

Table 18. Transmitter RF Specifications

Parameter

Minimum

Typical

Maximum

Unit

Transmitter Section

Frequency range

2402

–

2480

MHz

Output power adjustment range

–20

–

4

dBm

Default output power

–

4.0

–

dBm

Output power variation

–

2.0

–

dB

|M – N| = 2

–

–

–20

dBm

|M – N| 3

–

–

–30

dBm

–

–

–36.0

dBm

Adjacent Channel Power

Out-of-Band Spurious Emission

30 MHz to 1 GHz

1 GHz to 12.75 GHz

–

–

–30.0

dBm

1.8 GHz to 1.9 GHz

–

–

–47.0

dBm

5.15 GHz to 5.3 GHz

–

–

–47.0

dBm

–

–

±150

kHz

LO Performance

Initial carrier frequency tolerance

Frequency Drift

Frequency drift

–

–

±50

kHz

Drift rate

–

–

20

kHz/50 µs

Average deviation in payload

(sequence used is 00001111)

225

–

275

kHz

Maximum deviation in payload

(sequence used is 10101010)

185

–

–

kHz

Channel spacing

–

2

–

MHz

Frequency Deviation

Document Number: 002-16365 Rev. *D

Page 27 of 37

�CYW20737

3.3 Timing and AC Characteristics

In this section, use the numbers listed in the Reference column of each table to interpret the following timing diagrams.

3.3.1 UART Timing

Table 19. UART Timing Specifications

Reference

Characteristics

Min

–

Max

24

Unit

1

Delay time, UART_CTS_N low to UART_TXD valid

Baud out cycles

2

Setup time, UART_CTS_N high before midpoint of stop bit

–

10

ns

3

Delay time, midpoint of stop bit to UART_RTS_N high

–

2

Baud out cycles

Figure 9. UART Timing

Document Number: 002-16365 Rev. *D

Page 28 of 37

�CYW20737

3.3.2 SPI Timing

The SPI interface supports clock speeds up to 12 MHz with VDDIO ≥ 2.2V. The supported clock speed is 6 MHz when 2.2V > VDDIO

≥ 1.62V.

Figure 10 and Figure 11 show the timing requirements when operating in SPI Mode 0 and 2, and SPI Mode 1 and 3, respectively.

Table 20. SPI Interface Timing Specifications

Reference

Characteristics

Min

Typ

Max

1

Time from CSN asserted to first clock edge

1 SCK

100

∞

2

Master setup time

–

½ SCK

–

3

Master hold time

½ SCK

–

–

4

Slave setup time

–

½ SCK

–

5

Slave hold time

½ SCK

–

–

6

Time from last clock edge to CSN deasserted

1 SCK

10 SCK

100

Figure 10. SPI Timing – Mode 0 and 2

6

SPI_CSN

SPI_CLK

(M ode 0)

1

SPI_CLK

(M ode 2)

2

‐

SPI_M O SI

First Bit

3

Second Bit

4

SPI_M ISO

N ot Driven

First Bit

Last bit

‐

Last bit

N ot Driven

5

Second Bit

Figure 11. SPI Timing – Mode 1 and 3

6

SPI_CSN

SPI_CLK

(Mode 1)

1

SPI_CLK

(Mode 3)

2

SPI_MOSI

‐

Invalid bit

3

First bit

4

SPI_MISO

Not Driven

Invalid bit

Document Number: 002-16365 Rev. *D

First bit

Last bit

‐

Last bit

Not Driven

5

Page 29 of 37

�CYW20737

3.3.3 Serial Control Interface Timing

Table 21. Serial Control Interface Timing Specifications

Reference

1

Characteristics

Clock frequency

Min

–

Max

100

Unit

kHz

400

800

1000

2

START condition setup time

650

–

ns

3

START condition hold time

280

–

ns

4

Clock low time

650

–

ns

5

Clock high time

280

–

ns

6

Data input hold time[22]

0

–

ns

7

Data input setup time

100

–

ns

8

STOP condition setup time

280

–

ns

9

Output valid from clock

–

400

ns

10

Bus free time[23]

650

–

ns

Notes

22. As a transmitter, 300 ns of delay is provided to bridge the undefined region of the falling edge of SCL to avoid unintended generation of START or STOP conditions.

23. Time that the cbus must be free before a new transaction can start.

Figure 12. Serial Control Interface Timing Diagram

Document Number: 002-16365 Rev. *D

Page 30 of 37

�CYW20737

3.4 ESD Test Models

ESD can have serious detrimental effects on all semiconductor ICs and the system that contains them. Standards are developed to

enhance the quality and reliability of ICs by ensuring all devices employed have undergone proper ESD design and testing, thereby

minimizing the detrimental effects of ESD. Three major test methods are widely used in the industry today to describe uniform methods

for assessing ESD immunity at Component level, Human Body Model (HBM), Machine Model (MM), and Charged Device Model

(CDM). The following standards were used to test this device:

3.4.1 Human-Body Model (HBM) – ANSI/ESDA/JEDEC JS-001-2012

The HBM has been developed to simulate the action of a human body discharging an accumulated static charge through a device to

ground, and employs a series RC network consisting of a 100 pF capacitor and a 1500Ω (Ohm) resistor. Both positive and negative

polarities are used for this test. Although, a 100 ms delay is allowable per specification, the minimum delay used for testing was set

to 300 ms between each pulse.

3.4.2 Machine Model (MM) – JEDEC JESD22-A115C

The MM has been developed to simulate the rapid discharge from a charged conductive object, such as a metallic tool or fixture. The

most common application would be rapid discharge from charged board assembly or the charged cables of automated testers. This

model consists of a 200 pF capacitor discharged directly into a component with no series resistor (0Ω). One positive and one negative

polarity pulses are applied. The minimum delay between pulses is 500 ms.

3.4.3 Charged-Device Model (CDM) - JEDEC JESD22-C101E

CDM simulates charging/discharging events that occur in production equipment and processes. The potential for a CDM ESD events

occurs when there is metal-to-metal contact in manufacturing. CDM addresses the possibility that a charge may reside on the lead

frame or package (e.g., from shipping) and discharge through a pin that subsequently is grounded, causing damage to sensitive

devices in the path. Discharge current is limited only by the parasitic impedance and capacitance of the device. CDM testing consists

of charging package to a specified voltage, then discharging the voltage through relevant package leads. One positive and one

negative polarity pulse is applied. The minimum delay between pulses is 200 ms.

3.4.4 Results Summary

ESD Test Voltage Level Results:

■

HBM +/– 2KV PASS

■

CDM +/– 500V PASS

■

MM +/– 150V PASS

Document Number: 002-16365 Rev. *D

Page 31 of 37

�CYW20737

4. Mechanical Information

Figure 13. 32-pin QFN

Document Number: 002-16365 Rev. *D

Page 32 of 37

�CYW20737

4.1 Tape Reel and Packaging Specifications

Table 22. CYW20737 5 × 5 × 1 mm QFN, 32-Pin Tape Reel Specifications

Parameter

Quantity per reel

Value

2500 pieces

Reel diameter

13 inches

Hub diameter

7 inches

Tape width

12 mm

Tape pitch

8 mm

The top left corner of the CYW20737 package is situated near the sprocket holes, as shown in Figure 14.

Figure 14. Pin 1 Orientation

Pin 1: Top left corner of package toward sprocket holes

Document Number: 002-16365 Rev. *D

Page 33 of 37

�CYW20737

5. Ordering Information

Table 23. Ordering Information

Part Number

CYW20737A1KML2G

Package

Ambient Operating Temperature

32-pin QFN

–30°C to +85°C

6. Additional Information

6.1 Acronyms and Abbreviations

The following list of acronyms and abbreviations may appear in this document.

Term

ADC

Description

analog-to-digital converter

AFH

adaptive frequency hopping

AHB

advanced high-performance bus

APB

advanced peripheral bus

APU

audio processing unit

ARM7TDMI-S®

Acorn RISC Machine 7 Thumb instruction, Debugger, Multiplier, Ice, Synthesizable

BTC

Bluetooth controller

COEX

coexistence

DFU

device firmware update

DMA

direct memory access

EBI

external bus interface

HCI

Host Control Interface

HV

high voltage

IDC

initial digital calibration

IF

intermediate frequency

IRQ

interrupt request

JTAG

Joint Test Action Group

LCU

link control unit

LDO

low drop-out

LHL

lean high land

LPO

low power oscillator

LV

LogicVision™

MIA

multiple interface agent

PCM

pulse code modulation

PLL

phase locked loop

PMU

power management unit

POR

power-on reset

PWM

pulse width modulation

QD

quadrature decoder

RAM

random access memory

RF

radio frequency

ROM

read-only memory

RX/TX

receive, transmit

Document Number: 002-16365 Rev. *D

Page 34 of 37

�CYW20737

Term

Description

SPI

serial peripheral interface

SW

software

UART

universal asynchronous receiver/transmitter

UPI

µ-processor interface

WD

watchdog

In most cases, acronyms and abbreviations are defined on first use.

For a comprehensive list of acronyms and other terms used in Cypress documents, go to: http://www.cypress.com/glossary

6.2 IoT Resources

Cypress provides a wealth of data at http://www.cypress.com/internet-things-iot to help you to select the right IoT device for your

design, and quickly and effectively integrate the device into your design. Cypress provides customer access to a wide range of

information, including technical documentation, schematic diagrams, product bill of materials, PCB layout information, and software

updates. Customers can acquire technical documentation and software from the Cypress Support Community website

(https://community.cypress.com/)

Document Number: 002-16365 Rev. *D

Page 35 of 37

�CYW20737

Document History Page

Document Title: CYW20737 Single-Chip Bluetooth Low Energy-Only System-On-Chip

Document Number: 002-16365

Revision

ECN

Submission

Date

05/30/2014

Description of Change

20737-DS100-R

Initial release

**

*A

-

5525954

02/10/2016

20737-DS101-R

Added:

“ESD Test Models”

08/17/2016

20737-DS102-R

Updated:

• “Ordering Information” on page 45

11/22/2016

Added Cypress Part Numbering Scheme and Mapping Table on Page 1.

Updated to Cypress template.

*B

5738817

05/15/2017

Updated Cypress Logo and Copyright.

*C

5792463

07/05/2017

Updated the Title.

Replaced Alliance with Wireless Power to Airfuel - “Features” on page 1.

Removed (aka Bluetooth Smart) from Page 1.

Replaced 4.0 with 4.1 in “Integrated Radio Transceiver” on page 11.

Removed Wireless Charging Section from the datasheet.

*D

6893048

06/08/2020

Updated the Title ”CYW20737 Single-Chip Bluetooth Low Energy-Only System-On-Chip”.

Replaced Broadcom Serial control and BSC with “Serial control” throughout the document.

Removed “IR learning” from Features section.

Removed “Part Numbering Scheme” table.

Removed “Infrared Learning” section.

Document Number: 002-16365 Rev. *D

Page 36 of 37

�CYW20737

Sales, Solutions, and Legal Information

Worldwide Sales and Design Support

Cypress maintains a worldwide network of offices, solution centers, manufacturer’s representatives, and distributors. To find the office

closest to you, visit us at Cypress Locations.

PSoC® Solutions

Products

®

®

Arm Cortex Microcontrollers

Automotive

cypress.com/arm

cypress.com/automotive

Clocks & Buffers

Interface

cypress.com/clocks

cypress.com/interface

Internet of Things

Memory

cypress.com/iot

cypress.com/memory

Microcontrollers

cypress.com/mcu

PSoC

cypress.com/psoc

Power Management ICs

cypress.com/pmic

Touch Sensing

Cypress Developer Community

Community | Code Examples | Projects | Video | Blogs |

Training | Components

Technical Support

cypress.com/support

cypress.com/touch

USB Controllers

Wireless Connectivity

PSoC 1 | PSoC 3 | PSoC 4 | PSoC 5LP | PSoC 6 MCU

cypress.com/usb

cypress.com/wireless

37

© Cypress Semiconductor Corporation, 2014-2020. This document is the property of Cypress Semiconductor Corporation and its subsidiaries ("Cypress"). This document, including any software or

firmware included or referenced in this document ("Software"), is owned by Cypress under the intellectual property laws and treaties of the United States and other countries worldwide. Cypress reserves

all rights under such laws and treaties and does not, except as specifically stated in this paragraph, grant any license under its patents, copyrights, trademarks, or other intellectual property rights. If

the Software is not accompanied by a license agreement and you do not otherwise have a written agreement with Cypress governing the use of the Software, then Cypress hereby grants you a personal,

non-exclusive, nontransferable license (without the right to sublicense) (1) under its copyright rights in the Software (a) for Software provided in source code form, to modify and reproduce the Software

solely for use with Cypress hardware products, only internally within your organization, and (b) to distribute the Software in binary code form externally to end users (either directly or indirectly through

resellers and distributors), solely for use on Cypress hardware product units, and (2) under those claims of Cypress's patents that are infringed by the Software (as provided by Cypress, unmodified)

to make, use, distribute, and import the Software solely for use with Cypress hardware products. Any other use, reproduction, modification, translation, or compilation of the Software is prohibited.

TO THE EXTENT PERMITTED BY APPLICABLE LAW, CYPRESS MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARD TO THIS DOCUMENT OR ANY SOFTWARE

OR ACCOMPANYING HARDWARE, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. No computing

device can be absolutely secure. Therefore, despite security measures implemented in Cypress hardware or software products, Cypress shall have no liability arising out of any security breach, such

as unauthorized access to or use of a Cypress product. CYPRESS DOES NOT REPRESENT, WARRANT, OR GUARANTEE THAT CYPRESS PRODUCTS, OR SYSTEMS CREATED USING

CYPRESS PRODUCTS, WILL BE FREE FROM CORRUPTION, ATTACK, VIRUSES, INTERFERENCE, HACKING, DATA LOSS OR THEFT, OR OTHER SECURITY INTRUSION (collectively, "Security

Breach"). Cypress disclaims any liability relating to any Security Breach, and you shall and hereby do release Cypress from any claim, damage, or other liability arising from any Security Breach. In

addition, the products described in these materials may contain design defects or errors known as errata which may cause the product to deviate from published specifications. To the extent permitted

by applicable law, Cypress reserves the right to make changes to this document without further notice. Cypress does not assume any liability arising out of the application or use of any product or

circuit described in this document. Any information provided in this document, including any sample design information or programming code, is provided only for reference purposes. It is the responsibility

of the user of this document to properly design, program, and test the functionality and safety of any application made of this information and any resulting product. "High-Risk Device" means any

device or system whose failure could cause personal injury, death, or property damage. Examples of High-Risk Devices are weapons, nuclear installations, surgical implants, and other medical devices.

"Critical Component" means any component of a High-Risk Device whose failure to perform can be reasonably expected to cause, directly or indirectly, the failure of the High-Risk Device, or to affect

its safety or effectiveness. Cypress is not liable, in whole or in part, and you shall and hereby do release Cypress from any claim, damage, or other liability arising from any use of a Cypress product

as a Critical Component in a High-Risk Device. You shall indemnify and hold Cypress, its directors, officers, employees, agents, affiliates, distributors, and assigns harmless from and against all claims,

costs, damages, and expenses, arising out of any claim, including claims for product liability, personal injury or death, or property damage arising from any use of a Cypress product as a Critical

Component in a High-Risk Device. Cypress products are not intended or authorized for use as a Critical Component in any High-Risk Device except to the limited extent that (i) Cypress's published

data sheet for the product explicitly states Cypress has qualified the product for use in a specific High-Risk Device, or (ii) Cypress has given you advance written authorization to use the product as a

Critical Component in the specific High-Risk Device and you have signed a separate indemnification agreement.

Cypress, the Cypress logo, Spansion, the Spansion logo, and combinations thereof, WICED, PSoC, CapSense, EZ-USB, F-RAM, and Traveo are trademarks or registered trademarks of Cypress in

the United States and other countries. For a more complete list of Cypress trademarks, visit cypress.com. Other names and brands may be claimed as property of their respective owners.

Document Number: 002-16365 Rev. *D

Revised June 8, 2020

Page 37 of 37

�