Data Sheet

AS3977

M u l t i - C h a n n e l N a r r o w b a n d F S K Tr a n s m i t t e r

1 General Description

The AS3977 is a low-power fully integrated ETSI, FCC and ARIB

compliant FSK transmitter capable of operating at any ISM

frequency in the range of 300 to 928 MHz. It is based on a sigmadelta controlled fractional-N synthesizer phase locked loop (PLL)

with fully integrated voltage controlled oscillator (VCO). The power

amplifier (PA) output is programmable and can deliver power ranging

from –20dBm up to +10dBm. An on-chip low drop-out (LDO)

regulator is available in case an accurate output power independent

of voltage supply variation is required. The output signal can be

shaped using a programmable Gaussian filter to minimize the

occupied bandwidth and adjacent channel power. The maximum

data rate can be up to 100 kb/s – depending on the required filtering.

The FSK frequency deviation is programmable up to a maximum of

64 kHz.

The crystal oscillator can handle a wide range of frequencies. For

narrow-band applications, a temperature sensor with digital read-out

is included that allows compensation of the crystal frequency drift

due to temperature variation.

The AS3977 is connected to an external microcontroller via a bidirectional digital interface. The device operates at very low current

consumption with a power supply range from 2.0V to 3.6V and can

be powered down when not in use.

Main Characteristics

2.0 – 3.6V power supply

Power down current consumption 100 nA (3V, 25ºC)

Output power up to +10dBm

Occupied bandwidth 6 kHz (4.8 kb/s, FFSK, ARIB)

-40 to 85ºC temperature range

Additional Features

Sigma-Delta controlled fractional-N synthesizer

Resolution of synthesizer < 100Hz

Fully integrated PLL

Fully integrated voltage controlled oscillator (VCO)

4kV ESD protection (1.5kV for the Analog pins)

12 – 20 MHz crystal oscillator

On-chip temperature sensor with digital readout for AFC purposes

Fast frequency hopping with predefined channel selection

The device is fabricated in austriamicroystems advanced 0.35µm

SiGe-BiCMOS technology.

Microcontroller clock output to save addition crystal

2 Key Features

Integrated Manchester coder

Constant output power over battery life time

Digital lock detector

Fully integrated UHF transmitter

Low drop-out regulator

Compliant to ETSI EN 300-220, FCC CFR47 part 15 and ARIB

STD-T67

Bi-directional serial interface

Multi-channel with narrow bandwidth

300 – 928 MHz operating frequency range (ISM)

Filtered FSK

Data rate up to 100 kb/s

FSK deviation programmable up to 64kHz

Extremely low power consumption

www.austriamicrosystems.com/AS3977

Low Power Down Mode current consumption

3 Applications

The AS3977 is suitable for Remote keyless entry systems, Short

range radio data transmission, Domestic and consumer remote

control units, Cordless alarm systems, Remote metering, and Low

power telemetry.

Revision 3.6

1 - 47

�AS3977

Data Sheet - A p p l i c a t i o n s

Figure 1. AS3977 Block Diagram

VCCPLL

Phase

detector

XTAL IN

ΔΦ

÷4

XTAL OUT

Charge

pump

VCC PA

Loop

filter

÷

P

ΣΔ

÷T

RFchannel

Data

sync.

SDI interface/ Control Interface

DATA I/O

CLOCK

ENABLE

VREGDIG

U

VREGRF

Driving

amplifier

Pre Out

PA Out

RF Band

Synthesizer

RF-power

Temp

RF-power

RF-band

RFchannel

LPR

GND

www.austriamicrosystems.com/AS3977

Pre

Amplifier

÷N

Deviation

U

VCO

±Q

CLK Gen

Baudrate Gen.

MC CLK

VDD

VSS

GND exposed paddle

Revision 3.6

2 - 47

�AS3977

Data Sheet - C o n t e n t s

Contents

1 General Description ..................................................................................................................................................................

1

2 Key Features.............................................................................................................................................................................

1

3 Applications...............................................................................................................................................................................

1

4 Pin Assignments .......................................................................................................................................................................

5

4.1 Pin Descriptions....................................................................................................................................................................................

5

5 Absolute Maximum Ratings ......................................................................................................................................................

7

6 Electrical Characteristics...........................................................................................................................................................

8

7 Timing Characteristics ............................................................................................................................................................

15

7.1 Timing Parameters .............................................................................................................................................................................

8 Detailed System Description...................................................................................................................................................

16

17

8.1 Reference Frequency Generator........................................................................................................................................................

17

8.2 Phase Locked Loop............................................................................................................................................................................

17

8.3 Gaussian Filter and Digital Modulator ................................................................................................................................................

17

8.4 Power Amplifier ..................................................................................................................................................................................

17

8.5 Temperature Sensor ...........................................................................................................................................................................

17

8.6 Low Power Reset ...............................................................................................................................................................................

17

8.7 Low Drop Out Regulators ...................................................................................................................................................................

17

8.8 SDI / Control Interface ........................................................................................................................................................................

18

8.9 Baud Rate Generator .........................................................................................................................................................................

18

9 Application Information ...........................................................................................................................................................

19

9.1 Operation Modes ................................................................................................................................................................................

19

9.2 Transmitter Control Interface..............................................................................................................................................................

20

9.2.1

9.2.2

9.2.3

9.2.4

9.2.5

Configuration Diagram...............................................................................................................................................................

Power On Reset ........................................................................................................................................................................

Writing of Data to Addressable Registers..................................................................................................................................

Reading of Data from Addressable Registers ...........................................................................................................................

Transmitting Data ......................................................................................................................................................................

9.3 Transmitter Control States..................................................................................................................................................................

9.3.1

9.3.2

9.3.3

9.3.4

Power Down State .....................................................................................................................................................................

Active Edge of CLK....................................................................................................................................................................

Active State................................................................................................................................................................................

Transmit State ...........................................................................................................................................................................

21

22

22

23

25

25

25

26

26

26

9.4 ENABLE Signal Functionality .............................................................................................................................................................

27

9.5 Communication and Command Byte Structure ..................................................................................................................................

28

9.6 Transmitter Configuration Register.....................................................................................................................................................

29

9.7 Special Bits.........................................................................................................................................................................................

33

9.7.1

9.7.2

9.7.3

9.7.4

LT (Lock Transmit).....................................................................................................................................................................

LS (Low Power Supply Voltage) ................................................................................................................................................

MCCS, CLKS and PSC .............................................................................................................................................................

SETPD (Set Power Down).........................................................................................................................................................

9.8 Output Frequency Setting...................................................................................................................................................................

33

33

33

33

34

9.8.1 Implementation .......................................................................................................................................................................... 35

9.8.2 Optional Frequency Calculation with Overlapping Fractional Bands by Using the Bit INT.................................................. 36

9.8.3 FSK Deviation Setting and Frequency Trimming....................................................................................................................... 37

9.9 Baud Rate Generator .........................................................................................................................................................................

www.austriamicrosystems.com/AS3977

Revision 3.6

38

3 - 47

�AS3977

Data Sheet -

9.10 Reference Design PREOUT and PAOUT Connection .....................................................................................................................

38

9.10.1 Matching Circuit and PREOUT and PAOUT Connections to the Supply Voltage ................................................................... 38

10 Measurement Results...........................................................................................................................................................

41

10.0.1 Applicable Radio Standards .................................................................................................................................................... 43

11 Package Drawings and Markings..........................................................................................................................................

44

12 Ordering Information.............................................................................................................................................................

46

www.austriamicrosystems.com/AS3977

Revision 3.6

4 - 47

�AS3977

Data Sheet - P i n A s s i g n m e n t s

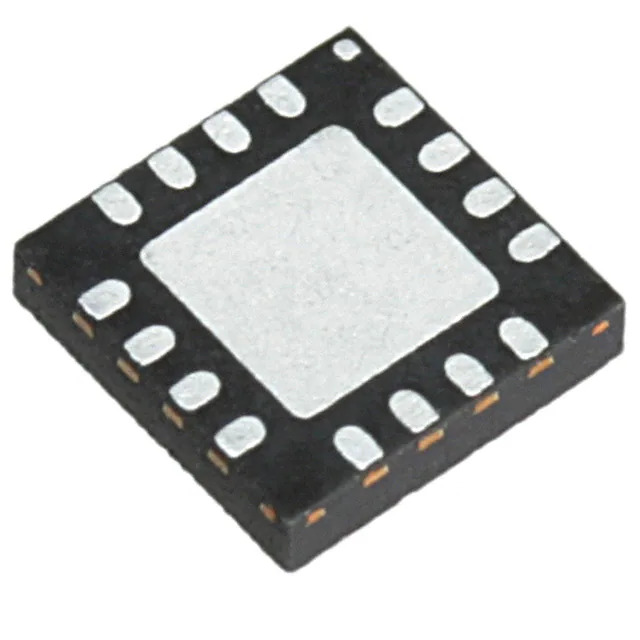

4 Pin Assignments

PREOUT

1

PAOUT

2

VREGRF

VCCPA

GND

VSS

Figure 2. Pin Assignments (Top View)

16

15

14

13

AS3977

12

MCCLK

11

DATAIO

VCCPLL

4

9

VREGDIG

5

6

7

8

XTALOUT

VDD

XTALIN

10

CLK

3

ENABLE

GND

4.1 Pin Descriptions

Table 1. Pin Descriptions

Pin Name

Pin Number

Type

Description

PREOUT

PREOUT

Open Collector preamplifier output, need a feeding coil

connected to VREGRF or VDD and is the input for the Power

amplifier

1

PAOUT

PAOUT

2

RESERVED

3

VCCPLL

4

Open Collector power amplifier output, need a feeding coil

connected to VREGRF or VDD

PREOUT

Must be connected to GND

Positive Power Pin

Positive supplies of VCO, for optimum performance, add

decoupling capacitors on this Pin.

ENABLE

ENABLE

5

www.austriamicrosystems.com/AS3977

Digital CMOS level input, internal Pull down resistor > 60k

Revision 3.6

5 - 47

�AS3977

Data Sheet - P i n A s s i g n m e n t s

Table 1. Pin Descriptions

Pin Name

Pin Number

CLK

6

Type

CLK

SDI clock

VDD

XTALIN

Description

VDD

XTAL oscillator input, DC Level approximately 1 Volt, needs an

DC Blocker in case of external clock

7

VDD

XTALOUT

XTALOUT

XTAL oscillator output, DC Level approximately 1 Volt

8

VDD

VREGDIG

9

VDD

10

DATAIO

11

MCCLK

12

VSS

13

Reserved

14

VCCPA

15

VREGDIG

Voltage regulator2 (VRegDig) output, requires a capacitor with

nominal 100 nF.

Positive Power Pin

16

GND

17

www.austriamicrosystems.com/AS3977

Digital CMOS level input Pin, SDI data input / output

DATAIO

MCCCLK

Micro controller clock output Digital output with variable driver

strength

Negative supply of digital part

GND Pin

Must be connected to GND

Positive Power Pin

VCCPA

VREGRF

Positive supply of digital part and voltage regulator2 (VRegDig)

VREGRF

GND Power Pin

Positive supply of PA and voltage regulator

Voltage regulator output to feed the RF Amplifier. For optimum

performance a capacitor with nominal 1µF and 100 nF is

recommended.

Negative supply of analogue part (exposed paddle)

Revision 3.6

6 - 47

�AS3977

Data Sheet - A b s o l u t e M a x i m u m R a t i n g s

5 Absolute Maximum Ratings

Stresses beyond those listed under “Absolute Maximum Ratings“ may cause permanent damage to the device. These are stress ratings only.

Functional operation of the device at these or any other conditions beyond those indicated under “Operating Conditions” (see Table 3) is not

implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

Table 2. Absolute Maximum Ratings

Parameter

Min

Max

Units

Comments

Positive supply voltage (VSUP)

-0.5

5.0

V

Voltage on all supply Pins VCCPA,VCCPLL,VDD

Negative supply voltage (GND, VSS)

0

0

V

Input current (latch-up immunity) (ISCR)

-40

40

mA

Norm: Jedec 17

ESDDHBM

±4

kV

Norm MIL 883 E method 3015

(Human Body Model)

ESDDMM

±200

V

Norm: EIJA IC-121

(Machine Model)

ESDAHBM

±1.5

kV

Norm MIL 883 E method 3015

(Human Body Model)

ESDAMM

±100

V

Norm: EIJA IC-121

(Machine Model)

ESDRFHBM

±1.5

kV

Norm MIL 883 E method 3015

(Human Body Model)

ESDRFMM

±100

V

Norm: EIJA IC-121

(Machine Model)

ESD for Digital Pins

ESD for Analog Pins

ESD for RF Pins

Total power dissipation

(all supplies and outputs)

Storage temperature, (TSTRG)

-55

Package body temperature (TBODY)

Humidity non-condensing

www.austriamicrosystems.com/AS3977

5

200

mW

125

ºC

260

ºC

85

%

Revision 3.6

Norm: IPC/JEDEC J-STD-020C.

The reflow peak soldering temperature (body

temperature) specified is in accordance with IPC/

JEDEC J-STD-020C “Moisture/Reflow Sensitivity

Classification for Non-Hermetic Solid State Surface

Mount Devices”.

7 - 47

�AS3977

Data Sheet - E l e c t r i c a l C h a r a c t e r i s t i c s

6 Electrical Characteristics

Table 3. Operating Conditions

Symbol

Parameter

Conditions

Min

VSUP

Positive supply voltage analog

Voltage on all supply

VCCPA,VCCPLL,VDD

GND

Max

Units

2.0

3.6

V

Negative supply voltage analog

0

0

V

VSS

Negative supply voltage digital

0

0

V

A-D

Difference of supplies

-0.1

0.1

V

TAMB

Ambient Temperature

-40

85

ºC

Max

Units

VCC-VDD, GND-VSS

Typ

Table 4. Block Specification

Symbol

Parameter

Conditions

fOUT315

fOUT434

fOUT868

Output Frequency Range

fOUT915

POUT

Output Power

Depends on Power Setting

fFSKdata

FSK Data Rate

Internal Manchester Coding

Min

Typ

300

320

425

450

865

870

902

928

1

100

0.5

50

0

±64

MHz

kbit/s

315MHz Frequency Band Section, FCC part 15 is applicable

ΔFSK1

FSK Deviation

programmable (8bit)

Resolution of FSK Deviation (see Table 5)

PSPE1

Spurious Emissions

(max. –19.6dBm radiated fundamental

1

power)

216-960MHz

at frequencies > 960Mhz

at harmonics

Phase noise @ 50 kHz

Phase noise @ 250 kHz

Phase noise @ 1 MHz

kHz

-49

-41

dBm

-40

-86

Charge pump setting: ICHP=50µA;

VSUP=2.0..3.6V,

TAMB=-40..85ºC

-92

dBc/Hz

-102

434MHz Frequency Band Section, EN 300 220 and/or ARIB STD-T67 are applicable

ΔFSK2

FSK Deviation

Phase noise @ 50 kHz

Phase noise @ 250 kHz

Phase noise @ 1 MHz

PACP2

OBW2

Adjacent Channel Power

Occupied Bandwidth

www.austriamicrosystems.com/AS3977

Small deviation (ARIB), programmable

(8bit)

Resolution of FSK Deviation (see Table 5)

±1.25

±4

0

±64

-86

Charge pump setting: ICHP=50µA;

VSUP=2.0…3.6V,

TAMB=-40…85ºC

-83

-94

dBc/Hz

-102

ARIB, fREF=4MHz, ICHP=50µA

-40

Channel spacing 12.5 kHz, FSK data rate

4.8 kbit/s (ARIB)

FSK Deviation ±1.8 KHz

8.5

GF Setting (see Gaussian Filter Clock

Setting on page 38)

Channel spacing 25 kHz,

FSK data rate 9.6 kbit/s (ARIB)

FSK Deviation ±3.0 KHz

Revision 3.6

kHz

8.5

16

dBc

kHz

8 - 47

�AS3977

Data Sheet - E l e c t r i c a l C h a r a c t e r i s t i c s

Table 4. Block Specification (Continued)

Symbol

Parameter

Conditions

1

excluding Harmonics

Spurious Emissions

1

and Harmonics

Max

Units

-54

dBm

at other frequencies < 1GHz

at ≥ 1GHz (EN 300 220)

-36

ARIB

-29

With ideal crystal,

VSUP=2.0…3.6V,

TAMB=-40…85ºC

±1

ppm

±64

kHz

-54

dBm

Output Frequency Error

fERROR

Typ

47-74MHz

87.5-118MHz

174-230MHz

470-862MHz (EN 300 220)

Spurious Emissions

PSPE2

Min

-30

dBm

868MHz Frequency Band Section, EN 300 220 is applicable

ΔFSK3

programmable (8bit)

Resolution of FSK Deviation (see Table 5)

FSK Deviation

47-74MHz

87.5-118MHz

174-230MHz

470-862MHz (@-10dBm radiated power)

Spurious Emissions

PSPE3

0

1

excluding Harmonics

Spurious Emissions

-36

at other frequencies < 1GHz

at frequencies ≥ 1GHz

1

and Harmonics

Phase noise @ 50 kHz

-30

-78

Charge pump setting: ICHP=50µA;

VSUP=2.0…3.6V,

TAMB=-40…85ºC

Phase noise @ 250 kHz

Phase noise @ 1 MHz

dBm

-85

dBc/Hz

-89

915MHz Frequency Band Section, FCC part 15 is applicable

ΔFSK4

FSK Deviation

programmable (8bit)

Resolution of FSK Deviation (see Table 5)

PSPE4

Spurious Emissions

(max. –1dBm radiated fundamental

1

power)

216-960MHz

at frequencies > 960MHz and harmonics

0

±64

kHz

-49

-41

dBm

1. These parameters will not be tested.

Table 5. Resolution of FSK Deviation

Symbol

Parameter

Conditions

Equation for Min. Resolution

For detailed information, See FSK

Deviation Setting and Frequency

Trimming on page 37

REF

ΔF = (INT +1). --------16

For detailed information, See FSK

Deviation Setting and Frequency

Trimming on page 37

REF

ΔF = (INT +1). --------15

Units

315MHz and 434MHz Frequency Band Section

ΔFSKres1

Resolution of FSK Deviation

1

f

Hz

2

868MHz and 915MHz Frequency Band Section

ΔFSKres2

Resolution of FSK Deviation

1

f

Hz

2

1. INT refer to Register Settings

Table 6. Reference Frequency Generator and Micro Controller Clock Driver

Symbol

Parameter

Conditions

Min

Typ

Max

Units

Crystal Oscillator

www.austriamicrosystems.com/AS3977

Revision 3.6

9 - 47

�AS3977

Data Sheet - E l e c t r i c a l C h a r a c t e r i s t i c s

Table 6. (Continued)Reference Frequency Generator and Micro Controller Clock Driver

Symbol

Parameter

Conditions

fXOSC

Crystal Oscillator Frequency

tXOSC

Crystal Oscillator Start up time

VSUP=2.0…3.6V,

TAMB=-40…85ºC

crystal series resistance ≤ 100Ω

RXOSC

Crystal Oscillator Oscillation Margin

Level

fXOSC=13.56MHz, CL=12pF

Δf/f0

Frequency Stability vs. Temperature

1

Min

Typ

Max

Units

12

16

20

MHz

1.5

ms

Ω

1500

AS3977 Only

±1

ppm

Micro Controller Clock Driver

fMCCLK

Clock output frequency

depending on configuration register

settings and crystal

4

MHz

VMCL

Low level output voltage

VSUP=3V, at nominal high level output

current

0.1*VSUP

V

VMCH

High level output voltage

VSUP=3V, at nominal high level output

current

CLMCC

Capacitive load

20

pF

tRMCC

Rise time

62.5

ns

tFMCC

Fall time

62.5

ns

IMCH

High level output current

1

mA

IMCL

Low level output current

1

mA

0.9*VSUP

V

1. These parameters will not be tested.

Table 7. Phase Locked Loop

Symbol

Parameter

Conditions

Min

Typ

Max

Units

fREF

Comparison Frequency

depending on fXOSC

(reference divider division ratio = 4)

3.0

4.0

5.0

MHz

ΔfO

Output Frequency Resolution

fOUT315 / fOUT434

fOUT868 / fOUT915

46

61

77

92

122

153

tSYNTH

Synthesizer Start up Time

tLOCK

Synthesizer Lock Time

500

Δf=600kHz,

fERROR @ tLOCK=10kHz

Hz

µs

50

200

µs

Typ

Max

Units

Table 8. Loop Filter Bandwidth

Symbol

Parameter

Conditions

Min

Filter Bandwidth at 315 MHz

@ 12.5 µA

fBW

Charge pump setting: @ 25 µA

ICHP

@ 37.5µA

55

Reference Frequency = 4MHz

VSUP = 3.0 V;

TAMB = 25ºC

@ 50 µA

85

115

kHz

170

Filter Bandwidth at 433 MHz

www.austriamicrosystems.com/AS3977

Revision 3.6

10 - 47

�AS3977

Data Sheet - E l e c t r i c a l C h a r a c t e r i s t i c s

Table 8. (Continued)Loop Filter Bandwidth

Symbol

Parameter

Conditions

Min

@ 12.5 µA

fBW

Typ

Max

Units

50

Reference Frequency = 4MHz

VSUP = 3.0 V;

TAMB = 25ºC

Charge pump setting: @ 25 µA

ICHP

@ 37.5µA

70

kHz

90

@ 50 µA

120

Filter Bandwidth at 868 MHz

@ 12.5 µA

fBW

50

Reference Frequency = 4MHz

VSUP = 3.0 V;

TAMB = 25ºC

Charge pump setting: @ 25 µA

ICHP

@ 37.5µA

70

kHz

90

@ 50 µA

120

Table 9. Power Amplifier (300 - 320 MHz and 425 - 450 MHz Bands)

Symbol

POUT

POUT

Parameter

Conditions

Min. Output Power @ 50Ω

VSUP=3V, @ 25ºC,

Power depending on power setting with or

without the use of the internal voltage

regulator, external matching network

included

-20

dBm

Max. Output Power @ 50Ω

VSUP=3V, @ 25ºC,

Power depending on power setting with or

without the use of the internal voltage

regulator, external matching network

included

8

dBm

POUT

POUT

POUT

Max

Units

1

-2.5

+2.5

dBm

1

VSUP=3V, @ 25ºC,

Power depending on register setting with

or without the use of the internal voltage

regulator,

external matching network included,

strong AB operation mode

-2.0

+2.0

dBm

VSUP=2.2…3.6V, TAMB=-40…85ºC, With

Output Power Variation vs. VDD and the use of the internal voltage regulator,

Temperature @ 50Ω

external matching network included,

strong AB operation mode

-2.8

1.0

dB

Variation@ 50Ω

(300 – 320MHz)

Output Power

POUT

Typ

VSUP=3V, @ 25ºC,

Power depending on register setting with

or without the use of the internal voltage

regulator,

external matching network included,

strong AB operation mode

Output Power

POUT

Min

Variation@ 50Ω

(425 – 450MHz)

+0.6 /

-1.5

Output Power Variation vs.

Temperature @ 50Ω

VSUP=3V, TAMB=-40..85ºC,

Without the use of the internal voltage

regulator,

external matching network included,

strong AB operation mode

+1.5 /

-2.0

dB

Max Output Power @ 50Ω

VSUP=3.6V, @ 25ºC,

Power depending on power setting

without the use of the internal voltage

regulator,

external matching network included

10

dBm

1. Limits by production test measurement uncertainties

www.austriamicrosystems.com/AS3977

Revision 3.6

11 - 47

�AS3977

Data Sheet - E l e c t r i c a l C h a r a c t e r i s t i c s

Table 10. Power Amplifier (865 - 870 MHz and 902 - 928 MHz Bands)

Symbol

POUT

POUT

POUT

Parameter

Conditions

Min Output Power

@ 50Ω

VSUP=3V, @ 25ºC,

Power depending on power setting with or

without the use of the internal voltage

regulator,

external matching network included

-20

dBm

Max Output Power

@ 50Ω

VSUP=3V, @ 25ºC,

Power depending on power setting with or

without the use of the internal voltage

regulator, external matching network

included

4

dBm

1

Output Power Variation @ 50Ω

VSUP=3V, @ 25ºC,

Power depending on register setting with

or without the use of the internal voltage

regulator, external matching network

included, strong AB operation mode

POUT

Output Power Variation vs.

Temperature @ 50Ω

Max

+3.5

Units

dBm

2

+2.0 /

-3.0

dB

+2.0 /

-3.0

dB

2

VSUP=3V,

TAMB=-40…85ºC,

Without the use of the internal voltage

regulator, external matching network

included, strong AB operation mode

Typ

-3.5

VSUP=2.2…3.6V,

TAMB= -40…85ºC,

Output Power Variation vs. VDD and With the use of the internal voltage

Temperature @ 50Ω

regulator, external matching network

included, strong AB operation mode

POUT

Min

2

1. Limits by production test measurement uncertainties

2. Power line matching needs to be adjusted to VDD to ensure strong AB operation mode

Table 11. Antenna Tuning Circuit

Symbol

Parameter

Conditions

CAtmin

Minimum Antenna tuning Capacitor

ATCPH = 0000

0.11

pF

Maximum Antenna tuning Capacitor

ATCPH = 1111

1.51

pF

CAtmax

Min

Typ

Max

Units

Table 12. Low Power Reset (Bit LT)

Symbol

Parameter

Conditions

Min

Typ

Max

Units

VLPR

Low Power Detection Threshold

Voltage

Decreasing Supply Voltage

1.85

1.95

2.05

V

VLPR

Low Power Release Threshold

Voltage

Rising Supply Voltage

2.05

V

Table 13. Low Supply Voltage Detector (Bit LS)

Symbol

Parameter

Conditions

Min

Typ

Max

Units

VLS

Low Supply Detection Threshold

Voltage

Decreasing Supply Voltage

2.0

2.1

2.2

V

VLS

Low Supply Release Threshold

Voltage

Rising Supply Voltage

www.austriamicrosystems.com/AS3977

Revision 3.6

2.17

12 - 47

�AS3977

Data Sheet - E l e c t r i c a l C h a r a c t e r i s t i c s

Table 14. Temperature Sensor

Symbol

Parameter

Conditions

Min

ERRTS

Absolute Error

TAMB = -40…85ºC

-5

ERRTSL

Absolute Error (limited temperature

range)

TAMB = -20…65ºC

±2

ºC

Conversion Factor

TAMB = -40…85ºC

0.19

ºC/bit

10

bit

ORTS

Output Resolution

CRTS

Conversion Rate

Typ

fTS = fCRYSTAL/12

after startup time of 256 / fTS

Max

Units

+5

ºC

fTS/1354

samples/

s

Max

Units

Table 15. Voltage Regulator for Power Amplifier

Symbol

Parameter

Conditions

Min

Typ

VREGRF

Output Voltage for supply Power

Amplifier

Adjustable, nominal value

1.7

2.0

V

D_VREGR

F

Regulator Tolerance

-0.15

0.1

V

Typ

Max

Units

VSUP=3V @ 25ºC

100

250

VSUP=2.0…3.6V,

TAMB=-40…85ºC

1000

5000

VSUP=3V @ 25ºC,

Cload≤20pF, fCLK=20MHz

1

1.25

VSUP=2.0…3.6V,

TAMB=-40..85ºC, Cload≤20pF,

fCLK=20MHz

1.25

1.6

Table 16. Current Consumption

Symbol

Parameter

IPDWN

Power Down Mode

ICLKEN

Clock Enable Mode

Conditions

Min

nA

mA

ITemp_sens

Temperature sensor Current

VSUP=2.0..3.6V,

TAMB=-40..85ºC

0.25

mA

IPLLEN

PLL Enable Mode

VSUP=2.0…3.6V,

TAMB=-40…85ºC

5.6

mA

VSUP=3V @ 25ºC

Transmit Mode @ 8dBm output

power,

ITX8dBm31 315 MHz band @ 50Ω including

5

matching network, strong AB

operation

VSUP=2.0…3.6V,

TAMB=-40…85ºC

VSUP=3V @ 25ºC

VSUP=2.2…3.6V,

TAMB=-40…85ºC

VSUP=3V @ 25ºC

Transmit Mode @ 8dBm output

power,

ITX8dBm43 433 MHz band @ 50Ω including

3

matching network, strong AB

operation

www.austriamicrosystems.com/AS3977

VSUP=2.0…3.6V,

TAMB=-40…85ºC

VSUP=3V @ 25ºC

VSUP=2.2…3.6V,

TAMB=-40…85ºC

without the use of

the internal

1

regulator

with the use of the

internal regulator

without the use of

the internal

regulator

with the use of the

internal regulator

Revision 3.6

13.5

16.5

mA

15.5

19

mA

14.0

17.0

mA

16.0

19.5

mA

12.5

15.5

mA

14.5

18

mA

13.0

16.0

mA

15

18.5

mA

13 - 47

�AS3977

Data Sheet - E l e c t r i c a l C h a r a c t e r i s t i c s

Table 16. Current Consumption

Symbol

Parameter

Conditions

VSUP=3V @ 25ºC

Transmit Mode @ 4dBm output

power,

ITX4dBm86 868 MHz and 906MHz band @

8

50Ω including matching

network, strong AB operation

VSUP=2.0…3.6V,

TAMB=-40…85ºC

VSUP=3V @ 25ºC

VSUP=2.2…3.6V,

TAMB=-40…85ºC

Min

without the use of

the internal

regulator

with the use of the

internal regulator

Typ

Max

Units

14.5

17.5

mA

16.5

19.0

mA

15.0

18.0

mA

17.0

19.5

mA

Max

Units

1. Power line matching needs to be adjusted to VDD to ensure strong AB operation mode

Table 17. DC/AC Characteristics for Digital Interface

Symbol

Parameter

Conditions

Min

Typ

CMOS Input

VIH

High Level Input Voltage

0.7 *

VSUP

VSUP +

0.1

V

VIL

Low Level Input Voltage

VGND -0.1

0.3 * VSUP

V

IIL

Low Level Input Leakage Current

no internal pull up/down

±1

µA

IIH

High Level Input Leakage Current

no internal pull up/down

±1

µA

IIHPD

High Level Input Leakage Current with

internal pull down

VSUP=3.6V, VIN=3.6V

60

µA

15

CMOS Output

Note: The following specification is valid for the DATAIO standard CMOS output. The MCCLK output can be programmed to different driver

strengths according MCCDS register.

VOH

High level output voltage

VSUP=3V, at nominal high level output

current

VOL

Low level output voltage

VSUP=3V, at nominal low level output

current

CL

tR

VSUP-0.5

V

VSS+0.4

V

Capacitive load

20

pF

Rise time

50

ns

tF

Fall time

50

ns

IOH

High level output current

1

mA

IOL

Low level output current

1

mA

www.austriamicrosystems.com/AS3977

Revision 3.6

14 - 47

�AS3977

Data Sheet - T i m i n g C h a r a c t e r i s t i c s

7 Timing Characteristics

16

Be aware that the Power Down Mode can be entered by setting ENABLE low for more than 2 XTAL cycles (Power Down Timer).

Figure 3. Write Data

ENABLE

tCS

tCHD

tCH

tEH

tCL

CLK

polarity

CLK

tMS

tMH

tDIS

MCCLK

behavior

DATAI

tDIH

DATAI

DATAI

DATAI

DATAO

Figure 4. Read Data

ENABLE

tCL

tCH

CLK

DATAI

DATAI

DATAI

tDIHZ

DATAO

www.austriamicrosystems.com/AS3977

tDOS

tDOH

DATAO (D7N)

Revision 3.6

tDOHZ

tDOD

DATAO (D00)

15 - 47

�AS3977

Data Sheet - T i m i n g C h a r a c t e r i s t i c s

7.1 Timing Parameters

Table 18. Timing Parameters

Symbol

Parameter

Condition

Min

Typ

Max

Units

2

Mbps

General

BRSDI

Bit rate

tCH

Clock high time

250

ns

tCL

Clock low time

250

ns

tDIS

Data in setup time

20

ns

tDIH

Data in hold time

10

ns

tEH

Enable hold time

20

ns

Write timing

Read timing

tDIHZ

Data in to high impedance delay

tDOS

Data out setup time

130

ns

tDOH

Data out hold time

135

ns

tDOD

Data out delay

tDOHZ

Data out to high impedance delay

time for the µC to release the DATAIO bus

45

time for the SDI to release the DATAIO

bus

ns

80

ns

80

ns

Timing parameters when leaving the Power Down Mode (for determination of CLK polarity and MCCLK behavior)

tCS

Clock setup time

(CLK polarity)

Setup time of CLK with respect to

ENABLE rising edge

20

ns

tCHD

Clock hold time

(CLK polarity)

Hold time of CLK with respect to ENABLE

rising edge

20

ns

tMS

Data in setup time

(MCCLK behavior)

DATAIO setup time with respect to

ENABLE rising edge

20

ns

tMH

Data in hold time

(MCCLK behavior)

DATAIO hold time with respect to

ENABLE rising edge

20

ns

www.austriamicrosystems.com/AS3977

Revision 3.6

16 - 47

�AS3977

Data Sheet - D e t a i l e d S y s t e m D e s c r i p t i o n

8 Detailed System Description

The AS3977 is based on a fully integrated sigma-delta controlled fractional-N synthesizer phase locked loop (PLL) and a power amplifier (PA). A

reference frequency generator including a crystal oscillator provides the comparison frequency of the PLL and a high-precision clock output. A

programmable Gaussian filter enables to minimize the occupied bandwidth and adjacent channel power. A temperature sensor with digital readout is included that allows compensation of the crystal frequency drift due to temperature variation. An on-chip low drop out regulator (LDO) is

available in case an accurate output power independent of supply voltage variation is required. A second LDO for the digital supply voltage helps

to minimize interference between the analog and digital part and decreases the current consumption of the digital part. A PROM enables the

compensation of process variation. The AS3977 is controlled by an external microcontroller via a bi-directional serial digital interface (SDI).

8.1 Reference Frequency Generator

The reference frequency generator consists of a crystal oscillator and frequency divider. The crystal oscillator can be driven externally in case an

external clock frequency is supplied.

8.2 Phase Locked Loop

The PLL is of standard charge pump type. The phase frequency detector is designed such that dead zone problems are avoided. The charge

pump current is programmable. All loop filter components are on-chip, the bandwidth is programmable through the charge pump current. The

differential based voltage controlled oscillator (VCO) has integrated inductors and varactors. The VCO operates at a center frequency around

1.8GHz. To cover the specified frequency range over process variation, the sufficiently wide overall tuning range is split into 16 overlapping

frequency bands. At start up of the PLL, an automatic range select circuit (ARS) selects the proper frequency band. The VCO output frequency

is divided by 2, 4, and 6, which enables to cover output frequencies in the range of 850 – 928 MHZ, 425 – 450 MHz and 300 – 320 MHz,

respectively. A lock detector enables to monitor the PLL lock status.

8.3 Gaussian Filter and Digital Modulator

The programmable sigma-delta modulator controls the output frequency of the PLL. The order of the modulator is programmable (MASH2 or

MASH3). In combination with the programmable Gaussian filter for the data signal, the modulator performs the FSK modulation with

programmable deviation, whereby the Gaussian Filter enables to minimize the occupied bandwidth and the adjacent channel power.

8.4 Power Amplifier

The power amplifier is single ended and consists of a preamplifier and an output stage, both with open collector. The necessary external chokes

can be connected to a LDO in case an accurate output power independent of supply voltage variation is required. The output power is

programmable up to 10dBm.

8.5 Temperature Sensor

The AS3977 includes a temperature sensor to measure the absolute temperature inside the chip. The analog value is converted to a digital value

and can then be read out by the microcontroller in order to control the output frequency and/or the transmission power. The value of the chip

temperature in degree can be obtained using following formula:

Temperature = TS < 9…0 > * 0.19 – 50

(EQ 1)

The temperature sensor can be used to compensate the crystal drift over temperature.

Note: AS3977 has the same temperature than the crystal only at start up and the temperature will increase immediately thereafter due to self

heating.

Temperature sensor must be used only in the Clock Enable Mode as a stand alone block. It is mandatory to be used with the PLL and Power

Amplifier switched off.

8.6 Low Power Reset

The low power reset (LPR) disables the power amplifier, if the supply voltage falls below the low power threshold.

8.7 Low Drop Out Regulators

In order to avoid stability issues, external capacitors are required. (see Table 1)

www.austriamicrosystems.com/AS3977

Revision 3.6

17 - 47

�AS3977

Data Sheet - D e t a i l e d S y s t e m D e s c r i p t i o n

8.8 SDI / Control Interface

This interface enables a serial and synchronous communication between external microcontroller and AS3977. Data can be written to and read

out from AS3977. Additionally, it facilitates the transmission of TX-data. The rising edge on the SDI enable signal (transition to the active state),

while the device is in Power Down Mode has various effects on the circuit:

- It wakes up the crystal oscillator (this takes maximum 1.5 ms with the specified Crystal parameters)

- It sets the transfer and sampling edge of the AS3977 SDI data signal.

- It activates the Micro Controller clock output depending on the register setting and the value of the data signal.

Thus, the wakeup event through the SDI interface determines the basic communication between AS3977 and the microcontroller. In addition it

takes some time to have a stable crystal oscillator clock available. Therefore all functions that require a stable crystal oscillator clock are not

immediately available after the wakeup.

8.9 Baud Rate Generator

This module generates two clocks; one used for the microcontroller (MCCLK) and one as baud rate clock with 50% duty cycle. The baud rate

clock is used by the microcontroller to properly synchronize the provided data during transmission with the internal Manchester coder.

The baud rate generator maintains the behavior of MCCLK and keeps it properly synchronized to the TX data clock. For example, a missing

synchronization can occur when clock settings are changed by an asynchronous event like SDI programming or when a new transmission starts.

The Baud rate generator offers different types of data outputs: one fully asynchronous, one synchronous and one synchronous but Manchester

coded. By means of AS3977 command control Byte, any of the three different output data types can be selected.

www.austriamicrosystems.com/AS3977

Revision 3.6

18 - 47

�AS3977

Data Sheet - A p p l i c a t i o n I n f o r m a t i o n

9 Application Information

Figure 5. Functional Description Diagram of Timers and Data Synchronization

Powerdown Timer

Set Powerdown

1

Powerdown

/ 2^16

reset

reset

Baudrate

Generator

ENABLE

Prescalar

/ 1,2,4,8,…

128

XTAL

Postscalar

/ 1,2,4,8

counter

8bit

3

PSC

ASC

Data

Synchronization

MC

2

compare

MCCLK

timer

compare

value

3

to

1

8

Data Generator

3

to

1

INV

2

CLK Source

TXDO

xor

TXDATA

The Prescaler divides the XTAL frequency by fOUT=2

-PSC

*fIN

The Compare timer divides by fOUT=fIN/(TCV+1) and the Postscaler divides the input frequency by fOUT=2

frequency of:

-(PSC+ASC+1)

fOUT=2

-ASC

*fIN which leads into a data

* fIN / (TCV+1)

(EQ 2)

9.1 Operation Modes

All modes are controlled by the SDI interface.

Power Down Mode

The AS3977 is connected to the power supply and can be switched to power down mode. The current consumption is limited by the leakage

current.

Clock Enable Mode

In this mode, only the reference frequency generator is switched on and a clock signal is supplied via the clock output.

PLL Enable Mode

The PLL is switched on and locked at the selected output frequency. The power amplifier is in power down mode. This mode enables OOKASK modulation by switching the PA on and off.

Transmit Mode

The PLL is switched on and locked at the selected output frequency. The power amplifier is in power on mode. This is the FSK mode for

transmitting data.

www.austriamicrosystems.com/AS3977

Revision 3.6

19 - 47

�AS3977

Data Sheet - A p p l i c a t i o n I n f o r m a t i o n

Figure 6. Operation Mode Relations

Power ON

ENABLE High

Pulse

16

ENABLE to LOW for 2

XTAL cycles

or

Software Power Down

command via SPI

External

Hardware

Reset

Power Down

Mode

ENABLE is

HIGH

Clock Enable

Mode

SPI

Command

PLL Enable

Mode

SPI

Command

Transmit Mode

9.2 Transmitter Control Interface

The AS3977 is controlled by an external micro controller (µC) via. a bi-directional communication interface (serial digital interface, SDI). The SDI

enables data to be read from and written to internal control registers without the necessity of an internal clock signal. Analog de-bouncing of

clock and data input is implemented in order to improve the overall system reliability.

The SDI-control interface includes a state machine, which expects a command control word as first byte and in reference to this byte, the

interface is configured as write, read, or transmit operation. This method enables an effective and easy control of basic transmitter functions.

Four preset independent output frequencies and two preset independent output power levels and modulation types can be selected using the

control-command byte, thus enabling fast channel hopping and/or fast changes to the output power level and modulation type. The selection of

the active output frequency and/or power level and modulation type is done using the so-called command byte.

As an additional feature, the AS3977 provides a configurable clock signal derived from the crystal frequency. The purpose of this clock signal is

to provide a µC clock and to enable data synchronization.

16

A timer is included to power down (Power Down Mode) the transmitter after a certain time, which is defined as 2 multiplied with the crystal

oscillator- Period.

www.austriamicrosystems.com/AS3977

Revision 3.6

20 - 47

�AS3977

Data Sheet - A p p l i c a t i o n I n f o r m a t i o n

9.2.1

Configuration Diagram

The interface has one clock signal for the external µC and the SDI input clock. As the MCCLK line can be used to clock the SDI Interface as well

as must have a high impedance pin during the clocking phase of the microcontroller, the Pin must be bi-directional. The pad behavior is selected

by configuration bits and by setting the SDI DATA-IO Line of the SDI interface when leaving PD. Possible configurations between the interface

and the µC are done using 4 wires as shown in Figure 7.

MCCLK is simply connected to the micro controller and can be used to clock a timer or interrupt logic.

Figure 7. Configuration Diagram

MCCLK

ENABLE

µC

CLK

AS3977

DATAIO

A connection using a set of three wires is required to implement the SDI protocol.

ENABLE signal is used to activate the interface and to wake up the whole IC. In addition, the rising edge of the ENABLE after power down

mode is used to set the starting point of the communication protocol.

CLK represents the SDI clock and both edges can be used for data transfer, dependable on the configuration after wake-up.

DATAIO is a bi-directional signal that goes from microcontroller to the Interface during write and transmit-commands, while it is in the other

direction when the interface is sending data read from the micro controller.

The interface supports the following functionality for the micro controller clock output (MCCLK).

MCCLK can be inactive (MCCLK level not defined), always active after start-up (MCCLK is clocking) or clocking only during transmit.

It is possible to configure and to maintain MCCLK settings (even when leaving PD).

Maximum frequency is specified to fXOSC (by using the prescaler output with a division ratio of 1, PSC=0).

Minimum frequency is fXOSC / 65280 (by using the baud rate generator output with prescaler division ratio of 128 and timer counter value of

255).

The rising edge of ENABLE after a Power Down Mode selects the transfer edge of the SDI-CLK by sampling the SDI clock value itself. This

configuration will be valid until the next PD. Each bit must be transferred and sampled according to the configured edges. For example, if at the

first rising edge of SDI enable SDI clock is LOW, then each bit is transferred from the microcontroller on the rising edge of SDI clock and it is

sampled from AS3977 on falling edge of the SDI clock. This is valid for read as well as for write commands.

During the first byte of the WRITE command communication (command and address), the SDI master drives each new data bit on the transfer

active edge and the SDI slave samples it on the next opposite edge. This protocol will be valid until the last data bit has been written to the

external registers. Data’ are transferred to the registers byte by byte after sampling of the last bit.

It is not necessary to enter the PD mode for reset the Interface. The rising edge of SDI-ENABLE signal starts the communication.

When the command is READ, a direction change on the SDI data wire will be done. This change has to be performed synchronously on SDI

master and slave side, however, the master always provide the SDI clock. After sampling the last addressed bit, the SDI slave pin becomes

active on the following SDI clock edge and the first readable bit read is transferred from SDI slave to the master.

In any case, the SDI master has to reset the SDI interface on the last bit of the data in order to stop the communication by applying an Enable

16

LOW pulse (duration: min > 1 SDI CLK cycle, max: < 1/fcrystal * 2 ).

www.austriamicrosystems.com/AS3977

Revision 3.6

21 - 47

�AS3977

Data Sheet - A p p l i c a t i o n I n f o r m a t i o n

9.2.2

Power On Reset

For stable start up of the AS3977 and to avoid unwanted crystal oscillation, it is strongly recommended to perform a power on reset (Hardware

Reset Method). This can be performed as described in Table 19 and must be carried out every time when the supply voltage is less than the

minimum allowed value (see Operating Conditions on page 8).

Table 19. Power On Reset

9.2.3

Step

Hardware Reset Method

1

Apply Power to the AS3977

2

Apply Enable high pulse (Low-High-Low transition)

3

Power on reset complete after xtal start up + 2 xtal cycles

16

Writing of Data to Addressable Registers

When the Power Down Mode is left, the level of CLK at the rising edge of ENABLE determines the sampling edge of CLK. If CLK is low, when

ENABLE rises, DATAI is sampled at the falling edge of CLK (see Figure 8 and Figure 9), if CLK is high when ENABLE rises, DATAI is sampled at

the rising edge of CLK.

An Enable LOW pulse indicates the end of the WRITE command after register has been written.

Figure 8 illustrates a write command in which the initialization of DATAIO take over condition is done at the falling edge of CLK signal.

Figure 8. Writing of a Single Byte (falling edge sampling)

16

Enable low must be shorter than 2 clock cycles to keep the power

conditions and the data takeover condition

ENABLE

CLK

DATAIO

0

1

A5

In case the ENABLE line has been longer than

16

2 clock cycles low, data take over condition is

determined here

A4

A3

A2

A1

A0

D7

D6

Data D7 is sampled from AS3977

at this edge

D5

D4

Data D4 is transferred from

Microcontroller

D3

D2

D1

D0

Data D7-D0 is

moved to

Address A5A0 here

ENABLE falling edge signals end of write

www.austriamicrosystems.com/AS3977

Revision 3.6

22 - 47

�AS3977

Data Sheet - A p p l i c a t i o n I n f o r m a t i o n

Figure 9. Writing of Data with Auto-Incrementing Address

Enable must be high

in order to keep the

power condition

ENABLE

CLK

DATAIO

0 0

A A A A A A D D D D D D D D D D D D D D D D D D D D D DD D D D D D D D D D D D D D D D D D

5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0

Data D7-D0 is

moved to

Address A5A0 here

9.2.4

Data D7-D0 is

moved to

Address

A5-A0+1 here

Data D7-D0 is

moved to

Address

A5-A0+2

here

Data D7-D0 is

moved to

Address

A5-A0+3 here

Data D7-D0 is

moved to

Address

A5-A0+4 here

Reading of Data from Addressable Registers

By leaving the Power Down Mode through a rising edge of ENABLE, the level of CLK determines the sampling edge of CLK. If CLK is low, DATAI

is sampled at the falling edge of CLK (see Figure 10 and Figure 11), if CLK is high when ENABLE rises, DATAI is sampled at the rising edge of

CLK. Consequently, data to be read from the microcontroller are driven by the slave (AS3977) at the transfer edge and sampled by the master

(µC) at the sampling edge of CLK. An Enable LOW pulse has to be performed after register data has been transferred in order to indicate the

end of the READ command and prepare the Interface to the next command control Byte.

The command control Byte for a read command consists of a command code and an address. The Command code has to be provided from least

significant bit (LSB) to most significant bit (MSB), e.g. for a read it is = “01”. After the command code, the address of register to be read

has to be provided from the MSB to the LSB. Then one or more data bytes can be transferred from the SDI slave to the master, always from the

MSB to the LSB. To transfer bytes from consecutive addresses, SDI master has to keep the SDI enable signal high and the SDI clock has to be

active as long as data need to be read from the slave.

Each bit of the command and address sections of the frame have to be driven by the SDI master on the SDI clock transfer edge and the SDI

slave samples it on the next SDI clock edge. Each bit of the data section of the frame has to be driven by the SDI slave on the SDI clock transfer

edge and the SDI master on the next SDI clock edge samples it. These edges are selected on the first access after PD and they cannot be

changed until next PD.

If the read access is interrupted (by de-asserting the SDI enable signal), data provided to the master is consistent to given address, but it is only

the register content from MSB to LSB. If more SDI clock cycles are provided, data remains consistent and each data byte belongs to given or

incremented address.

In the following figures (Figure 10 and Figure 11), two examples for a read command (without and with address self-increment) are given. The

initialization base for this timing diagram is a “LOW” on the CLK line during Initialization.

www.austriamicrosystems.com/AS3977

Revision 3.6

23 - 47

�AS3977

Data Sheet - A p p l i c a t i o n I n f o r m a t i o n

Figure 10. Reading of a Single Byte (falling edge sampling)

16

Enable low must be shorter than 2 clock cycles to keep the power

conditions and the data takeover condition

ENABLE

CLK

DATAIO line driver control changes from

microcontroller to AS3977

DATAI

0

A5

1

A4

A3

A2

A1

A0

DATAO

DATAIO

0

A5

1

16

A4

In case the enable has been longer than 2 clock cycles

low, the power down state is left and data take over condition is determined here

A3

A2

A1

A0

D7

D6

D5

D4

D3

D2

D1

D0

D7

D6

D5

D4

D3

D2

D1

D0

Data D7-D0 at Address A5-A0 is transferred to the Output Register of AS3977

Signals

end of

read

Figure 11. Reading of Data with Auto-Incrementing Address

ENABLE

CLK

DATAI

(µC Driven)

0 1 A A A A A A

5 4 3 2 1 0

DATAO

(AS3977

Driven)

DATAIO

D D D D D D D D D D D D D D D D D D D D D DD D D D D D D D D D D D D D D D D D

7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0

0 1

A A A A A A D D D D D D D D D D D D D D D D D D D D D DD D D D D D D D D D D D D D D D D D

5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0

Data D7-D0 at

Address A5-A0 is

transferred here

www.austriamicrosystems.com/AS3977

Data D7-D0 at

Address A5-A0+1 is

transferred here

Data D7-D0 at

Address A5-A0+2 is

transferred here

Revision 3.6

Data D7-D0 at

Address A5-A0+3 is

transferred here

Data D7-D0 at

Address A5-A0+4 is

transferred here

24 - 47

�AS3977

Data Sheet - A p p l i c a t i o n I n f o r m a t i o n

9.2.5

Transmitting Data

Command code has to be provided from LSB to MSB and for transmit it is = “11”. After the command code, further configuration has to

be provided from the MSB to the LSB. Then a bit-stream, the data to be sent, can be transferred from the SDI master by keeping SDI enable

signal to high. No SDI clock is required for data synchronization or the input bit stream.

Each bit of the command and address sections of the frame have to be driven by the SDI master on the SDI clock transfer edge and the SDI

slave on the next SDI clock edge samples it.

The transmission starts as follows:

After the last configuration bit has been sampled, the micro controller has to provide an additional SDI clock edge to activate the output amplifier.

This allows the SDI state machine to switch to the TX status and to activate MCCLK. Then, together with the first TX data bit, the next SDI clock

sampling edge provided by the master starts the transmission itself and powers on the analog output driver.

In case, the MCCLK output is properly configured, the transmission will be stopped by the microcontroller by setting the clock to a high

impedance state and the MCCLK output of the Transceiver became active and takes over the communication of the Interface.

The power amplifier is switched on (if not already on) at the subsequent sampling edge of CLK after receiving the transmit command byte. This

allows to delay the PAON signal, e.g. to enable locking of the PLL in case a channel hop has to be performed.

The following figure (Figure 12) shows an example (sampling falling edge) of the transmit command with MCCLK active during TX. It is important

to note in this mode the sequence of events labelled 1-4 in the diagram, which lead to transmission. This mode allows the baud clock to be

synchronized to the external data. In such a case, the synchronization (A5=1) bit should be set within the transmitter configuration.

Figure 12. Transmit Command with MCCLK Active During Tx (falling edge sampling)

ENABLE

Tx Configuration and pre-configuration for

MCLK set

2

CLK

Tx configuration parameter ready

DATAIO

1

1

A5

A4

A3

A2

A1

1

4

uController triggers falling edge of CLK after rising edge of MCLK

Power Amplifier is switched on

A0

Power Amplifier is

switched off or data is sent

continuously

Data to be sent

3

MCLK started synchronous to

internal baud clock

MCCLK

9.3 Transmitter Control States

9.3.1

Power Down State

When the Power Down Mode is entered, the crystal oscillator ends running and two very important bits of the registers are set to their inactive

values:

1. Lock transmit: which is set (1) during PD to forbid any transmission.

2. Setpd: it is reset (0) to avoid a locked Power Down Mode.

When the circuit is in Power Down Mode, the crystal oscillator and all the other analog/digital circuits are OFF. The transmitter interface is the

only supplied circuit and it is sensitive to SDI signals. The current consumption is limited by the leakage current. The configuration registers do

not alter as long as the minimum supply requirements are met. The state can only be left by the rising edge of ENABLE. The state can be

16

entered either by setting the set power down bit (SETPD) via. SDI communication or by setting ENABLE low for more than 2 XTAL cycles

(Power Down Timer). When the Power Down Mode is left (by the rising edge of ENABLE), the crystal oscillator is activated.

www.austriamicrosystems.com/AS3977

Revision 3.6

25 - 47

�AS3977

Data Sheet - A p p l i c a t i o n I n f o r m a t i o n

Software Power Down Method.

Step

Software Power Down Method

1

Set power Down Bit =1 and put ENABLE to LOW level

2

Power on reset complete with next xtal cycle

Lock Transmit Bit. When the Power Down Mode is left, the lock transmit bit (LT) is set high. The power amplifier can not be switched on as

long as the bit is set to high.

9.3.2

State

ENABLE

LT

Description

Power Down Mode

↑

1

LT is set to High

All other states

↑

LT-1

LT is unchanged except the Supply

voltage drops down below the

threshold level

Active Edge of CLK

When the Power Down Mode is left, the level of CLK at the rising edge of ENABLE determines the active edge of CLK (CLK polarity). Once the

CLK polarity is set, it stays unchanged until the next Power Down Mode is re-entered.

9.3.3

State

ENABLE

CLK

Description

Power Down Mode

↑

0

DATAIO is sampled at the falling edge of CLK

Power Down Mode

↑

1

DATAIO is sampled at the rising edge of CLK

All other states

↑

X

CLK behavior is unchanged

Active State

The Active state is entered at the rising edge of ENABLE, which as well resets the Power Down timer. Possible previous states are Power Down

Mode, Transmit state. DATAIO is set to SDI data input and the Interface expects a command control byte to configure the state-machine. The

16

SDI state can be left by programming another state or by setting ENABLE low for more than 2 XTAL cycles (Power Down timer).

9.3.4

Transmit State

The state is entered upon command. The transmit command byte defines in combination with the configuration registers the transmit

configuration. The power amplifier (PA) will be activated on the subsequent sampling edge of CLK after receiving the command byte only if the

lock transmit bit has been reset (0) by a previous SDI command. Here (only here) the baud rate and data generator counters are reset, i.e. if

Transmit was interrupted by a SDI communication and is re-entered again (with active PA), the baud rate generator is kept synchronized with the

previous transmitted string. DATAIO is set to TX data input. If during transmit a low power reset (LPR) occurs, the lock transmit bit is set high and

hence the power amplifier is switched off.

The state can be left at the falling edge of ENABLE, or increasing the Supply Voltage above the threshold and setting the register bit (LT) to zero.

The control of the power amplifier is determined by the command byte (bit A4 and A5).

Table 20. PA Control Modes

State

LT

A4

A5

ENABLE

Description

All States

1

X

X

X

PAON low

Transmit

0

X

X

1

PAON high on the subsequent sampling edge of CLK after

receiving the command byte

Transmit

0

0

0

↓

PAON low at the falling edge of ENABLE

Transmit

0

0

1

↓

PAON low at the falling edge of ENABLE but synchronized with

baud rate, DATAIO is latched

Transmit

0

1

X

↓

PAON stays high, DATAIO is latched

www.austriamicrosystems.com/AS3977

Revision 3.6

26 - 47

�AS3977

Data Sheet - A p p l i c a t i o n I n f o r m a t i o n

9.4 ENABLE Signal Functionality

Figure 21 summarizes the function of ENABLE in combination with the SDI state and the logical level of CLK and DATAIO.

Table 21. ENABLE Signal Functionality

State

Power Down Mode

ENABLE

↑

CLK

DATAIO

Description

X

X

resets the SDI and state machine

activates the crystal oscillator (PD is set to low)

sets the lock transmit bit

0

X

indicates data are sampled at the falling edge of CLK

1

X

indicates data are sampled at the rising edge of CLK

X

0

activates MCCLK, fMCCLK=fXOSC/16

X

1

MCCLK configuration is unchanged

All

↑

X

X

resets the Power Down Timer

resets the SDI Interface

(re-)enters the Active state

Active, Transmit

↓

X

X

activates the Power Down Timer; after 2 crystal clock

cycles the IC reaches the Power Down Mode

X

X

Active, Transmit

16

indicates the end of Read/Write

16

(duration: min > 1 SDI CLK cycle, max: < 1/fcrystal * 2 )

All

0

X

X

disables CLK and DATAIO

sets DATAIO to high impedance

Transmit

↓

X

X

switches off the PA (if enabled)

latches DATAIO (if enabled)

www.austriamicrosystems.com/AS3977

Revision 3.6

27 - 47

�AS3977

Data Sheet - A p p l i c a t i o n I n f o r m a t i o n

9.5 Communication and Command Byte Structure

A frame consists of a command byte including address/configuration and a following bit stream that can either represent an integer number of

bytes or a random sequence of bits when the command is transmit. Command is encoded in the 2 first bits, while address is given on 6 bits. In

case if the command is neither read nor write, these bits are used to configure the transmission and they will be stored until the next

configuration.

The first byte of every SDI sequence is the command byte.

Function Code

C0

C1

Register Address or Transmission Configuration

A5

A4

A3

A2

A1

A0

The function code defines the command to be performed.

C0

C1

Command

0

0

Write data to register at address

0

1

Read data from register at address

1

0

Not defined

1

1

Transmit data. A0…A5 defines the transmit configuration:

www.austriamicrosystems.com/AS3977

Bit

Function

Frequency

Selection

A2

Power level /

modulation type

selection

A3

Manchester coding

A4

PA mode

A5

Data

Synchronization

Revision 3.6

Value, Description

0 (00): selects frequency setting 1

1 (00): selects frequency setting 2

2 (10): selects frequency setting 3

3 (11): selects frequency setting 4

0: selects power level / modulation type 1

1: selects power level / modulation type 2

0: off

1: on

0: PA off at the falling edge of ENABLE (synchronized

with baud rate if A5 high)

1: DATAIO is latched at the falling edge of ENABLE

(i.e. TX data are kept constant, PA stays on)

0: off

1: on

28 - 47

�AS3977

Data Sheet - A p p l i c a t i o n I n f o r m a t i o n

9.6 Transmitter Configuration Register

All configuration registers are readable and writable. The registers are arranged as addressable bytes. The first byte (A) is addressed by 0,

the consecutive bytes (A, B, etc.) are addressed by 1,2, etc. The configuration register settings (except the registers with default

setting when entering or leaving the Power down mode), do not alter during Power down mode as long as the minimum supply requirements are

met.

Table 22. Configuration Registers

8

7

6

5

4

DIVR

ARSDRS

PLLON

FRAC1

INT1

D

INT2

F

INT3

FRAC3

0

BSEL

FRAC4

reserved

INT3

INT4

M

MCCDS

CLKS

reserved

N

ASC

reserved

LS

LT

MCCS

reserved

O

RPAOV2

FSK1

PREOP1

reserved

TCV

FSK2

PSC

reserved

LD

GFBP

reserved

TSON

PAOP2

PREOP2

PSC

ATCPH

TSRST

RPAOV1

SETPD

K

PAOP1

GFCS

reserved

DF

PREOP1

I

FRAC4

REGEN

G

L

1

FRAC2

FRAC3

J

2

FRAC1

E

H

3

reserved

9

CPSC

reserved

B

C

10

SD3

11

reserved ARSRST

12

PN9INT

A

13

reserved

14

CPSEC

15

TS

Default settings given are recommendations according to application note (not set at power up).

Table 23. Configuration Registers Description

Register

Name

Default Value

Description

Synthesizer section

A

SEL

application dependent

A

ARSRST

0

www.austriamicrosystems.com/AS3977

Revision 3.6

Frequency band selection

0 (00): 315MHz frequency band

1 (01): 434 MHz and ARIB frequency band

2 (10): 868MHz frequency band

3 (11): 915MHz frequency band

Automatic range select reset, active high

29 - 47

�AS3977

Data Sheet - A p p l i c a t i o n I n f o r m a t i o n

Table 23. Configuration Registers Description

Register

Name

Default Value

Description

A

ARSDRS

11

Automatic range select division ratio setting

0 (00): fREF/64

1 (01): fREF/128

2 (10): fREF/256

3 (11): fREF/512

A

DIVR

010

Reference divider division ratio setting must be set to

Binary 010

A

CPSEC

0

Charge pump sections setting

0: One section active

1: Two sections active

application dependent

Charge pump current setting

0 (00): 12.5 µA/Section

1 (01): 25.0 µA/Section

2 (10): 37.5 µA/Section

3 (11): 50.0 µA/Section

A

CPCS

00000

A

B

B

SD3

B

B

PN9INT

B

B

reserved Bits: set to Binary 00000 for normal mode of

operation

0

0: normal mode of operation

1: reserved for test purposes only

1

ΣΔ order selection

0: MASH2

1: MASH3

0

0: reserved Bit; set to zero

0

0: normal mode

1: reserved for test purposes only

0

0: normal mode

1: reserved for test purposes only

C

FRAC1

application dependent

Synthesizer fractional setting 1

C

INT1

application dependent

Synthesizer integer setting 1

C

PLLON

1

D

FRAC2

application dependent

Synthesizer fractional setting 2

E

INT2

application dependent

Synthesizer integer setting 2

E

FRAC3

application dependent

Synthesizer fractional setting 3

INT3

application dependent

Synthesizer integer setting 3

H

FRAC4

application dependent

Synthesizer fractional setting 4

H

INT4

application dependent

Synthesizer integer setting 4

F

F

G

G

H

www.austriamicrosystems.com/AS3977

00

Revision 3.6

0: Phase locked loop off

1: Phase locked loop on

reserved Bits: set to Binary 00 for normal mode of

operation

30 - 47

�AS3977

Data Sheet - A p p l i c a t i o n I n f o r m a t i o n

Table 23. Configuration Registers Description

Register

Name

Default Value

Description

Modulation and Power Amplifier section

I

GFCS

application dependent

Gaussian filter clock setting

I

DF

application dependent

FSK deviation setting

J

GFBP

0