NJW4170

Current Mode Control High Speed Frequency

Internal 1A MOSFET Switching Regulator IC for Buck Converter

GENERAL DESCRIPTION

■ PACKAGE OUTLINE

The NJW4170 is a high speed oscillating frequency buck

converter with 40V/1A MOSFET. Current mode control and built-in

phase compensation circuit minimize external parts and contribute

to using a Low ESR Output Capacitor(MLCC) within wide input

range from 4.5V to 40V. Therefore, the NJW4170 can realize

downsizing of applications.

Also, it has a soft start function, an external clock synchronization

function, an over current protection and a thermal shutdown circuit.

Over 2MHz of Switching frequency can avoid interference with

the AM radio frequency.

It is suitable for supplying power to a Car Accessory, Audio

Automation Equipment, Industrial Instrument and so on.

FEATURES

Oscillating Frequency

NJW4170U2

NJW4170KV1

2.4MHz typ. (A ver.)

2.1MHz typ. (B ver.)

80ns typ.(A ver.)

85ns typ.(B ver.)

Minimum ON time

Current mode Control

External Clock Synchronization

Wide Operating Voltage Range

4.5V to 40V

Switching Current

1.4A min.

PWM Control

Built-in Compensation Circuit

Correspond to Ceramic Capacitor (MLCC)

Soft Start Function

4ms typ.

UVLO (Under Voltage Lockout)

Over Current Protection (Hiccup type)

Thermal Shutdown Protection

Standby Function

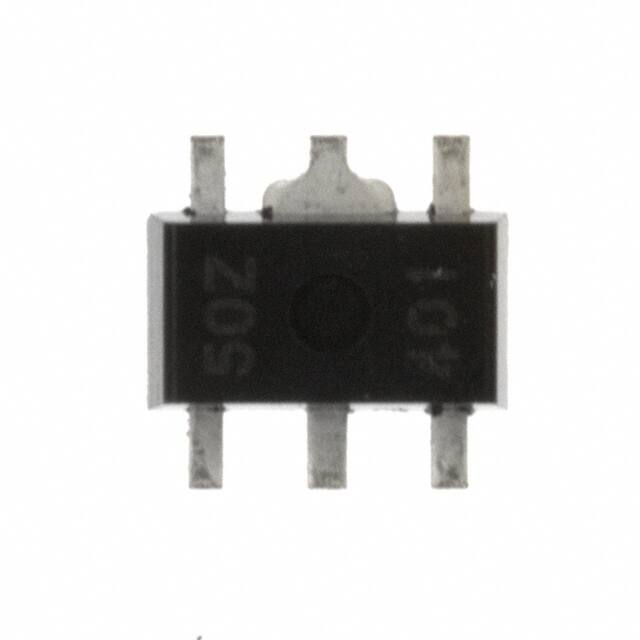

Package Outline

NJW4170U2 : SOT-89-5

NJW4170KV1 : DFN8-V1(ESON8-V1)

PRODUCT CLASSIFICATION

Version

Oscillating

Frequency

Package

NJW4170U2-A

A

2.4MHz typ.

SOT-89-5

NJW4170KV1-A

A

2.4MHz typ.

DFN8-V1

(ESON8-V1)

NJW4170U2-B

B

2.1MHz typ.

SOT-89-5

Part Number

Ver.2020-09-14

Operating

Temperature Range

General Spec.

-40 C to +125 C

General Spec.

-40 C to +125 C

General Spec.

-40 C to +125 C

-1-

�NJW4170

PIN CONFIGURATION

5 V+

EN/SYNC 1

GND 2

(2) GND

IN- 3

SW

N.C.

V+

N.C.

1

2

3

4

8

7

6

5

INN.C.

GND

EN/SYNC

4 SW

8

7

6

5

1

2

3

4

Exposed PAD on backside

connect to GND.

(Top View)

(Bottom View)

NJW4170KV1

NJW4170U2

PIN DESCRIPTIONS

PIN NAME

PIN NUMBER

DFN8-V1

SOT-89-5

(ESON8)

EN/SYNC

1

5

GND

2

6

IN-

3

8

SW

V+

N.C.

Exposed

PAD

4

5

–

1

3

2, 4, 7

–

–

-2-

FUNCTION

Standby Control pin

The EN/SYNC pin internally pulls down with 100k . Normal

Operation at the time of High Level. Standby Mode at the time of

Low Level or OPEN.

Moreover, it operates by inputting clock signal at the oscillatory

frequency that synchronized with the input signal.

GND pin

Output Voltage Detecting pin

Connects output voltage through the resistor divider tap to this pin in

order to voltage of the IN- pin become 0.8V.

Switch Output pin of Power MOSFET

Power Supply pin for Power Line

Non connection

Connect to GND (Only DFN8-V1 PKG)

Ver.2020-09-14

�NJW4170

BLOCK DIAGRAM

V+

SLOPE

COMP.

CURRENT

SENSE

UVLO

OCP

EN/SYNC

High: ON

Low: OFF(Standby)

Enable

(Standby)

SYNC

OSC

S Q

Buffer

R

SW

TSD

PWM

INER·AMP

Soft Start

Vref

0.8V

GND

Ver.2020-09-14

-3-

�NJW4170

ABSOLUTE MAXIMUM RATINGS

PARAMETER

SYMBOL

Supply Voltage

V+

V+- SW pin Voltage

VV-SW

EN/SYNC pin Voltage

VEN/SYNC

IN- pin Voltage

VINPower Dissipation

Junction Temperature Range

Operating Temperature Range

Storage Temperature Range

PD

MAXIMUM RATINGS

-0.3 to +45

+45

-0.3 to +45

-0.3 to +6

625 (*1)

SOT-89-5

2,400 (*2)

mW

DFN8-V1

(ESON8-V1)

Tj

Topr

Tstg

(Ta=25°C)

UNIT

V

V

V

V

600 (*3)

1,800 (*4)

-40 to +150

-40 to +125

-50 to +150

C

C

C

(*1): Mounted on glass epoxy board. (76.2×114.3×1.6mm:based on EIA/JDEC standard size, 2Layers, Cu area 100mm2)

(*2): Mounted on glass epoxy board. (76.2×114.3×1.6mm:based on EIA/JDEC standard, 4Layers)

(For 4Layers: Applying 74.2×74.2mm inner Cu area and a thermal via hall to a board based on JEDEC standard JESD51-5)

(*3): Mounted on glass epoxy board. (101.5 114.5 1.6mm: based on EIA/JEDEC standard, 2Layers FR-4, with Exposed Pad)

(*4): Mounted on glass epoxy board. (101.5 114.5 1.6mm: based on EIA/JEDEC standard, 4Layers FR-4, with Exposed Pad)

(For 4Layers: Applying 99.5 99.5mm inner Cu area and a thermal via hole to a board based on JEDEC standard JESD51-5)

RECOMMENDED OPERATING CONDITIONS

PARAMETER

SYMBOL

Supply Voltage

V+

External Clock Input Range

A version

fSYNC

B version

-4-

MIN.

4.5

TYP.

–

MAX.

40

UNIT

V

2.3

2.0

–

–

2.8

2.5

MHz

Ver.2020-09-14

�NJW4170

(Unless otherwise noted, V+=VEN/SYNC=12V, Ta=25 C)

ELECTRICAL CHARACTERISTICS

PARAMETER

SYMBOL

Under Voltage Lockout Block

ON Threshold Voltage

OFF Threshold Voltage

Hysteresis Voltage

VT_ON

VT_OFF

VHYS

tSS

Soft Start Block

Soft Start Time

TEST CONDITION

MIN.

TYP.

MAX.

UNIT

V+= L → H

V+= H → L

4.2

4.11

70

4.35

4.26

90

4.5

4.41

–

V

V

mV

VB=0.75V

2.5

4

8

ms

A version, VIN-=0.7V

B version, VIN-=0.7V

A version, VIN-=0.2V

B version, VIN-=0.2V

2.2

1.9

–

–

2.4

2.1

340

290

2.6

2.3

–

–

MHz

MHz

kHz

kHz

Oscillator Block

Oscillating Frequency

Oscillating Frequency

(Low Frequency Control)

Oscillating Frequency

deviation (Supply voltage)

Oscillating Frequency

deviation (Temperature)

Error Amplifier Block

Reference Voltage

Input Bias Current

PWM Comparate Block

Maximum Duty Cycle

Minimum ON Time1

(Use Built-in Oscillator)

Minimum ON Time2

(Use Ext CLK)

Ver.2020-09-14

fOSC

fOSC_LOW

fDV

V+=4.5 to 40V

–

1

–

%

fDT

Ta= -40 C to +85 C

–

5

–

%

-1.0%

-0.1

0.8

–

+1.0%

+0.1

V

A

77.5

–

–

–

–

82

80

85

80

85

–

115

120

115

120

%

ns

ns

ns

ns

VB

IB

MAXDUTY

tON-min1

tON-min2

A, B version, VIN-=0.7V

A version

B version

A version, fSYNC =2.6kHz

B version, fSYNC =2.3kHz

-5-

�NJW4170

(Unless otherwise noted, V+=VEN/SYNC=12V, Ta=25 C)

ELECTRICAL CHARACTERISTICS

PARAMETER

SYMBOL

Over Current Protection Block

Cool Down Time

tCOOL

Output Block

Output ON Resistance

Switching Current Limit

SW Leak Current

RON

ILIM

ILEAK

Standby Control / Sync Block

EN/SYNC pin

High Threshold Voltage

EN/SYNC pin

Low Threshold Voltage

Input Bias Current

(EN/SYNC pin)

MIN.

TYP.

MAX.

UNIT

–

75

–

ms

VEN/SYNC=0V, V+=40V, VSW=0V

–

1.4

–

0.4

1.9

–

0.65

2.4

1

A

A

VTHH_EN/SYNC

VEN/SYNC= L → H

1.6

–

V+

V

VTHL_EN/SYNC

VEN/SYNC= H → L

0

–

0.5

V

VEN/SYNC=12V

–

270

390

A

–

2.0

2.4

mA

–

–

1

A

IEN

TEST CONDITION

ISW=1A

General Characteristics

Quiescent Current

Standby Current

-6-

IDD

IDD_STB

A, B version,

RL=no load, VIN-=0.9V

VEN/SYNC=0V

Ver.2020-09-14

�NJW4170

POWER DISSIPATION vs. AMBIENT TEMPERATURE

NJW4170KV1 (DFN8-V1 Package)

Power Dissipation vs. Ambient Temperature

(Tj=~150°C)

NJW4170U2 (SOT89-5 Package)

Power Dissipation vs. Ambient Temperature

(Tj=~150°C)

3000

At on 4 layer PC Board (*6)

At on 2 layer PC Board (*5)

2500

Power Dissipation PD (mW)

Power Dissipation PD (mW)

3000

2000

1500

1000

500

At on 4 layer PC Board (*8)

At on 2 layer PC Board (*7)

2500

2000

1500

1000

500

0

0

-50

-25

0

25

50

75

100

125

-50

150

-25

0

25

50

75

100

125

150

Ambient Temperature Ta (°C)

Ambient Temperature Ta (°C)

(*5): Mounted on glass epoxy board. (76.2×114.3×1.6mm:based on EIA/JDEC standard size, 2Layers, Cu area 100mm2)

(*6): Mounted on glass epoxy board. (76.2×114.3×1.6mm:based on EIA/JDEC standard, 4Layers)

(For 4Layers: Applying 74.2×74.2mm inner Cu area and a thermal via hall to a board based on JEDEC standard JESD51-5)

(*7): Mounted on glass epoxy board. (101.5 114.5 1.6mm: based on EIA/JEDEC standard, 2Layers FR-4, with Exposed Pad)

(*8): Mounted on glass epoxy board. (101.5 114.5 1.6mm: based on EIA/JEDEC standard, 4Layers FR-4, with Exposed Pad)

(For 4Layers: Applying 99.5 99.5mm inner Cu area and a thermal via hole to a board based on JEDEC standard JESD51-5)

TYPICAL APPLICATIONS

L

VIN

VOUT

CIN

V+

CFB

SW

R2

NJW4170

EN/

SYNC

GND

IN-

SBD

COUT

R1

EN/SYNC

High: ON

Low: OFF

(Standby)

Ver.2020-09-14

-7-

�NJW4170

TYPICAL CHARACTERISTICS (A, B version)

Reference Voltage vs. Supply Voltage

(Ta=25ºC)

Reference Voltage :VB (V)

0.81

0.805

0.8

0.795

0.79

Switching Current Limit :ILIM (A)

10

20

30

Supply Voltage :V+ (V)

0.795

40

-50

Switching Current Limit vs. Temperature

2.4

2.2

2

V+=12V

V+=40V

1.8

1.6

V+=5V

1.4

1.2

-25

0

25 50 75 100 125 150

Temperature : (ºC)

Output ON Resistance vs. Temperature

(ISW=1A)

0.8

0.7

0.6

0.5

0.4

V+=5V

V+=40V

V+=12V

0.3

0.2

0.1

0

-50

-25

0

25 50 75 100 125 150

Temperature : (ºC)

-50

-25

0

25 50 75 100 125 150

Temperature : (ºC)

Maximum Duty Cycle vs. Temperature

(V+=12V, VIN-=0.7V)

90

Maximum Duty Cycle :MAXDUTY (%)

0.8

0.79

0

2.6

0.805

Output ON Resistance :RON (Ω)

Reference Voltage :VB (V)

0.81

Reference Voltage vs. Temperature

(V+=12V)

88

86

84

82

80

78

76

-50

-8-

-25

0

25 50 75 100 125 150

Temperature : (ºC)

Ver.2020-09-14

�NJW4170

TYPICAL CHARACTERISTICS (A, B version)

Under Voltage Lockout Voltage vs. Temperature

4.5

8

Soft Start Time :tSS (ms)

Threshold Voltage : (V)

4.45

4.4

4.35

VT_ON

4.3

4.25

4.2

VT_OFF

4.1

6

5

4

2

-50

-25

0

25 50 75 100 125 150

Temperature : (ºC)

-50

Switching Leak Current vs. Temperature

(V+=40V, VEN/SYNC=0V, VSW=0V)

1.5

1

0.5

0

-25

0

25 50 75 100 125 150

Temperature : (ºC)

Standby Current vs. Temperature

(VEN/SYNC=0V)

1

Standby Current :IDD_STB (μA)

2

Switching Leak Current :ILEAK (μA)

7

3

4.15

0.8

0.6

0.4

V+=40V

V+=12V

V+=4.5V

0.2

0

-50

-25

0

25 50 75 100 125 150

Temperature : (ºC)

-50

Quiescent Current vs. Supply Voltage

(RL=no Load, VIN-=0.9V, Ta=25ºC)

3

2.5

2

1.5

1

0.5

0

-25

0

25 50 75 100 125 150

Temperature : (ºC)

Quiescent Current vs. Temperature

(RL=no Load, VIN-=0.9V)

3

Quiescent Current :IDD (mA)

Quiescent Current :IDD (mA)

Soft Start Time vs. Temperature

(V+=12V, VB=0.75V)

2.5

2

V+=4.5V, 12V, 40V

1.5

1

0.5

0

0

Ver.2020-09-14

10

20

30

Supply Voltage :V+ (V)

40

-50

-25

0

25 50 75 100 125 150

Temperature : (ºC)

-9-

�NJW4170

TYPICAL CHARACTERISTICS (A version)

Oscillating Frequency vs. Supply Voltage

(A ver., VIN-=0.7V, Ta=25ºC)

2.8

Oscillating Frequency :fOSC (MHz)

Oscillating Frequency :fOSC (MHz)

2.8

2.7

2.6

2.5

2.4

2.3

2.2

2.1

2

2.7

2.6

2.5

2.4

2.3

2.2

2.1

2

0

10

20

30

Supply Voltage : V+ (V)

40

-50

-25

0

25 50 75 100 125 150

Temperature : (ºC)

Minimum ON Time1 vs. Temperature

(A ver., V+=12V)

120

Minimum ON Time1 :tON-min1 (ns)

Oscillating Frequency vs Temperature

(A ver., V+=12V, VIN-=0.7V)

110

100

90

80

70

60

50

40

-50

- 10 -

-25

0

25 50 75 100 125 150

Temperature : (ºC)

Ver.2020-09-14

�NJW4170

TYPICAL CHARACTERISTICS (B version)

Oscillating Frequency vs. Supply Voltage

(B ver., VIN-=0.7V, Ta=25ºC)

2.4

Oscillating Frequency :fOSC (MHz)

Oscillating Frequency :fOSC (MHz)

2.4

2.3

2.2

2.1

2

1.9

1.8

2.3

2.2

2.1

2

1.9

1.8

0

10

20

30

Supply Voltage :V+ (V)

40

-50

-25

0

25 50 75 100 125 150

Temperature : (ºC)

Minimum ON Time1 vs. Temperature

(B ver., V+=12V)

120

Minimum ON Time1 :tON-min1 (ns)

Oscillating Frequency vs Temperature

(B ver., V+=12V, VIN-=0.7V)

110

100

90

80

70

60

50

40

-50

Ver.2020-09-14

-25

0

25 50 75 100 125 150

Temperature : (ºC)

- 11 -

�NJW4170

NJW4170Application Manual

Technical Information

Description of Block Features

1. Basic Functions / Features

Error Amplifier Section (ER AMP)

0.8V±1% precise reference voltage is connected to the non-inverted input of this section.

To set the output voltage, connects converter's output to inverted input of this section (IN- pin). If requires output

voltage over 0.8V, inserts resistor divider.

Because the optimized compensation circuit is built-in, the application circuit can be composed of minimum

external parts.

PWM Comparator Section (PWM), Oscillating Circuit Section (OSC)

The NJW4170 uses a constant frequency, current mode step down architecture. The oscillating frequency are

2.4MHz (typ.) at A version and 2.1MHz (typ.) at B version. The PWM signal is output by feedback of output voltage

and slope compensation switching current at the PWM comparator block.

The maximum duty ratio is 82% (typ.).

The minimum ON time are limited to 80ns (typ.) at A version and 85ns (typ.) at B version.

The buck converter of ON time is decided the following formula.

ton

VOUT

s

VIN fOSC

VIN shows input voltage and VOUT shows output voltage.

When the ON time becomes below in tON-min, in order to maintain output voltage at a stable state, change of duty or

pulse skip operation may be performed.

Power MOSFET (SW Output Section)

The power is stored in the inductor by the switch operation of built-in power MOSFET. The output current is limited

to 1.4A(min.) the overcurrent protection function. In case of step-down converter, the forward direction bias voltage is

generated with inductance current that flows into the external regenerative diode when MOSFET is turned off.

The SW pin allows voltage between the V+ pin and the SW pin up to +45V. However, you should use an Schottky

diode that has low saturation voltage.

Power Supply, GND pin (V+ and GND)

In line with switching element drive, current flows into the IC according to frequency. If the power supply

impedance provided to the power supply circuit is high, it will not be possible to take advantage of IC performance

due to input voltage fluctuation. Therefore insert a bypass capacitor close to the V+ pin – the GND pin connection in

order to lower high frequency impedance.

- 12 -

Ver.2020-09-14

�NJW4170 Application

Manual

NJW4170

Technical Information

Description of Block Features (Continued)

2. Additional and Protection Functions / Features

Under Voltage Lockout (UVLO)

The UVLO circuit operating is released above V+=4.35V(typ.) and IC operation starts. When power supply voltage

is low, IC does not operate because the UVLO circuit operates. There is 90mV(typ.) width hysteresis voltage at rise

and decay of power supply voltage. Hysteresis prevents the malfunction at the time of UVLO operating and

releasing.

Soft Start Function (Soft Start)

The output voltage of the converter gradually rises to a set value by the soft start function. The soft start time is

4ms (typ.). It is defined with the time of the error amplifier reference voltage becoming from 0V to 0.75V. The soft

start circuit operates after the release UVLO and/or recovery from thermal shutdown. The operating frequency is

controlled with a low frequency 340kHz (typ.) at A version and 290kHz (typ.) at B version, until voltage or the IN- pin

becomes approximately 0.4V.

0.8V

Vref,

IN- pin Voltage

OSC Waveform

ON

SW pin

OFF

UVLO(4.35V typ.) Release,

Standby,

Recover from Thermal

Shutdown

Low Frequency Control

VIN-=approx 0.4V

Soft Start time: Tss=4ms(typ.) to VB=0.75V

Steady

Operaton

Soft Start effective period to VB=0.8V

Fig. 1. Startup Timing Chart

Ver.2020-09-14

- 13 -

�NJW4170

NJW4170Application Manual

Technical Information

Description of Block Features (Continued)

Over Current Protection Circuit (OCP)

NJW4170 contains overcurrent protection circuit of hiccup architecture. The overcurrent protection circuit of hiccup

architecture is able to decrease heat generation at the overload.

The NJW4170 output returns automatically along with release from the over current condition.

At when the switching current becomes ILIM or more, the overcurrent protection circuit is stopped the MOSFET

output. The switching output holds low level down to next pulse output at OCP operating.

When IN- pin voltage becomes 0.3V or less, it operates with 340kHz (typ.) at A version and 290kHz (typ.) at B

version.

At the same time starts pulse counting, and stops the switching operation when the overcurrent detection

continues 128 pulses.

After NJW4170 switching operation was stopped, it restarts by soft start function after the cool down time of approx

75ms (typ.).

IN- pin

Voltage

0.8V

0.3V

0V

Oscillating Frequency

A ver.=2.4MHz typ.

B ver.=2.1MHz typ.

OCP Operates

Oscillating Frequency

A ver.=340kHz typ.

B ver.=290kHz typ.

ON

SW pin

OFF

Switching

Current

ILIM

0

Pulse by

Pulse

Static Status

Pulse Count :128 pulse

Cool Down time :75ms typ.

Detect

Overcurrent

Soft Start

Fig. 2. Timing Chart at Over Current Detection

Thermal Shutdown Function (TSD)

When Junction temperature of the NJW4170 exceeds the 165°C*, internal thermal shutdown circuit function stops

SW function. When junction temperature decreases to 150°C* or less, SW operation returns with soft start operation.

The purpose of this function is to prevent malfunctioning of IC at the high junction temperature. Therefore it is not

something that urges positive use. You should make sure to operate within the junction temperature range rated

(150 C). (* Design value)

Standby Function

The NJW4170 stops the operating and becomes standby status when the EN/SYNC pin becomes less than 0.5V.

The EN/SYNC pin internally pulls down with 100k , therefore the NJW4170 becomes standby mode when the

EN/SYNC pin is OPEN. You should connect this pin to V+ when you do not use standby function.

- 14 -

Ver.2020-09-14

�NJW4170 Application

Manual

NJW4170

Technical Information

Description of Block Features (Continued)

External Clock Synchronization

By inputting a square wave to EN/SYNC pin, can be synchronized to an external frequency.

You should fulfill the following specification about a square wave. (Table 1.)

Table 1. The input square wave to an EN/SYNC pin.

A version

B version

(fOSC =2.4MHz)

(fOSC =2.1MHz)

Input Frequency

2.3MHz to 2.8MHz

2.0MHz to 2.5MHz

Duty Cycle

40% to 60%

Voltage

1.6V or more at High level

magnitude

0.5V or less at Low level

The trigger of the switching operating at the external synchronized mode is detected to the rising edge of the input

signal. At the time of switching operation from standby or asynchronous to synchronous operation, it has set a delay

time approx 5 s to 10 s in order to prevent malfunctions. (Fig. 3.)

High

EN/SYNC pin

Low

ON

SW pin

OFF

Standby

Delay Time

External Clock Synchronization

Fig. 3. Switching Operation by External Synchronized Clock

Ver.2020-09-14

- 15 -

�NJW4170

NJW4170Application Manual

Technical Information

Application Information

Inductors

Because a large current flows to the inductor, you should select the inductor with the large current capacity not to

saturate. Optimized inductor value is determined by the input voltage and output voltage.

Reducing L decreases the size of the inductor. However a peak current increases and adversely affects the

efficiency. (Fig. 4.)

Moreover, you should be aware that the output current is limited because it becomes easy to operating to the

overcurrent limit.

The peak current is decided the following formula.

IL

Ipk

VIN VOUT VOUT

[A]

L VIN fOSC

IL

[A]

2

IOUT

Current

Peak Current IPK

Indunctor

Ripple Current IL

Peak Current IPK

Output Current

IOUT

Indunctor

Ripple Current IL

0

tON

tOFF

Reducing L Value

tON

tOFF

Increasing L value

Fig. 4. Inductor Current State Transition (Continuous Conduction Mode)

- 16 -

Ver.2020-09-14

�NJW4170 Application

Manual

NJW4170

Technical Information

Application Information (Continued)

Input Capacitor

Transient current flows into the input section of a switching regulator responsive to frequency. If the power supply

impedance provided to the power supply circuit is large, it will not be possible to take advantage of the NJW4170

performance due to input voltage fluctuation. Therefore insert an input capacitor as close to the MOSFET as

possible. A ceramic capacitor is the optimal for input capacitor.

The effective input current can be expressed by the following formula.

IRMS

VOUT

IOUT

VIN

VIN

VOUT

[A]

In the above formula, the maximum current is obtained when VIN = 2 VOUT, and the result in this case is

IRMS = IOUT (MAX) 2.

When selecting the input capacitor, carry out an evaluation based on the application, and use a capacitor that has

adequate margin.

Output Capacitor

An output capacitor stores power from the inductor, and stabilizes voltage provided to the output.

Because NJW4170 corresponds to the output capacitor of low ESR, the ceramic capacitor is the optimal for

compensation.

In addition, you should consider varied characteristics of capacitor (a frequency characteristic, a temperature

characteristic, a DC bias characteristic and so on) and unevenness peculiar to a capacitor supplier enough.

Therefore when selecting a capacitors, you should confirm the characteristics with supplier datasheets.

When selecting an output capacitor, you must consider Equivalent Series Resistance (ESR) characteristics, ripple

current, and breakdown voltage.

The output ripple noise can be expressed by the following formula.

Vripple( p

p)

IL

ESR

1

8 fOSC C OUT

[V]

The effective ripple current that flows in a capacitor (Irms) is obtained by the following equation.

Irms

Ver.2020-09-14

IL

2 3

[ Arms]

- 17 -

�NJW4170

NJW4170Application Manual

Technical Information

Application Information (Continued)

Catch Diode

When the switch element is in OFF cycle, power stored in the inductor flows via the catch diode to the output

capacitor. Therefore during each cycle current flows to the diode in response to load current. Because diode's

forward saturation voltage and current accumulation cause power loss, a Schottky Barrier Diode (SBD), which has a

low forward saturation voltage, is ideal.

An SBD also has a short reverse recovery time. If the reverse recovery time is long, through current flows when

the switching transistor transitions from OFF cycle to ON cycle. This current may lower efficiency and affect such

factors as noise generation.

Setting Output Voltage, Compensation Capacitor

The output voltage VOUT is determined by the relative resistances of R1, R2. The current that flows in R1, R2 must

be a value that can ignore the bias current that flows in ER AMP.

R2

R1

VOUT

1

VB [ V ]

The zero points are formed with R2 and CFB, and it makes for the phase compensation of NJW4170.

The zero point is shown the following formula.

f Z1

2

1

[Hz]

R 2 C FB

You should set the zero point as a guide from 60kHz to 80kHz.

- 18 -

Ver.2020-09-14

�NJW4170 Application

Manual

NJW4170

Technical Information

Application Information (Continued)

Board Layout

In the switching regulator application, because the current flow corresponds to the oscillating frequency, the

substrate (PCB) layout becomes an important.

You should attempt the transition voltage decrease by making a current loop area minimize as much as possible.

Therefore, you should make a current flowing line thick and short as much as possible. Fig.5. shows a current loop

at step-down converter. Especially, should lay out high priority the loop of CIN-SW-SBD that occurs rapid current

change in the switching. It is effective in reducing noise spikes caused by parasitic inductance.

NJW4170

Built-in SW

VIN

CIN

NJW4170

Built-in SW

L

SBD

COUT

VIN

CIN

(a) Buck Converter SW ON

L

SBD

COUT

(b) Buck Converter SW OFF

Fig. 5. Current Loop at Buck Converter

Concerning the GND line, it is preferred to separate the power system and the signal system, and use single

ground point.

The voltage sensing feedback line should be as far away as possible from the inductance. Because this line has

high impedance, it is laid out to avoid the influence noise caused by flux leaked from the inductance.

Fig. 6. shows example of wiring at buck converter. Fig. 7 shows the PCB layout example.

L

V+

VIN

VOUT

SW

CIN

SBD

COUT

RL

The capacitor is

connected near an IC.

NJW4170

CFB

INR2

GND

Separate Digital(Signal)

GND from Power GND

R1

To avoid the influence of the voltage

drop, the output voltage should be

detected near the load.

Because IN- pin is high impedance, the

voltage detection resistance: R1/R2 is

put as much as possible near IC(IN-).

Fig. 6. Board Layout at Buck Converter

Ver.2020-09-14

- 19 -

�NJW4170

NJW4170Application Manual

Technical Information

Application Information (Continued)

GNDOUT

VOUT

Power GND Area

COUT

GND IN

L

SBD

CIN1

VIN

CIN2

Feed back

signal

1pin

R2

EN/SYNC

R1

RFB CFB

Signal GND Area

Connect Signal GND line and Power GND line on backside pattern

Fig. 7. Layout Example (upper view)

- 20 -

Ver.2020-09-14

�NJW4170 Application

Manual

NJW4170

Technical Information

Calculation of Package Power

A lot of the power consumption of buck converter occurs from the internal switching element (Power MOSFET).

Power consumption of NJW4170 is roughly estimated as follows.

Input Power:

Output Power:

Diode Loss:

NJW4170 Power Consumption:

Where:

VIN

VOUT

VF

OFF duty

PIN = VIN IIN [W]

POUT = VOUT IOUT [W]

PDIODE = VF IL(avg) OFF duty [W]

PLOSS = PIN POUT PDIODE [W]

: Input Voltage for Converter

: Output Voltage of Converter

: Diode's Forward Saturation Voltage

: Switch OFF Duty

IIN

IOUT

IL(avg)

: Input Current for Converter

: Output Current of Converter

: Inductor Average Current

Efficiency ( ) is calculated as follows.

= (POUT PIN) 100 [%]

You should consider temperature derating to the calculated power consumption: PD.

You should design power consumption in rated range referring to the power dissipation vs. ambient temperature

characteristics.

Ver.2020-09-14

- 21 -

�NJW4170

NJW4170Application Manual

Technical Information

Application Design Examples

Buck Converter Application Circuit

IC

: NJW4170U2

Input Voltage

: VIN=12V

Output Voltage

: VOUT=5V

Output Current

: IOUT=1A

Oscillating frequency : A version fOSC=2.4MHz

: B version fOSC=2.1MHz

L 3.3 H/2.33A

VIN=12V

CIN

10mF/50V

V+

VOUT=5V

CFB

120pF

SW

R2

16kW

NJW4170

EN/

SYNC

GND

IN-

SBD

COUT

22mF/6.3V

R1

3kW

EN/SYNC

High: ON

Low: OFF

(Standby)

Reference

IC

L

SBD

CIN

COUT

CFB

R1

R2

- 22 -

Qty.

1

1

1

1

1

1

1

1

Part Number

NJW4170U2

VLF504015MT-3R3M

CMS16

UMK325BJ106MM

GRM31CB30J226ME18

120pF

3k

16k

Description

Internal 1A MOSFET SW.REG. IC

Inductor 3.3 H, 2.33A

Schottky Diode 40V, 3A

Ceramic Capacitor 3225 10 F, 50V, X5R

Ceramic Capacitor 3216 22 F, 6.3V, B

Ceramic Capacitor 1608 120pF, 50V, CH

Resistor 1608 3k , 1%, 0.1W

Resistor 1608 16k , 1%, 0.1W

Manufacturer

New JRC

TDK

Toshiba

Taiyo Yuden

Murata

Std.

Std.

Std.

Ver.2020-09-14

�NJW4170 Application

Manual

NJW4170

Technical Information

Application Characteristics

A version

Efficiency vs. Output Current

(VOUT=5V, Ta=25ºC)

f=2.4MHz

L=3.3 H

90

6

80

(%)

70

VIN=18V

Efficiency :

60

VIN=12V

50

f=2.4MHz

L=3.3 H

5.8

VIN=8V

40

30

20

Output Voltage :VOUT (V)

100

Output Voltage vs. Output Current

(Ta=25ºC)

5.6

5.4

5.2

VIN=8V, 12V, 18V

5

4.8

4.6

4.4

4.2

10

4

0

1

10

100

Output Current :IOUT (mA)

1

1000

10

100

Output Current :IOUT (mA)

1000

B version

Efficiency vs. Output Current

(VOUT=5V, Ta=25ºC)

f=2.1MHz

L=3.3 H

90

Efficiency :

(%)

80

70

6

VIN=18V

60

VIN=12V

50

f=2.4MHz

L=3.3 H

5.8

VIN=8V

Output Voltage :VOUT (V)

100

Output Voltage vs. Output Current

(Ta=25ºC)

40

30

20

10

5.6

5.4

5.2

VIN=8V, 12V, 18V

5

4.8

4.6

4.4

4.2

0

4

1

Ver.2020-09-14

10

100

Output Current :IOUT (mA)

1000

1

10

100

Output Current :IOUT (mA)

1000

- 23 -

�NJW4170

MEMO

[CAUTION]

The specifications on this databook are only

given for information , without any guarantee

as regards either mistakes or omissions. The

application circuits in this databook are

described only to show representative usages

of the product and not intended for the

guarantee or permission of any right including

the industrial rights.

- 24 -

Ver.2020-09-14

�