Digital Pressure Sensor with Auto-reference Function

Digital

Auto reference

DP5/DPH

Head-separated

PRESSURE SENSORS

DP3 SERIES

DP2

DP3

Digital Display

DP4

High accuracy sensing

at all times with autoreference function

* Passed the UL 991 Environment Test

* UL 61010C-1 compatible, Passed the UL 991 Environment Test based on SEMI S2-0200.

[Category applicable for semiconductor manufacturing: TWW2, Process Equipment]

[Applicable standards: UL 61010C-1]

[Additional test / evaluation standards as per intended use: UL991, SEMI S2-0200]

Conforming to

EMC Directive

UL Recognition

Example of air-leak test

Threshold level

Auto-reference function follows

reference pressure changes

OK

NG

Reference pressure

e

sur

• Unaffected by changes in reference pressure

By an external signal, the set (threshold) values are

corrected by being shifted by an amount equal to the

pressure change. Hence, judgment by the sensor is

as accurate as before the reference pressure change.

This function is extremely suitable in places having

intense variations in the reference pressure or where

fine settings are required.

res

ep

enc

fer

Re hange

c

Reference

pressure

Before reference pressure change

NG?

NG

OK

NG

Reference

pressure

Reference

pressure

Pressure sensor not incorporating

auto-reference function

DP3 series

After reference pressure change

• Total cost reduction

Till now...one sensor was required for each suction

nozzle

Since the threshold level differs with the suction nozzle, a

sensor was required for each suction nozzle, increasing

the cost significantly.

( Atmospheric

pressure )

In case of DP3...operation efficiency UP!

Since the threshold level can be automatically changed

by the auto-reference function, two suction nozzles can

be used, alternately, with one sensor.

DP3-80

Suction nozzle for trimmers

Auto-reference input

PE

LED Bar Display

DP-M

Incorporates auto-reference function

Suction nozzle for

chip components

For chip components

Vacuum

Before suction Suction OK Suction NG Suction over

Threshold

level for

suction nozzle

for trimmers

Threshold

level for

suction nozzle

for chip

components

MODE

Electromagnetic valve

For trimmers

808

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

�2.5 ms or less

Comparative ON

Output 1

OFF

Hysteresis

Repeatability

Hysteresis Hysteresis

Set Value 1 Set Value 2 Set Value 3 Set Value 4

(P-1) (P-2)

(P-3)

(P-4)

High pressure

(Positive pressure type)

High vacuum

(Vacuum pressure type)

Set Value 1 Set Value 2 Set Value 3 Set Value 4

(P-1)

(P-2)

(P-3)

(P-4)

High pressure

(Positive pressure type)

High vacuum

(Vacuum pressure type)

Hysteresis: 1 digit (2 digits when using psi unit)

Note: The auto-reference function acts only on

Set Value 3 (P-3) and Set Value 4 (P-4) of

Comparative Output 2.

Note: The auto-reference function acts only on

Set Value 3 (P-3) and Set Value 4 (P-4) of

Comparative Output 2.

Optimum for leak test

Leak test mode

This mode is optimally suitable for a

leak test since Comparative Output 1

can be set to the hysteresis mode and

Comparative Output 2 can be set to the

window comparator mode.

Forced output mode Suitable for start-up check

The comparative outputs are forcibly

maintained in the OFF state in the

sensing mode, irrespective of the set

values.

Also, since the comparative outputs

can be forcibly made ON or OFF with

key operation, without actually applying

pressure, this mode is suitable for an

operation check or a start-up check.

3

Hysteresis

(Variable)

Comparative ON

Output 1 OFF

Hysteresis Hysteresis

(Fixed)

(Fixed)

MODE

key

Press

MODE

Selection can be made according to

mounting method or place of use.

Standard type / DP3-2�

DP

2-20

–101

.3k

Pa

OU

T1

0-A

DJ

OU

T2

MO

DE

Direct piping

Mounting on a

panel

Light weight type / DP3-80

Total weight

70 g approx.

ON

OFF

ON

Comparative

Output 2

Sensing mode

OFF

Forced output mode

Sensing mode

MO

DE

Hysteresis (fixed): 1 digit (2 digits when using psi unit)

Note: The auto-reference function acts only on

Set Value 3 (P-3) and Set Value 4 (P-4) of

Comparative Output 2.

The sensor

can be

mounted on

the suction

head of a chip

mounter.

Direct mounting on a wall

Selection from six pressure units

Analog bar display

Peak hold / bottom hold display

The pressure unit can be selected from

six different systems to suit your

requirement.

The selectable pressure units differ

with the sensor type. When the pressure unit is changed, the measured

pressure value and the set values

are automatically converted.

Pressure changes can also be displayed

in an analog fashion using LED bars.

Hence, sudden pressure changes can be

recognized at a glance.

LED bars indicate the pressure level

in steps of 10 % F.S., regardless of

the pressure unit.

The peak value or the bottom value of

the varying pressure can be displayed.

This function is convenient for finding

the pressure variation range or for

determining a reference for pressure

settings.

(

)(

)

Analog bar display

Digital display

International

System of

Units (SI)

kPa (Note)

kgf/cm2

mmHg

psi

bar

Pressure

DP3-41

inHg

Peak

value

OUT1

100kPa

OUT2

MODE

0-ADJ

Peak value is displayed if

key is pressed continuously.

DP3-41

: Vacuum pressure type

: Positive pressure type

Note: ‘MPa’ in case of DP3-22 and DP3-42.

PRESSURE SENSORS

A wide variety of models

Flat type / DP3-4�

key

Comparative

Output 1

Set Value 1 Set Value 2 Set Value 3 Set Value 4

(P-1)

(P-2)

(P-3)

(P-4)

High pressure

(Positive pressure type)

High vacuum

(Vacuum pressure type)

Within�1 % F.S.

Note: The response time is 7.5 ms, or less, at the

time of auto-reference input.

4

Press

Temperature characteristics

Within�0.2 % F.S.�1 digit

ON

Comparative

Output 2 OFF

(Note)

0

DP4

Comparative ON

Output 1

OFF

ON

Comparative

Output 2 OFF

(Note)

0

Response time

Hysteresis Hysteresis

Hysteresis

ON

Comparative

Output 2 OFF

(Note)

0

It achieves a 2.5 ms, or less, response

time at a high resolution of 1/1,000.

It enables highly accurate sensing with its

excellent repeatability and temperature

characteristics.

DP-M

2 Window comparator mode

The comparative outputs can be made

ON or OFF by a pressure within the set

range.

Since Comparative Output 1 can be used

as a self-diagnosis output, it is possible

to specify the auto-reference input range.

LED Bar Display

PE

1 Hysteresis mode

The hysteresis of the comparative

outputs can be set, as desired, with the

set values.

High accuracy • high resolution • high speed

Digital Display

DP3

DP2

Two outputs with four independent settings and four output modes

enable control as per your requirement

Head-separated

DP5/DPH

DP3

Bottom

value

OUT1

100kPa

OUT2

MODE

0-ADJ

Bottom value is

displayed if

key is pressed

continuously.

Time

Note: The above graph is for a positive pressure

type sensor.

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

809

�PRESSURE SENSORS

DP5/DPH

Head-separated

DP3

APPLICATIONS

Confirmation of chip component suction

The auto-reference function can compensate for the difference in suction

levels due to suction nozzle separation

distance. The vacuum type can be

mounted close to the chip mounter

suction head since it weighs only 70 g.

Air-leak test for PET bottles

Leak test mode, which is an output

mode optimally suitable for an air-leak

test, has been incorporated. It can reliably detect even a small air-leak.

Because of the auto-reference function, it is safe even if the filling pressure

varies.

DP3-41

DP3-80

10

0k

DP4

OU

MO

MO

Pa

3-41

DP

OU

DE

T2

DE

T1

DJ

0-A

IC

Model No.

�101 kPa type

Appearance

0 to�101.3 kPa

DP3-20

0 to 100.0 kPa

DP3-21

0 to 1.000 MPa

DP3-22

Pressure port

Comparative outputs

Rc (PT) 1/8

female thread

�101 kPa type

0 to�101.3 kPa

DP3-80

100 kPa type

NPN

open-collector

transistor

0 to 100.0 kPa

DP3-41

1 MPa type

Positive pressure

Vacuum pressure

Positive pressure

Flat

Light weight

PE

LED Bar Display

Standard

DP-M

Vacuum

pressure

Type

810

Rated pressure range

100 kPa type

ORDER GUIDE

1 MPa type

DP2

DP3

Digital Display

IC tray

0 to 1.000 MPa

M5 female thread

Rc (PT) 1/8

female thread

DP3-42

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

�OPTIONS

Sensor mounting bracket

MS-DPX

Sensor mounting

bracket

(For standard type)

Mounting bracket for standard type

Two M4 (length 6 mm 0.236 in) pan head screws and two spring

washers are attached.

[

• MS-DPX-4

]

DP

3-2

0

–101

.3k

Pa

OU

T1

Back angled mounting bracket for standard type

Two M4 (length 6 mm 0.236 in) pan head screws and two spring

washers are attached.

DPX-03

Changes the pressure port from female thread [Rc (PT) 1/8] to

male thread [R (PT) 1/8].

Panel mounting

bracket

(For standard type)

MS-DPX-2

It can be used for mounting on a panel

(1 to 3.2 mm 0.039 to 0.126 in thick).

Front protection

cover

(For standard type)

DPX-04

It protects the sensor’s adjustment panel.

(It can be fitted when the panel mounting bracket is used.)

[

0-AD

J

]

Two M4 (length 6 mm 0.236 in)

pan head screws and two

spring washers are attached.

OU

T2

MOD

E

Two M4 (length 6 mm 0.236 in)

pan head screws and two

spring washers are attached.

DP4

MS-DPX-4

Straight bush

• MS-DPX

Description

Straight bush

• DPX-01 [Pressure port attachment (Standard type only)]

• DPX-02 [Hexagon-socket-head plug for pressure port (Standard type only)]

Pressurer port attachment DPX-01

Straight

bush

Digital Display

DP3

DP2

Accessories

• DPX-03

Panel mounting bracket,

Front protection cover

• MS-DPX-2

• DPX-04

Front protection

cover DPX-04

DP

2-20

–10

OU

1.3

kPa

T1

OU

0-A

DJ

T2

MO

DE

Panel mounting bracket

MS-DPX-2

Suitable for 1 to 3.2 mm

0.039 to 0.126 in thick panel

(

)

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

LED Bar Display

PE

Hexagon-socket-head plug

for pressure port DPX-02

DP-M

Model No.

Head-separated

DP5/DPH

Designation

PRESSURE SENSORS

DP3

811

�PRESSURE SENSORS

DP5/DPH

Head-separated

DP4

DP3

SPECIFICATIONS

Type

Item

Model No.

Vacuum pressure

�101 kPa type

Standard

Light weight

DP3-20

DP3-80

DP3-21

Type of pressure

0 to�101.3 kPa

Rated pressure range

DP3-22

DP3-42

0 to 100.0 kPa

0 to 1.000 MPa

Set pressure range

(Note 1)

5.1 to�101.3 kPa

0.052 to�1.033 kgf/cm2, 0.051 to�1.013 bar

0.74 to�14.70 psi, 38 to�760 mmHg

1.5 to�29.9 inHg

�5.0 to 100.0 kPa

�0.051 to 1.020 kgf/cm2, �0.050 to 1.000 bar

�0.72 to 14.50 psi

�0.050 to 1.000 MPa

�0.51 to 10.20 kgf/cm2, �0.50 to 10.00 bar

�7.2 to 145.0 psi

Settable range

(Note 2)

101.3 to�101.3 kPa

1.033 to�1.033 kgf/cm2, 1.013 to�1.013 bar

14.70 to�14.70 psi, 760 to�760 mmHg

29.9 to�29.9 inHg

�100.0 to 100.0 kPa

�1.020 to 1.020 kgf/cm2, �1.000 to 1.000 bar

�14.50 to 14.50 psi

�1.000 to 1.000 MPa

�10.20 to 10.20 kgf/cm2,�10.00 to 10.00 bar

�145.0 to 145.0 psi

490 kPa

Applicable fluid

kPa, kgf/cm2, bar, psi, mmHg, inHg

Current consumption

(

50 mA or less

)

DC-12 or DC-13

Equipped with 4 types of modes: hysteresis mode, window comparator mode, leak test mode, forced output mode

(selectable by key operation)

Output modes

Hysteresis

1 digit (however, variable in hysteresis mode, variable for Comparative Output 1 only when using leak test mode, and 2 digits when using psi unit)

Within�0.2 % F.S.�1 digit

Repeatability

Response time

2.5 ms or less [7.5 ms or less with auto-reference input (Note 3)]

Short-circuit protection

Incorporated

NPN non-contact input [operates in Low (fall) state]

• Input signal condition: High...5 to 30 V or open

Low...0.4 V or less (0.5 mA, or less, source current)

Low level input time...1 ms or more

Reference pressure duration...1 ms or more

Auto-reference input

Display

31/2 digit red LED display (Sampling rate: 4 times/sec. approx.)

Displayable pressure range

Analog bar display

5.1 to�101.3 kPa

0.052 to�1.033 kgf/cm2, 0.051 to�1.013 bar

0.74 to�14.70 psi, 38 to�760 mmHg

1.5 to�29.9 inHg

�5.0 to 100.0 kPa

�0.051 to 1.020 kgf/cm2,�0.050 to 1.000 bar

�0.72 to 14.50 psi

�0.050 to 1.000 MPa

�0.51 to 10.20 kgf/cm2,�0.50 to 10.00 bar

�7.2 to 145.0 psi

LED bar display in steps of 10 % F.S. approx.

Operation Comparative Output 1

indicators Comparative Output 2

Pollution degree

Environmental resistance

MPa, kgf/cm2, bar, psi

NPN open-collector transistor

• Maximum sink current: 100 mA

• Applied voltage: 30 V DC or less (between comparative output and 0 V)

• Residual voltage: 1 V or less (at 100 mA sink current)

0.4 V or less (at 16 mA sink current)

Utilization category

DP-M

kPa, kgf/cm2, bar, psi

10

12 to 24 V DC �

�15 % Ripple P-P 10 % or less

Supply voltage

Comparative outputs

Comparative Output 1

Comparative Output 2

1.47 MPa

Non-corrosive gas

Selectable units

DP2

DP3

Digital Display

DP3-41

Gauge pressure

Pressure withstandability

PE

LED Bar Display

Positive pressure

100 kPa type

1 MPa type

Standard

Flat

Standard

Flat

Orange LED (lights up when Comparative Output 1 is ON)

Green LED (lights up when Comparative Output 2 is ON)

3 (Industrial environment)

Protection

IP40 (IEC)

Ambient temperature

�10 to�50 �C �14 to�122 �F (No dew condensation or icing allowed), Storage: �10 to�60 �C �14 to�140 �F

Ambient humidity

35 to 85 % RH, Storage: 35 to 85 % RH

EMC

EN 50081-2, EN 50082-2, EN 61000-6-2

Voltage withstandability

1,000 V AC for one min. between all supply terminals connected together and enclosure

Insulation resistance

50 MΩ, or more, with 500 V DC megger between all supply terminals connected together and enclosure

Vibration resistance

10 to 150 Hz frequency, 0.75 mm 0.030 in amplitude in X, Y and Z directions for two hours each

100 m/s2 acceleration (10 G approx.) in X, Y and Z directions for three times each

Shock resistance

Temperature characteristics

Pressure port

Material

Cable

Cable extension

Weight

Accessories

Over ambient temperature range �10 to�50 �C �14 to�122 �F: within�1 % F.S. of detected pressure at �20 �C �68 �F

Standard type: Rc (PT) 1/8 female thread, Flat type: Rc (PT) 1/8 female thread, Light weight type: M5 female thread

Front case: ABS, Rear case: PPS (glass fiber reinforced), Display surface: Acrylic

Pressure port attachment: Die-cast zinc alloy [Light weight type: POM (glass fiber reinforced), pressure port is brass (nickel plated)]

0.15 mm2 5-core oil resistant cabtyre cable, 2 m 6.562 ft long

Extension up to total 100 m 328.084 ft (less than 10 m 32.808 ft when conforming to CE marking) is possible with 0.3 m2, or more, cable.

Standard type: 95 g approx., Flat type: 120 g approx., Light weight type: 70 g approx.

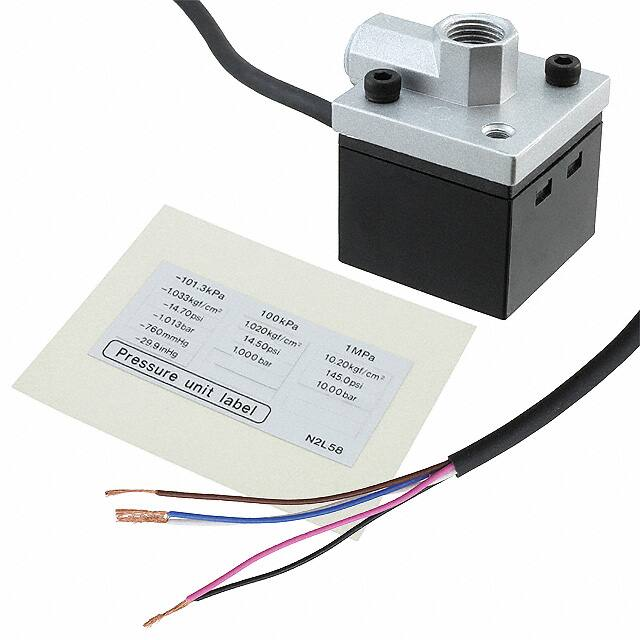

DPX-02 (Hexagon-socket-head plug for pressure port): 1 pc. (Standard type only), Pressure unit label: 1 pc.

Notes: 1) The set pressure range is the settable pressure range for Set Value 1 (P-1) and Set Value 2 (P-2).

2) The settable range is the settable pressure range for Set Value 3 (P-3) and Set Value 4 (P-4). It caters to the auto-reference function and is much wider

than the rated pressure range.

3) Refer to ‘Time chart’ under ‘Auto-reference function’ on p.816.

812

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

�I/O CIRCUIT AND WIRING DIAGRAMS

Wiring diagram

Color code

(Brown)�V

Auto-reference

(Pink) input (Note)

(Black) Comparative Output 1

Tr1

ZD1

Tr2

ZD2

Internal circuit

Load

Load

100 mA max.

(White) Comparative Output 2

(Blue) 0 V

� 12 to 24 V DC

10

� �

�15 %

100 mA max.

DP3-80

–101.3kPa

OUT1

OUT2

MODE

0-ADJ

Users’ circuit

Note: If you do not use the auto-reference input (pink),

always connect it to �V (brown).

DP4

Sensor circuit

D

Head-separated

DP5/DPH

I/O circuit diagram

PRESSURE SENSORS

DP3

Brown

Load

Pink

Symbols ... D: Reverse supply polarity protection diode

ZD1, ZD2 : Surge absorption zener diode

Tr 1 , Tr 2 : NPN output transistor

Black

Load

� 12 to 24 V DC

10

� �

�15 %

Digital Display

DP3

DP2

White

Blue

PRECAUTIONS FOR PROPER USE

Operation

• If setting is impossible even with pressing the MODE key,

verify whether the key-protect function is enabled. Please

note that pressing down on the MODE key for an

extended moment will enable the key-protect function as

soon as the key is released.

• If using the window comparator mode, set the pressure

values so that there is a difference of 3 digits, or more,

between Set Value 1 (P-1) and Set Value 2 (P-2), and

between Set Value 3 (P-3) and Set Value 4 (P-4). No

output will be possible with a 0 to 2 digit difference.

Wiring

• Make sure that the power supply is off while wiring.

• Verify that the supply voltage variation is within the rating.

• If power is supplied from a commercial switching regulator,

ensure that the frame ground (F.G.) terminal of the power

supply is connected to an actual ground.

• In case noise generating equipment (switching regulator,

inverter motor, etc.) is used in the vicinity of this sensor,

connect the frame ground (F.G.) terminal of the equipment

to an actual ground.

• Do not run the wires together with high-voltage lines or

power lines or put them in the same raceway. This can

cause malfunction due to induction.

Conditions in use for CE conformity

• The DP3 series is a CE conformity product complying with

EMC Directive. The harmonized standard with regard to

immunity that applies to this product is EN 61000-6-2

(Note) and the following condition must be met to conform

to that standard.

Condition

• The sensor should be connected less than 10 m 32.808 ft

from the power supply.

Note: The EN 50082-2 that previously applied to the products for conforming

to EMC Directive was replaced by EN 61000-6-2 staring April 1st, 2002.

Others

• Use within the rated pressure range.

• Do not apply pressure exceeding the pressure withstandability value. The diaphragm will get damaged and

correct operation shall not be maintained.

• Do not use during the initial transient time (0.5 sec.) after

the power supply is switched on.

• Avoid dust, dirt, and steam.

• Take care that the sensor does not come in direct contact

with water, oil, grease, or organic solvents, such as,

thinner, etc.

• Do not insert wires, etc., into the pressure port. The

diaphragm will get damaged and correct operation shall

not be maintained.

• Do not operate the keys with pointed or sharp objects.

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

813

LED Bar Display

PE

• This product is not a safety sensor. Its use is not

intended or designed to protect life and prevent

body injury or property damage from dangerous

parts of machinery. It is a normal pressure

detection sensor.

• The DP3 series is designed for use with noncorrosive gas. It cannot be used with liquid or corrosive gas.

DP-M

All models

�PRECAUTIONS FOR PROPER USE

All models

Functional description

–101.3kPa

3

2

Cause

Overcurrent due to short- Switch off the power supply

circuit.

and check the load.

OUT2

MODE

Applied pressure at the

Pressure is being applied pressure port should be

during zero-point adjust- brought to atmospheric presment.

sure and zero-point adjustment should be done again.

0-ADJ

DP4

4

6

5

Displays measured pressure, settings, error

messages and key-protect status.

Comparative Output

2 1 operation indicator

(Orange)

Lights up when Comparative Output 1 is ON.

Comparative Output

3 2 operation indicator

(Green)

Lights up when Comparative Output 2 is ON.

4

• In the initial setting mode, pressing the

key changes the settable digit.

• In the Set Value 1 to 4 modes, pressing the key changes the set value to

the high pressure side in case of

positive pressure type sensor and to

the high vacuum side in case of

vacuum pressure type sensor.

• In the sensing mode, if the key is

pressed continuously for 4 sec. or more,

the display shows peak hold value.

Increment key (

5 Decrement key (

6

)

• In the initial setting mode, pressing the

key changes the set conditions.

• In the Set Value 1 to 4 modes, pressing the key changes the set value to

the low pressure side in case of

)

positive pressure type sensor and to

the low vacuum side in case of

vacuum pressure type sensor.

• In the sensing mode, if the key is

pressed continuously for 4 sec. or more,

the display shows bottom hold value.

Mode selection key

( MODE )

In the sensing mode, if both the keys are pressed

simultaneously, zero-point adjustment is done.

PE

LED Bar Display

Function

31/2 digit LED

1

display (Red)

DP-M

DP2

DP3

Digital Display

Description

Applied pressure

exceeds the upper

limit of displayable

pressure range.

Applied pressure

exceeds the lower

limit of displayable

Applied pressure should be

pressure range.

brought within the rated

Applied pressure pressure range.

exceeds the lower

limit of displayable

pressure range.

Applied pressure

exceeds the upper

limit of displayable

pressure range.

Label for change in pressure unit

• When a pressure unit other than ‘kPa’ ( ) or ‘MPa’ ( ) has

been selected in the initial setting mode, the label (supplied

as accessory) which corresponds to the selected unit

should be stuck at the position shown in the figure below.

Pressure unit label (accessory)

• Each press of the key changes the selected

mode to sensing mode, Set Value 1 (P-1) to

Set Value 4 (P-4) set mode.

• In the sensing mode, if the key is pressed

continuously for about 3 sec., key-protect can

be set / released.

• In the sensing mode, if the mode selection

key is pressed while pressing the increment

key(

), the initial setting mode is obtained.

DP3-80

–101.3kPa

OUT1

OUT2

Stick the pressure unit label

at the position shown.

MODE

0-ADJ

Conversion of pressure units

• In the DP3 series, the conversion

to different units is automatically

done on changing the setting of

the pressure unit. However, this

conversion can also be obtained

by multiplying the values by the

coefficients given in the table on

the right.

Conversion procedure

• For example, if 2 kPa is to be expressed

in kgf/cm2,

since 1 kPa�1.01972 10�2 kgf/cm2,

2 kPa becomes

2 1.01972 10�2c0.020 kgf/cm2.

814

Corrective action

Positive

pressure

type

OUT1

Error message

Vacuum

pressure

type

DP3-80

Positive

pressure

type

1

Error messages

• When an error occurs, take the following corrective action.

Vacuum

pressure

type

DP5/DPH

Head-separated

PRESSURE SENSORS

DP3

Conversion table for pressure units

kPa

kgf/cm2

MPa

1

1 kPa

1

1 MPa

1 103

10�3

1.01972

1

1.01972 10

1 kgf/cm2 9.80665 10 9.80665

10�2

1bar

1 102

1psi

6.89473

1 10�1

10�2

1

1.01972

bar

psi

1

10�2

1 10

9.80665

10�1

1

6.89473 10�3 7.03065 10�2 6.89473 10�2

1.45038

10�1

3.3864 10�3 3.4531 10�2 3.3864 10�2

3.3864

1 atm

1.01325

102

1.01325

10�1

1.03323

1.01325

inHg

atm

7.50062

0.2953

9.86923 10�3

1.45038 102 7.50062 103 0.2953 103

9.86923

1.42234 10 7.35559 102 2.8959 10 9.67841 10�1

1.45038 10 7.50062 102

1

1 mmHg

1.33322 10�1 1.33322 10�4 1.35951 10�3 1.33322 10�3 1.93368 10�2

(1Torr)

1 inHg

mmHg

(Torr)

0.4912

5.17147 10

2.953 10

9.86923 10�1

2.036

6.80457 10�2

3.9370

1

2.5400 10

1.46960 10 7.60000

102

10�2

1.31579 10�3

1

3.342 10�2

2.9921 10

1

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

�Setting

• If key-protect has been set, make sure to release key-protect before operating the keys.

(Please refer to ‘Key-protect function’ on p.817 for the procedure.)

• Set Value 1 to 4 (P-1 to P-4) can be made common for all the output modes.

• In the positive pressure type sensor, Set Value 2 (P-2) and Set Value 4 (P-4) can be set only towards the high pressure side

with respect to Set Value 1 (P-1) and Set Value 3 (P-3), respectively.

In the vacuum pressure type sensor, Set Value 2 (P-2) and Set Value 4 (P-4) can be set only towards the high vacuum

side with respect to Set Value 1 (P-1) and Set Value 3 (P-3), respectively.

• Auto-reference function acts on Set Value 3 (P-3) and Set Value 4 (P-4) only.

• Set Value 5 (P-5) is the auto-reference input value. If auto-reference input is not applied, Set Value 5 (P-5) is zero.

• The conditions which are set are stored in an EEPROM. Kindly note that the EEPROM has a life span and its guaranteed

life is 100,000 write operation cycles. However, since the auto-reference input value [Set Value 5 (P-5)] is not written into

the EEPROM, it is not included in the number of write operation cycles.

PRESSURE SENSORS

All models

DP4

PRECAUTIONS FOR PROPER USE

Head-separated

DP5/DPH

DP3

1 Zero-point adjustment

2 Initial setting

3 Pressure value setting

Measurement

Adjust zero-point

Set ‘Display’, ‘Output mode’,

and ‘Unit’

Enter Set Value 1 to 4

(P-1 to P-4)

Commence measurement

on completion of setting

1 Zero-point adjustment

3 Pressure value setting

• The displayed pressure when the pressure port is left

open is adjusted to zero.

• Set Value 1 to 4 (P-1 to P-4) of the comparative outputs are set.

• The sensor will automatically enter the sensing

mode when power is supplied.

• Let the pressure port be at atmospheric pressure

(i.e., no applied pressure condition), and press,

simultaneously, the increment and decrement

keys continuously.

•

is displayed and, when the fingers are

released, zero-point adjustment is completed and

the sensor returns to the sensing mode.

2 Initial setting

DP3-80

–101.3kPa

OUT1

OUT2

DP3-80

–101.3kPa

OUT1

OUT2

MODE

0-ADJ

• At each press of MODE key, the mode changes, in

rotation, to Set Value 1 (P-1) set mode, Set Value 2

(P-2) set mode, Set Value 3 (P-3) set mode, Set

Value 4 (P-4) set mode, Set Value 5 (P-5) display

mode and sensing mode.

Digital Display

DP3

DP2

Setting procedure

MODE

OUT1

–101.3kPa

• In the sensing mode, press

ing

key.

MODE

MODE

0-ADJ

Press

is

• The settable digit blinks.

• The settable digit changes when

key is pressed.

• The setting is changed when

key is pressed.

Change with

3rd digit

displayed.

2

Vacuum

Positive

pressure type pressure type

MODE

key

Press

Set Value 1 (P-1) set mode

Output mode

MODE

key

Set Value 5 (P-5) display mode

6

• Enter Set Value 1 (P-1)

using

key and

key.

• Auto-reference input value

is displayed.

In case auto-reference input has not

been applied, zero is displayed.

1st digit

Press

Unit

• At the time of auto-reference

input,

is displayed, and

the sensed pressure value is

recorded in Set Value 5 (P-5).

key

2nd digit

Sensing mode

key while press-

• Initial setting is displayed.

• If sensor is being used for the first time,

displayed.

OUT2

1’

Display

: kPa or

MPa

: Hysteresis

mode

: Digital

display

: kgf/cm2

: Window

comparator

mode

: Analog

bar

display

: bar

: Leak test

mode

: psi

: Forced output

mode

: mmHg

: inHg

• If the output mode has been set to the window comparator

mode ( ), set the pressure values so that there is a difference

of 3 digits, or more, between Set Value 1 (P-1) and Set Value 2

(P-2), and between Set Value 3 (P-3) and Set Value 4 (P-4).

Also, if the output mode has been set to the leak test mode ( ), set

the pressure values so that there is a difference of 3 digits, or more,

between Set Value 3 (P-3) and Set Value 4 (P-4). However, when

unit is set to ‘psi’ ( ), the difference should be 6 digits, or more.

3

MODE

key

Press

Set Value 2 (P-2) set mode

5

• Enter Set Value 2 (P-2)

using

key and

key.

Press

4

MODE

key

Set Value 4 (P-4) set mode

• Enter Set Value 4 (P-4) using

key and

key.

MODE

key

Press

MODE

key

Set Value 3 (P-3) set mode

• Enter Set Value 3 (P-3)

using

key and

key.

• The pressure values can be set only when the output mode has

been set to hysteresis mode ( ), window comparator

mode ( ) or leak test mode ( ). If the output mode has been set

to the forced output mode ( ), pressure values cannot be set.

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

815

LED Bar Display

PE

• Sensed pressure value is

• Pressure ‘Unit’, ‘Display’ and ‘Output mode’ of the

comparative outputs are set.

DP3-80

Sensing mode

Auto-reference

input

1

DP-M

0-ADJ

�PRECAUTIONS FOR PROPER USE

All models

Auto-reference function

Principle

• Auto-reference function corrects Set Value 3 (P-3) and Set Value 4

(P-4) of Comparative Output 2 by taking the pressure measured at

the time of auto-reference input as the reference pressure.

Comparative

Output 2

OFF

Atmospheric pressure

P-3

Pressure

P-4

DP2

DP3

Digital Display

• When there is no auto-reference input, the atmospheric pressure

is taken as the reference pressure for Set Value 3 (P-3) and Set

Value 4 (P-4).

DP-M

P-2 Suction nozzle clogging error range

OK product

P-1

Auto-reference input

ON

P-3’�P-3�P-5

Comparative

Output 2

OFF

Atmospheric pressure P-5

P-3’

P-4’

Pressure

that instant is temporarily recorded as Set Value 5 (P-5) and

becomes the reference pressure.

• With Set Value 5 (P-5) as the reference pressure, Set Value 3

(P-3) and Set Value 4 (P-4) are automatically corrected to ‘Set

Value 3 (P-3)�Set Value 5 (P-5)’ and ‘Set Value 4 (P-4)�Set

Value 5 (P-5)’, respectively.

Settable range and set pressure range after correction

• The settable range of Set Value 3 (P-3) and Set Value 4 (P-4) is wider

than the rated pressure range to cater to the auto-reference function.

• At the time of auto-reference input, if the corrected set value

exceeds the set pressure range, the set value is automatically

corrected to be within the set pressure range. Hence, please

see that the set pressure range is not exceeded.

Settable range (P-3, P-4)

Set pressure range (P-3 and P-4 after correction)

Rated pressure range

P-4’�P-4�P-5

b P-3’�P-3�P-5

a

NG product

P-5

Auto-reference input

Suction level can be specified with respect to

the atmospheric pressure

P-4

P-3

b

0 a

P-4’�P-4�P-5

Pressure change

• At the time of auto-reference input, the pressure value detected at

PE

LED Bar Display

Application examples

(1) Confirmation of PCB mount component suction (Using hysteresis mode)

• Pressure judgment errors due to suction nozzle type, suction

nozzle clogging, reference pressure changes, etc., are eliminated

by the auto-reference function.

• The confirmation of PCB mount component suction is done with

Comparative Output 2, which is acted upon by the auto-reference

function, and error due to nozzle clogging is simultaneously

detected by Comparative Output 1.

Pressure

DP4

ON

• When the power supply is switched on again, the auto-reference

input value [Set Value 5 (P-5)] is set to zero.

• Although it is not possible to display the corrected Set Value 3

(P-3’) and Set Value 4 (P-4’), it is possible to display the autoreference input value [Set Value 5 (P-5)].

• In case the auto-reference input (pink) is not used, make sure to

connect it to �V (brown).

Time

1. By making the auto-reference input ‘Low’ when the PCB mount

components are not being sucked, the reference pressure value

is recorded in Set Value 5 (P-5), and Set Value 3 (P-3) and Set

Value 4 (P-4) are corrected.

2. Suction confirmation is done by Comparative Output 2, 7.5 ms,

or more, after the application of the auto-reference input.

If suction is OK, Comparative Output 2 is ON, and if it is NG,

Comparative Output 2 is OFF.

3. Error due to suction nozzle clogging is detected by the setting of

Comparative Output 1.

If the nozzle is OK, Comparative Output 1 is OFF, and if it is NG,

Comparative Output 1 is ON.

(

)

(

)

(2) Air-leak test for PET bottles (Using leak test mode)

• The effect of dispersion in the filling pressure of the PET bottle is

eliminated by using the auto-reference function.

• Comparative Output 1 is used to detect the filling pressure, while

Comparative Output 2 is used to detect the leakage. Since

Comparative Output 1 is not affected by the auto-reference input

function, the filling pressure is detected with reference to the

atmospheric pressure.

Auto-reference input

�101 kPa type

101.3 101.2

5.1

0 �0.1

�101.2 �101.3

100 kPa type Lo �100.0 �99.9

�5.0

0

1 MPa type

0.1

99.9 100.0 UP

�1.000 �0.999

�0.050

0 0.001

0.999 1.000

Pressure

PRESSURE SENSORS

DP5/DPH

Head-separated

DP3

Time chart

High

Auto-reference input

Low

b

a

Leakage can be specified with respect to

the atmospheric pressure

P-3

Time

7.5 ms or less

Output response time at the time

of auto-reference input

• Maintain the pressure at a constant level for at least 1 ms after

the auto-reference input is made Low. If used in a transient state,

it will result in wrong operation.

• Use Comparative Output 2 at least 7.5 ms after the autoreference input is made low.

• At the time of auto-reference input,

is displayed on the 31/2

digit LED display for 1 sec. approx., the pressure at that instant is

stored temporarily in Set Value 5 (P-5), and Set Value 3 (P-3) and

Set Value 4 (P-4) are corrected.

• Since Set Value 5 (P-5) and the corrected Set Value 3 (P-3’) and

Set Value 4 (P-4’), after the auto-reference input, are not stored in

an EEPROM, they are erased when the power is switched off.

816

NG product

0

1 ms or more

Comparative Output 2

(ON / OFF)

P-3’�P-3�P-5

OK product

P-4

Low level

input time

P-4’�P-4�P-5

b

a

P-5

P-2

P-1

1. Pressure is increased in the PET bottle, and when Set Value 2

(P-2) is reached, Comparative Output 1 is turned ON and the

filling is tightly shut off.

2. After shutting off the filling pressure, the auto-reference input is

made ‘Low’. The filled pressure is recorded in Set Value 5 (P-5)

as the reference value, and Set Value 3 (P-3) and Set Value 4

(P-4) are corrected.

3. The leakage is measured by Comparative Output 2, 7.5 ms, or

more, after the application of the auto-reference input.

If the leakage is OK, Comparative Output 2 is ON, and if it is

NG, Comparative Output 2 is OFF.

(

)

If it is a simple air-leak test, it can be done by directly applying

the Comparative Output 1 signal (falling signal) to the autoreference input.

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

�The figure below is for a vacuum pressure type sensor with the

unit set to ‘kPa’ ( ).

Sensing mode

Peak hold display

DP3-80

–101.3kPa

OUT1

OUT2

Digital Display

DP3

DP2

• Please note that the peak value and the bottom value data is

erased when it is no longer displayed.

• The response time of the comparative outputs becomes slower

during the peak hold and bottom hold display.

Forced output mode

• In the initial setting, if the output mode is set to the forced output

mode ( ), Comparative Output 1, 2 are forcibly maintained at

OFF level in the sensing mode, irrespective of Set Value 1 to 4

(P-1 to P-4). Hence, this mode is useful when it is desired to only

display the pressure value without using the comparative

outputs.

Further, if the keys are operated as per the procedure given

below, Comparative Output 1, 2 can be forcibly switched either

ON or OFF without applying pressure at the pressure port. This

is convenient for an operation check of Comparative Output 1, 2

or for an inspection before commencing work.

MODE

0-ADJ

–101.3kPa

OUT1

OUT2

MODE

0-ADJ

Displayed

alternately

DP3-80

–101.3kPa

OUT1

OUT2

MODE

0-ADJ

Press

MODE

key

Forced output mode

DP3-80

–101.3kPa

OUT1

OUT2

pressure range, error message (

or

)

and

are displayed alternately. In this case,

bring back the applied pressure to within the rated

pressure range.

• The figure on the left shows the display of a

vacuum type sensor when the pressure unit has

been set to ‘kPa’ ( ).

Blinking display of measured pressure

Each time

key is pressed, Comparative

Output 2 switches between ON and OFF.

(Operation indicator also lights up, turns off.)

MODE

0-ADJ

Each time

key is pressed, Comparative

Output 1 switches between ON and OFF.

(Operation indicator also lights up, turns off.)

Press

MODE

DP-M

DP3-80

Initiating peak hold display

• In the sensing mode, keep

key pressed until

is displayed. (4 sec. approx.)

• When the finger is released after

is displayed, the peak value and

are displayed

alternately.

• If the applied pressure exceeds the displayable

key

[• Sensor returns to sensing mode.]

Time chart

DP3-80

–101.3kPa

Ending peak hold display

• Press

key.

[• Sensor returns to sensing mode.]

Press

MODE

key

Press

MODE

key

ON

Comparative

Output 1

OFF

OUT1

OUT2

MODE

ON

Comparative

Output 2

0-ADJ

OFF

Sensing mode

Bottom hold display

DP3-80

–101.3kPa

OUT1

OUT2

MODE

0-ADJ

Displayed

alternately

DP3-80

–101.3kPa

OUT1

OUT2

MODE

0-ADJ

Initiating bottom hold display

• In the sensing mode, keep

key pressed until

is displayed. (4 sec. approx.)

• When the finger is released after

is

displayed, the bottom value and

are

displayed alternately.

• If the applied pressure exceeds the displayable

pressure range, error message (

or

)

and

are displayed alternately. In this case,

bring back the applied pressure to within the rated

pressure range.

• The figure on the left shows the display of a

vacuum type sensor when the pressure unit has

been set to ‘kPa’ ( ).

Forced output mode

Sensing mode

• The comparative outputs are held at the OFF level from the

time a change is made to the forced output mode ( ) from the

other modes.

• Even if a comparative output is held at the ON level in the

forced output mode, it is forcibly brought to the OFF level at the

time the sensor returns to the sensing mode.

Key-protect function

• Key-protect is a function which prevents any unintentional change

in the conditions which have been entered in each setting mode

by making the sensor not to respond to the key operations.

DP3-80

–101.3kPa

OUT1

OUT2

MODE

0-ADJ

Setting of key-protect

• In the sensing mode, press MODE key continuously

for about 3 sec. and release it immediately

when

is displayed.

• Key-protect is set and the sensor returns to the

sensing mode.

DP3-80

OUT1

–101.3kPa

Ending bottom hold display

• Press

key.

[• Sensor returns to sensing mode.]

DP3-80

–101.3kPa

OUT1

OUT2

OUT2

MODE

0-ADJ

MODE

0-ADJ

Release of key-protect

• In the sensing mode, press MODE key continuously

for about 3 sec. and release it immediately

when

is displayed.

• Key-protect is released and the sensor returns to

the sensing mode.

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

817

LED Bar Display

PE

Peak hold & bottom hold functions

• Peak hold and bottom hold functions enable the display of

the peak value (maximum pressure value in case of the

positive pressure type sensor and maximum vacuum pressure value in case of the vacuum pressure type sensor)

and the bottom value (minimum pressure value in case of

the positive pressure type sensor and minimum vacuum

pressure value in case of the vacuum pressure type sensor) of the varying measured pressure.

• These functions are convenient for finding the pressure

variation range or for determining the reference for pressure settings.

PRESSURE SENSORS

All models

DP4

PRECAUTIONS FOR PROPER USE

Head-separated

DP5/DPH

DP3

�PRESSURE SENSORS

DP5/DPH

Head-separated

DP3

PRECAUTIONS FOR PROPER USE

Standard type

Setting of pressure lead direction

• The pressure lead direction can be changed by

dismantling the pressure port attachment and changing

the mounting direction. The tightening torque of the

hexagon-socket-head bolt (length: 9 mm 0.354 in or less)

should be 0.29 N

m or less.

DP4

Note: Make sure to close any unused pressure port with the hexagonsocket-head plug supplied as accessory.

Main body

DP2

DP3

Digital Display

DP-M

M4 (length 6 mm 0.236 in)

pan head screw

(Accessory for MS-DPX)

Spring washer

(Accessory for MS-DPX)

Hexagon-socket-head bolts

PE

LED Bar Display

Mounting

• When mounting the sensor with the sensor mounting

bracket, etc., the tightening torque should be 1.2 N

m or

less.

Sensor mounting bracket

MS-DPX (optional)

Pressure

ports

Pressure port

attachment

Hexagon-socket-head plug

Piping

• When connecting a hexagon-socket-head plug or coupling

to the pressure port, hold the hexagonal part of the

pressure port with a 12 mm 0.472 in spanner and make

sure that the tightening torque is 9.8 N

m or less. Also, in

order to prevent any leakage, wind a sealing tape on the

coupling when connecting.

12 mm 0.472 in spanner

Flat type

Light weight type

Setting of pressure lead direction

• The pressure lead direction can be changed by

dismantling the pressure port attachment and changing

the mounting direction. The tightening torque of the

hexagon-socket-head bolt (length: 9 mm 0.354 in or less)

should be 0.29 N

m or less.

Piping

• When connecting a coupling to the pressure port, hold the

pressure port attachment with a 16 mm 0.630 in (light

weight type: 10 mm 0.394 in) spanner and make sure that

the tightening torque is 9.8 N

m or less (light weight type:

1.47 N

m or less). Also, in order to prevent any leakage,

wind a sealing tape on the coupling when connecting.

Pressure port attachment

Hexagon-socket-head bolts

Main body

2-"4.3 mm "0.169 in

mounting holes

Pressure port

818

16 mm 0.630 in

(light weight type: 10 mm 0.394 in)

spanner

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

�DIMENSIONS (Unit: mm in)

31.6

1.244

30

1.181

(25.8)

(1.016)

(2.1)

(0.083)

38.5

1.516

23.5

0.925

31/2 digit

LED display (Red)

5

0.197

2-M3 hexagon-socket-head bolts

20

0.787

2-M4

(11)

(0.433) 30 31.6

1.181 1.244

(18.9)

(0.744) (10.9)

(0.429)

20

0.787

DP4

(6)

(0.236)

Head-separated

DP5/DPH

Standard type

MODE

Comparative Output 2

operation indicator (Green)

Increment key

Pressure port

Rc (PT) 1/8 female thread

Mode selection key

Decrement key

Comparative Output 1

operation indicator (Orange)

(9)

(0.354)

8

0.315

12

0.472

13

0.512

14

0.551

(18)

(0.709)

Digital Display

DP3

DP2

DP3-20 DP3-21

DP3-22

The CAD data in the dimensions can be downloaded from the SUNX website: http://www.sunx.co.jp/

"3.7 "0.146 cable, 2 m 6.562 ft long

DP3-80

Light weight type

30

1.181

(25.8)

(1.016)

(11)

(0.433)

41

1.614 (23.7)

(0.933) (15.7)

(0.618) (10.8)

(0.425)

33.5

1.319

23.5

0.925

31/2 digit

LED display (Red)

DP-M

(2.1)

(0.083)

30

1.181

LED Bar Display

PE

MODE

Comparative Output 2

operation indicator (Green)

Mode selection key

6.2

0.244

2-"8 "0.315,

4.4 0.173 deep

Comparative Output 1

operation indicator (Orange)

(9)

(0.354)

(18)

(0.709)

20

0.787

2-"4.3 "0.169

mounting holes

DP3-41

DP3-42

Decrement key

Increment key

10

0.394

Pressure port

M5 female thread, 4 0.157 deep

5

0.197

18

0.709

"3.7 "0.146 cable, 2 m 6.562 ft long

Flat type

(2.1)

(0.083)

30

1.181

(25.8)

(1.016)

31/2 digit

LED display (Red)

35

1.378

23.5

0.925

(11)

(0.433) 30

1.181

44.7

1.760 (27.9)

(1.098) (19.9)

(0.783)

MODE

(15)

(0.591)

Comparative Output 2

operation indicator (Green)

Mode selection key

5.7

0.224

2-"8 "0.315,

4.4 0.173 deep

2-"4.3 "0.169

mounting holes

PRESSURE SENSORS

DP3

(9)

(0.354)

(18)

(0.709)

20

0.787

Comparative Output 1

operation indicator (Orange)

Decrement key

Increment key

16

0.630

19.5

0.768

Pressure port

Rc (PT) 1/8 female thread

8.2

0.323

"3.7 "0.146 cable, 2 m 6.562 ft long

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

819

�DIMENSIONS (Unit: mm in)

MS-DPX

The CAD data in the dimensions can be downloaded from the SUNX website: http://www.sunx.co.jp/

Sensor mounting bracket for standard type (Optional)

Assembly dimensions

DP5/DPH

Head-separated

PRESSURE SENSORS

DP3

40

1.575

25

0.984

2-"4.2 "0.165

mounting holes

2-"4.2 "0.165

mounting holes

25

0.984

11

0.433 20

0.787

DP4

11

0.433

48.5

39.5 1.909

28.5 1.555

1.122

DP2

DP3

Digital Display

31.5

1.240

20

0.787

12.5

0.492

2-"4.2 "0.165

mounting holes

DP-M

30

1.181

38.5

1.516

31.6

1.244

5.8

0.228

8

0.315

20

0.787

45.5

1.791

20

0.787

MODE

30

1.181

45.8

1.803

30

1.181

14.2

0.559

40

1.575

t 1.6

t 0.063

5.8

0.228

PE

LED Bar Display

3.6

0.142

24

0.945

Material: Cold rolled carbon steel (SPCC)

(Uni-chrome plated)

Two M4 (length 6 mm 0.236 in) pan head screws

and two spring washers are attached.

MS-DPX-4

Back angled mounting bracket for standard type (Optional)

Assembly dimensions

3-"4.2 "0.165

mounting

holes

30

1.181

20

0.787

12.5

0.492

11.4

0.449

41.5

1.634

28.5

1.122

31.6

1.244

20

0.787

MODE

50

1.969

28.2

1.110

24.5

0.965

14.5 11.5

0.571 0.453

"4.5 "0.177

mounting hole

1.6

0.063

6 0.236

4.5

0.177

5.5

0.217

20

0.787

Mounting oblong hole

50.3

1.980

34.5

1.358

18.7

0.736

20

"4.5 "0.177

0.787

mounting hole

30

1.181

Mounting oblong hole

24

0.945

Material: Cold rolled carbon steel (SPCC)

(Uni-chrome plated)

Two M4 (length 6 mm 0.236 in) pan head screws

and two spring washers are attached.

820

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

�DIMENSIONS (Unit: mm in)

MS-DPX-2

DPX-04

The CAD data in the dimensions can be downloaded from the SUNX website: http://www.sunx.co.jp/

Panel mounting bracket, front protection cover for standard type (Optional)

Head-separated

DP5/DPH

Assembly dimensions

PRESSURE SENSORS

DP3

Panel cut-out dimensions

56

2.205

36�0.5

0

1.417�0.020

0

40

1.575

30

1.181

43.7

1.720

34

1.339

4.5

0.177

3

0.118

80

3.150

36�0.5

0

1.417�0.020

0

Digital Display

DP3

DP2

9.7

0.382

42.7

1.681

40

30

1.575 1.181

MODE

portion shows the front protection cover.

DP4

42.7

1.681

Note: The panel thickness should be 1 to 3.2 mm 0.039 to 0.126 in.

LED Bar Display

PE

DP-M

Material: Polycarbonate (Front protection cover)

Nylon 6, Stainless steel (SUS304)(Panel mounting bracket)

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

821

�