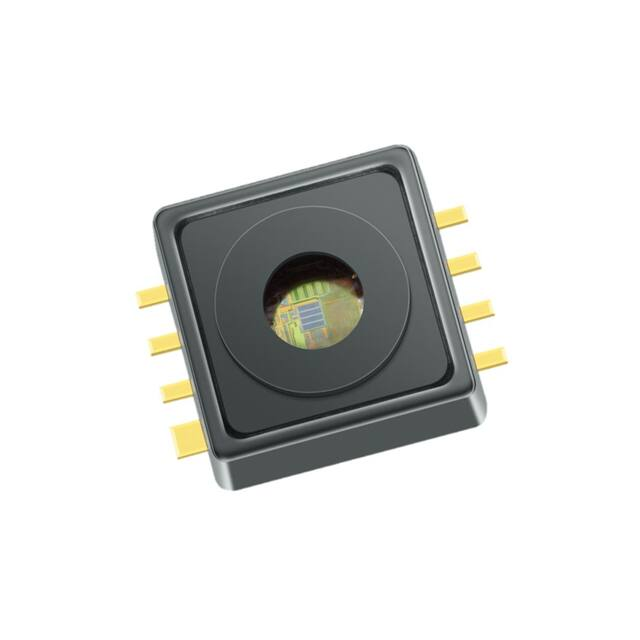

KP212F1701

Analog Absolute Pressure Sensor

Features

•

High precision pressure sensing (± 1.4 kPa)

•

Ratiometric analog output

•

Large temperature range (-40 °C to 125 °C)

•

Broken wire detection

•

Clamping

•

“Green” 8 pin SMD housing

•

Automotive qualified

Applications

The KP212F1701 is defined for use in following target applications:

•

Two wheeler applications (manifold air pressure measurement)

•

Industrial control

•

Consumer application

•

Medical application

Description

The KP212F1701 is a miniaturized Analog Manifold Air Pressure Sensor IC based on a capacitive principle. It is

surface micromachined with a monolithic integrated signal conditioning circuit implemented in BiCMOS

technology.

The sensor converts a pressure into an analog output signal. The calibrated transfer function converts a pressure

of 10 kPa to 115 kPa into a voltage range of 0.4 V to 4.65 V.

The chip is packaged in a “green” SMD housing. The sensor has been primarily developed for measuring manifold

air pressure, but can also be used in other application fields. The high accuracy and the high sensitivity of the

device makes it a perfect fit for advanced automotive applications as well as in industrial and consumer

applications.

Type

Package

Ordering Code

Marking

KP212F1701

PG-DSOF-8-16

SP005435487

KP212F1701

Data Sheet

www.infineon.com/sensors

1

Revision 1.0

2020-07-08

�KP212F1701

Analog Absolute Pressure Sensor

Table of Contents

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1

1.1

1.2

1.3

1.4

1.5

1.5.1

1.5.2

1.6

1.7

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Pin Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Transfer Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ratiometric Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Overall Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Output Voltage versus Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Timing Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2

2.1

2.2

2.3

2.4

Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Circuit Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

3.1

3.2

Package Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

PG-DSOF-8-16 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Identification Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Data Sheet

2

11

11

12

13

14

Revision 1.0

2020-07-08

�KP212F1701

Analog Absolute Pressure Sensor

Functional Description

1

Functional Description

The pressure is detected by an array of capacitive surface micromachined sensor cells. The sensor cell output is

amplified, temperature compensated and linearized to obtain an output voltage that is proportional to the applied

pressure.

The transfer function for linearization is computed in the digital part of the sensor using a third order polynomial

calculation. The transfer function is created from the following parameters:

•

Minimum and maximum rated pressure

•

Voltage level at minimum and maximum rated pressure

•

Clamping levels

The output is analog and ratiometric with respect to the supply voltage.

All parameters needed for the complete calibration algorithm — such as offset, gain, temperature coefficients of

offset and gain, and linearization parameters — are determined after assembly. The parameters are stored in an

integrated E²PROM. The E²PROM content is protected with forward error correction (a one bit error is detected

and corrected, errors of more than one bit are detected and the output signal is switched to ground potential).

Clamping

The output voltage is limited internally to two clamping threshold levels. Based on this feature, the open bond

detection (OBD) is simplified and improved.

Open Bond Detection

The open bond detection, in conjunction with the clamping levels, eases the implementation of error and

malfunction detection strategies (e.g. for On-Board Diagnosis requirements). The microcontroller can sample the

output of the sensor and compare it with programmed overvoltage and undervoltage limits. When the sensor’s

output voltage exceeds those limits, a broken wire condition is identified.

When the chip is not powered properly, the JFET transistors of the broken wire detection stage are self-conducting.

For example, if the GND connection is interrupted, the output is drawn strongly to VDD. Similarly, if the VDD

connection is broken, the output is drawn to GND.

Data Sheet

3

Revision 1.0

2020-07-08

�KP212F1701

Analog Absolute Pressure Sensor

Functional Description

1.1

Pin Configuration

Figure 1 shows the pin configuration.

Figure 1

1.2

TEST

1

8

GND

CLOCK / VPROG

2

7

VOUT

DATA IN

3

6

GND

DATA OUT

4

5

VDD

Pin configuration (top view, figure not to scale)

Pin Description

Table 1 shows the pin description.

Table 1

Pin Description

Pin No.

Name

Function

1

TEST

Test pin1)

2

CLOCK / VPROG

External clock for communication / programming

voltage1)

3

DATA IN

Serial data input pin1)

4

DATA OUT

Serial data output pin1)

5

VDD

Supply voltage

6

GND

Circuit ground potential2)

7

VOUT

Analog pressure signal output

8

GND

Circuit ground potential2)

1) Digital pins are used only during calibration and test. It is recommended to leave these pins floating (in case of an open

GND connection, the floating pins prevent from a cross grounding through the corresponding ESD diodes).

2) It is recommended to connect both GND pins.

Data Sheet

4

Revision 1.0

2020-07-08

�KP212F1701

Analog Absolute Pressure Sensor

Functional Description

1.3

Block Diagram

Figure 2 shows the functional block diagram.

CLOCK /

VPROG

VDD

Internal

Reference

Voltage

EEPROM

( 90+22 bit )

DATA

IN

DATA

OUT

Test and Programming

Interface

Digital

Control

Temperature

Compensation

VOUT

A

D

1 bit

1 kHz

12 bit

D

Clamping

Linearization

10 bit

10 bit

A

30kHz

VDD

Clock

Generator

OBD

GND

Figure 2

Data Sheet

Functional block diagram

5

Revision 1.0

2020-07-08

�KP212F1701

Analog Absolute Pressure Sensor

Functional Description

1.4

Transfer Function

The KP212F1701 device is fully calibrated on delivery. The sensor has a linear transfer function between the

applied pressure and the output signal:

V OUT = VDD x (a x P + b)

The output signal is ratiometric. Gain a and offset b are determined during calibration in order to generate the

required transfer function.

Calibrated Transfer Function

The following calibration is adjusted with the parameters a and b:

Table 2

Transfer function

Pressure

Output Voltage @ VDD = VDD,Typ

Gain and Offset

Values

Unit

Symbol

Values

Unit

Symbol

Value

Unit

pIN,1

10

kPa

VOUT,1

0.40

V

a

0.00810

1/kPa

pIN,2

115

kPa

VOUT,2

4.65

V

b

-0.00095

–

Note:

The points pIN,1/VOUT,1 and pIN,2/VOUT,2 define the calibrated transfer function and not the operating

range. The operating pressure range is defined by the parameter 2.4 “Ambient operating pressure

range” on Page 13.

VOUT [V]

Symbol

5.0

4.0

3.0

2.0

1.0

0.0

10

30

50

70

90

110

130

150

pressure [kPa]

operating pressure range

maximum input pressure range

Figure 3

Note:

Data Sheet

Transfer function

The application circuitry determines the current driven by the device and thus may have an impact

on the output voltage delivered by the sensor.

6

Revision 1.0

2020-07-08

�KP212F1701

Analog Absolute Pressure Sensor

Functional Description

1.5

Accuracy

The accuracy of the KP212F1701 sensor is influenced by the supply voltage (ratiometric error) as well as by

pressure, temperature and aging effects. The specified value, calculated with the transfer function, represents the

theoretical value (see Figure 3). The error equals the deviation between the measured output voltage value and the

specified output voltage value.

1.5.1

Ratiometric Error

Ideally the sensor is ratiometric - the output (VOUT) scales by the same ratio that VDD increases or decreases. The

ratiometric error is defined as the difference between the ratio that VDD changed and the ratio that VOUT changed,

expressed as a percentage.

ERAT (%) =

VOUT(@VDD) - V OUT(@5V) x

5V

VDD

5V

x 100%

The output voltage VOUT is ratiometric to VDD. VDD must be in the operating range provided in Table 7.

Table 3

Ratiometric Error

Supply voltage (V)

Max. ratiometric error (ERAT in % of VDD, Typ)

VDD,Min

± 0.5

VDD,Typ

0

VDD,Max

± 0.5

ERAT (%)

0.5

0

-0.5

VDD,MIN

VDD,TYP

VDD,MAX

VDD

Figure 4

1.5.2

Ratiometric error

Overall Accuracy

Overall accuracy covers the entire pressure and temperature range from different sources of error including the

following:

•

Pressure:

Output deviation from target transfer function over the specified pressure range

•

Temperature:

Output deviation over the temperature range

•

Aging:

Parameter drift over life time

Data Sheet

7

Revision 1.0

2020-07-08

�KP212F1701

Analog Absolute Pressure Sensor

Functional Description

Note:

Ratiometric signal error is not included in the overall accuracy. For error measurements, the supply

voltage must have the nominal value (VDD = VDD,Typ).

The error band is determined by three continuous lines through four relevant breakpoints.

Accuracy

Error [kPa]

Error Multiplier

-40

±2.1

1.50

0

±1.4

1.00

85

±1.4

1.00

125

±2.1

1.5

error multiplier

Temperature [°C]

2.5

2.0

1.5

2.1

1.0

1.4

absolute error [kPa]

Table 4

0.5

0.0

-40

0

85

125

temperature [°C]

Figure 5

Data Sheet

Accuracy for pressure acquisition

8

Revision 1.0

2020-07-08

�KP212F1701

Analog Absolute Pressure Sensor

Functional Description

1.6

Output Voltage versus Load

The output voltage limits depend on:

The value of the external load resistor.

•

The type of connection (pull-up or pull-down).

VOUT [V]

•

20

50

5.00

pull-down resistance [kΩ]

5

10

4.90

4.85

4.80

4.70

4.60

4.50

0.0

Figure 6

0.1

0.2

0.4

0.6

0.8

1.0

source current [mA]

Maximum output voltage limit with pull-down load

pull-up resistance [kΩ]

VOUT [V]

50

20

10

5

0.50

0.40

0.30

0.20

0.10

0

0.0

Figure 7

Note:

Data Sheet

0.1

0.2

0.4

0.6

0.8

1.0

source current [mA]

Minimum output voltage limit with pull-up load

The values in the diagrams are valid for the entire specified temperature range.

The two diagrams above do not take into account clamping levels. In case clamping levels are

implemented, the output voltage is clamped accordingly.

9

Revision 1.0

2020-07-08

�KP212F1701

Analog Absolute Pressure Sensor

Functional Description

1.7

Timing Properties

voltage [V]

Power-up Time

The power-up time tUP is defined as the maximum time between the supply voltage reaching its operating range

and the output voltage reaching 90% of its final value (assuming pin VOUT open and constant input pressure).

5

VDD

4

VOUT

3

90% of Final Value

tUP

2

1

constant input pressure

0

2.5

0

5

7.5

10

12.5

15

time [ms]

Figure 8

Power-up time

120

5

input pressure

tS

within required accuracy

4

90% of final value

VOUT

3

100

80

60

tR

2

pressure [kPa]

voltage [V]

Response Time and Stabilization Time

The response time tR is defined as the time required by the output to change from 10% to 90% of its final value

after a specified pressure step (assuming pin VOUT open).

The stabilization time tS is defined as the time required by the output to meet the specified accuracy after the

pressure has been stabilized (assuming pin VOUT open).

40

10% of final value

1

20

0

0

0

1

2

3

4

5

time [ms]

Figure 9

Response and stabilization time

Note:

The values in the diagrams are valid for the entire specified temperature range.

Data Sheet

10

Revision 1.0

2020-07-08

�KP212F1701

Analog Absolute Pressure Sensor

Specification

2

Specification

2.1

Application Circuit Example

It is recommended to protect the pressure sensor IC against overload and electro-magnetic interferences (as shown

in Figure 10.

The output circuit acts as a low-pass decoupling filter between the sensor IC output and the A/D input of the

microcontroller.

The shown application circuit example considers an increased cable length between the sensor and the

microcontroller. A combined location on a PCB with reduced distance between the sensor and the controller

allows a reduction of the numbers of the passive components (e.g. C2, R1 and R2 can be omitted).

5V

n.c.

n.c.

1

2

VDD

Test

CLOCK /

VPROG

KP

2xx

GND

5

6

n.c.

3

DATA IN

VOUT

7

n.c.

4

DATA OUT

GND

8

Ref

C1

R1

C2

ADC

A/D in

*)

R3

C3

R 2 *)

Microcontroller

GND

*) R1 and R2 only alternatively

Figure 10

Note:

Table 5

Application circuit example

It is recommended to leave the digital pins CLOCK/VPROG, DATA IN and DATA OUT floating (in

case of an open GND connection, the floating pins prevent from a cross grounding through the

corresponding ESD diodes).

Component Values

Component

Symbol

Values

Unit

Min.

Typ.

Max.

Pull-Up Resistor

R1

5

59

100

kΩ

Pull-Down Resistor

R2

5

59

100

kΩ

Low Pass Resistor

R3

3.9

22

100

kΩ

Supply Blocking Capacitor

C1

10

100

100

nF

Output Blocking Capacitor

C2

0

100

100

nF

Low Pass Capacitor

C3

10

100

100

nF

Data Sheet

11

Revision 1.0

2020-07-08

�KP212F1701

Analog Absolute Pressure Sensor

Specification

2.2

Table 6

Absolute Maximum Ratings

Absolute Maximum Ratings

Parameter

Symbol

Values

Min.

Typ.

Max.

Unit

Note or Test Condition Number

Supply voltage

VDD_max

-0.3

–

-6.51)

–

–

–

6.5

16.5

–

V

V

V

–

1.1

1 h @ 70°C

Limited time: Max. 300 s

Output voltage

VOUT

-0.3

–

VDD +

0.3

V

–

1.2

Voltage on

CLOCK / VPROG

pin

VCLK

–

–

20

V

–

1.3

Voltage on

DATA IN &

DATA_OUT pins

VDATA

–

–

5

V

–

1.4

Storage

temperature

TS

-60

–

150

°C

–

1.5

Thermal resistance RthJA

–

–

180

K/W

Thermal resistance

between the die and

ambient; according to

JESD51-2

1.6

Maximum input

pressure

pamb_max

10

–

150

600

kPa

kPa

ESD robustness

(HBM: 1.5 kΩ,

100 pF)

VESD

–

2

kV

–

1.7

Limited time: Max. 300 s

According to

EIA / JESD22-A114-E

1.8

1) Reverse polarity; IDD < 300 mA

Attention: Stresses above the max. values listed in Table 6 may cause permanent damage to the device.

Exposure to absolute maximum rating conditions for extended periods may affect device

reliability. Maximum ratings are absolute ratings; exceeding only one of these values may cause

irreversible damage to the integrated circuit.

Data Sheet

12

Revision 1.0

2020-07-08

�KP212F1701

Analog Absolute Pressure Sensor

Specification

2.3

Operating Range

The following operating conditions must not be exceeded in order to ensure correct operation of the device. All

parameters specified in the following sections refer to these operating conditions, unless noted otherwise.

Table 7

Operating Range

Parameter

Symbol

Values

Min.

Typ.

Max.

Unit

Note or

Test Condition

Number

Supply voltage

VDD

4.5

5.0

5.5

V

VOUT is ratiometric to 2.1

VDD

Output current on

VOUT pin

IOUT

–

–

1

mA

pull-down resistor used 2.2

-1

–

–

mA

pull-up resistor used

Operating

temperature

Ta

-40

–

125

°C

2.3

Ambient operating

pressure range

pamb

10

–

115

kPa

2.4

Lifetime1)

tlive

15

–

–

years

2.5

1) The life time shall be considered as anticipation with regard to the product that shall not extend the agreed warranty

period.

Data Sheet

13

Revision 1.0

2020-07-08

�KP212F1701

Analog Absolute Pressure Sensor

Specification

2.4

Table 8

Characteristics

Electrical Characteristics

Parameter

Symbol

Values

Min.

Typ.

Max.

Unit

Note or

Test Condition

Number

3.1

Output voltage

range

VOUT_R

0.10

–

4.85

V

See also section

“Output Voltage

versus Load” on

Page 9

Supply current

IDD

–

8

10

mA

During power up a peak 3.2

supply current of max.

22 mA is possible

Output referred

noise

VNOISE

–

–

–

–

2.5

1.8

mVRMS Frequency > 1 kHz1)

mVRMS Frequency < 1 kHz

Response time2)

tR

–

0.65

1.03)

ms

10% to 90% of the final 3.4

output value

Stabilization time2) tS

–

–

10

ms

For full accuracy

–

–

5

ms

90% of the final output 3.6

value

tOBD

Broken wire:

Diagnosis response

time4)

–

–

1

ms

3.7

OBD transistor on

resistance

–

–

160

Ω

3.8

2)

Power-up time

tUP

RDSON

3.3

3.5

1) 200 measurements in sequence, bandwidth limited to 40kHz

2) More details in section “Timing Properties” on Page 10

3) The maximum response time considers a maximal value of 100nF for the output blocking capacitor C2 and a maximum

pressure pulse equivalent 4.0V output change

4) In the event of a broken wire (broken VDD line or broken GND line), the output changes to certain voltage levels within

the broken wire response time. The OBD ranges are determined by the application circuitry

Data Sheet

14

Revision 1.0

2020-07-08

�KP212F1701

Analog Absolute Pressure Sensor

Specification

Table 9

Transfer Function

Parameter

Symbol

Values

Unit

Min.

Typ.

Max.

Note or

Test Condition

Number

Sensitivity

S

–

40.5

–

mV

/kPa

4.1

Accuracy pressure

(overall)1)

accp

-1.4

-2.1

-2.1

–

–

–

1.4

2.1

2.1

kPa

kPa

kPa

Ratiometric error2)

ERAT

-25

–

25

mV

4.3

Lower clamping

level

VCl_low

–

0.3

–

V

4.4

Upper clamping

level

VCl_high

–

4.8

–

V

4.5

Clamping level

error

ΔVCl

-30

–

30

mV

0°C up to 85 °C

@ -40°C

@ 125°C

4.2

Accuracy of lower and 4.6

upper clamping level

1) More details in section “Overall Accuracy” on Page 7

2) More details in section “Ratiometric Error” on Page 7

Data Sheet

15

Revision 1.0

2020-07-08

�KP212F1701

Analog Absolute Pressure Sensor

Package Information

3

Package Information

For passivation the sensor is covered with a transparent gel. The PG-DSOF-8-16 package is optimized regarding

external mechanical stress influences. The package fulfills the solder conditions for lead-free board assembly.

3.1

PG-DSOF-8-16 Outline

OUTER DIMENSIONS DOES NOT INCLUDE PROTUSION

OR INTRUSION OF 0.2 MAX. PER SIDE

1)

VALID FOR THE WHOLE SEATING PLANE INCLUDED

TIE BAR AREA

Figure 11

Data Sheet

Package outline

16

Revision 1.0

2020-07-08

�KP212F1701

Analog Absolute Pressure Sensor

Package Information

Green Product (RoHS compliant)

To meet the world-wide customer requirements for environmentally friendly products and to be compliant with

government regulations the device is available as a green product. Green products are RoHS-Compliant (i.e Pbfree finish on leads and suitable for Pb-free soldering according to IPC/JEDEC J-STD-020).

3.2

Identification Code

Figure 12

Date Code

Sales Code I

Sales Code II

K P 2 1 2

F 1 7 0 1

Data Matrix Code

8 x 18 Dots

Dot Size:

0.15 mm x 0.15 mm

B Y Y WW

The identification code is provided in a machine readable format. The date and sales code are provided in human

readable format.

B:

YY:

WW:

BE Location

Year

Week

Identification code

The identification code for the KP212F1701 is on the same side of the package as pin 8 (GND).

For further information on alternative packages, please visit our website:

http://www.infineon.com/packages.

Data Sheet

17

Dimensions in mm

Revision 1.0

2020-07-08

�KP212F1701

Analog Absolute Pressure Sensor

Revision history

4

Revision history

Revision

Date

1.0

2020-07-08

Data Sheet

Changes

18

Revision 1.0

2020-07-08

�Please read the Important Notice and Warnings at the end of this document

Trademarks of Infineon Technologies AG

µHVIC™, µIPM™, µPFC™, AU-ConvertIR™, AURIX™, C166™, CanPAK™, CIPOS™, CIPURSE™, CoolDP™, CoolGaN™, COOLiR™, CoolMOS™,

CoolSET™, CoolSiC™, DAVE™, DI-POL™, DirectFET™, DrBlade™, EasyPIM™, EconoBRIDGE™, EconoDUAL™, EconoPACK™, EconoPIM™,

EiceDRIVER™, eupec™, FCOS™, GaNpowIR™, HEXFET™, HITFET™, HybridPACK™, iMOTION™, IRAM™, ISOFACE™, IsoPACK™, LEDrivIR™,

LITIX™, MIPAQ™, ModSTACK™, my-d™, NovalithIC™, OPTIGA™, OptiMOS™, ORIGA™, PowIRaudio™, PowIRStage™, PrimePACK™,

PrimeSTACK™, PROFET™, PRO-SIL™, RASIC™, REAL3™, SmartLEWIS™, SOLID FLASH™, SPOC™, StrongIRFET™, SupIRBuck™, TEMPFET™,

TRENCHSTOP™, TriCore™, UHVIC™, XHP™, XMC™.

Trademarks updated November 2015

Other Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2020-07-08

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2020 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about any

aspect of this document?

Email: erratum@infineon.com

IMPORTANT NOTICE

The information given in this document shall in no event

be regarded as a guarantee of conditions or

characteristics ("Beschaffenheitsgarantie").

With respect to any examples, hints or any typical values

stated herein and/or any information regarding the

application of the product, Infineon Technologies

hereby disclaims any and all warranties and liabilities of

any kind, including without limitation warranties of noninfringement of intellectual property rights of any third

party.

In addition, any information given in this document is

subject to customer's compliance with its obligations

stated in this document and any applicable legal

requirements, norms and standards concerning

customer's products and any use of the product of

Infineon Technologies in customer's applications.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer's technical departments to

evaluate the suitability of the product for the intended

application and the completeness of the product

information given in this document with respect to such

application.

For further information on technology, delivery terms

and conditions and prices, please contact the nearest

Infineon Technologies Office (www.infineon.com).

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types in

question please contact your nearest Infineon

Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon Technologies,

Infineon Technologies’ products may not be used in any

applications where a failure of the product or any

consequences of the use thereof can reasonably be

expected to result in personal injury.

�