Datasheet

2.7V to 5.5V Input, 3A Integrated MOSFET

Single Synchronous Buck DC/DC Converter

For Automotive

BD9S300MUF-C

General Description

Key Specifications

BD9S300MUF-C is a synchronous buck DC/DC

Converter with built-in low On Resistance power

MOSFETs. It is capable of providing current up to 3A.

The SLLMTM control provides excellent efficiency

characteristics in light-load conditions which make the

product ideal for reducing standby power consumption of

equipment. Small inductor is applicable due to high

switching frequency of 2.2MHz. It is a current mode

control DC/DC Converter and features high-speed

transient response. Phase compensation can also be set

easily.

It can also be synchronized to external pulse.

Input Voltage:

2.7V to 5.5V

Output Voltage Setting:

0.8V to VPVIN x 0.8V

Output Current:

3A(Max)

Switching Frequency:

2.2MHz(Typ)

High Side MOSFET ON Resistance: 35mΩ (Typ)

Low Side MOSFET ON Resistance: 35mΩ (Typ)

Shutdown Circuit Current:

0μA (Typ)

Operating Temperature:

-40°C to +125°C

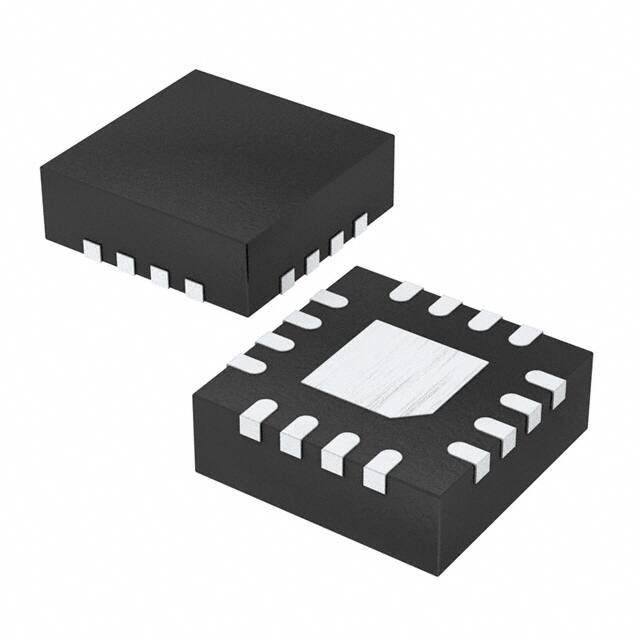

Package

VQFN16FV3030

W(Typ) x D(Typ) x H(Max)

3.00mm x 3.00mm x 1.00mm

Features

SLLMTM (Simple Light Load Mode) Control

AEC-Q100 Qualified(Note 1)

Single Synchronous Buck DC/DC Converter

Adjustable Soft Start Function

Power Good Output

Input Under Voltage Lockout Protection

Short Circuit Protection

Output Over Voltage Protection

Over Current Protection

Thermal Shutdown Protection

Wettable Flank QFN Package

Enlarged View

VQFN16FV3030

Wettable Flank Package

(Note 1) Grade 1

Applications

Automotive Equipment

(Cluster Panel, Infotainment Systems)

Other Electronic Equipment

Typical Application Circuit

VIN

CIN1

CIN2

VMODE/SYNC

VEN

PVIN

PGD

AVIN

BOOT

C1

MODE/SYNC

SW

EN

VOUT

L1

SS

COUT

ITH

R1

R3

PGND

FB

AGND

C3

R2

C2

Figure 1. Application Circuit

SLLMTM is a trademark of ROHM Co., Ltd.

〇Product structure : Silicon monolithic integrated circuit

.www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 14 • 001

〇This product has no designed protection against radioactive rays

1/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

PVIN

1

PVIN

2

AVIN

EN

PGD

BOOT

Pin Configuration

16

15

14

13

12 SW

11 SW

EXP-PAD

PGND

4

9

AGND

5

6

7

8

MODE

/SYNC

10 SW

ITH

3

FB

PGND

SS

(TOP VIEW)

Figure 2. Pin Configuration

Pin Descriptions

Pin No.

Pin Name

Function

1, 2

PVIN

Power supply pins for the DC/DC Converter.

Connecting a 10µF ceramic capacitor is recommended.

3, 4

PGND

Ground pins for the DC/DC Converter.

5

AGND

Ground pin.

6

FB

7

ITH

VOUT voltage feedback pin. An inverting input node for the gm error amplifier. Connect output

voltage divider to this pin to set the output voltage. See page 17 on how to compute for the

resistor values.

An output pin of the gm error amplifier and the input of PWM comparator.

Connect phase compensation components to this pin. See page 20 on calculate the resistance

and capacitance of phase compensation.

8

MODE

/SYNC

Pin for selecting the SLLMTM control mode and the Forced PWM mode. Turning this pin signal

Low forces the device to operate in the Forced PWM mode. Turning this pin signal High enables

the SLLMTM control and the mode is automatically switched between the SLLMTM control and

PWM mode according to the load current. In addition, external synchronization operation is

started by inputting synchronous pulse signal to this pin.

9

SS

Pin for setting the soft start time. The rise time of the output voltage can be specified by

connecting a capacitor to this pin. See page 19 on calculate the capacitance.

10, 11, 12

SW

Switch pin. These pins are connected to the source of the High Side MOSFET and drain of the

Low Side MOSFET. Connect a bootstrap capacitor of 0.1µF between these pins and the BOOT

pin.

13

BOOT

14

PGD

Power Good pin, an open drain output. Use of pull up resistor is needed. See page 12 on setting

the resistance.

15

EN

Pin for controlling the device. Turning this pin signal Low forces the device to enter the shutdown

mode. Turning this pin signal High enables the device.

16

AVIN

Power supply input pin of the analog circuitry. Connect this pin to PVIN. Connecting a 0.1µF

ceramic capacitor is recommended.

-

EXP-PAD

A backside heat dissipation pad. Connecting to the internal PCB ground plane by using via

provides excellent heat dissipation characteristics.

Connect a bootstrap capacitor of 0.1µF between this pin and the SW pins.

The voltage of this capacitor is the gate drive voltage of the High Side MOSFET.

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

2/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Block Diagram

VIN

VIN

AVIN

PVIN

16

1

2

Slope

EN

15

VREF

PWM

Comparator

Error

Amplifier

FB

BOOT

R

6

13

Q

S

REF_OCP

Driver

Logic

SS

9

SW

OSC

Soft

Start

10

VOUT

PVIN

AVIN

11

UVLO

12

SCP

ITH

PGND

3

7

OVP

4

Power

Good

TSD

AGND

5

14

PGD

8

MODE/

SYNC

Figure 3. Block Diagram

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

3/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Description of Blocks

1. VREF

The VREF block generates the internal reference voltage.

2. UVLO (Under Voltage Lockout)

The UVLO block is for under voltage lockout protection. It will shutdown the device when the VIN falls to 2.45V(Typ) or

lower. The threshold voltage has a hysteresis of 100mV(Typ).

3. SCP (Short Circuit Protection)

This is the short circuit protection circuit. After soft start is judged to be completed, if the FB pin voltage falls to 0.56V(Typ)

or less and remain in that state for 1ms(Typ), output MOSFET will turn OFF for 14ms(Typ) and then restart the operation.

4. OVP (Over Voltage Protection)

This is the output over voltage protection circuit. When the FB pin voltage becomes 0.880V(Typ) or more, it turns the

output MOSFET OFF. After output voltage falls 0.856V(Typ) or less, the output MOSFET returns to normal operation.

5. TSD (Thermal Shutdown)

This is the thermal shutdown circuit. It will shutdown the device when the junction temperature (Tj) reaches to 175°C(Typ)

or more. When the Tj falls below the TSD threshold, the circuits are automatically restored to normal operation with

hysteresis of 25°C(Typ).

6. OCP (Over Current Protection)

The Over Current Protection function operates by limiting the current that flows through High Side MOSFET at each cycle

of the switching frequency.

7. Soft Start

The Soft Start circuit slows down the rise of output voltage during startup, which allows the prevention of output voltage

overshoot. The soft start time of the output voltage can be specified by connecting a capacitor to the SS pin. See page 19

on calculate the capacitance. A built-in soft start function is provided and a soft start is initiated in 1ms(Typ) when the SS

pin is open.

8. Error Amplifier

The Error Amplifier block is an error amplifier and its inputs are the reference voltage 0.8V(Typ) and the FB pin voltage.

Phase compensation can be set by connecting a resistor and a capacitor to the ITH pin. See page 20 on calculate the

resistance and capacitance of phase compensation.

9. PWM Comparator

The PWM Comparator block compares the output voltage of the Error Amplifier and the Slope signal to determine the

switching duty.

10. OSC (Oscillator)

This block generates the oscillating frequency.

11. Driver Logic

This block controls switching operation and various protection functions.

12. Power Good

When the FB pin voltage reaches 0.8V(Typ) within ±7%, the built-in Nch MOSFET turns OFF and the PGD output turns

high. In addition, the PGD output turns low when the FB pin voltage reaches outside ±10% of 0.8V(Typ).

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

4/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Absolute Maximum Ratings (Ta=25°C)

Parameter

Input Voltage

Symbol

Rating

Unit

VPVIN, VAVIN

-0.3 to +7

V

EN Voltage

MODE / SYNC Voltage

VEN

-0.3 to VAVIN

V

VMODE/SYNC

-0.3 to VAVIN

V

VPGD

-0.3 to +7

V

PGD Voltage

BOOT Voltage

VBOOT

-0.3 to +14

V

ΔVBOOT

-0.3 to +7

V

VFB, VITH, VSS

-0.3 to VAVIN

V

Tjmax

150

°C

Tstg

-55 to +150

°C

Voltage from SW to BOOT

FB ITH SS Voltage

Maximum Junction Temperature

Storage Temperature Range

Caution 1: Operating the IC over the absolute maximum ratings may damage the IC. The damage can either be a short circuit between pins or an open circuit

between pins and the internal circuitry. Therefore, it is important to consider circuit protection measures, such as adding a fuse, in case the IC is

operated over the absolute maximum ratings.

Caution 2: Should by any chance the maximum junction temperature rating be exceeded the rise in temperature of the chip may result in deterioration of the

properties of the chip. In case of exceeding this absolute maximum rating, design a PCB boards with thermal resistance taken into consideration by

increasing board size and copper area so as not to exceed the maximum junction temperature rating.

Thermal Resistance(Note 1)

Parameter

Symbol

Thermal Resistance (Typ)

Unit

1s(Note 3)

2s2p(Note 4)

θJA

189.0

57.5

°C/W

ΨJT

23

10

°C/W

VQFN16FV3030

Junction to Ambient

Junction to Top Characterization

Parameter(Note 2)

(Note 1) Based on JESD51-2A(Still-Air)

(Note 2) The thermal characterization parameter to report the difference between junction temperature and the temperature at the top center of the outside

surface of the component package.

(Note 3) Using a PCB board based on JESD51-3.

Layer Number of

Measurement Board

Single

Material

Board Size

FR-4

114.3mm x 76.2mm x 1.57mmt

Top

Copper Pattern

Thickness

Footprints and Traces

70μm

(Note 4) Using a PCB board based on JESD51-5, 7.

Layer Number of

Measurement Board

4 Layers

Thermal Via(Note 5)

Material

Board Size

FR-4

114.3mm x 76.2mm x 1.6mmt

Top

Pitch

1.20mm

2 Internal Layers

Diameter

Φ0.30mm

Bottom

Copper Pattern

Thickness

Copper Pattern

Thickness

Copper Pattern

Thickness

Footprints and Traces

70μm

74.2mm x 74.2mm

35μm

74.2mm x 74.2mm

70μm

(Note 5) This thermal via connects with the copper pattern of all layers.

Recommended Operating Conditions

Parameter

Input Voltage

Operating Temperature

Symbol

Min

Max

Unit

VPVIN, VAVIN

2.7

5.5

V

Topr

-40

+125

°C

Output Current

IOUT

-

3

A

Output Voltage Setting

VOUT

0.8(Note 1)

VPVIN x 0.8

V

SW Minimum ON Time

tON_MIN

-

95

ns

External Clock Frequency

fSYNC

1.8

2.4

MHz

Synchronous Operation Input Duty

DSYNC

25

75

%

(Note 1) Although the output voltage is configurable at 0.8V and higher, it may be limited by the SW min ON pulse width. For the configurable range,

please refer to the Output Voltage Setting in Selection of Components Externally Connected.

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

5/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Electrical Characteristics (Unless otherwise specified Ta=-40°C to +125°C, AVIN=PVIN=5V, EN=5V)

Parameter

Symbol

Min

Typ

Max

Unit

Conditions

Shutdown Circuit Current

ISDN

-

0

10

µA

Circuit Current

ICC

400

650

900

µA

VUVLO1

VUVLO2

VUVLO-HYS

2.30

2.40

50

2.45

2.55

100

2.60

2.70

125

V

V

mV

VEN=0V, Ta=25°C

IOUT=0mA

Non-switching, Ta=25°C

VAVIN Falling

VAVIN Rising

Ta=25°C

VENH

VENL

IEN

2.0

GND

2

5

VIN

0.8

8

V

V

µA

VEN=5V, Ta=25°C

MODE/SYNC Threshold Voltage High

VMODESYNCH

2.0

-

VIN

V

MODE/SYNC Threshold Voltage Low

VMODESYNCL

GND

-

0.8

V

IMODESYNC

4

10

16

µA

VFB

IFB

IITHSI

IITHSO

0.788

12

-25

0.8

0

19

-19

0.812

0.2

25

-12

V

µA

µA

µA

0.5

1.0

2.0

ms

0.6

1.2

2.4

ms

ISS

-2.34

-1.8

-1.26

µA

fSW

2.0

2.2

2.4

MHz

VFB

x 0.87

VFB

x 0.90

VFB

x 1.07

VFB

x 1.04

10

0.01

VFB

x 0.90

VFB

x 0.93

VFB

x 1.10

VFB

x 1.07

0

30

0.03

VFB

x 0.93

VFB

x 0.96

VFB

x 1.13

VFB

x 1.10

2

60

0.06

10

35

15

38

10

AVIN

UVLO Detection Voltage

UVLO Release Voltage

UVLO Hysteresis Voltage

ENABLE

EN Threshold Voltage High

EN Threshold Voltage Low

EN Input Current

MODE/SYNC

MODE/SYNC Input Current

VMODESYNC=5V, Ta=25°C

Reference Voltage, Error Amplifier

FB Pin Voltage

FB Input Current

ITH Sink Current

ITH Source Current

Soft Start Time

SS Charge Current

tSS

VFB=0.8V, Ta=25°C

VFB=0.9V, Ta=25°C

VFB=0.7V, Ta=25°C

VAVIN=5V,

The SS Pin OPEN

VAVIN=3.3V,

The SS Pin OPEN

Switching Frequency

Switching Frequency

Power Good

PGD Falling (Fault) Voltage

VPGDTH_FF

PGD Rising (Good) Voltage

VPGDTH_RG

PGD Rising (Fault) Voltage

VPGDTH_RF

PGD Falling (Good) Voltage

VPGDTH_FG

PGD Output Leakage Current

PGD FET ON Resistance

PGD Output Low Level Voltage

ILEAKPGD

RPGD

VPGDL

V

VFB Falling

V

VFB Rising

V

VFB Rising

V

VFB Falling

µA

Ω

V

VPGD=5V, Ta=25°C

60

mΩ

VPVIN=5V

65

mΩ

VPVIN=3.3V

35

60

mΩ

VPVIN=5V

15

38

65

mΩ

VPVIN=3.3V

VPVIN=5.5V, VSW=0V

Ta=25˚C

VPVIN=5.5V, VSW=5.5V

Ta=25˚C

IPGD=1mA

Switch MOSFET

High Side FET ON Resistance

RONH

Low Side FET ON Resistance

RONL

High Side FET Leakage Current

ILEAKSWH

-

0

5

µA

Low Side FET Leakage Current

ILEAKSWL

-

0

5

µA

IOCP

3.6

5.0

6.6

A

VSCP

0.45

0.56

0.67

V

VOVP

0.856

0.880

0.904

V

SW Current of Over Current

Protection(Note1)

SCP, OVP

Short Circuit Protection Detection

Voltage

Output Over Voltage Protection

Detection Voltage

(Note 1) This is design value. Not production tested.

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

6/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

10

900

9

850

8

800

Circuit Current : ICC[µA]

Shutdown Circuit Current : ISDN[µA]

Typical Performance Curves

7

6

5

4

VIN = 5.0V

3

VIN = 3.3V

750

700

650

600

2

500

1

450

0

400

-50

-25

0

25

50

75

100

125

VIN = 5.0V

550

VIN = 3.3V

-50

-25

0

50

75

100

125

Temperature[°C]

Temperature[°C]

Figure 4. Shutdown Circuit Current vs Temperature

Figure 5. Circuit Current vs Temperature

2.40

0.812

2.35

VIN = 5.0V

FB Pin Voltage : VFB[V]

Switching Frequency : fSW [MHz]

25

2.30

2.25

2.20

2.15

VIN = 3.3V

0.808

VIN = 5.0V

0.804

0.800

0.796

VIN = 3.3V

2.10

0.792

2.05

0.788

2.00

-50

-25

0

25

50

75

100

-50

125

0

25

50

75

100

125

Temperature[°C]

Temperature[°C]

Figure 6. Switching Frequency vs Temperature

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

-25

7/42

Figure 7. FB Pin Voltage vs Temperature

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

30

-10

28

-12

26

ITH Source Current : IITHSO[µA]

ITH Sink Current : IITHSI[µA]

Typical Performance Curves – continued

VIN = 5.0V

24

22

20

18

VIN = 2.7V

16

14

12

VIN = 2.7V

-14

-16

-18

-20

-22

VIN = 5.0V

-24

-26

-28

10

-30

-50

-25

0

25

50

75

100

125

-50

-25

Temperature[°C]

25

50

75

100

125

Temperature[°C]

Figure 8. ITH Sink Current vs Temperature

Figure 9. ITH Source Current vs Temperature

20

2.0

VIN = 5.0V

MODE/SYNC Input Current : IMODE/SYNC[µA]

MODE/SYNC Threshold Voltage : VMODE/SYNCTH[V]

0

VMODESYNCH

1.8

1.6

1.4

VMODESYNCL

1.2

1.0

0.8

-50

-25

0

25

50

75

100 125

16

VMODE/SYNC = 5.0V

14

12

10

8

6

4

VMODE/SYNC = 3.3V

2

0

-50

-25

0

25

50

75

100

125

Temperature[°C]

Temperature[°C]

Figure 10. MODE/SYNC Threshold Voltage vs Temperature

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

18

8/42

Figure 11. MODE/SYNC Input Current vs Temperature

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Typical Performance Curves – continued

-1.26

2.0

CSS = OPEN

-1.44

SS Charge Current : ISS[µA]

Soft Start Time : tSS[ms]

VIN = 3.3V

VIN = 3.3V

1.5

1.0

VIN = 5.0V

0.5

-1.80

-1.98

VIN = 5.0V

-2.16

-2.34

0.0

-50

-25

0

25

50

75

100

-50

125

-25

0

25

50

75

100

125

Temperature[°C]

Temperature[°C]

Figure 12. Soft Start Time vs Temperature

Figure 13. SS Charge Current vs Temperature

65

65

60

60

55

Low Side FET ON Resistance : RONL[mΩ]

High Side FET ON Resistance : RONH[mΩ]

-1.62

VIN = 3.3V

50

45

40

35

VIN = 5.0V

30

25

20

15

10

-50

-25

0

25

50

75

100

125

VIN = 3.3V

50

45

40

35

30

VIN = 5.0V

25

20

15

10

-50

-25

0

25

50

75

100

125

Temperature[°C]

Temperature[°C]

Figure 14. High Side FET ON Resistance vs Temperature

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

55

9/42

Figure 15. Low Side FET ON Resistance vs Temperature

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Typical Performance Curves – continued

60

VIN = 5.0V

VIN = 5.0V

0.88

55

PGD FET ON Resistance : RPGD[Ω]

PGD Threshold Voltage : VPGDTH[V]

0.90

0.86

0.84

Falling Good

0.82

Rising Fault

0.80

0.78

Falling Fault

0.76

Rising Good

0.74

0.72

0.70

50

45

40

35

30

25

20

15

10

-50

-25

0

25

50

75

100

125

-50

-25

0

25

50

75

100

125

Temperature[°C]

Temperature[°C]

Figure 16. PGD Threshold Voltage vs Temperature

Figure 17. PGD FET ON Resistance vs Temperature

2.0

2.70

VIN = 5.0V

1.8

VUVLO2

2.60

EN Threshold Voltage : VENTH [V]

UVLO Voltage : VUVLO[V]

2.65

2.55

2.50

2.45

2.40

VUVLO1

2.35

VENH

1.6

1.4

1.2

VENL

1.0

0.8

2.30

-50

-25

0

25

50

75

100

125

-50

-25

0

25

50

75

100

125

Temperature[°C]

Temperature[°C]

Figure 18. UVLO Voltage vs Temperature

Figure 19. EN Threshold Voltage vs Temperature

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

10/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Typical Performance Curves – continued

10

SW Current of Over Current Protection : IOCP[A]

6.6

EN Input Current : IEN[µA]

9

8

7

VEN = 5.0V

6

5

4

3

2

VEN = 3.3V

1

0

-50

-25

0

25

50

75

100

125

6.1

5.6

5.1

4.6

4.1

3.6

-50

-25

Temperature[°C]

0.615

0.560

Detection

0.505

0.450

25

50

75

100

125

75

100

125

0.904

0.896

0.888

0.88

0.872

0.864

0.856

-50

-25

0

25

50

75

100

125

Temperature[℃]

Temperature[℃]

Figure 22. Short Circuit Protection Detection Voltage

vs Temperature

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

Output Over Voltage Protection Detection Voltage : VOVP[V]

Short Circuit Protection Detection Voltage : VSCP[V]

Release

0

50

Figure 21 SW Current of Over Current Protection

vs Temperature

0.670

-25

25

Temperature[°C]

Figure 20. EN Input Current vs Temperature

-50

0

Figure 23. Output Over Voltage Protection Detection Voltage

vs Temperature

11/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Function Explanations

1.

Enable Control

The device shutdown can be controlled by the voltage applied to the EN pin. When VEN becomes 2.0V or more, the

internal circuit is activated and the device starts up with soft start. When VEN becomes 0.8V or less, the device will be

shutdown.

VIN

0

t

VEN

VENH

VENL

0

t

VOUT

VOUT×0.93(Typ)

0

t

tSS

t_wait

200µs(Typ)

Figure 24. Enable ON/OFF Timing Chart

2.

Power Good Function

When the FB pin voltage reaches 0.8V(Typ) within ±7%, the PGD pin open drain MOSFET turns OFF and the output

turns high. In addition, when the FB pin voltage reaches outside ±10% of 0.8V(Typ), the PGD pin open drain MOSFET

turns ON and the PGD pin is pulled down with impedance of 30Ω(Typ). It is recommended to use a pull-up resistor of

about 10kΩ to 100kΩ for the power source.

+10%(Typ)

+7%(Typ)

VOUT

-7%(Typ)

-10%(Typ)

PGD

Figure 25. Power Good Timing Chart

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

12/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Function Explanations – continued

3.

External Synchronization Function

By inputting synchronous pulse signal to the MODE/SYNC pin, the switching frequency can be synchronized to

external synchronous pulse signal. When pulse signal is applied at a frequency of 1.8MHz or higher, the external

synchronization operation is started after the falls of the synchronous pulse are detected 7 times.

Input the signal with the synchronization frequency range between 1.8MHz and 2.4MHz and the duty range between

25% and 75%.

Please note that the output voltage fluctuates by about 2% for a moment when switching between the synchronized

operation to external signal and internal CLK frequency.

MODE/SYNC

1

2

3

4

5

6

7

SW

Internal CLK operation

Synchronizing operation

Figure 26. External Synchronization Function Timing Chart

When using the external synchronization function, connect a capacitor of 10pF in parallel to the phase compensation

components (resistor and capacitor) connected to the ITH pin, as a countermeasure against the interference to the

ITH pin of the Error Amplifier output.

7

10pF

ITH

8

MODE/

SYNC

RITH

CITH

Figure 27. Recommended Circuit When Using External Synchronization Function

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

13/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Function Explanations – continued

4.

SLLMTM Control and Forced PWM Control

SLLM TM(Simple Light Load Mode) is a technology that enables the OFF control of switching pulses while operating

with Pulse Width Modulation(PWM) control loop under light load condition. Therefore, it allows the linear operation

without excessive voltage drop or deterioration in transient response during the switching from light load to heavy load

or vice versa.

By utilizing this technology, BD9S300MUF-C operates in PWM mode switching under heavy load condition and

automatically switches to SLLMTM control under light load condition in order to improve the efficiency. By keeping the

MODE/SYNC pin voltage level 0.8V or less, it forces the device to operate with Forced PWM mode. And, by applying

2.0V or more to MODE/SYNC pin, it allows the device to operate with SLLMTM control. As for the Forced PWM mode, it

has lower efficiency compared to SLLMTM control under light load condition. However, since the device operates with a

constant switching frequency under varying load conditions, the countermeasure against noise is relatively easier.

Please note that SLLMTM does not operate adequately when the switching Duty is 50% or more.

Efficiency [%]

① SLLMTM Control

② Forced PWM Control

Output Current IOUT [A]

Figure 28. Efficiency (SLLMTM Control and Forced PWM Control)

① SLLMTM Control

②

VOUT =50mV/div

Forced PWM Control

VOUT =50mV/div

Time=2µs/div

Time=2µs/div

SW=2V/div

SW=2V/div

Figure 29. SW Waveform (SLLMTM Control)

(VIN=5.0V, VOUT=1.8V, IOUT=50mA)

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

Figure 30. SW Waveform (Forced PWM Control)

(VIN=5.0V, VOUT=1.8V, IOUT=1A)

14/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Protection

Short Circuit Protection (SCP)

The Short Circuit Protection block compares the FB pin voltage with the internal reference voltage VREF. When the

FB pin voltage has fallen to 0.56V(Typ) or less and remained there for 1ms(Typ), SCP stops the operation for

14ms(Typ) and subsequently initiates a restart. This protection circuit is effective in preventing damage due to sudden

and unexpected incidents. However, the device should not be used in applications characterized by continuous

operation of the protection circuit (e.g. when a load that significantly exceeds the output current capability of the chip is

connected).

1.

The EN Pin

Short Circuit

Protection

The FB Pin

≤0.56V(Typ)

2.0V or higher

ON

Enabled

≥0.60V(Typ)

0.8V or lower

Short Circuit

Protection Operation

OFF

Disabled

-

OFF

Soft Start

VOUT

SCP Delay Time

1ms (Typ)

0.8V

FB

SCP Delay Time

1ms (Typ)

VSCP : 0.56V(Typ)

SCP OFF

SW

LOW

IOCP

Inductor Current

(Output Load

Current)

Internal

HICCUP

Delay Signal

14ms (Typ)

SCP Reset

Figure 31. Short Circuit Protection (SCP) Timing Chart

2.

Over Current Protection (OCP)

The Over Current Protection function operates by limiting the current that flows through High Side MOSFET at each

cycle of the switching frequency. This protection circuit is effective in preventing damage due to sudden and

unexpected incidents. However, the device should not be used in applications characterized by continuous operation

of the protection circuit (e.g. when a load that significantly exceeds the output current capability of the chip is

connected).

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

15/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Protection – continued

Under Voltage Lockout Protection (UVLO)

It will shutdown the device when the AVIN pin falls to 2.45V(Typ) or lower.

The threshold voltage has a hysteresis of 100mV(Typ).

3.

VIN

VUVLO-HYS

VUVLO2

VUVLO1

0V

t_wait

VOUT

SoftSstart

FB

SW

Normal operation

UVLO

Normal operation

Figure 32. UVLO Timing Chart

4.

Thermal Shutdown

This is the thermal shutdown circuit that prevents heat damage to the IC. Normal operation should always be within

the IC’s power dissipation rating. However, if the rating is exceeded for a continued period, the junction temperature

(Tj) will rise which will activate the TSD circuit[Tj ≥175°C (Typ)] that will turn OFF output MOSFET. When the Tj falls

below the TSD threshold, the circuits are automatically restored to normal operation. Note that the TSD circuit

operates in a situation that exceeds the absolute maximum ratings and therefore, under no circumstances, should the

TSD circuit be used in a set design or for any purpose other than protecting the IC from heat damage.

5.

Over Voltage Protection (OVP)

The device incorporates an over voltage protection circuit to minimize the output voltage overshoot when recovering

from strong load transients or output fault conditions. If the FB pin voltage exceeds Output Over Voltage Protection

Detection Voltage at 0.880V(Typ), the MOSFET on the output stage is turned OFF to prevent the increase in the

output voltage. After the detection, the switching operation resumes if the output decreases and the over voltage state

is released. Output Over Voltage Protection Detection Voltage and release voltage have a hysteresis of 3%.

VOUT

VOVP : 0.880V(Typ)

hys

FB

OVP Release

Threshold

SW

Internal OVP

Signal

Figure 33. OVP Timing Chart

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

16/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Selection of Components Externally Connected

Contact us if not use the recommended constant in the application circuit.

Necessary parameters in designing the power supply are as follows:

Table 1. Application Specification

Parameter

Input Voltage

Output Voltage

Switching Frequency

Inductor Ripple Current

Output Capacitor

Soft Start Time

Maximum Output Current

Symbol

VIN

VOUT

fSW

ΔIL

COUT

tSS

IOUTMAX

Example Value

5.0V

1.2V

2.2MHz(Typ)

0.4A

44μF

4.5ms(Typ)

3A

Application Example

R4

VIN

CIN1

CIN2

Enable

PVIN

PGD

AVIN

BOOT

PGD

MODE/SYNC

EN

C1

SW

VOUT

L1

SS

R100

ITH

R1

R3

COUT2

PGND

FB

AGND

R2

C2

C3

COUT1

Figure 34. Typical Application

1.

Switching Frequency

The switching frequency fSW is fixed at 2.2MHz(Typ) inside the IC.

2.

Selection of Output Voltage Setting

The output voltage value can be set by the feedback resistance ratio.

𝑉𝑂𝑈𝑇 =

VOUT

𝑅1 +𝑅2

𝑅2

× 0.8 [V]

R1

FB

R2

SW Minimum ON Time that BD9S300MUF-C can output

stably in the entire load range is 95ns.

Use this value to calculate the input and output conditions

that satisfy the following equation

0.8V(Typ)

95 [ns] ≤

𝑉𝑂𝑈𝑇

𝑉𝐼𝑁 × 𝑓𝑂𝑆𝐶

Figure 35. Feedback Resistor Circuit

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

17/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Selection of Components Externally Connected – continued

3.

Selection of Input Capacitor

The input capacitor requires a large capacitor value for CIN1 and a small capacitor value for CIN2. Please use ceramic

type capacitor for these capacitors. CIN1 is used to suppress the ripple noise, and CIN2 is used to suppress the switching

noise. These ceramic capacitors are effective by being placed as close as possible to the PVIN pin and the AVIN pin.

Capacitor with value 4.7μF or more for CIN1, and 0.06μF or more for CIN2 are necessary. In addition, the voltage rating for

both capacitors has to be twice the typical input voltage. Set the capacitor value so that it does not fall to its minimum

required value against the capacitor value variances, temperature characteristics, DC bias characteristics, aging

characteristics, and etc. Please use components which are comparatively same with the components used in

“Application Example” on page 22. Moreover, factors like the PCB layout and the position of the capacitor may lead to IC

malfunction. Please refer to “Notes on the PCB layout Design” on page 34 and 35.

4.

Selection of Output LC Filter

In order to supply a continuous current to the load, the DC/DC converter requires an LC filter for smoothing the output

voltage. When an inductor with a higher inductance value is selected, the ripple current flowing through the inductor ΔIL

and the ripple voltage generated in the output voltage are reduced. However, the load transient response characteristic

becomes slow. If an inductor with a lower inductance value is selected, its transient response characteristic is faster.

However, the ripple current flowing through the inductor becomes larger and the ripple voltage in the output voltage

becomes larger, causing a trade-off between the response characteristic and the ripple current and voltage. Here, the

inductance value is selected so that the ripple current component is in the range between 200mA and 1000mA.

VIN

IL

Inductor Saturation Current > IOUTMAX + ∆IL/2

∆IL

Driver

L1

VOUT

Maximum Output Current IOUTMAX

COUT

t

Figure 36. Waveform of Current Through Inductor

Figure 37. Output LC Filter Circuit

Inductor ripple current ΔIL can be represented by the following equation.

∆𝐼𝐿 = 𝑉𝑂𝑈𝑇 × (𝑉𝐼𝑁 − 𝑉𝑂𝑈𝑇 ) × 𝑉

1

𝐼𝑁 ×𝑓𝑆𝑊 ×𝐿1

= 414 [mA]

where

𝑉𝐼𝑁

𝑉𝑂𝑈𝑇

𝐿1

𝑓𝑆𝑊

is the 5.0V

is the 1.2V

is the 1.0µH

is the 2.2MHz (Switching Frequency)

The rated current of the inductor must be larger than the sum of the maximum output current and 1/2 of the inductor

ripple current ΔIL. The output capacitor COUT affects the output ripple voltage characteristics. The output capacitor C OUT

must satisfy the required ripple voltage characteristics.

The output ripple voltage can be represented by the following equation.

1

∆𝑉𝑅𝑃𝐿 = ∆𝐼𝐿 × (𝑅𝐸𝑆𝑅 + 8×𝐶

𝑂𝑈𝑇 ×𝑓𝑆𝑊

) [V]

Where

𝑅𝐸𝑆𝑅

is the Equivalent Series Resistance (ESR) of the output capacitor

The output ripple voltage ΔVRPL can be represented by the following equation.

1

∆𝑉𝑅𝑃𝐿 = 0.414 × (10 + 8×44×2.2) = 4.67 [mV]

where

𝐶𝑂𝑈𝑇

𝑅𝐸𝑆𝑅

is the 44µF

is the 10mΩ

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

18/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Selection of Components Externally Connected – continued

In addition, for the total value of capacitance in the output line COUT(Max), choose a capacitance value less than the

value obtained by the following equation:

𝐶𝑂𝑈𝑇(𝑀𝑎𝑥) <

(𝑡𝑆𝑆(𝑀𝑖𝑛) −200[µs])×(𝐼𝑂𝐶𝑃(𝑀𝑖𝑛) −𝐼𝑆𝑊𝑆𝑇𝐴𝑅𝑇 )

𝑉𝑂𝑈𝑇

[F]

Where:

𝐼𝑆𝑊𝑆𝑇𝐴𝑅𝑇

𝐼𝑂𝐶𝑃(𝑀𝑖𝑛)

𝑡𝑆𝑆(𝑀𝑖𝑛)

𝑉𝑂𝑈𝑇

is the maximum output current during startup

is the minimum OCP operation SW current 3.6A

is the minimum Soft Start Time

is the output voltage

Startup failure may happen if the limits from the above-mentioned are exceeded. Especially if the capacitance value is

extremely large, over current protection may be activated by the inrush current at startup and prevented to turn on the

output. Please confirm this on the actual application. Stable transient response and the loop is dependent to COUT.

Please select after confirming the setting of the phase compensation circuit.

Also, in case of large changing input voltage and output current, select the capacitance accordingly by verifying that the

actual application setup meets the required specification.

5.

Selection of Soft Start Capacitor

Turning the EN pin signal high activates the soft start function. This causes the output voltage to rise gradually while the

current at startup is placed under control. This allows the prevention of output voltage overshoot and inrush current. The

rise time tSS_EXT depends on the value of the capacitor connected to the SS pin. The capacitance value should be set to

0.22μF or less.

VEN

𝑡𝑆𝑆_𝐸𝑋𝑇 =

(𝐶3 ×𝑉𝐹𝐵 )

𝐼𝑆𝑆

[s]

VENH

VENL

0

t

where

𝑡𝑆𝑆_𝐸𝑋𝑇

𝐶3

𝑉𝐹𝐵

𝐼𝑆𝑆

is the Soft Start Time

VOUT

is the Capacitor connected to the SS pin

is the FB pin Voltage 0.8V(Typ)

is the SS Charge Current 1.8µA(Typ)

0

With C3=0.01μF

𝑡𝑆𝑆_𝐸𝑋𝑇 =

t

tSS_EXT

t_wait

200µs(Typ)

(0.010×0.8)

1.8

= 4.44 [ms]

Figure 38. Soft Start Timing chart

Turning the EN pin High without connecting capacitor to the SS pin and keeping the SS pin either OPEN condition or

about 10kΩ to 100kΩ pull up condition to power source, the output will rise in 1ms(Typ).

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

19/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Selection of Components Externally Connected – continued

6.

Selection of Phase Compensation Components

A current mode control buck DC/DC converter is two-pole, one-zero system. Two poles are formed by an error amplifier

and load, and the one zero point is added by phase compensation. The phase compensation resistor R 3 determines the

crossover frequency fCRS that the total loop gain of the DC/DC converter is 0dB.The crossover frequency should be set

20kHz to 100kHz. A high value fCRS provides a good load transient response characteristic but instability. Conversely, a

low value fCRS greatly stabilizes the characteristics but the load transient response characteristic is impaired.

(1) Selection of Phase Compensation Resistor R3

The Phase Compensation Resistance R3 can be determined by using the following equation.

𝑅3 =

2𝜋×𝑉𝑂𝑈𝑇 ×𝑓𝐶𝑅𝑆 ×𝐶𝑂𝑈𝑇

𝑉𝐹𝐵 ×𝐺𝑀𝑃 ×𝐺𝑀𝐴

[Ω]

where

𝑉𝑂𝑈𝑇

𝑓𝐶𝑅𝑆

𝐶𝑂𝑈𝑇

𝑉𝐹𝐵

𝐺𝑀𝑃

𝐺𝑀𝐴

is the Output Voltage

is the Crossover Frequency

is the Output Capacitance

is the Feedback Reference Voltage 0.8V(Typ)

is the Current Sense Gain 14.3A/V(Typ)

is the Error Amplifier Trans conductance 260µA/V(Typ)

(2) Selection of Phase Compensation Capacitance C2

For stable operations of DC/DC converter, the zero point (phase lead) to cancel the phase lag formed by loads is

determined with C2.

C2 can be calculated with the following equation.

𝐶2 =

1

2𝜋×𝑓𝐶𝑅𝑆 ×

1

×𝑉𝑂𝑈𝑇

0.003

[F]

(3) Loop Stability

Actually, characteristics will vary depending on PCB layout, arrangement of wiring, kinds of parts used and use

conditions (temperature, etc.). Be sure to check stability and responsiveness with actual apparatus. Phase margin of at

least 45° in the worst conditions is recommended. Gain Phase Analyzer or Frequency Response Analyzer FRA is used

to check frequency characteristics with actual apparatus. Contact the measurement apparatus manufacturer for

measurement method. When these measurement apparatuses are not available, there is a method of assuming Phase

margin by load response. Monitor variation of output when the apparatus shifts from no load state to maximum load. And

it can be said that responsiveness is low if variation amount is large, and phase margin is small if ringing occurs

frequently (twice or more as a guide) after variation.

However, confirmation of quantitative phase margin is not possible.

Maximum load

Load

IOUT

Inadequate phase margin

Output voltage

VOUT

Adequate phase margin

0

t

Figure 39. Load Response

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

20/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Selection of Components Externally Connected – continued

7.

Input Voltage Startup

VIN

VIN ×0.8 ≥ VOUT

VOUT

UVLO release

Figure 40. Input Voltage Startup Time

The soft start function starts up the device according to the specified soft start time. After UVLO is released, the voltage

range that can be outputted during the soft start operation is 80% or less of the input voltage. Note that the input voltage

during the startup with soft start should satisfy the following expression

𝑉𝐼𝑁 ≥

8.

𝑉𝑂𝑈𝑇

0.8

[V]

Bootstrap Capacitor

Bootstrap capacitor C1 shall be 0.1μF. Connect a bootstrap capacitor between the SW pin and the BOOT pin.

For capacitance of bootstrap capacitor, take temperature characteristics, DC bias characteristics and etc. into

consideration to set minimum value to no less than 0.047μF.

Recommended Parts Manufacturer List

Shown below is the list of the recommended parts manufacturers for reference.

Table 2.

Device

Type

Manufacturer

C

Ceramic capacitors

Murata

www.murata.com

C

Ceramic capacitors

TDK

product.tdk.com

L

Inductors

Coilcraft

www.coilcraft.com

L

Inductors

Cyntec

www.cyntec.com

L

Inductors

Murata

www.murata.com

L

Inductors

Sumida

www.sumida.com

L

Inductors

TDK

R

Resisters

ROHM

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

21/42

URL

www.product.tdk.com

www.rohm.com

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Application Example 1

Table 3. Specification Example 1

Parameter

Product Name

Supply Voltage

Output Voltage

Soft Start Time

Maximum Output Current

Operation Temperature Range

Symbol

IC

VIN

VOUT

tSS

IOUTMAX

Topr

Example Value

BD9S300MUF-C

3.3V

1.0V

1.0ms(Typ)

3.0A

-40°C to +125°C

R4

VIN

CIN1

PVIN

PGD

AVIN

BOOT

PGD

MODE/SYNC

CIN2

Enable

EN

C1

SW

VOUT

L1

SS

R100

ITH

C4

PGND

R3

COUT1

COUT2

FB

AGND

R2

C2

C3

R1

Figure 41. Reference Circuit 1

Table 4. Parts List 1

No

Package

L1

Parameters

Part Name(Series)

Type

Manufacturer

1.0μH

CLF5030NIT-1R0N-D

Inductor

TDK

COUT1

3216

22μF, X7R, 6.3V

GCM31CR70J226K

Ceramic Capacitor

Murata

COUT2

3216

22μF, X7R, 6.3V

GCM31CR70J226K

Ceramic Capacitor

Murata

CIN1

2012

10μF, X7R, 10V

GCM21BR71A106K

Ceramic Capacitor

Murata

CIN2

1005

0.1μF, X7R, 16V

GCM155R71C104K

Ceramic Capacitor

Murata

R100

-

SHORT

-

-

-

R1

1005

7.5kΩ, 1%, 1/16W

MCR01MZPF7501

Chip Resistor

ROHM

R2

1005

30kΩ, 1%, 1/16W

MCR01MZPF3002

Chip Resistor

ROHM

R3

1005

8.2kΩ, 1%, 1/16W

MCR01MZPF8201

Chip Resistor

ROHM

R4

1005

100kΩ, 1%, 1/16W

MCR01MZPF1003

Chip Resistor

ROHM

C1

1005

0.1μF, X7R, 16V

GCM155R71C104K

Ceramic Capacitor

Murata

C2

1005

4700pF, X7R, 50V

GCM155R71H472K

Ceramic Capacitor

Murata

C3

-

-

-

-

-

C4

-

-

-

-

-

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

22/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Characteristic Data (Application Examples 1)

100

90

80

180

60

135

40

90

20

45

0

0

60

Gain[dB]

Efficiency [%]

70

50

40

-20

-45

30

Gain

-40

20

Phase[deg]

80

-90

Phase

-60

10

0

0.0

0.5

1.0

1.5

2.0

Output Current [A]

2.5

-135

-80

3.0

0.1

Figure 42. Efficiency vs Output Current

1

10

100

Frequency[kHz]

-180

1000

Figure 43. Frequency Characteristics

(IOUT=2A)

Time: 500ns/div

Time: 100μs/div

VOUT: 20mV/div

VOUT: 100mV/div

IOUT: 500mA/div

IOUT: 1A/div

Figure 44. Load Transient Response

(IOUT=0A↔2A)

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

Figure 45. Output Ripple Voltage

(IOUT=2A)

23/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Application Example 2

Table 5. Specification Example 2

Parameter

Product Name

Supply Voltage

Output Voltage

Soft Start Time

Maximum Output Current

Operation Temperature Range

Output Capacitor

Symbol

IC

VIN

VOUT

tSS

IOUTMAX

Topr

COUT

Example Value

BD9S300MUF-C

3.3V

1.0V

1.0ms(Typ)

3.0A

-40°C to +125°C

88μF

R4

VIN

CIN1

PVIN

PGD

AVIN

BOOT

MODE/SYNC

CIN2

Enable

EN

PGD

C1

SW

VOUT

L1

SS

R100

COUT1 COUT2 COUT3 COUT4

ITH

C4

PGND

R3

FB

AGND

R2

C2

C3

R1

Figure 46. Reference Circuit 2

Table 6. Parts List 2

No

Package

L1

Parameters

Part Name(Series)

Type

Manufacturer

0.47μH

XEL4030-471ME

Inductor

Coilcraft

COUT1

3216

22μF, X7R, 6.3V

GCM31CR70J226K

Ceramic Capacitor

Murata

COUT2

3216

22μF, X7R, 6.3V

GCM31CR70J226K

Ceramic Capacitor

Murata

COUT3

3216

22μF, X7R, 6.3V

GCM31CR70J226K

Ceramic Capacitor

Murata

COUT4

3216

22μF, X7R, 6.3V

GCM31CR70J226K

Ceramic Capacitor

Murata

CIN1

2012

10μF, X7R, 10V

GCM21BR71A106K

Ceramic Capacitor

Murata

CIN2

1005

0.1μF, X7R, 16V

GCM155R71C104K

Ceramic Capacitor

Murata

R100

-

SHORT

-

-

-

R1

1005

7.5kΩ, 1%, 1/16W

MCR01MZPF7501

Chip Resistor

ROHM

R2

1005

30kΩ, 1%, 1/16W

MCR01MZPF3002

Chip Resistor

ROHM

R3

1005

30kΩ, 1%, 1/16W

MCR01MZPF3002

Chip Resistor

ROHM

R4

1005

100kΩ, 1%, 1/16W

MCR01MZPF1003

Chip Resistor

ROHM

C1

1005

0.1μF, X7R, 16V

GCM155R71C104K

Ceramic Capacitor

Murata

C2

1005

1000pF, X7R, 50V

GCM155R71H102K

Ceramic Capacitor

Murata

C3

-

-

-

-

-

C4

-

-

-

-

-

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

24/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Characteristic Data (Application Examples 2)

100

80

180

90

60

135

40

90

20

45

0

0

80

50

40

-20

Phase[deg]

60

Gain[dB]

Efficiency [%]

70

-45

30

Gain

-40

-90

Phase

20

-60

10

-135

-80

0

0.0

0.5

1.0

1.5

2.0

2.5

3.0

0.1

Output Current [A]

Figure 47. Efficiency vs Output Current

1

10

100

Frequency[kHz]

-180

1000

Figure 48. Frequency Characteristic

(IOUT=2A)

Time: 500ns/div

Time: 100μs/div

VOUT: 20mV/div

VOUT: 100mV/div

IOUT: 500mA/div

IOUT: 1A/div

Figure 49. Load Transient Response

(IOUT=0A↔2A)

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

Figure 50. Output Ripple Voltage

(IOUT=2A)

25/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Application Example 3

Table 7. Specification Example 3

Parameter

Product Name

Supply Voltage

Output Voltage

Soft Start Time

Maximum Output Current

Operation Temperature Range

Symbol

IC

VIN

VOUT

tSS

IOUTMAX

Topr

Example Value

BD9S300MUF-C

5.0V

1.2V

1.0ms(Typ)

3.0A

-40°C to +125°C

R4

VIN

CIN1

PVIN

PGD

AVIN

BOOT

PGD

MODE/SYNC

CIN2

Enable

EN

C1

SW

VOUT

L1

SS

R100

ITH

C4

PGND

R3

COUT1

COUT2

FB

AGND

R2

C2

C3

R1

Figure 51. Reference Circuit 3

Table 8. Parts List 3

No

Package

Parameters

Part Name(Series)

Type

Manufacturer

L1

COUT1

1.0μH

CLF5030NIT-1R0N-D

Inductor

TDK

3216

22μF, X7R, 6.3V

GCM31CR70J226K

Ceramic Capacitor

Murata

COUT2

3216

22μF, X7R, 6.3V

GCM31CR70J226K

Ceramic Capacitor

Murata

CIN1

2012

10μF, X7R, 10V

GCM21BR71A106K

Ceramic Capacitor

Murata

Murata

CIN2

1005

0.1μF, X7R, 16V

GCM155R71C104K

Ceramic Capacitor

R100

-

SHORT

-

-

-

R1

1005

10kΩ, 1%, 1/16W

MCR01MZPF1002

Chip Resistor

ROHM

R2

1005

20kΩ, 1%, 1/16W

MCR01MZPF2002

Chip Resistor

ROHM

R3

1005

8.2kΩ, 1%, 1/16W

MCR01MZPF8201

Chip Resistor

ROHM

R4

1005

100kΩ, 1%, 1/16W

MCR01MZPF1003

Chip Resistor

ROHM

Murata

C1

1005

0.1μF, X7R, 16V

GCM155R71C104K

Ceramic Capacitor

C2

1005

4700pF, X7R, 50V

GCM155R71H472K

Ceramic Capacitor

Murata

C3

-

-

-

-

-

C4

-

-

-

-

-

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

26/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Characteristic Data (Application Examples 3)

100

90

80

180

60

135

40

90

20

45

Efficiency [%]

70

Gain[dB]

60

50

40

0

0

-20

-45

30

Gain

-40

20

Phase[deg]

80

-90

Phase

-60

10

0

0.0

0.5

1.0

1.5

2.0

2.5

-135

-80

3.0

0.1

1.0

Output Current [A]

Figure 52. Efficiency vs Output Current

10.0

100.0

Frequency[kHz]

-180

1000.0

Figure 53. Frequency Characteristics

(IOUT=2A)

Time: 500ns/div

Time: 100μs/div

VOUT: 20mV/div

VOUT: 100mV/div

IOUT: 500mA/div

IOUT: 1A/div

Figure 54. Load Transient Response

(IOUT=0A↔2A)

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

Figure 55. Output Ripple Voltage

(IOUT=2A)

27/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Application Example 4

Table 9. Specification Example 4

Parameter

Product Name

Supply Voltage

Output Voltage

Soft Start Time

Maximum Output Current

Operation Temperature Range

Symbol

IC

VIN

VOUT

tSS

IOUTMAX

Topr

Example Value

BD9S300MUF-C

5.0V

1.5V

1.0ms(Typ)

3.0A

-40°C to +125°C

R4

VIN

CIN1

PVIN

PGD

AVIN

BOOT

PGD

MODE/SYNC

CIN2

Enable

EN

C1

SW

VOUT

L1

SS

R100

ITH

C4

PGND

R3

COUT1

COUT2

FB

AGND

R2

C2

C3

R1

Figure 56. Reference Circuit 4

Table 10. Parts List 4

No

Package

L1

Parameters

Part Name(Series)

Type

Manufacturer

1.0μH

CLF5030NIT-1R0N-D

Inductor

TDK

COUT1

3216

22μF, X7R, 6.3V

GCM31CR70J226K

Ceramic Capacitor

Murata

COUT2

3216

22μF, X7R, 6.3V

GCM31CR70J226K

Ceramic Capacitor

Murata

CIN1

2012

10μF, X7R, 10V

GCM21BR71A106K

Ceramic Capacitor

Murata

CIN2

1005

0.1μF, X7R, 16V

GCM155R71C104K

Ceramic Capacitor

Murata

R100

-

SHORT

-

-

-

R1

1005

16kΩ, 1%, 1/16W

MCR01MZPF1602

Chip Resistor

ROHM

R2

1005

18kΩ, 1%, 1/16W

MCR01MZPF1802

Chip Resistor

ROHM

R3

1005

12kΩ, 1%, 1/16W

MCR01MZPF1202

Chip Resistor

ROHM

R4

1005

100kΩ, 1%, 1/16W

MCR01MZPF1003

Chip Resistor

ROHM

C1

1005

0.1μF, X7R, 16V

GCM155R71C104K

Ceramic Capacitor

Murata

C2

1005

3300pF, X7R, 50V

GCM155R71H332K

Ceramic Capacitor

Murata

C3

-

-

-

-

-

C4

-

-

-

-

-

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

28/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Characteristic Data (Application Examples 4)

100

80

180

90

60

135

40

90

20

45

0

0

80

50

40

-20

Phase[deg]

60

Gain[dB]

Efficiency [%]

70

-45

30

Gain

-40

20

-90

Phase

-60

10

0

0.0

0.5

1.0

1.5

2.0

Output Current(A)

2.5

-135

-80

3.0

0.1

1

10

100

-180

1000

Frequency[kHz]

Figure 57. Efficiency vs Output Current

Figure 58. Frequency Characteristics

(IOUT =2A)

Time: 100μs/div

Time: 500ns/div

VOUT: 100mV/div

VOUT: 20mV/div

IOUT: 500mA/div

IOUT: 1A/div

Figure 59. Load Transient Response

(IOUT = 0A↔2A)

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

Figure 60. Output Ripple Voltage

(IOUT=2A)

29/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Application Example 5

Table 11. Specification Example 5

Parameter

Product Name

Supply Voltage

Output Voltage

Soft Start Time

Maximum Output Current

Operation Temperature Range

Symbol

IC

VIN

VOUT

tSS

IOUTMAX

Topr

Example Value

BD9S300MUF-C

5.0V

1.8V

1.0ms(Typ)

3.0A

-40°C to +125°C

R4

VIN

CIN1

PVIN

PGD

AVIN

BOOT

PGD

MODE/SYNC

CIN2

Enable

EN

C1

SW

VOUT

L1

SS

R100

ITH

C4

PGND

R3

COUT1

COUT2

FB

AGND

R2

C2

C3

R1

Figure 61. Reference Circuit 5

Table 12. Parts List 5

No

Package

L1

Parameters

Part Name(Series)

Type

Manufacturer

1.0μH

CLF5030NIT-1R0N-D

Inductor

TDK

COUT1

3216

22μF, X7R, 6.3V

GCM31CR70J226K

Ceramic Capacitor

Murata

COUT2

3216

22μF, X7R, 6.3V

GCM31CR70J226K

Ceramic Capacitor

Murata

CIN1

2012

10μF, X7R, 10V

GCM21BR71A106K

Ceramic Capacitor

Murata

CIN2

1005

0.1μF, X7R, 16V

GCM155R71C104K

Ceramic Capacitor

Murata

R100

-

SHORT

-

-

-

R1

1005

30kΩ, 1%, 1/16W

MCR01MZPF3002

Chip Resistor

ROHM

R2

1005

24kΩ, 1%, 1/16W

MCR01MZPF2402

Chip Resistor

ROHM

R3

1005

13kΩ, 1%, 1/16W

MCR01MZPF1302

Chip Resistor

ROHM

R4

1005

100kΩ, 1%, 1/16W

MCR01MZPF1003

Chip Resistor

ROHM

C1

1005

0.1μF, X7R, 16V

GCM155R71C104K

Ceramic Capacitor

Murata

C2

1005

3300pF, X7R, 50V

GCM155R71H332K

Ceramic Capacitor

Murata

C3

-

-

-

-

-

C4

-

-

-

-

-

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

30/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Characteristic Data (Application Examples 5)

100

90

80

180

60

135

40

90

20

45

0

0

60

Gain[dB]

Efficiency [%]

70

50

40

-20

-45

30

Phase[deg]

80

Gain

-40

20

10

-90

Phase

-60

0

0.0

0.5

1.0

1.5

2.0

2.5

-135

-80

3.0

0.1

1

Output Current (A)

Figure 62. Efficiency vs Output Current

10

100

Frequency[kHz]

-180

1000

Figure 63. Frequency Characteristics

(IOUT=2A)

Time: 100μs/div

Time: 500ns/div

VOUT: 100mV/div

VOUT: 20mV/div

IOUT: 500mA/div

IOUT: 1A/div

Figure 64. Load Transient Response

(IOUT=0A↔2A)

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

Figure 65. Output Ripple Voltage

(IOUT=2A)

31/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Application Example 6

Table 13. Specification Example 6

Parameter

Product Name

Supply Voltage

Output Voltage

Soft Start Time

Maximum Output Current

Operation Temperature Range

Symbol

IC

VIN

VOUT

tSS

IOUTMAX

Topr

Example Value

BD9S300MUF-C

5.0V

3.3V

1.0ms(Typ)

3.0A

-40°C to +125°C

R4

VIN

CIN1

PVIN

PGD

AVIN

BOOT

PGD

MODE/SYNC

CIN2

Enable

EN

C1

SW

VOUT

L1

SS

R100

ITH

C4

PGND

R3

COUT1

COUT2

FB

AGND

R2

C2

C3

R1

Figure 66. Reference Circuit 6

Table 14. Parts List 6

No

Package

Parameters

Part Name(Series)

Type

Manufacturer

L1

COUT1

1.0μH

CLF5030NIT-1R0N-D

Inductor

TDK

3216

22μF, X7R, 6.3V

GCM31CR70J226K

Ceramic Capacitor

Murata

COUT2

3216

22μF, X7R, 6.3V

GCM31CR70J226K

Ceramic Capacitor

Murata

CIN1

2012

10μF, X7R, 10V

GCM21BR71A106K

Ceramic Capacitor

Murata

CIN2

1005

0.1μF, X7R, 16V

GCM155R71C104K

Ceramic Capacitor

Murata

R100

-

SHORT

-

-

-

R1

1005

75kΩ, 1%, 1/16W

MCR01MZPF7502

Chip Resistor

ROHM

R2

1005

24kΩ, 1%, 1/16W

MCR01MZPF2402

Chip Resistor

ROHM

R3

1005

20kΩ, 1%, 1/16W

MCR01MZPF2002

Chip Resistor

ROHM

R4

1005

100kΩ, 1%, 1/16W

MCR01MZPF1003

Chip Resistor

ROHM

C1

1005

0.1μF, X7R, 16V

GCM155R71C104K

Ceramic Capacitor

Murata

C2

1005

2200pF, X7R, 50V

GCM155R71H222K

Ceramic Capacitor

Murata

C3

-

-

-

-

-

C4

-

-

-

-

-

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

32/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Characteristic Data (Application Examples 6)

100

90

80

180

60

135

40

90

20

45

0

0

60

Gain[dB]

Efficiency [%]

70

50

40

-20

-45

30

Gain

-40

-90

Phase

20

-60

10

0

-135

-80

0.0

0.5

1.0

1.5

2.0

2.5

3.0

Phase[deg]

80

0.1

1

10

100

-180

1000

Frequency[kHz]

Output Current [A]

Figure 67. Efficiency vs Output Current

Figure 68. Frequency Characteristics

(IOUT=2A)

Time: 100μs/div

Time: 500ns/div

VOUT: 100mV/div

VOUT: 20mV/div

IOUT: 500mA/div

IOUT: 1A/div

Figure 69. Load Transient Response

(IOUT=0A↔2A)

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

Figure 70. Output Ripple Voltage

(IOUT=2A)

33/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

PCB Layout Design

PCB layout design for DC/DC converter is as important as the circuit design. Appropriate layout can avoid various problems

concerning power supply circuit. Figure 71-a to 71-c show the current path in a buck DC/DC converter circuit. The Loop 1 in

Figure 71-a is a current path when H-side switch is ON and L-side switch is OFF, the Loop 2 in Figure 71-b is when H-side

switch is OFF and L-side switch is ON. The thick line in Figure 71-c shows the difference between Loop1 and Loop2. The

current in thick line change sharply each time the switching element H-side and L-side switch change from OFF to ON, and

vice versa. These sharp changes induce a waveform with harmonics in this loop. Therefore, the loop area of thick line that is

consisted by input capacitor and IC should be as small as possible to minimize noise. For more details, refer to application

note of switching regulator series “PCB Layout Techniques of Buck Converter”.

Loop1

VIN

H-side Switch

VOUT

L

CIN

COUT

L-side Switch

GND

GND

Figure 71-a. Current Path when H-side Switch = ON, L-side Switch = OFF

VIN

VOUT

L

H-side Switch

CIN

COUT

Loop2

L-side Switch

GND

GND

Figure 71-b. Current Path when H-side Switch = OFF, L-side Switch = ON

VIN

VOUT

L

CIN

COUT

H-side FET

L-side FET

GND

GND

Figure 71-c. Difference of Current and Critical Area in Layout

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

34/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

PCB Layout Design – continued

When designing the PCB layout, please pay extra attention to the following points:

• Connect the input capacitor as close as possible to the PVIN pin on the same plane as the IC.

• Switching nodes such as SW are susceptible to noise due to AC coupling with other nodes. Route the inductor pattern as

thick and as short as possible.

• R1 and R2 shall be located as close as possible to the FB pin and the wiring between R1 and R2 to the FB pin shall be as

short as possible.

• Provide lines connected to FB and ITH far from the SW nodes.

• When using the external synchronization function, there is concern that the ITH node might be affected by noise.

Therefore, place the ITH node as far as possible from the external clock input node.

• Influence from the switching noise can be minimized, by isolating Power (Input and Output Capacitor) GND and

Reference (FB, ITH) GND.

• R100 is provided for the measurement of feedback frequency characteristics (optional). By inserting a resistor into R100, it

is possible to measure the frequency characteristics of feedback (phase margin) using FRA etc. R100 is short-circuited

for normal use.

C1

L1

CIN1

CIN2

IC

C3

COU T1

R2

R1

C4

R3

COU T2

C2

R100

Example of Evaluation Board Layout (Top View)

Example of Evaluation Board Layout (Bottom View)

Figure 72. Example of Evaluation Board Layout

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

35/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Power Dissipation

For thermal design, be sure to operate the IC within the following conditions.

(Since the temperatures described hereunder are all guaranteed temperatures, take margin into account.)

1.

2.

The ambient temperature Ta is to be 125 °C or less.

The chip junction temperature Tj is to be 150 °C or less.

The chip junction temperature Tj can be considered in the following two patterns:

1.

To obtain Tj from the package surface center temperature Tt in actual use

𝑇𝑗 = 𝑇𝑡 + 𝜓𝐽𝑇 × 𝑊 [°C]

2.

To obtain Tj from the ambient temperature Ta

𝑇𝑗 = 𝑇𝑎 + 𝜃𝐽𝐴 × 𝑊 [°C]

Where:

𝜓𝐽𝑇

𝜃𝐽𝐴

is junction to top characterization parameter (Refer to page 5)

is junction to ambient (Refer to page 5)

The heat loss W of the IC can be obtained by the formula shown below:

𝑉𝑂𝑈𝑇

𝑉𝑂𝑈𝑇

+ 𝑅𝑂𝑁𝐿 × 𝐼𝑂𝑈𝑇 2 (1 −

)

𝑉𝐼𝑁

𝑉𝐼𝑁

1

+𝑉𝐼𝑁 × 𝐼𝐶𝐶 + 2 × (𝑡𝑟 + 𝑡𝑓) × 𝑉𝐼𝑁 × 𝐼𝑂𝑈𝑇 × 𝑓𝑆𝑊 [W]

𝑊 = 𝑅𝑂𝑁𝐻 × 𝐼𝑂𝑈𝑇 2 ×

Where:

𝑅𝑂𝑁𝐻

𝑅𝑂𝑁𝐿

𝐼𝑂𝑈𝑇

𝑉𝑂𝑈𝑇

𝑉𝐼𝑁

𝐼𝐶𝐶

𝑡𝑟

𝑡𝑓

𝑓𝑆𝑊

is the High Side FET ON Resistance (Refer to page 6) [Ω]

is the Low Side FET ON Resistance (Refer to page 6) [Ω]

is the Output Current [A]

is the Output Voltage [V]

is the Input Voltage [V]

is the Circuit Current (Refer to page 6) [A]

is the Switching Rise Time [s] (Typ:6ns)

is the Switching Fall Time [s] (Typ:6ns)

is the Switching Frequency (Refer to page 6) [Hz]

1.

𝑅𝑂𝑁𝐻 × 𝐼𝑂𝑈𝑇 2

2.

𝑅𝑂𝑁𝐿 × 𝐼𝑂𝑈𝑇 2

3.

1

2

× (𝑡𝑟 + 𝑡𝑓) × 𝑉𝐼𝑁 × 𝐼𝑂 × 𝑓𝑆𝑊

Figure 73. SW Waveform

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

36/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

I/O Equivalent Circuits

6. FB

7. ITH

20kΩ

10kΩ

FB

AVIN

AGND

10kΩ

ITH

AGND

40Ω

5kΩ

10kΩ

10kΩ

AGND

8. MODE/SYNC

AGND

AGND

9. SS

20kΩ

150kΩ

MODE /

SYNC

AVIN

AGND

SS

1kΩ

350kΩ

80kΩ

1kΩ

10kΩ

AGND

AGND

AGND

AGND

10.11.12. SW, 13. BOOT

AGND

AGND

14. PGD

PVIN

BOOT

PGD

PVIN

25Ω

SW

PVIN

AGND

AGND

PGND

15. EN

EN

430kΩ

10kΩ

570kΩ

AGND

www.rohm.com

© 2017 ROHM Co., Ltd. All rights reserved.

TSZ22111 • 15 • 001

AGND

AGND

37/42

TSZ02201-0J1J0AL01360-1-2

27.Nov.2017 Rev.001

�BD9S300MUF-C

Operational Notes

1.

Reverse Connection of Power Supply

Connecting the power supply in reverse polarity can damage the IC. Take precautions against reverse polarity when

connecting the power supply, such as mounting an external diode between the power supply and the IC’s power

supply pins.

2.

Power Supply Lines

Design the PCB layout pattern to provide low impedance supply lines. Furthermore, connect a capacitor to ground at

all power supply pins. Consider the effect of temperature and aging on the capacitance value when using electrolytic

capacitors.

3.

Ground Voltage

Ensure that no pins are at a voltage below that of the ground pin at any time, even during transient condition. However,

pins that drive inductive loads (e.g. motor driver outputs, DC-DC converter outputs) may inevitably go below ground

due to back EMF or electromotive force. In such cases, the user should make sure that such voltages going below

ground will not cause the IC and the system to malfunction by examining carefully all relevant factors and conditions

such as motor characteristics, supply voltage, operating frequency and PCB wiring to name a few.

4.

Ground Wiring Pattern

When using both small-signal and large-current ground traces, the two ground traces should be routed separately but

connected to a single ground at the reference point of the application board to avoid fluctuations in the small-signal

ground caused by large currents. Also ensure that the ground traces of external components do not cause variations

on the ground voltage. The ground lines must be as short and thick as possible to reduce line impedance.

5.

Recommended Operating Conditions

The function and operation of the IC are guaranteed within the range specified by the recommended operating

conditions. The characteristic values are guaranteed only under the conditions of each item specified by the electrical

characteristics.

6.

Inrush Current

When power is first supplied to the IC, it is possible that the internal logic may be unstable and inrush current may flow

instantaneously due to the internal powering sequence and delays, especially if the IC has more than one power

supply. Therefore, give special consideration to power coupling capacitance, power wiring, width of ground wiring, and

routing of connections.

7.

Testing on Application Boards

When testing the IC on an application board, connecting a capacitor directly to a low-impedance output pin may

subject the IC to stress. Always discharge capacitors completely after each process or step. The IC’s power supply

should always be turned off completely before connecting or removing it from the test setup during the inspection

process. To prevent damage from static discharge, ground the IC during assembly and use similar precautions during

transport and storage.

8.

Inter-pin Short and Mounting Errors

Ensure that the direction and position are correct when mounting the IC on the PCB. Incorrect mounting may result in

damaging the IC. Avoid nearby pins being shorted to each other especially to ground, power supply and output pin.

Inter-pin shorts could be due to many reasons such as metal particles, water droplets (in very humid environment) and

unintentional solder bridge deposited in between pins during assembly to name a few.

9.

Unused Input Pins

Input pins of an IC are often connected to the gate of a MOS transistor. The gate has extremely high impedance and

extremely low capacitance. If left unconnected, the electric field from the outside can easily charge it. The small

charge acquired in this way is enough to produce a significant effect on the conduction through the transistor and