High Efficiency Buck Dual

LED Driver with Integrated

Current Sensing for

Automotive Front Lighting

NCV78723

The NCV78723 is a single-chip and high efficient Buck Dual LED

Driver designed for automotive front lighting applications like high

beam, low beam, DRL (daytime running light), turn indicator, fog

light, static cornering, etc. The NCV78723 is in particular designed for

high current LEDs and provides a complete solution to drive 2 LED

strings of up-to 60 V. It includes 2 independent current regulators for

the LED strings and required diagnostic features for automotive front

lighting with a minimum of external components – the chip doesn’t

need any external sense resistor for the buck current regulation.

The available output current and voltages can be customized per

individual LED string. When more than 2 LED channels are required

on 1 module, then 2, 3 or more devices NCV78723 can be combined;

also with NCV78713 device – the derivative of the NCV78723

incorporating Buck Single LED Driver. Thanks to the SPI

programmability, one single hardware configuration can support

various application platforms.

www.onsemi.com

1

24

1

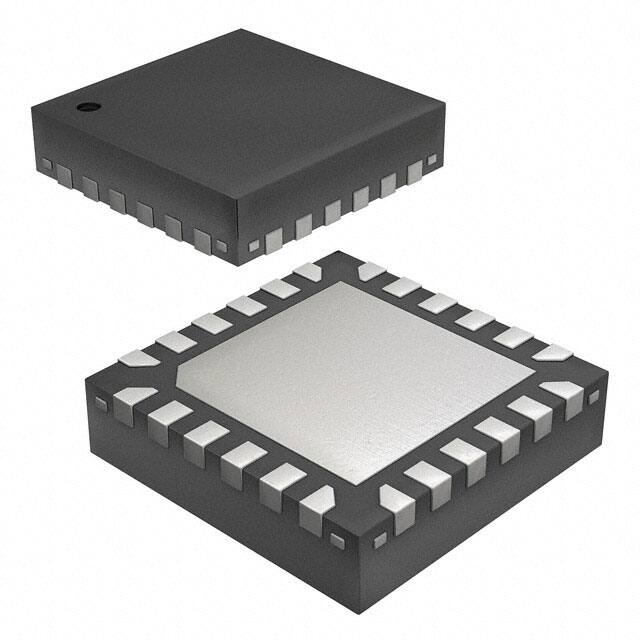

QFN24

CASE 485CS

24

QFNW24

CASE 484AF

MARKING DIAGRAM

1

ON

N78723−0

AWLYYWWG

G

Features

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Single Chip

Buck Topology

2 LED Strings up-to 60 V

High Current Capability up to 1.6 A DC per Output

High Overall Efficiency

Minimum of External Components

Integrated High Accuracy Current Sensing

Integrated Switched Mode Buck Current Regulator

Average Current Regulation through the LEDs

High Operating Frequencies to Reduce Inductor Sizes

Low EMC Emission for LED Switching and Dimming

SPI Interface for Dynamic Control of System Parameters

Fail Safe Operating (FSO) Mode, Stand-Alone Mode

These Devices are Pb−Free, Halogen Free/BFR Free and are RoHS

Compliant

1

ON

N78723−2

FAWLYYWWG

G

N78723−0

N78723−2

F

A

WL

YY

WW

G

= Specific Device Code

= Specific Device Code

= Fab Indicator

= Assembly Location

= Wafer Lot

= Year

= Work Week

= Pb−Free Package

(Note: Microdot may be in either location)

ORDERING INFORMATION

See detailed ordering and shipping information on page 31 of

this data sheet.

Typical Applications

•

•

•

•

•

•

•

High Beam

Low Beam

DRL

Position or Park Light

Turn Indicator

Fog

Static Cornering

© Semiconductor Components Industries, LLC, 2015

January, 2020 − Rev. 4

1

Publication Order Number:

NCV78723/D

�NCV78723

TYPICAL APPLICATION SCHEMATIC

VBOOST

C_M3V

VBOOSTM3V VBOOST

LED-String 1

VINBCK1

LBCKSW1

L_BCK_1

D_1

LBCKSW1

External

VCC of MCU

R_LED_1

VLED1

ON Semiconductor

LED Driver

2-Channel Buck

NCV78723

VDD

VINBCK2

VDD Supply

C_DD

C_LED_1

LED-String 2

LBCKSW2

R_SDO

LBCKSW2

RSTB

C_BCK_2

L_BCK_2

D_2

R_LED_2

VLED2

LEDCTRL1

mC

C_BCK_1

C_LED_2

LEDCTRL2

SCLK

SDI

SDO

EXPOSED

PAD

GND

TEST2

TEST1

TEST

CSB

Figure 1. Typical Application Schematic

Table 1. EXTERNAL COMPONENTS

Component

Function

Typical Value

Unit

L_BCK_x

Buck Regulator Coil (see Buck Regulator Chapter for Details)

47

mH

C_BCK_x

Buck Regulator Output Capacitor (see Buck Regulator Chapter for Details)

220

nF

(see Table 6 − VBOOSTM3V)

nF

470

nF

1

nF

Min. 1

kW

1

kW

C_M3V

C_DD

Capacitor for M3V Regulator

VDD Decoupling Capacitor

C_LED_x

Optional VLEDx Pin Filter Capacitor (Note 2)

R_LED_x

VLEDx Pin Serial Resistor (Notes 2 and 3)

R_SDO

D_x

SPI Pull-Up Resistor

Buck Regulator Free-Wheeling Diode

e.g. MBRS2H100T3G

1. Pin TEST has to be connected to ground. TEST1 and TEST2 pins can be connected to ground or left floating.

2. C_LED_x is optional. If used, time constant of the C_LED_x and R_LED_x filter has to be lower than minimal LEDCTRLx ON time in PWM

dimming for proper VLED measurement.

3. R_LED_x is necessary to ensure Absolute Maximum Ratings of IVLEDx current (see Table 3).

www.onsemi.com

2

�NCV78723

BLOCK DIAGRAM

Buck

VBOOST

VDD

OTP

Bandgap

Vref

VBOOSTM3V

Current

Sense CMP

POR

CTRL

Digital control

Bias

OSC

LEDCTRL1

LEDCTRL2

VBOOSTM3V

Regulator

VINBCK1

Predriver

LBCKSW1

Current

Sense CMP

5 V Input

VINBCK2

RSTB

CTRL

SDI

SCLK

CSB

Predriver

5 V Input/

OD Output

LBCKSW2

SDO

TEST

TEST1

VLED2

LV IOs

Temp

VLED1

TEST2

ADC

MUX

Dividers

EXPOSED PAD

GND

Figure 2. Block Diagram

www.onsemi.com

3

VBOOST,

VDD,

VLEDx

�NCV78723

NC

VINBCK1

NC

LEDCTRL1

21

20

19

LBCKSW1

23

22

VLED1

SELF PROT PDMOS

12

6

LEDCTRL2

GND

11

5

NC

TEST2

10

4

VINBCK2

VBOOST

9

3

NC

VBOOSTM3V

8

2

LBCKSW2

TEST1

SELF PROT PDMOS

7

1

VLED2

TEST

24

ESD SCHEMATIC

Figure 3. ESD Schematic

www.onsemi.com

4

18

VDD

17

SDI

16

SCLK

15

CSB

14

SDO

13

RSTB

�NCV78723

PACKAGE AND PIN DESCRIPTION

24

23

22

21

20

19

VLED1

LBCKSW1

GND/NC

VINBCK1

GND/NC

LEDCTRL1

VDD

18

SDI

17

SCLK

16

VBOOST

CSB

15

5

TEST2

SDO

14

6

GND

RSTB

13

1

TEST

2

TEST1

3

VBOOSTM3V

4

VLED2

LBCKSW2

GND/NC

VINBCK2

GND/NC

LEDCTRL2

NCV78723

7

8

9

10

11

12

Figure 4. Pin Connections

Table 2. PIN DESCRIPTION

Pin No.

Pin Name

Description

I/O Type

1

TEST

Test Pin

LV In

2

TEST1

Test Pin

LV IN/OUT HV Tolerant

3

VBOOSTM3V

VBOOSTM3V Regulator Output Pin

HV OUT (Supply)

4

VBOOST

Booster Input Voltage Pin

HV Supply

5

TEST2

Test Pin

LV IN/OUT HV Tolerant

6

GND

Ground

Ground

7

VLED2

LED String 2 Forward Voltage Sense Input

HV IN

8

LBCKSW2

Buck 2 Switch Output

HV OUT

9, 11, 20, 22

GND/NC

GND/NC Connection in Application

NC

10

VINBCK2

Buck 2 High Voltage Supply

HV Supply

12

LEDCTRL2

LED String 2 Enable

MV IN

13

RSTB

External Reset Signal

MV IN

14

SDO

SPI Data Output

MV Open-Drain

15

CSB

SPI Chip Select (Chip Select Bar)

MV IN

16

SCLK

SPI Clock

MV IN

17

SDI

SPI Data Input

MV IN

18

VDD

3 V Logic Supply

LV Supply

19

LEDCTRL1

LED String 1 Enable

MV IN

21

VINBCK1

Buck 1 High Voltage Supply

HV Supply

23

LBCKSW1

Buck 1 Switch Output

HV OUT

24

VLED1

LED String 1 Forward Voltage Sense Input

HV IN

www.onsemi.com

5

�NCV78723

Table 3. ABSOLUTE MAXIMUM RATINGS

Characteristic

VBOOST Supply Voltage

VINBCKx Supply Voltage (Note 4)

VBOOSTM3V Supply Voltage (Note 5)

VLED Sense Voltage

Logic Supply Voltage (Note 6)

Medium Voltage IO Pins (Note 7)

Test Pins (Note 8)

Symbol

Minimum

Maximum

Unit

VBOOST

−0.3

+68

V

VINBCKx

Max of VBOOSTM3V − 0.3, −0.3

Min of VBOOST + 0.3, 68

V

VBOOSTM3V

Max of VBOOST − 3.6, −0.3

Min of VBOOST + 0.3, 68

V

VLEDx

−0.3

Min of VBOOST + 0.3, 68

V

VDD

−0.3

3.6

V

IOMV

−0.3

7.0

V

TESTx

−0.3

Min of VBOOST + 0.3, 68

V

LBCKSWx

−2.0

VINBCKx + 0.3

V

VLED Sink/Source Current

IVLEDx

−30

30

mA

Storage Temperature (Note 9)

TSTRG

−50

150

°C

The Exposed Pad (Note 10)

EXPAD

GND − 0.3

GND + 0.3

V

VESD_HBM

VESD_CDM

−2

−500

+2

+500

kV

V

Buck Switch Low Side (Note 4)

Electrostatic Discharge on Component

Level (Note 11)

Human Body Model

Charge Device Model

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

4. V(VINBCKx − LBCKSWx) < 70 V, the driver in off state.

5. The VBOOSTM3V regulator in off state.

6. Absolute maximum rating for pins: VDD, TEST. Also valid for relative difference VBOOST − VBOOSTM3V.

7. Absolute maximum rating for pins: SCLK, CSB, SDI, SDO, LEDCTRL1, LEDCTRL2, RSTB. The mC interface pins (the IOMV pins) accept

5 V while the device is in the power-off mode (VDD = 0 V).

8. Absolute maximum rating for pins: TEST1, TEST2.

9. For limited time up to 100 hours. Otherwise the max storage temperature is 85°C.

10. The exposed pad must be hard wired to GND pin in an application to ensure both electrical and thermal connection.

11. This device series incorporates ESD protection and is tested by the following methods:

ESD Human Body Model tested per AEC*Q100*002 (EIA/JESD22*A114)

ESD Charge Device Model tested per EIA/JESD22*C101

Latch-up Current Maximum Rating: ≤100 mA per JEDEC standard: JESD78

Operating ranges define the limits for functional

operation and parametric characteristics of the device.

A mission profile (Note 12) is a substantial part of the

operation conditions; hence the Customer must contact

ON Semiconductor in order to mutually agree in writing on

the allowed missions profile(s) in the application.

Table 4. RECOMMENDED OPERATING RANGES

Characteristic

Boost Supply Voltage

N78723−0 Device

N78723−2 Device

VINBCKx Supply Voltage (Note 13)

Low Voltage Supply

Buck Switch Output Current

Symbol

Min

VBOOST

Typ

+8

+6

Max

+67

+67

Unit

V

VINBCKx

VBOOST − 0.1

VBOOST

VBOOST + 0.1

V

VDD

3.05

3.3

3.6

V

1.9

A

I_LBCKSW

Functional Operating Junction Temperature

Range (Note 14)

TJF

−40

155

°C

Parametric Operating Junction Temperature

Range (Note 15)

TJP

−40

150

°C

EXPOSED_PAD

GND − 0.1

GND + 0.1

V

The Exposed Pad Connection (Note 16)

GND

Functional operation above the stresses listed in the Recommended Operating Ranges is not implied. Extended exposure to stresses beyond

the Recommended Operating Ranges limits may affect device reliability.

12. A mission profile describes the application specific conditions such as, but not limited to, the cumulative operating conditions over life time,

the system power dissipation, the system’s environmental conditions, the thermal design of the customer’s system, the modes, in which the

device is operated by the customer, etc. No more than 100 cumulated hours in life time above TTW.

13. Hard connection of VINBCKx to VBOOST on PCB.

14. The circuit functionality is not guaranteed outside the functional operating junction temperature range. Also please note that the device is

verified on bench for operation up to 170°C but that the production test guarantees 155°C only.

15. The parametric characteristics of the circuit are not guaranteed outside the Parametric operating junction temperature range.

16. The exposed pad must be hard wired to GND pin in an application to ensure both electrical and thermal connection.

www.onsemi.com

6

�NCV78723

Table 5. THERMAL RESISTANCE

Characteristic

Thermal Resistance Junction to Exposed Pad (Note 17)

Package

Symbol

Min

Typ

Max

Unit

QFN24 5x5

Rthjp

−

5

−

°C/W

17. Includes also typical solder thickness under the Exposed Pad (EP).

Table 6. ELECTRICAL CHARACTERISTICS

(All Min and Max parameters are guaranteed over full junction temperature (TJP) range (−40°C; 150°C), unless otherwise specified)

Min

Typ

Max

Unit

I_VDD

−

−

6

mA

POR Toggle Level on VDD

Rising

POR3V_H

2.7

−

3.05

V

POR Toggle Level on VDD

Falling

POR3V_L

2.45

−

2.8

V

POR3V_HYST

0.01

0.2

0.75

V

OTP_UV

13

−

15

V

OTP_UV_HYST

0.01

0.2

0.75

V

−3.6

−3.3

−3.0

V

Characteristic

Symbol

Condition

VDD: 3 V LOW VOLTAGE ANALOG AND DIGITAL SUPPLY

The VDD Current

Consumption

POR Hysteresis

OTP UV Toggle Level on

VBOOST

OTP UV Toggle Level

Hysteresis

VBOOSTM3V: HIGH SIDE AUXILIARY SUPPLY

VBSTM3 Regulator Output

Voltage

DC Output Current

Consumption

N78723−0 Device

VBSTM3

Referenced to VBOOST

M3V_IOUT

mA

N78723−2 Device

−

5

−

5

28

(Note 18)

22.5

(Note 19)

Output Current Limitation

M3V_ILIM

−

−

200

mA

VBSTM3 External Decoupling

Cap.

CVBSTM3V

Referenced to VBOOST

0.3

−

2.2

mF

VBSTM3 Ext. Decoupling

Cap. ESR

CVBSTM3V_ESR

Referenced to VBOOST

−

−

200

mW

VBOOST POR Level on

N78723−2 Device (Note 20)

M3V_VBSTPOR

3.5

−

5.5

V

8

10

12

MHz

−

8

−

OSC10M: SYSTEM OSCILLATOR CLOCK

System Oscillator Frequency

FOSC10M

ADC FOR MEASURING VBOOST, VDD, VLED1, VLED2, TEMP

ADC Resolution

Nonlinearity

Integral (INL)

Differential (DNL)

ADC_RES

ADC_INL

ADC_DNL

Full Path Gain Error for

Measurements of VDD, VLEDx,

VBOOST

ADC_GAINER

Offset at Output of ADC

ADC_OFFSET

Time for 1 SAR Conversion

ADC_CONV

ADC Full Scale for VDD

Measurement

ADCFS_VDD

Best Fitting Straight Line

Method

Full Conversion of 8 Bits

Bits

LSB

−1.5

−2.0

−

−

+1.5

+2.0

−3.25

−

3.25

%

−2

−

2

LSB

6.67

8

10

ms

3.87

4

4.13

V

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

18. VBOOST = 68 V, VLED1,2 = 34 V, fBUCK = 2 MHz, maximum total gate charge for both activated BUCK channels QGATE = 14 nC.

19. VBOOST = 68 V, VLED1,2 = 34 V, fBUCK = 1.61 MHz, maximum total gate charge for both activated BUCK channels QGATE = 14 nC.

20. On N78723−2 device, the Buck switch is switched off when VBOOST drops below M3V_VBSTPOR level. When VBOOST returns back

above M3V_VBSTPOR level, normal operation is restored.

www.onsemi.com

7

�NCV78723

Table 6. ELECTRICAL CHARACTERISTICS (continued)

(All Min and Max parameters are guaranteed over full junction temperature (TJP) range (−40°C; 150°C), unless otherwise specified)

Characteristic

Symbol

Condition

Min

Typ

Max

Unit

The VLED Range Code is “00”

The VLED Range Code is “01”

The VLED Range Code is “10”

The VLED Range Code is “11”

67.725

48.375

38.700

29.025

70

50

40

30

72.275

51.625

41.300

30.975

V

67.725

70

72.275

V

ADC FOR MEASURING VBOOST, VDD, VLED1, VLED2, TEMP

ADC Full Scale for VLEDx

Measurement

ADCFS_VLED00

ADCFS_VLED01

ADCFS_VLED10

ADCFS_VLED11

ADC Full Scale for VBOOST

Measurement

ADCFS_VBST

ADC Full Scale for Temp.

Measurement

N78723−0 Device

N78723−2 Device

ADCFS_TEMP

TSD Threshold Level

°C

193.5

190

200

200

206.5

210

ADC_TSD

ADC Measurement of Junction

Temperature

163

169

175

°C

Temperature Measurement

Accuracy at Hot

ADC_TEMPHOT

t = 125°C

−8

−

8

°C

Temperature Measurement

Accuracy at Cold

ADC_TEMPCOLD

t = −40°C

−15

−

15

°C

210

280

−

−

650

790

VLEDx Input Impedance

N78723−0 Device

N78723−2 Device

VLED_RES

kW

BUCK REGULATOR − SWITCH

On Resistance, Range 1

On Resistance at Hot,

Range 1

On Resistance, Range 2

On Resistance at Hot,

Range 2

On Resistance, Range 3

On Resistance at Hot,

Range 3

On Resistance, Range 4

On Resistance at Hot,

Range 4

Rdson1

At Room-Temperature,

I(VINBCKx) = 0.18 A,

V(BOOST − VINBCKx) ≤ 0.2 V

−

−

5.2

W

Rdson1_hot

At Tj = 150 °C,

I(VINBCKx) = 0.18 A,

V(BOOST − VINBCKx) ≤ 0.2 V

−

−

7.2

W

Rdson2

At Room-Temperature,

I(VINBCKx) = 0.375 A,

V(BOOST − VINBCKx) ≤ 0.2 V

−

−

2.6

W

Rdson2_hot

At Tj = 150 °C,

I(VINBCKx) = 0.375 A,

V(BOOST − VINBCKx) ≤ 0.2 V

−

−

3.6

W

Rdson3

At Room-Temperature,

I(VINBCKx) = 0.75 A,

V(BOOST − VINBCKx) ≤ 0.2 V

−

−

1.3

W

Rdson3_hot

At Tj = 150 °C,

I(VINBCKx) = 0.75 A,

V(BOOST − VINBCKx) ≤ 0.2 V

−

−

1.8

W

Rdson4

At Room-Temperature,

I(VINBCKx) = 1.5 A,

V(BOOST − VINBCKx) ≤ 0.2 V

−

−

0.65

W

Rdson4_hot

At Tj = 150 °C,

I(VINBCKx) = 1.5 A,

V(BOOST − VINBCKx) ≤ 0.2 V

−

−

0.9

W

Switching Slope – ON Phase

(Note 21)

TRISE

−

3

−

V/ns

Switching Slope – OFF Phase

(Notes 21 and 22)

TFALL

−

3

−

V/ns

23.905

28.125

32.344

mA

BUCK REGULATOR − CURRENT REGULATION

Current Sense Threshold

Level, Range 1, Min Value

ITHR1_000

[BUCKx_VTHR = 00000000]

End of the BUCK ON-Phase

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

21. When DRV_SLOW_EN bit is 1 on N78723−2 device, the switching slopes are typically by 30% slower.

22. Falling switching slope depends on used current (range, current sense threshold level) and free-wheeling diode capacitance.

www.onsemi.com

8

�NCV78723

Table 6. ELECTRICAL CHARACTERISTICS (continued)

(All Min and Max parameters are guaranteed over full junction temperature (TJP) range (−40°C; 150°C), unless otherwise specified)

Characteristic

Symbol

Condition

Min

Typ

Max

Unit

BUCK REGULATOR − CURRENT REGULATION

Current Sense Threshold

Level, Range 1, Spec. Value

ITHR1_110

[BUCKx_VTHR = 01101110]

End of the BUCK ON-Phase.

Min. Value for Specified

Precision

−

112.5

−

mA

Current Sense Threshold

Level, Range 1, Max Value

ITHR1_255

[BUCKx_VTHR = 11111111]

End of the BUCK ON-Phase

−

224.15

−

mA

Current Sense Threshold

Level, Range 2, Min Value

ITHR2_000

[BUCKx_VTHR = 00000000]

End of the BUCK ON-Phase

47.813

56.25

64.688

mA

Current Sense Threshold

Level, Range 2, Spec. Value

ITHR2_110

[BUCKx_VTHR = 01101110]

End of the BUCK ON-phase.

Min. Value for Specified

Precision

−

225

−

mA

Current Sense Threshold

Level, Range 2, Max Value

ITHR2_255

[BUCKx_VTHR = 11111111]

End of the BUCK ON-Phase

−

448.3

−

mA

Current Sense Threshold

Level, Range 3, Min Value

ITHR3_000

[BUCKx_VTHR = 00000000]

End of the BUCK ON-Phase

95.625

112.5

129.375

mA

Current Sense Threshold

Level, Range 3, Spec. Value

ITHR3_110

[BUCKx_VTHR = 01101110]

End of the BUCK ON-Phase.

Min. Value for Specified

Precision

−

450

−

mA

Current Sense Threshold

Level, Range 3, Max Value

ITHR3_255

[BUCKx_VTHR = 11111111]

End of the BUCK ON-phase

−

896.6

−

mA

Current Sense Threshold

Level, Range 4, Min Value

ITHR4_000

[BUCKx_VTHR = 00000000]

End of the BUCK ON-Phase

191.25

225

258.75

mA

Current Sense Threshold

Level, Range 4, Spec. Value

ITHR4_110

[BUCKx_VTHR = 01101110]

End of the BUCK ON-Phase.

Min. Value for Specified

Precision

−

900

−

mA

Current Sense Threshold

Level, Range 4, Max Value

ITHR4_255

[BUCKx_VTHR = 11111111]

End of the BUCK ON-Phase

−

1791.75

−

mA

Current Sense Threshold

Increase per Code, Range 1

dITHR1

8 Bit, Linear Increase

−

0.77

−

mA

Current Sense Threshold

Increase per Code, Range 2

dITHR2

8 Bit, Linear Increase

−

1.54

−

mA

Current Sense Threshold

Increase per Code, Range 3

dITHR3

8 Bit, Linear Increase

−

3.08

−

mA

Current Sense Threshold

Increase per Code, Range 4

dITHR4

8 Bit, Linear Increase

−

6.15

−

mA

Current Threshold Accuracy

Only with Trimming Constant

for the Highest Range

(Note 23)

N78723−0

N78723−2

ITHR_ERR_DD

Specified for BUCKx_VTHR ≥

01101110, without the Delta of

the Trimming Code and without

Temp. Compensation

Current Threshold Accuracy

without Temperature

Compensation (Note 23)

N78723−0

N78723−2

ITHR_ERR_D

Current Threshold Accuracy

(Note 23)

N78723−0

N78723−2

ITHR_ERR

Specified for BUCKx_VTHR ≥

01101110, with the Delta of the

Trimming Code and without

Temp. Compensation

Specified for BUCKx_VTHR ≥

01101110, the Delta of the

Trimming Code and Temp.

Compensation

%

−8

−9

−

−

+8

+9

%

−6

−7

−

−

+6

+7

%

−3

−4

−

−

+3

+4

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

23. Measured as comparator DC threshold value, without comparator delay and switch falling slope.

www.onsemi.com

9

�NCV78723

Table 6. ELECTRICAL CHARACTERISTICS (continued)

(All Min and Max parameters are guaranteed over full junction temperature (TJP) range (−40°C; 150°C), unless otherwise specified)

Characteristic

Symbol

Condition

Min

Typ

Max

Unit

−10

−

+10

mV

BUCK REGULATOR − CURRENT REGULATION

Offset of Peak Current

Comparator on N78723−2

Device

CMP_OFFSET

Over-Current Detection Level,

Range 1

OCDR1

Typ. 1.5 × ITHR1_255

286

−

388

mA

Over-Current Detection Level,

Range 2

OCDR2

Typ. 1.5 × ITHR2_255

573

−

776

mA

Over-Current Detection Level,

Range 3

OCDR3

Typ. 1.5 × ITHR3_255

1148

−

1553

mA

Over-Current Detection Level,

Range 4

OCDR4

Typ. 1.5 × ITHR4_255

2295

−

3105

mA

Time Constant for Longest Off

Time

TC_00

[BUCKx_TOFF = 00000]

−

50

−

ms·V

Time Constant for Shortest Off

Time

TC_31

[BUCKx_TOFF = 11111]

−

5

−

ms·V

TOFF Time Relative Error

TOFF_ERR

TC = TOFF × VLED

@ VLED > 2 V,

TOFF > 350 ns

−10

−

+10

%

TOFF Time Absolute Error

TOFF_ERR_ABS

TC = TOFF × VLED

@ VLED > 2 V,

TOFF ≤ 350 ns

−35

−

+35

ns

Time Constant Decrease per

Code

dTC

5 Bits, Exponential Decrease

−

7.16

−

%

Detection Level of VLED to be

Too Low

VLED_LMT

1.62

1.8

1.98

V

TOFF Time for Low VLED

Voltages

N78723−0 Device

N78723−2 Device (Note 24)

TC_LOW

The Zero-cross Detection

Threshold Level (Note 25)

VLED < VLED_LMT

ms

78

72

105

105

120

140

TC_ZCD

−0.125

−

−0.005

V

The Zero-cross Detection

Filter Time

TC_ZCD_FT

20

−

350

ns

OpenLEDx Detection Time

TON_OPEN

40

50

60

ms

Buck Minimum TON Time

TON_MIN

For

VINBCKx – LBCKSWx < 2.4 V,

No Failure at LBCKSWx Pin

50

−

250

ns

Delay from BUCKx ISENS

Comparator Input Voltage

Balance to BUCKx Switch

Going OFF

ISENSCMP_DEL

ISENS Cmp. Over-Drive

ramp > 1 mV/10 ns

−

70

−

ns

5 V TOLERANT DIGITAL INPUTS (SCLK, CSB, SDI, LEDCTRL1, LEDCTRL2, RSTB)

High-Level Input Voltage

VINHI

2

−

−

V

Low-Level Input Voltage

VINLO

−

−

0.8

V

Pull Resistance (Note 26)

LED PWM Propagation Delay

(Note 27)

Sampling Resolution

RSTB Debouncer Time

RPULL

40

−

160

kW

4.4

5.5

6.95

ms

LEDCTRL_SR

−

100

125

ns

RSTB_DEB

−

100

200

ns

BUCKx_SW_DEL

Activation Time of the BUCKx

Switch from the LEDCTRLx Pin

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

24. Unless zero-cross detection stops the TOFF time on N78723−2 device.

25. The voltage at LBCKSWx pin when the comparator toggles, rising edge.

26. Pull down resistor (RPD) for RSTB, LEDCTRLx, SDI and SCLK, pull up resistor (RPU) for CSB to VDD.

27. Jitter is present due to the internal resynchronization.

www.onsemi.com

10

�NCV78723

Table 6. ELECTRICAL CHARACTERISTICS (continued)

(All Min and Max parameters are guaranteed over full junction temperature (TJP) range (−40°C; 150°C), unless otherwise specified)

Characteristic

Symbol

Condition

Min

Typ

Max

Unit

5 V TOLERANT OPEN-DRAIN DIGITAL OUTPUT (SDO)

Low-Voltage Output Voltage

VOUTLO

IOUT = −10 mA

(Current Flows into the Pin)

−

−

0.4

V

Equivalent Output Resistance

RDSON

Low-Side Switch

−

10

40

W

SDO Pin Leakage Current

SDO_ILEAK

−

−

2

mA

SDO Pin Capacitance

SDO_C

−

−

10

pF

CLK to SDO Propagation

Delay

SDO_DL

−

−

60

ns

Low-Side Switch Activation/

Deactivation Time; @ 1 kW to

5 V, 100 pF to GND, for Falling

Edge V(SDO) Goes below

0.5 V

3 V DIGITAL INPUTS (TEST, TEST1, TEST2)

High-Level Input Voltage

VIN3HI

2.3

−

−

V

Low-Level Input Voltage

VIN3LO

−

−

0.8

V

−

−

60

kW

Pull Resistance

RPD3

Pull-Down Resistance

SPI INTERFACE

CSB Setup Time

tCSS

0.5

−

−

ms

CSB Hold Time

tCSH

0.25

−

−

ms

SCLK Low Time

tWL

0.5

−

−

ms

SCLK High Time

tWH

0.5

−

−

ms

Data-In (DIN) Setup Time,

Valid Data before Rising Edge

of CLK

tSU

0.25

−

−

ms

Data-In (DIN) Hold Time, Hold

Data after Rising Edge of CLK

tH

0.275

−

−

ms

Output (DOUT) Disable Time

(Note 28)

tDIS

0.08

−

0.32

ms

Output (DOUT) Valid

(Note 28)

tV1→0

−

−

0.32

ms

Output (DOUT) Valid

(Note 29)

tV0→1

−

−

0.32 +

t(RC)

ms

Output (DOUT) Hold Time

tHO

0.01

−

−

ms

CSB High Time

tCS

1

−

−

ms

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

28. SDO low-side switch activation time.

29. Time depends on the SDO load and pull-up resistor.

tCS

Initial State of SCLK after CSB Falling Edge

is Don’t Care, It Can be Low or High

VIH

CSB

VIL

tCSS

tWH

tWL

tCSH

VIH

SCLK

DIN

VIL

VIH

DOUT

VIL

ÉÉ

ÉÉ

ÉÉ

ÉÉ

ÉÉ

ÉÉ

tSU tH

VIL

VIH

HI−Z

DIN15

DOUT15

ÉÉ

ÉÉ

ÉÉ

ÉÉ

ÉÉ

ÉÉ

DIN14

ÉÉ

ÉÉ

ÉÉ

ÉÉ

ÉÉ

ÉÉ

tHO

tV

DOUT14

DIN13

ÉÉ

ÉÉ

ÉÉ

ÉÉ

ÉÉ

ÉÉ

DOUT13

Figure 5. SPI Communication Timing

www.onsemi.com

11

DIN1

DOUT1

ÉÉ

ÉÉ

ÉÉ

ÉÉ

ÉÉ

ÉÉ

DIN0

ÉÉÉ

ÉÉÉ

ÉÉÉ

tDIS

DOUT0

HI−Z

�NCV78723

TYPICAL CHARACTERISTICS

2000

Accuracy (±3%/±6%/±8%) Guaranteed from VTHR Code 110 [dec]

1791.15 mA at VTHR = 255 in Range 4

1600

1400

+6.15 mA/step in Range 4

1200

ITHR = 4

1000

896.6 mA at VTHR = 255 in Range 3

225 mA at VTHR = 0 in Range 4

800

+3.08 mA/step in Range 3

112.5 mA at VTHR = 0 in Range 3

ITHR = 3

600

400

56.25 mA at VTHR = 0 in Range 2

ITHR = 2

448.3 mA at VTHR = 255 in Range 2

+1.54 mA/step in Range 2

224.15 mA at VTHR = 255 in Range 1

200

0

0

32

64

96

110

ITHR = 1

128

+0.77 mA/step in Range 1

160

192

224

256

28.125 mA at VTHR = 0 in Range 1

Buck VTHR Code (−)

Figure 6. Buck Peak Current vs. Ranges and VTHR Code

120

Buck RDSON Relative to Value at 1505C (%)

Buck Current Threshold (mA)

1800

100

80

60

40

20

0

−60

−40

−20

0

20

40

60

80

100

120

140

Temperature (5C)

Figure 7. Typical Temperature Behavior of Buck Switch RDSON Relative to the Value at 1505C

www.onsemi.com

12

160

�NCV78723

TYPICAL CHARACTERISTICS

5.20

52.0

TOFF ⋅ VLED = 5 ms ⋅ V

TOFF V VLED (ms V V)

TOFF V VLED (ms V V)

5.15

5.10

5.05

5.00

51.0

TOFF ⋅ VLED = 50 ms ⋅ V

50.0

49.0

4.95

4.90

−40

0

40

80

48.0

−40

120

0

Temperature (5C)

40

80

120

Temperature (5C)

Figure 8. Typical Temperature Dependency of TOFF V VLED Constant

(Shortest TOFF V VLED = 5 ms V V and Longest TOFF V VLED = 50 ms V V)

140

120

−40°C

Delay (ns)

100

25°C

80

150°C

60

40

20

0

0.001

0.01

0.1

1

Slope (A/ms) (for Range 4*)

* In lower ranges, the same current slope (A/s) translates into a higher voltage slope (V/s) at the input of the comparator,

because of the higher RDSON. Resulting equations for all ranges:

Range 4: Comp. Delay [ns] = (0.0365 · Temp [°C] − 10.41) · ln(Slope [A/ms, Range 4]) + 46

Range 3: Comp. Delay [ns] = (0.0365 · Temp [°C] − 10.41) · ln(Slope · 2 [A/ms, Range 4]) + 46

Range 2: Comp. Delay [ns] = (0.0365 · Temp [°C] − 10.41) · ln(Slope · 4 [A/ms, Range 4]) + 46

Range 1: Comp. Delay [ns] = (0.0365 · Temp [°C] − 10.41) · ln(Slope · 8 [A/ms, Range 4]) + 46

Figure 9. Typical Comparator Delay vs. Slope

www.onsemi.com

13

10

�NCV78723

DETAILED OPERATING DESCRIPTION

Supply Concept in General

Two voltages have to be supplied to the NCV78723 chip

– low voltage VDD logic supply and high voltage VBOOST

for providing energy to the buck regulators. More detailed

description follows.

Buck Current Regulation Principle

Each buck controls the individual inductor peak current

(IBUCKpeak) and incorporates a constant ripple

(DIBUCKpkpk) control circuit to ensure also stable average

current through the LED string, independently from the

string voltage. The buck average current is in fact described

by the formula:

VDD Supply

The VDD supply is the low voltage digital and analog

supply for the chip. NCV78723 does not contain internal

VDD regulator and this voltage is supposed to be provided

externally by a dedicated voltage regulator that fulfills

specified voltage and current needs or can be supplied from

the NCV78702/NCV78703 VDD pin.

The Power-On-Reset circuit (POR) monitors the VDD

voltage and RSTB pin to control the out-of-reset and reset

entering state. At power-up, the chip will exit from reset

state when VDD > POR3V_H and RSTB pin is in “log. 1”.

No SPI communication is possible in reset state.

DI BUCK

I BUCK

AVG

+ I BUCK

peak

*

pkpk

(eq. 1)

2

This is graphically exemplified by Figure 10.

Buck Peak Current

Buck

Current

Buck Average Current

Buck Current Ripple

= TOFF_V_BUCK / LBUCK

TOFF

time

VBOOST Supply

Figure 10. Buck Regulator Controlled

Average Current

The VBOOST supply voltage is the main high voltage

supply for the chip. The voltage is supposed to be provided

by booster chip such as NCV78702/NCV78703 or

NCV878763 in an application. VINBCKx pins have to be

connected by low impedance track to this supply to ensure

proper buck performance.

The VBOOST voltage is monitored by under-voltage

comparator to check sufficient zapping voltage at VBOOST

pin during OTP programming operation.

The parameter IBUCKpeak is programmable through the

device by means of the internal registers for range selection

BUCKx_ISENS_THR[1:0] and code BUCKx_VTHR[7:0].

The formula that defines the total ripple current over the

buck inductor is also hereby reported:

DI BUCK

pkpk

VBOOSTM3V Supply

+

^

The VBOOSTM3V is the high side auxiliary supply for

the gate drive of the buck regulators’ integrated high-side

P-MOSFET switches. This supply receives energy directly

from the VBOOST pin.

T OFF @ ǒV LED ) V DIODEǓ

L BUCK

T OFF @ V LED

L BUCK

+

^

(eq. 2)

T OFF_V LED_i SPI

L BUCK

In the formula above, TOFF represents the buck switch off

time, VLED is the LED voltage feedback sensed at the

NCV78723 VLEDx pin and LBUCK is the buck inductance

value. The parameter TOFF_VLED_iSPI is programmable by

SPI (BUCKx_TOFF[4:0] register), with values related to

Table 6 − Buck Regulator – Current Regulation. In order to

achieve a constant ripple current value, the device varies

the TOFF time inversely proportional to the VLED sensed at

the device pin, according to the selected factor

TOFF_VLED_iSPI. As a consequence to the constant ripple

control and variable off time, the buck switching frequency

depends on the boost voltage and LED voltage in the

following way:

Internal Clock Generation – OSC10M

An internal RC clock named OSC10M is used to run all

the digital functions in the chip. The clock is trimmed in the

factory prior to delivery. Its accuracy is guaranteed under

full operating conditions and is independent from external

component selection (refer to Table 6 − OSC10M: System

Oscillator Clock for details). All timings depend on

OSC10M accuracy.

Buck Regulator

General

f BUCK +

The NCV78723 contains two high-current integrated

buck current regulators, which are the sources for the LED

strings. The bucks are powered from the external booster

regulator.

+

www.onsemi.com

14

ǒVBOOST * VLEDǓ

V BOOST

ǒV BOOST * V LEDǓ

V BOOST

@

@

1

+

T OFF

V LED

T OFF_V LED_i SPI

(eq. 3)

�NCV78723

The LED average current in time (DC) is equal to the buck

time average current. Therefore, to achieve a given LED

current target, it is sufficient to know the buck peak current

and the buck current ripple. A rule of thumb is to count a

minimum of 50% ripple reduction by means of the capacitor

CBUCK and this is normally obtained with a low cost ceramic

component ranging from 100 nF to 470 nF (such values are

typically used at connector sides anyway, so this is included

in a standard BOM). The following figure reports a typical

example waveform:

Figure 11. LED Current AC Components Filtered Out by Output Impedance (Oscilloscope Snapshot)

The use of CBUCK is a cost effective way to improve EMC

performances without the need to increase the value of

VBOOST

Supply

VBOOSTM3V

CM3V

LBUCK, which would be certainly a far more expensive

solution.

VBOOST

VBOOSTM3V

Reg.

POWER STAGE

VINBCKx

Driver

LBCKSWx

ISENSE/OC

L

D

Digital

Control

LED String

C

VLEDx

Constant

Ripple Control

Figure 12. Buck Regulator Circuit Diagram

Buck Offset Compensation

of the polarity change, the peak current is toggling between

two threshold values, one high value and one low, as shown

in the picture below. The related sub-harmonic frequency

(half the buck switching frequency) will appear in the

spectrum. This has to be taken into account from EMC point

of view. The use of the offset cancellation is very effective

in case of high precision levels for low currents.

The N78723−2 device features a peak current offset

compensation that can be disabled by the corresponding

BUCKx_OFF_CMP_DIS SPI bit. When this bit is “0”

(offset compensation is enabled), the offset changes polarity

each buck period, so that the average effect over time on the

peak current is minimized (ideally zero). As a consequence

Figure 13. Buck Offset Compensation Feature

www.onsemi.com

15

�NCV78723

SW Compensation of the Buck Current Accuracy

In order to ensure buck current accuracy as specified in Table 6 − Buck Regulator – Current Regulation, set of constants

trimmed during manufacturing process is available. Microcontroller should use them in the following way:

To Reach ±8% (±9% for N78723−2) Accuracy (±6% for Range 4) Over Whole Temperature Operating Range:

All ranges: BUCKx_ISENS_TRIM[6:0] = BUCKx_ISENS_RNG[6:0]

BUCKx_ISENS_RNG[6:0] is trimming constant for the highest current range (Range 4) at hot temperature.

BUCKx_ISENS_RNG[6:0] constant is loaded into BUCKx_ISENS_TRIM[6:0] register automatically after the reset of the

device.

To Reach ±6% (±7% for N78723−2) Accuracy Over Whole Temperature Operating Range:

BUCKx_ISENS_Dx[3:0] registers, meaning delta of the trimming constant with respect to the higher current range at hot

temperature, have to be used. Trimming constant for the particular range at hot temperature can be then calculated as:

Range 4: BUCKx_R4_trim_hot = BUCKx_ISENS_RNG[6:0],

Range 3: BUCKx_R3_trim_hot = BUCKx_ISENS_RNG[6:0] + BUCKx_ISENS_D3[3:0],

Range 2: BUCKx_R2_trim_hot = BUCKx_ISENS_RNG[6:0] + BUCKx_ISENS_D3[3:0] + BUCKx_ISENS_D2[3:0],

Range 1: BUCKx_R1_trim_hot = BUCKx_ISENS_RNG[6:0] + BUCKx_ISENS_D3[3:0] + BUCKx_ISENS_D2[3:0] +

BUCKx_ISENS_D1[3:0],

where:

delta of the trimming constant BUCKx_ISENS_Dx[3:0] is signed, coded as two’s complement. Range of this constant is

decadic , binary .

Calculated trimming constant has to be then written into trimming SPI register:

BUCKx_ISENS_TRIM[6:0] = BUCKx_Ry_trim_hot

To Reach ±3% (±4% for N78723−2) Accuracy Over Whole Temperature Operating Range:

In addition to BUCKx_ISENS_Dx[3:0] registers, the BUCK_ISENS_TCx[3:0] registers, meaning temperature coefficients

for the appropriate ranges, have to be used.

When TC_VERSION = 0, trimming value for a certain temperature should be calculated as:

Range 4: BUCKx_R4_trim = BUCKx_R4_trim_hot + kL3 · (Tj – Thot) + kQ · (Tj – Thot) 2,

Range 3: BUCKx_R3_trim = BUCKx_R3_trim_hot + kL2 · (Tj – Thot) + kQ · (Tj – Thot) 2,

Range 2: BUCKx_R2_trim = BUCKx_R2_trim_hot + kL1 · (Tj – Thot) + kQ · (Tj – Thot) 2,

Range 1: BUCKx_R1_trim = BUCKx_R1_trim_hot + kL0 · (Tj – Thot) + kQ · (Tj – Thot) 2,

When TC_VERSION = 1, trimming value for a certain temperature should be calculated as:

Range 4: BUCK2_R4_trim = BUCK2_R4_trim_hot + kL3 · (Tj – Thot) + kQ · (Tj – Thot) 2,

Range 3: BUCK2_R3_trim = BUCK2_R3_trim_hot + kL3 · (Tj – Thot) + kQ · (Tj – Thot) 2,

Range 2: BUCK2_R2_trim = BUCK2_R2_trim_hot + kL2 · (Tj – Thot) + kQ · (Tj – Thot) 2,

Range 1: BUCK2_R1_trim = BUCK2_R1_trim_hot + kL2 · (Tj – Thot) + kQ · (Tj – Thot) 2,

Range 4: BUCK1_R4_trim = BUCK1_R4_trim_hot + kL1 · (Tj – Thot) + kQ · (Tj – Thot) 2,

Range 3: BUCK1_R3_trim = BUCK1_R3_trim_hot + kL1 · (Tj – Thot) + kQ · (Tj – Thot) 2,

Range 2: BUCK1_R2_trim = BUCK1_R2_trim_hot + kL0 · (Tj – Thot) + kQ · (Tj – Thot) 2,

Range 1: BUCK1_R1_trim = BUCK1_R1_trim_hot + kL0 · (Tj – Thot) + kQ · (Tj – Thot) 2,

where:

buck temperature coefficient BUCK_ISENS_TCx[3:0] is signed, coded as two’s complement. Range of this constant is

decadic , binary ,

kLx is linear coefficient for each current range calculated: kLx = (BUCK_ISENS_TCx[3:0] – kQ · (170°C)2)/(−170°C)

[code/°C] when TC_VERSION = 0

kLx is linear coefficient for each current range calculated: kLx = (BUCK_ISENS_TCx[3:0] – kQ · (200°C)2)/(−200°C)

[code/°C] when TC_VERSION = 1

kQ is quadratic constant for all current ranges: kQ = 2.18 · 10−4 [code/(°C)2]

Tj is junction temperature in °C calculated from VTEMP[7:0] SPI register value according to the equation defined in chapter

ADC: Device Temperature ADC: VTEMP

Thot temperature is constant equal to 125°C when TC_VERSION = 0

Thot temperature is constant equal to 155°C when TC_VERSION = 1.

www.onsemi.com

16

�NCV78723

Calculated trimming constant has to be then written into trimming SPI register:

BUCKx_ISENS_TRIM[6:0] = BUCKx_Ry_trim

Note: The BUCKx_ISENS_TRIM[6:0] SPI register allows compensation of the peak current app. in range ±40 % from

actual value according to the following equation:

IBUCKx = (ITHRx_000 + dITHRx · BUCKx_VTHR[7:0]) · (1 + 0.4 · ((BUCKx_ISENS_TRIM[6:0] − 63)/63)),

where:

ITHRx_000 is current for VTHR code 0 in ITHRx range (see Table 6 − Buck Regulator – Current Regulation),

dITHRx code step in range ITHRx (see Table 6 − Buck Regulator – Current Regulation).

Paralleling the Bucks for Higher Current Capability

logic status of the LEDCTRLx pins. The only difference is

the controlled phase shift of typical 5.5 ms (Table 6 − 5 V

Tolerant Digital Inputs) that allows synchronized

measurements of the VLEDx pins via the ADC (see

dedicated section for more details). As the phase shift is

applied both to rising edges and falling edges, with a very

limited jitter, the PWM duty cycle is not affected. Apart from

the phase shift and the system clock OSC10M, there is no

limitation to the PWM duty cycle values or resolutions at the

bucks, which is a copy of the reference provided at the

inputs.

Different buck channels can be paralleled at the module

output (after the buck inductors) for higher current

capability on a unique channel, summing up together the

individual DC currents.

Buck Overcurrent Protection

Being a current regulator, the NCV78723 buck is by

nature preventing overcurrent in all normal situations.

However, in order to protect the system from overcurrent

even in case of failures, protection mechanism is available.

This protection is based on internal sensing over the buck

switch: when the peak current rises above the maximum

limit (OCDRx level, see see Table 6 − Buck Regulator –

Current Regulation), an internal counter starts to increment

at each period, until the count written in

BUCKx_OC_OCCMP_THR[1:0] + 1 is attained. The count

is reset if the current drops below OCDRx level or the buck

channel is disabled and also at each dimming cycle. From the

moment the count is reached onwards, the buck is kept

continuously off, until the SPI error flag OCLEDx is read.

After reading the flag, the buck channel “x” is automatically

re-enabled and will try to regulate the current again.

ZOOM: Buck Inductor Switching Current

DIM_DUTY = DIM_TON / DIM_T = DIM_TON ⋅ F

DIM_TON

DIM_T

Figure 14. Buck Current Digital or PWM Dimming

ADC

General

The built-in analog to digital converter (ADC) is an 8-bit

successive approximation register (SAR). This embedded

peripheral can be used to provide the following

measurements to the external Micro Controller Unit

(MCU):

• VBOOST Voltage: Sampled at the VBOOST Pin

• VDD Voltage: Sampled at the VDD Pin

• VLED1ON, VLED2ON Voltages

• VLED1 and VLED2 Voltages

• VTEMP Measurement (Chip Temperature)

Dimming

The NCV78723 supports both analog and digital

dimming (or so called PWM dimming). Analog dimming is

performed by controlling the LED amplitude current during

operation. This can be done by means of changing the peak

current level and/or the TOFF_VLED_iSPI constants by SPI

commands (see Buck Regulator section).

In this section, we only describe PWM dimming as this is

the preferred method to maintain the desired LED color

temperature for a given current rating. In PWM dimming,

the LED current waveform frequency is constant and the

duty cycle is set according to the required light intensity. In

order to avoid the beats effect, the dimming frequency

should be set at “high enough” values, typically above

300 Hz.

PWM dimming is controlled externally by means of

LEDCTRLx inputs.

The internal NCV78723 ADC state machine samples all

the above channels automatically, taking care for setting the

analog MUX and storing the converted values in memory.

The external MCU can read out all ADC measured values

via the SPI interface, in order to take application specific

decisions. Please note that none of the MCU SPI commands

interfere with the internal ADC state machine sample and

conversion operations: the MCU will always get the last

available data at the moment of the register read.

The state machine sampling and conversion scheme is

represented in the figure below.

Digital Dimming

The two independent control inputs LEDCTRLx handle

the dimming signals for the related channel “x”. In digital

dimming, the buck activation is transparently linked to the

www.onsemi.com

17

�NCV78723

default selection is given to channel “1”. Then an internal

flag keeps priority tracking, toggling at each time between

channels pre-selection. Therefore, up to two dimming

periods will be required to obtain a full measurement update

of the two channels. This is not considered however

a limitation, as typical periods for dimming signals are in the

order of 1 ms period, thus allowing very fast failure

detection.

A flow chart referring to the ADC interrupts is also

displayed.

VDD Sample & Convert

VBOOST Sample & Convert

VTEMP Sample & Convert

Update

LED_SEL_DUR

Count; When Counter

Ripples, Trigger

VLEDx Interrupt for

Once

VBOOST Sample & Convert

Interrupts

Enabled?

Figure 15. ADC Sample and Conversion Main

Sequence

YES

VLEDx

Synchronization

Signal?

NO

YES

NO

VLEDx Sample & Convert

Referring to the figure above, the typical rate for a full

SAR plus digital conversion per channel is 8 ms (Table 6 −

ADC for Measuring VBOOST, VDD, VLED1, VLED2,

TEMP). For instance, each new VBOOST ADC converted

sample occurs at 16 ms typical rate, whereas for both the

VDD and VTEMP channel the sampling rate is typically

32 ms, that is to say a complete cycle of the depicted

sequence. This time is referred to as TADC_SEQ.

If the SPI setting LED_SEL_DUR[8:0] is not zero, then

interrupts for the VLEDx measurements are allowed at the

points marked with a rhombus, with a minimum cadence

corresponding to the number of the elapsed ADC sequences

(forced interrupt). In formulas:

T VLEDx_INT_Forced + LED_SEL_DUR[8 : 0] @ T ADC_SEQ

Toggle Channel “x” Selection

In Case of Interrupt on Second

Channel do Not Serve Immediately

and Complete the ADC Sequence

First

Proceed to Next Step in the ADC Sequence

Figure 16. ADC VLEDx Interrupt Sequence

(eq. 4)

All NCV78723 ADC registers data integrity is protected

by ODD parity on the bit 8 (that is to say the 9th bit if

counting from the LSbit named “0”). Please refer to the SPI

map section for further details.

In general, prior to the forced interrupt status,

the VLEDxON ADC interrupts are generated when a falling

edge on the control line for the buck channel “x” is detected

by the device. In case of digital dimming, this interrupt start

signal corresponds to the LEDCTRLx falling edge together

with a controlled phase delay (Table 6 − 5 V Tolerant Digital

Inputs). The purpose of the phase delay is to allow

completion the ongoing ADC conversion before starting the

one linked to the VLEDx interrupt: if at the moment of the

conversion LEDCTRLx pin is logic high, then the updated

registers are VLEDxON[7:0] and VLEDx[7:0]; otherwise,

if LEDCTRLx pin is logic low, the only register refreshed is

VLEDx[7:0]. This mechanism is handled automatically by

the NCV78723 logic without need of intervention from the

user, thus drastically reducing the MCU cycles and

embedded firmware and CPU cycles overhead that would be

otherwise required.

To avoid loss of data linked to the ADC main sequence,

one LED channel is served at a time also when interrupt

requests from both channels are received in a row and a full

sequence is required to go through to enable a new interrupt

VLEDx. In addition, possible conflicts are solved by using

a defined priority (channel pre-selection). Out of reset, the

Logic Supply Voltage ADC: VDD

The logic supply voltage is sampled at VDD pin. The

(8-bit) conversion ratio is 4/255 (V/dec) = 0.0157 (V/dec)

typical. The converted value can be found in the SPI register

VDD[7:0], protected with ODD parity bit.

Boost Voltage ADC: VBOOST

This measurement refers to the boost voltage at the

VBOOST pin, with an 8 bit conversion ratio of 70/255

(V/dec) = 0.274 (V/dec) typical, result can be found inside

the SPI register VBOOST[7:0]. The value is protected by

ODD parity bit. This measurement can be used by the MCU

for diagnostics and booster control loop monitoring.

Device Temperature ADC: VTEMP

By means of the VTEMP measurement, the MCU can

monitor the device junction temperature (TJ) over time.

The conversion formula is:

T J + (VTEMP[7 : 0] * 50.5)ń0.805

www.onsemi.com

18

(eq. 5)

�NCV78723

VTEMP[7:0] is the value read out directly from the

related 8bit-SPI register (please refer to the SPI map).

The value is also used internally by the device for the

thermal warning and thermal shutdown functions. More

details on these two can be found in the dedicated sections

in this document. The value is protected by ODD parity bit.

LED String Voltages ADC: VLEDx, VLEDxON

The voltage at the pins VLEDx (1, 2) is measured. There

are 4 ranges available, that can be selected by means of

ADC_VLEDx_RNG_SEL[1:0] register, to obtain higher

resolution for LED voltage measurement.

Conversion ratios in dependency on selected range are:

0x0: 70/255 (V/dec) = 0.274 (V/dec);

0x1: 50/255 (V/dec) = 0.196 (V/dec);

0x2: 40/255 (V/dec) = 0.157 (V/dec);

0x3: 30/255 (V/dec) = 0.118 (V/dec).

•

•

This information, found in registers VLEDxON[7:0] and

VLEDx[7:0], can be used by the MCU to infer about the

LED string status, for example, individual shorted LEDs. As

for the other ADC registers, the values are protected by

ODD parity.

Please note that in the case of constant LEDCTRLx inputs

and no dimming (in other words dimming duty cycle equals

to 0% or 100%) the VLEDx interrupt is forced with a rate

equal to TVLEDx_INT_forced, given in the ADC general

section. This feature can be exploited by MCU embedded

algorithm diagnostics to read the LED channels voltage

even when in OFF state, before module outputs activation

(module startup pre-check).

•

Diagnostics

The NCV78723 features a wide range of embedded

diagnostic features. Their description follows. Please also

refer to the previous SPI section for more details.

•

Diagnostic Description

• Thermal

•

Warning:

this

mechanism

detects

a user-programmable junction temperature which is in

principle close, but lower, to the chip maximum allowed,

thus providing the information that some action (power

de-rating) is required to prevent overheating that would

cause Thermal Shutdown. A typical power de-rating

technique consists in reducing the output dimming duty

cycle in function of the temperature: the higher the

temperature above the thermal warning, the lower the

duty cycle. The thermal warning flag (TW) is given in

status register 0x14 and is latched. When VTEMP[7:0]

raises to or above THERMAL_WARNING_THR[7:0]

threshold, the TW flag is set. At power up the default

thermal warning threshold is typically 159°C (SPI code

179).

Thermal Shutdown: this safety mechanism intends to

protect the device from damage caused by overheating,

by disabling the both buck channels. The diagnostic is

displayed per means of the TSD bit in status register 0x14

•

•

•

(latched). Once occurred, the thermal shutdown condition

is exited when the temperature drops below the thermal

warning level, thus providing hysteresis for thermal

shutdown recovery process. Outputs are re-enabled

automatically if BUCKx_TSD_AUT_RCRV_EN = 1, or

they are re-enabled by rising edge on BUCKx_EN if

BUCKx_TSD_AUT_RCRV_EN = 0. The application

thermal design should be made as such to avoid the

thermal shutdown in the worst case conditions. The

thermal shutdown level is not user programmable and is

factory trimmed (see ADC_TSD in Table 6 − Buck

Regulator – Switch).

SPI Error: in case of SPI communication errors the

SPIERR bit in status register 0x14 is set. The bit is

latched. For more details, please refer to section “SPI

protocol: Framing and Parity Error”.

Open LEDx String: individual open LED diagnostic flags

indicate whether the “x” string is detected open. The

detection is based on a counter overflow of typical 50 ms

when the related channel is activated. Both OPENLED1

and OPENLED2 flags (latched) are contained in status

register 0x13. Please note that the open detection does not

disable the buck channel(s).

Short LEDx String: a short circuit detection is available

independently for each LED channel per means of the flag

SHORTLEDx (latched, status register 0x13). The

detection is based on the voltage measured at the VLEDx

pins via a dedicated internal comparator: when the

voltage drops below the VLED_LMT minimum

threshold (typical 1.8 V, see Table 6 − Buck Regulator –

Current Regulation) the related flag is set. Together with

the detection, a fixed TOFF is used. On N78723−2 device,

TOFF time is terminated immediately when the inductor

current reaches zero. This improves the dimming

behavior via external short switches (pixel control).

Overcurrent on Channel x: this diagnostics protects the

LEDx and the buck channel x electronics from

overcurrent. As the overcurrent is detected, the OCLEDx

flag (latched, status register 0x13) is raised and the related

buck channel is disabled. More details about the detection

mechanisms and parameters are given in section “Buck

Overcurrent Protection”.

Buckx Status: register BUCKx_STATUS shows the

actual status of Buckx output. When BUCKx_STATUS is

1, the corresponding output regulates current to the LED.

LEDCTRLx Pin Status: SPI registers LED1VAL resp.

LED2VAL indicate the actual logic level of the

debounced LEDCTRLx pins. These signals follow the

output of 200 ns digital debouncers implemented on

LEDCTRLx pins.

Buckx Running at Minimum TON Time: register

BUCKx_MIN_TON (latched) indicates that minimal

TON time is detected on the corresponding channel. It is

clear by read flag. This information can be used for

www.onsemi.com

19

�NCV78723

•

detection of transition period during which the BUCKx

output current decreases due to the change of

BUCKx_VTHR code or BUCKx_ISENS_THR range.

Buckx

TON

Time

Duration:

SPI

register

BUCKx_TON_DUR[7:0] reflects the last measured

Buckx TON time (1LSB = 200 ns) on the corresponding

channel. When Buckx runs with TON time < typ. 200 ns,

the BUCKx_TON_DUR[7:0] SPI register returns value

0x00.

When

Buckx

is

stopped,

the

•

BUCKx_TON_DUR[7:0] register keeps the last

measured TON time.

HW Reset: the out of reset condition is reported through

the HWR bit (latched). This bit is set only at each Power

On Reset (POR) and indicates the device is ready to

operate.

A short summary table of the main diagnostic bits related

to the LED outputs follows.

Table 7. LED OUTPUT DIAGNOSTIC SUMMARY

Diagnose

Flag

Description

Detection Level

LED Output

Latched

TW

Thermal Warning

SPI Register Programmable

Not Disabled

(If No TSD, otherwise Disabled)

Yes

TSD

Thermal Shutdown

Factory Trimmed

Disabled

(Automatically Re-Enabled when

Temp Falls below TW and

BUCKx_TSD_AUT_RCVR_EN = 1)

Yes

SPIERR

SPI Error

(See SPI Section)

Not Disabled

Yes

OPENLEDx

LED String Open Circuit

Buck on Time > TON_OPEN

Not Disabled

Yes

SHORTLEDx

LED String Short Circuit

VLEDx < VLED_LMT

Not Disabled

(Fixed Buck TOFF or Zero Cross

TOFF Applied when output is On)

Yes

OCLEDx

LED String Overcurrent

Ibuckx > OCDR{1..4}

Disabled

Yes

Mode = RESET (0)

Transition Priority

(0) − Highest

(1)

(2)

(3) − Lowest

TSD = 1 (1)

OFF

LED is Off

OCLED = 1 or

BUCKx_EN = 0 (2)

OCLED = 0 and

BUCKx_EN = 1 (2)

DIMMING

NORMAL Mode: LED is On if LEDCTRLx = 1

FSO/STANDALONE Mode: LED is On

BUCKx_TSD_AUT_RCVR_EN = 1

or Rising Edge on BUCKx_EN

Detected (3)

TSD = 1 (1)

RECOVERY

(BUCKx_TSD_AUT_RCVR_EN = 1

or Rising Edge on BUCKx_EN Detected)

and (OCLED = 1 or BUCKx_EN = 0) (2)

TSD = 1 (1)

LED is Off

TSD

LED is Off

VTEMP < THERMAL_WARNING_THR(1)

Figure 17. LED Dimming State Diagram

www.onsemi.com

20

�NCV78723

Functional Mode Description

Overview of all functional modes is in accordance to the state diagram on Figure 18. Individual states are described below.

Transition Condition (Priority Level)

Action Executed when Transition is

Performed

Transition Priority:

(0) − Highest

(1)

(2) − Lowest

POR (0)

RESET

SPI Disabled

Dimming Disabled

HWR:=1

RSTB = 0 (1)

RSTB = 1 (1)

INIT

SPI Disabled

Dimming Disabled

OTP Refresh Ongoing

RSTB = 0 and

(FSO_MD = 000 or

001 or 110 or 111)

(1)

RSTB = 0 (1)

150 ms Timeout Expired

(2)

SPI Pre-Load from OTPs when

FSO_MD = 001 or 100 or 101

or 110 or 111

(FSO_MD = 110 or 111) and

OTP_CUST_LOCK = 1

(2)

SPI Pre-Load from OTPs

FSO:=1

NORMAL

SPI Enabled

Dimming: LEDCTRLx

RSTB = 0 and

(FSO_MD = 010 or 011

or 100 or 101) and

OTP_CUST_LOCK = 1

(2)

SPI Pre-Load from OTPs

FSO:=1

FSO_MD = 000 or 001

(2)

RSTB = 1 or

(FSO_MD = 000 or 001)

(1)

FSO

SPI Enabled when

FSO_MD = 010 or 100

Dimming: BUCKx_EN

Figure 18. Functional Modes State Diagram

www.onsemi.com

21

STANDALONE

SPI Disabled when

FSO_MD = 110

Dimming: BUCKx_EN

�NCV78723

Reset

BUCKx_ISENS_TRIM[6:0] register is preloaded from

corresponding BUCKx_ISENS_RNG[6:0] register.

In FSO (entered via falling edge on RSTB pin) and

Stand-Alone modes, BUCK1_EN & BUCK2_EN are

controlled from SPI register map (SPI registers are updated

from OTP’s after entrance into these modes).

BUCK1_EN and BUCK2_EN are supposed to be set ‘1’

for the BUCKx operation in the FSO/stand-alone mode.

When control registers are pre-loaded from OTP’s after

POR and FSO mode is not entered (valid for FSO_MD[2:0]

= 100 or 101), BUCK1_EN and BUCK2_EN are kept

inactive (‘0’) until the first valid SPI operation is finished to

avoid potential activation of buck regulators immediately

after POR (to prevent undefined state of LEDCTRLx pins in

case MCU leaves POR later than NCV78723).

In FSO and Stand-Alone modes, the logic level at

LEDCTRLx pins is ignored and digital PWM dimming

with LEDCTRLx pins is not available. The outputs can be

dimmed only by means of BUCKx_EN register.

A falling edge on RSTB pin may trigger either entrance

into FSO mode or reset in dependency on FSO_MD[2:0]

register value. Please refer to Table 8 and Figure 18 for more

details.

Once FSO mode is entered via falling edge on RSTB pin,

reset function of RSTB pin is blocked until FSO mode is

exited. FSO mode can be exited by the rising edge on RSTB

pin or by writing FSO_MD[2:0] = 000 or 001 (possible only

in FSO modes, where SPI control register update is allowed:

FSO_MD[2:0] = 011 or 101).

In stand-alone mode (FSO_MD[2:0] = 110 or 111), RSTB

has always reset functionality.

During entrance into FSO mode, value of FSO_MD[2:0]

SPI register (preloaded from OTP at power-up only) is

latched into internal register and all FSO related functions

are then controlled according to it. Purpose is to avoid the

reset of the device when FSO mode is active and

FSO_MD[2:0] is changed to value corresponding to

stand-alone mode, where RSTB pin has reset functionality.

The internal register is cleared after POR or when FSO mode

is exited.

Asynchronous reset is caused either by POR (POR always

causes asynchronous reset − transition to reset state) or by

falling edge on RSTB pin (in normal/stand-alone mode,

when FSO_MD[2:0] = 000 or 001 or 110 or 111).

Init and Normal Mode

Normal mode is entered through Init state after internal

delay of 150 ms. In Init state, OTP refresh is performed. If

OTP bits for FSO_MD[2:0] register and OTP Lock Bit are

programmed, transition to FSO/SA mode is possible.

FSO/Stand-Alone Mode

FSO (Fail-Safe Operation)/Stand-Alone modes can be

used for two main purposes:

• Default power-up operation of the chip (Stand-Alone

functionality without external microcontroller or

preloading of the registers with default content for default

operation before microcontroller starts sending SPI

commands for chip settings)

• Fail-Safe functionality (chip functionality definition in

fail-safe mode when the external microcontroller

functionality is not guaranteed)

FSO/stand-alone function is controlled according to

Table 8. Entrance into FSO/Stand-alone mode is possible

only after customer OTP zapping when OTP Lock Bit is set.

After FSO mode activation, the FSO bit in status register is

set. FSO register is cleared by read register.

When FSO/Stand-Alone mode is activated, content of the

following SPI registers is preloaded from OTP memory:

BUCK1_VTHR[7:0],

BUCK1_ISENS_THR[1:0],

BUCK2_VTHR[7:0],

BUCK2_ISENS_THR[1:0],

BUCK1_TOFF[4:0],

BUCK2_TOFF[4:0],

BUCK1_EN,

BUCK2_EN,

FSO_MD[2:0],

BUCK1_TSD_AUT_RCVR_EN,

BUCK2_TSD_AUT_RCVR_EN,

BUCKx_OC_OCCMP_THR[1:0]].

www.onsemi.com

22

�NCV78723

RSTB in Normal or Stand-Alone Mode

PORB

(Internal)

RSTB

Normal Mode

(SPI Possible)

Power-Up

Reset Mode (No SPI)

Normal Mode

Reset

Mode

Possible OTP Pre-Load

Possible OTP Pre-Load

RSTB iN FSO Mode

PORB

(Internal)

RSTB

Normal Mode

(SPI Possible)

Power-Up

OTP Pre-Load

FSO Mode

(SPI Possible/No SPI)

OTP Pre-Load

Normal Mode

FSO

Mode

OTP Pre-Load

Figure 19. RSTB Pin Functionality in Normal, Stand-Alone and FSO Modes

Table 8. FSO MODES

FSO_MD[2:0]

Description

000b = 0

FSO Mode Disabled, Registers are Loaded with Safe Value = 0x00h after POR, Default

• After the reset, control registers are loaded with 0x00h value.

• Entrance into FSO mode is not possible unless dedicated SPI write command to change FSO_MD[2:0] value is

sent

• RSTB pin has reset functionality

• LEDCTRLx pins are functional (buck enable/disable, digital PWM dimming available)

001b = 1

FSO Mode Disabled, Registers are Loaded with Data from OTP Memory after POR

• After the reset, control registers are loaded with data stored in OTP memory (device’s OTP memory has to be

programmed, OTP Lock Bit has to be set). It reduces number of SPI transfers needed to configure the device

after the reset.

• Entrance into FSO mode is not possible

• RSTB pin has reset functionality

• LEDCTRLx pins are functional (buck enable/disable, digital PWM dimming available)

010b = 2

FSO Entered after Falling Edge on RSTB Pin, Registers (except FSO_MD[2:0]) are Loaded with

Safe Value = 0x00h after POR

• After FSO mode activation, control registers are loaded with data stored in OTP memory.

• SPI register update (SPI write/read operation) in FSO mode is disabled (SPI write operation is blocked; clearing

of SPI registers is blocked; in case of invalid SPI frame, SPIERR flag is set).

• RSTB pin serves to enter/exit FSO mode.

• LEDCTRLx pins are not functional (buck enable/disable only by means of BUCKx_EN SPI/OTP bits, digital PWM

dimming not available).

011b = 3

FSO Entered after Falling Edge on RSTB Pin, Registers (except FSO_MD[2:0]) are Loaded with

Safe Value = 0x00h after POR

• After FSO mode activation, control registers are loaded with data stored in OTP memory.

• SPI register update (SPI write/read operation) in FSO mode is enabled

• FSO mode can be exited by writing FSO_MD[2:0] = 000 or 001

• RSTB pins serves to enter/exit FSO mode.

• LEDCTRLx pins are not functional (buck enable/disable only by means of BUCKx_EN SPI/OTP bits, digital PWM

dimming not available).

100b = 4

FSO Entered after Falling Edge on RSTB Pin, Registers are Loaded with Data from OTP Memory after POR

• After FSO mode activation, control registers are loaded with data stored in OTP memory.

• SPI register update (SPI write/read operation) in FSO mode is disabled (SPI write operation is blocked; clearing

of SPI registers is blocked; in case of invalid SPI frame, SPIERR flag is set).

• RSTB pin serves to enter/exit FSO mode.

• LEDCTRLx pins are not functional (buck enable/disable only by means of BUCKx_EN SPI/OTP bits, digital PWM

dimming not available).

www.onsemi.com

23

�NCV78723

Table 8. FSO MODES (continued)

FSO_MD[2:0]

Description

101b = 5

FSO Entered after Falling Edge on RSTB Pin, Registers are Loaded with Data from OTP Memory after POR

• After FSO mode activation, control registers are loaded with data stored in OTP memory.

• SPI register update (SPI write/read operation) in FSO mode is enabled

• FSO mode can be exited by writing FSO_MD[2:0] = 000 or 001

• RSTB pin serves to enter/exit FSO mode.

• LEDCTRLx pins are not functional (buck enable/disable only by means of BUCKx_EN SPI/OTP bits, digital PWM

dimming not available).

110b = 6

SA (Stand-Alone)/FSO Entered after POR (RSTB Pin Rising Edge), Registers are Loaded with Data from

OTP Memory

• After FSO/SA mode activation, control registers are loaded with data from OTP memory

• SPI register update (SPI write/read operation) in SA/FSO mode is disabled (SPI write operation is blocked;

clearing of SPI registers is blocked; in case of invalid SPI frame, SPIERR flag is set).

• RSTB pin has reset functionality

• LEDCTRLx pins are not functional (buck enable/disable only by means of BUCKx_EN SPI/OTP bits, digital PWM

dimming not available).

111b = 7

SA (Stand-Alone)/FSO Entered after POR (RSTB Pin Rising Edge), Registers are Loaded with Data from

OTP Memory

• After SA/FSO mode activation, control registers are loaded with data from OTP memory

• SPI register update (SPI write/read operation) in SA/FSO mode is enabled

• FSO mode can be exited by writing FSO_MD[2:0] = 000 or 001

• RSTB pin has reset functionality

• LEDCTRLx pins are not functional (buck enable/disable only by means of BUCKx_EN SPI/OTP bits, digital PWM

dimming not available).

SPI Interface

General

A slave or chip select line (CSB) allows individual

selection of a slave SPI device in a time multiplexed

multiple-slave system.

The CSB line is active low. If an NCV78723 is not

selected, SDO is in high impedance state and it does not

interfere with SPI bus activities. Since the NCV78723

always clocks data out on the falling edge and samples data

in on rising edge of clock, the MCU SPI port must be

configured to match this operation.

The implemented SPI allows connection to multiple

slaves by means of star connection (CSB per slave) or by

means of daisy chain.

An SPI star connection requires a bus = (3 + N) total lines,

where N is the number of Slaves used, the SPI frame length

is 16 bits per communication.

The serial peripheral interface (SPI) is used to allow

an external microcontroller (MCU) to communicate

with the device. NCV78723 acts always as a slave and it

cannot initiate any transmission. The operation of the device

is configured and controlled by means of SPI registers,

which are observable for read and/or write from the master.

The NCV78723 SPI transfer size is 16 bits.

During an SPI transfer, the data is simultaneously

transmitted (shifted out serially) and received (shifted in

serially). A serial clock line (SCLK) synchronizes shifting

and sampling of the information on the two serial data lines:

SDO and SDI. The SDO signal is the output from the Slave

(NCV78723), and the SDI signal is the output from the

Master.

SCB1

SCB2

MCU

(SPI Master)

SCBN

MCU

(SPI Master)

NCV78723 Dev#1

(SPI Slave)

MOSI

MISO

SDO 1

SDI2

NCV78723 Dev#2

(SPI Slave)

SDO 2

SDIN

NCV78723 Dev#N

(SPI Slave)

SDON

NCV78723 Dev#1

(SPI Slave)

NCV78723 Dev#2

(SPI Slave)

NCV78723 Dev#N

(SPI Slave)

Figure 20. SPI Star vs. Daisy Chain Connection

SPI Daisy Chain Mode

SPI daisy chain connection bus width is always four lines

independently on the number of slaves. However, the SPI

transfer frame length will be a multiple of the base frame

length so N × 16 bits per communication: the data will be

interpreted and read in by the devices at the moment the CSB

rises.

A diagram showing the data transfer between devices in

daisy chain connection is given further: CMDx represents

www.onsemi.com

24

�NCV78723

Device in the same time replies to the master (on the

SDO):

• If the previous command was a write and no SPI error had

occurred, a copy of the command, address and data

written fields,