NV6117

650 V GaNFast™ Power IC

2. Description

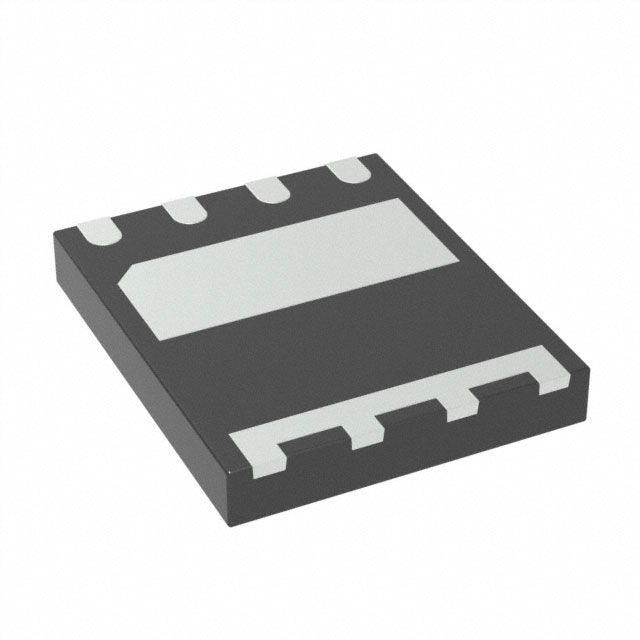

QFN 5 x 6 mm

The NV6117 is a 650 V GaNFast™ power IC,

optimized for high frequency, soft-switching topologies.

Monolithic integration of FET, drive and logic creates

an easy-to-use ‘digital-in, power-out’ high-performance

powertrain building block, enabling designers to create

the fastest, smallest, most efficient integrated

powertrain in the world.

The highest dV/dt immunity, high-speed integrated

drive and industry-standard low-profile, low-inductance,

5 x 6 mm SMT QFN package allow designers to exploit

Navitas GaN technology with simple, quick, dependable

solutions for breakthrough power density and efficiency.

Navitas’ GaNFast™ power ICs extend the

capabilities of traditional topologies such as flyback,

half-bridge, resonant, etc. to MHz+ and enable the

commercial introduction of breakthrough designs.

Simplified schematic

1. Features

GaNFast™ Power IC

• Monolithically-integrated gate drive

• Wide logic input range with hysteresis

• 5 V / 15 V input-compatible

• Wide VCC range (10 to 30 V)

• Programmable turn-on dV/dt

• 200 V/ns dV/dt immunity

• 650 V eMode GaN FET

3. Topologies / Applications

•

•

•

•

•

•

•

•

• Low 120 mΩ resistance

• Zero reverse recovery charge

• 2 MHz operation

Small, low-profile SMT QFN

• 5 x 6 mm footprint, 0.85 mm profile

• Minimized package inductance

Environmental

• RoHS, Pb-free, REACH-compliant

AC-DC, DC-DC, DC-AC

Buck, boost, half bridge, full bridge

Active Clamp Flyback, LLC resonant, Class D

Mobile fast-chargers, adapters

Notebook adaptors

LED lighting, solar micro-inverters

TV / monitor, wireless power

Server, telecom & networking SMPS

4. Typical Application Circuits

DCIN(+)

DCOUT(+)

DCIN(+)

D

VCC

PWM

D

10V to 24V

PWM

Half

Bridge

Driver

IC

REG

VDD

DZ

REG

VDD

VCC

dV/dt

DZ

dV/dt

NV6117

S

D

VCC

PWM

REG

VDD

NV6117

DZ

S

dV/dt

10V to 24V

NV6117

S

DCIN(-)

DCIN(-)

DCOUT(-)

Half-bridge

Boost

Final Datasheet

PGND

1

Rev 6-4-2018

�NV6117

5. Table of Contents

1. Features ...................................................................1

8. Functional Description ........................................ 11

2. Description ..............................................................1

8.1. Start Up ............................................................ 11

3. Topologies / Applications ......................................1

8.2. Normal Operating Mode ................................... 12

4. Typical Application Circuits ..................................1

8.3. Standby Mode .................................................. 12

6. Specifications .........................................................3

8.4. Programmable Turn-on dV/dt Control .............. 12

6.1. Absolute Maximum Ratings ................................3

8.5. Current Sensing ............................................... 13

6.2. Recommended Operating Conditions .................3

8.6. Paralleling Devices ........................................... 13

6.3. ESD Ratings........................................................4

8.7. 3.3V PWM Input Circuit .................................... 14

6.4. Thermal Resistance ............................................4

8.8. PCB Layout Guidelines .................................... 14

6.5. Electrical Characteristics .....................................5

8.9. Recommended Component Values ................. 15

6.6. Switching Waveforms .........................................6

9. Recommended PCB Land Pattern ..................... 16

6.7. Characteristic Graphs .........................................7

10. PCB Layout Guidelines ..................................... 17

7. Internal Schematic, Pin Configurations and

Functions ...................................................................10

12. QFN Package Outline ........................................ 19

13. Tape and Reel Dimensions ............................... 20

14. Ordering Information ......................................... 21

Final Datasheet

2

Rev 6-4-2018

�NV6117

6. Specifications

6.1. Absolute Maximum Ratings(1)

(with respect to Source (pad) unless noted)

SYMBOL

VDS

PARAMETER

Drain-to-Source Voltage

VTDS

Transient Drain-to-Source Voltage

VCC

Supply Voltage

(2)

MAX

UNITS

-7 to +650

V

750

V

30

V

VPWM

PWM Input Pin Voltage

-3 to +30

V

VDZ

VDD Setting Pin Voltage

6.6

V

VDD

Drive Supply Voltage

7.2

V

ID

Continuous Drain Current (@ TC = 100ºC)

12

A

ID PULSE

Pulsed Drain Current (10 µs @ TJ = 25ºC)

24

A

ID PULSE

Pulsed Drain Current (10 µs @ TJ = 125ºC)

16

A

Slew Rate on Drain-to-Source

200

V/ns

Operating Junction Temperature

-55 to 150

ºC

Storage Temperature

-55 to 150

ºC

dV/dt

TJ

TSTOR

(1) Absolute maximum ratings are stress ratings; devices subjected to stresses beyond these ratings may cause permanent damage.

(2) < 1 µS. VTDS is intended for surge rating during non-repetitive events (for example start-up, line interruption).

6.2. Recommended Operating Conditions(3)

SYMBOL

PARAMETER

MIN

TYP

MAX

UNITS

6.2

6.6

V

7.0

V

3.0

mA

25

200

Ω

5

Min. of

(VCC or 20)

V

520

V

VDZ

Drive Supply Set Zener Voltage(4)

5.8

VDD

Drive Supply Voltage

5.5

IDD_EXT

RDD

Regulator External Load Current

Gate Drive Turn-On Current Set Resistance

(5)

10

VPWM

PWM Input Pin Voltage

VDS

Drain-to-Source Voltage

VCC

Supply Voltage

10

24

V

Operating Junction Temperature

-40

125

ºC

TJ

0

(3) Exposure to conditions beyond maximum recommended operating conditions for extended periods of time may affect device reliability.

(4) Use of zener diode other than 6.2 V is not recommended. See Table I for recommended part numbers of 6.2 V zener diodes.

(5) RDD resistor must be used. Minimum 10 Ohm to ensure application and device robustness.

Final Datasheet

3

Rev 6-4-2018

�NV6117

6.3. ESD Ratings

SYMBOL

PARAMETER

MAX

UNITS

HBM

Human Body Model (per JS-001-2014)

1,000

V

CDM

Charged Device Model (per JS-002-2014)

1,000

V

TYP

UNITS

Junction-to-Case

1.8

ºC/W

Junction-to-Ambient

50

ºC/W

6.4. Thermal Resistance

SYMBOL

RɵJC

(6)

RɵJA (6)

PARAMETER

(6) Rɵ measured on DUT mounted on 1 square inch 2 oz Cu (FR4 PCB)

Final Datasheet

4

Rev 6-4-2018

�NV6117

6.5. Electrical Characteristics

Typical conditions: VDS = 400 V, VCC = 15 V, VDZ = 6.2 V, FSW = 1 MHz, TAMB = 25 ºC, ID = 6 A, RDD = 10 Ω (or specified)

SYMBOL

PARAMETER

MIN

TYP

MAX

UNITS

CONDITIONS

VCC Supply Characteristics

IQCC

VCC Quiescent Current

0.85

IQCC-SW

VCC Operating Current

2.85

VPWMH

Input Logic High Threshold (rising edge)

VPWML

Input Logic Low Threshold (falling edge)

VI-HYS

Input Logic Hysteresis

0.5

V

TON

Turn-on Propagation Delay

11

ns

Fig.1, Fig.2

TOFF

1.5

mA

VPWM = 0 V

mA

FSW = 1 MHz, VDS = Open

Low-Side Logic Input Characteristics

4

1

V

V

Turn-off Propagation Delay

9

ns

Fig.1, Fig.2

TR

Drain rise time

6

ns

Fig.1, Fig.2

TF

Drain fall time

3

ns

Fig.1, Fig.2

Switching Characteristics

FSW

Switching Frequency

tPW

Pulse width

0.02

2

MHz

1000

µs

GaN FET Characteristics

IDSS

Drain-Source Leakage Current

0.3

IDSS

Drain-Source Leakage Current

10

Drain-Source Resistance

120

VSD

Source-Drain Reverse Voltage

3.2

QOSS

Output Charge

27

nC

QRR

Reverse Recovery Charge

0

nC

COSS

Output Capacitance

27

pF

VDS = 400 V, VPWM = 0 V

41

pF

VDS = 400 V, VPWM = 0 V

67

pF

VDS = 400 V, VPWM = 0 V

RDS(ON)

CO(er)

(7)

CO(tr)(8)

Effective Output Capacitance, Energy

Related

Effective Output Capacitance, Time

Related

µA

VDS = 650 V, VPWM = 0 V

µA

VDS = 650 V, VPWM = 0 V, TC = 125 ºC

170

mΩ

VPWM = 6 V, ID = 6 A

5

V

VPWM = 0 V, ISD = 6 A

25

VDS = 400 V, VPWM = 0 V

(7) CO(er) is a fixed capacitance that gives the same stored energy as COSS while VDS is rising from 0 to 400 V

(8) CO(tr) is a fixed capacitance that gives the same charging time as COSS while VDS is rising from 0 to 400 V

Final Datasheet

5

Rev 6-4-2018

�NV6117

6.6. Switching Waveforms

(TC = 25 ºC unless otherwise specified)

VPWM

50%

NV6117

VCC

VDS

1

t

VDS

90%

PWM

D

VDD

DZ

S

10%

TOFF

TON

TF

t

Fig.2. Propagation delay and rise/fall time definitions

Fig.1. Inductive switching circuit

Final Datasheet

TR

6

Rev 6-4-2018

�NV6117

6.7. Characteristic Graphs

(GaN FET, TC = 25 ºC unless otherwise specified)

Fig.3. Pulsed Drain current (ID PULSE) vs.

Fig.4. Pulsed Drain current (ID PULSE) vs.

drain-to-source voltage (VDS) at T = 25 °C

drain-to-source voltage (VDS) at T = 125 °C

Fig.5. Source-to-drain reverse conduction voltage

Fig.6. Drain-to-source leakage current (IDSS) vs.

drain-to-source voltage (VDS)

Fig.7. VPWMH and VPWML vs. junction temperature(TJ)

Fig.8. Normalized on-resistance (RDS(ON)) vs.

junction temperature (TJ)

Final Datasheet

7

Rev 6-4-2018

�NV6117

Characteristic Graphs (Cont.)

Fig.9. Output capacitance (COSS) vs.

drain-to-source voltage (VDS)

Fig.10. Energy stored in output capacitance (EOSS) vs.

drain-to-source voltage (VDS)

Fig.11. Charge stored in output capacitance (QOSS) vs.

drain-to-source voltage (VDS)

Fig.12. VCC operating current (IQCC-SW ) vs.

operating frequency (FSW)

Fig.13. VCC quiescent current (IQCC) vs.

Fig.14. Propagation delay (TON and TOFF) vs.

junction temperature(TJ)

supply voltage (VCC)

Final Datasheet

8

Rev 6-4-2018

�NV6117

Characteristic Graphs (Cont.)

Fig.16. Power dissipation (PTOT) vs.

case temperature (TC)

Fig.15. Slew rate (dV/dt) vs. gate drive turn-on current

set resistance (RDD) at T = 25 °C

Fig.17. Max. thermal transient impedance (ZthJC) vs.

pulse width (tP)

Final Datasheet

9

Rev 6-4-2018

�NV6117

7. Internal Schematic, Pin Configurations and Functions

1

4

3

VCC

D

DZ

REG

VDD

8

7

6

5

dV/dt

2

PWM

S

PAD

Package Top View

Pin

I/O(1)

Description

Number

Symbol

1

VCC

P

Supply voltage (10V to 24V)

2

PWM

I

PWM input

3

VDD

I

Gate drive supply voltage. Gate drive turn-on current set pin (using RDD).

4

DZ

I

Gate drive supply voltage set pin (6.2 V zener to GND).

5,6,7,8

D

P

Drain of power FET

PAD

S

O, G

Source of power FET & GaN IC supply ground. Metal pad on bottom of package.

(1) I = Input, O = Output, P = Power, G = GaN IC Ground

Final Datasheet

10

Rev 6-4-2018

�NV6117

8. Functional Description

The following functional description contains additional

information regarding the IC operating modes and pin

functionality.

NV6117

8.1. Start Up

10V to 24V

VCC

1

PWM

When the VCC supply is first applied to the NV6117, care

should be taken such that the VDD and DZ pins are up at

their correct voltage levels before the PWM input signal

starts. The VDD pin ramp up time is determined by the

internal regulator current at this pin and the external

CVDD capacitor. Also, since the DZ pin voltage sets the

VDD voltage level, the VDD pin will ramp up together with

the DZ pin (Fig.18).

D

VDD

DZ

10nF

6.2V

S

Fig.18. Quick start-up circuit

For half-bridge configurations, it is important that the VCC

supply, the DZ pin, and the VDD supply of the high-side

NV6117 are all charged up to their proper levels before

the first high-side PWM pulses start. For LLC

applications, a long on-time PWM pulse to the low-side

(> 10 µs) is typically provided by the LLC controller to

allow the supply pins of the high-side NV6117 to charge

up (through the external bootstrap diode) to their correct

levels before the first high-side PWM pulses start

(Fig.19).

For active clamp flyback (ACF) applications, the halfbridge must be ready very quickly due to the soft-start

mode of the ACF controller. When the first few PWM

pulses are generated by the ACF controller, the highside supply pins of the NV6117 will require a few lowside pulses to charge up (through the external bootstrap

diode) before the high-side starts to switch (Fig.20).

Fig.19. LLC half-bridge start-up timing diagram

Fig.20. ACF half-bridge start-up timing diagram

Final Datasheet

11

Rev 6-4-2018

�NV6117

8.2. Normal Operating Mode

NV6117

During Normal Operating Mode, all of the internal circuit

blocks are active. VCC is operating within the

recommended range of 10 V to 24 V, the VDD pin is at

the voltage set by the zener diode at the DZ pin (6.2 V),

and the internal gate drive and power FET are both

enabled. The external PWM signal at the PWM pin

determines the frequency and duty-cycle of the internal

gate of the power FET. As the PWM voltage toggles

above and below the rising and falling input thresholds

(4 V and 1 V), the internal gate of the power FET toggles

on and off between VDD and 0 V (Fig.21). The drain of

the power FET then toggles between the source voltage

(typically power ground) and a higher voltage level

(650 V max), depending on the external power

conversion circuit topology.

1

D

VDD

DZ

SI1330EDL

ENABLE

S

Fig.22. Standby mode VCC cut-off circuit

8.4. Programmable Turn-on dV/dt Control

During first start-up pulses or during hard-switching

conditions, it is desirable to limit the slew rate (dV/dt) of

the drain of the power FET during turn-on. This is

necessary to reduce EMI or reduce circuit switching

noise. To program the turn-on dV/dt rate of the internal

power FET, a resistor (RDD) is placed in between the VDD

capacitor and the VDD pin. This resistor (RDD) sets the

turn-on current of the internal gate driver and therefore

sets the turn-on falling edge dV/dt rate of the drain of the

power FET (Fig.23). A typical turn-on slew-rate change

with respect to RDD is shown in Fig.15.

Minimum 10 Ω RDD is required.

t

VDS

VBUS

TON

VCC

PWM

100K

VPWM

TOFF

BSS84A

10V to 24V

t

TPERIOD

VPWM

Fig.21. Normal operating mode timing diagram

8.3. Standby Mode

TOFF

For applications where a low standby power is required,

an external series cut-off circuit (Fig.22) can be used to

disconnect VCC of the NV6117 from the main VCC supply

of the power supply. This will reduce VCC current

consumption when the converter is in burst mode during

light-load or open load conditions. The VCC cut-off circuit

consists of a series PMOS FET that is turned on and off

with a pull-down NMOS FET. The gate of the NMOS is

controlled by an external ENABLE signal that should be

provided by the main controller of the power supply. The

capacitor value at the VCC pin should then be selected

according to the desired start-up speed of the NV6117

each time the ENABLE signal toggles high. A 22 nF

capacitor at VCC, for example, will give a typical start-up

time of approximately 2 µs.

Final Datasheet

t

TON

VDS

VBUS

Drain turn-on

Falling edge

Increase RDD to

Decrease dv/dt

t

Fig.23. Turn-on dV/dt slew rate control

12

Rev 6-4-2018

�NV6117

8.5. Current Sensing

8.6. Paralleling Devices

For many applications it is necessary to sense the cycleby-cycle current flowing through the power FET. To

sense the current flowing through the NV6117, a

standard current-sensing resistor can be placed in

between the source and power ground (Fig.24). In this

configuration, all of the components around the NV6117

(CVCC, CVDD, DZ, etc.) should be grounded with a single

connection at the source. Also, an additional RC filter

can be inserted between the PWM signal and the PWM

pin (100 Ω, 100 pF typical). This filter is necessary to

prevent false triggering due to high-frequency voltage

spikes occurring at the source node due to external

parasitic inductance from the source PCB trace or the

current-sensing resistor itself.

For some applications it is desirable to parallel ICs in

order to reduce conduction losses and temperatures.

Two NV6117 ICs can be connected in parallel in a PFC

boost application working in boundary-conduction mode

(BCM) only. The parallel configuration for two NV6117

ICs is shown in Fig.25. The paired pins that are

connected together include the drain pins (D), the

source pins (S), the VCC pins, the PWM pins, and the DZ.

A single DZ diode can be shared by both ICs. The VDD

pins are not connected together and require separate

VDD supply capacitors (CVDD1, CVDD2) and separate turnon current set resistors (RDD1, RDD2). Each IC should

have its own local VCC supply filter capacitor (CVCC1,

CVCC2). The PWM pins can have a single filter resistor

(RPWM) but separate filter capacitors (CPWM1, CPWM2)

should be placed at the PWM pin of each IC. When

designing the PCB layout for the two paralleled ICs, the

drain and source connections should be made as

symmetrical as possible two avoid any parasitic

inductance or capacitance mismatch. A proper PCB

layout example for paralleling is shown in Section 11.

NV6117

10V to 24V

VCC

1

PWM

100R

100pF

D

VDD

DZ

DCIN(+)

DCOUT(+)

S

NV6117

NV6117

D

D

S

S

RCS

RDD1

RPWM

CVDD1

CVCC2

VDD

VCC

DZ

VDD

VCC

PWM

CVCC1

10V to 24V

Fig.24. Current sensing circuit

DZ

PWM

1

1

PGND

DZ

CS

RDD2

CVDD2

CPWM2

CPWM1

CS

RCS

DCIN(-)

DCOUT(-)

Fig.25. Boost schematic using two parallel ICs

Final Datasheet

13

Rev 6-4-2018

�NV6117

The following rules should be followed carefully during

the design of the PCB layout:

8.7. 3.3V PWM Input Circuit

For some applications where a 3.3 V PWM signal is

required (DSP, MCU, etc.) an additional buffer can be

placed before the PWM input pin (Fig.26) with the buffer

supply voltage connected to the VDD capacitor.

1) Place all IC filter and programming components

directly next to the IC. These components

include (CVCC, CVDD, RPWM, CPWM, RDD and DZ).

2) Keep ground trace of IC filter and programming

components separate from power GND trace.

Do not run power GND currents through ground

trace of filter components!

10V to 24V

3) For best thermal management, place thermal

vias in the source pad area to conduct the heat

out through the bottom of the package and

through the PCB board to other layers (see

Sections 10 and 11 for correct layout examples).

4) Use large PCB thermal planes (connected with

thermal vias to the source pad) and additional

PCB layers to reduce IC temperatures as much

as possible (see Sections 10 and 11 for correct

layout examples).

Fig.26. 3.3 V PWM input buffer circuit

5) For half-bridge layouts, do not extend copper

planes from one IC across the components or

pads of the other IC!

8.8. PCB Layout Guidelines

6) For high density designs, use a 4-layer PCB

and 2 oz. copper to route signal connections.

This allows layout to maintain large thermal

copper planes and reduce power device

temperature.

The design of the PCB layout is critical for good noise

immunity, sufficient thermal management, and proper

operation of the IC. Typical PCB layout examples for

without current sensing resistor, with current sensing

resistor, and paralleling, are all shown in Sections 10

and 11.

Final Datasheet

14

Rev 6-4-2018

�NV6117

8.9. Recommended Component Values

The following table (Table I) shows the recommended component values for the external filter capacitors, zener

diode, and RDD connected to the pins of the NV6117. These components should be placed as close as possible to

the IC. Please see PCB Layout guidelines for more information. The zener diode at the DZ pin should be a lowcurrent type with a flat zener, and the min/max limits must be followed. RDD must be a minimum of 10 Ω to ensure

application and device robustness.

SYM

DESCRIPTION

PART NO.

SUPPLIER

MIN

TYP

MAX

UNITS

CVCC Maximum VCC supply capacitor

0.1

µF

CVDD VDD supply capacitor

0.01

µF

RDD

Gate drive turn-on current set resistor

DZ

VDD set zener diode (DZ pin)

BZT52B6V2 RHG

MM3Z6V2ST1G

Taiwan Semiconductor

Corporation

ON-Semiconductor

10

25

200

Ω

5.8

6.2

6.6

V

RPWM PWM filter resistor

100

Ω

CPWM PWM filter capacitor

100

pF

Table I. Recommended component values.

8.9.1. Zener Selection

The zener voltage is a critical parameter that sets the internal reference for gate drive voltage and other circuitry.

The zener diode needs to be selected such that the voltage on the D Z pin is within recommended operating

conditions (5.8 V to 6.6 V) across operating temperature (-40°C to 125°C) and bias current (10 µA to 1 mA). To

ensure effective operation, the current vs. voltage characteristics of the zener diode should be measured down to

10 µA to ensure flat characteristics across the current operating range (10 µA to 1 mA). The recommended part

numbers meet these requirements. If the zener selected by user does not ensure that the voltage on the zener pin

is always within the recommended operating range, the functionality and reliability of the NV6117 can be impacted.

An external resistor (~47 k Ω) between VCC and DZ can improve zener voltage stability by adding bias current to the

zener pin to ensure the voltage on the DZ pin is always within the recommended operating range (Error! Reference

source not found.). This will add ~200 µA of quiescent current.

10V to 24V

Fig.27. Increasing Zener Bias Current for Stable Zener Voltage

Final Datasheet

15

Rev 6-4-2018

�NV6117

9. Recommended PCB Land Pattern

All dimensions are in mm

Final Datasheet

16

Rev 6-4-2018

�NV6117

10. PCB Layout Guidelines

PCB

Via

Top Layer

Bottom Layer

Component Landing

Pad (Top Layer)

Without Current Sensing Resistor

Bottom Layer

Thermal Copper Area

(adjust size as necessary)

Place supply filter

capacitor (CVCC) at

VCC pin

NV6117

CVCC

VCC Supply

1

Drain

Switching

Node

PWM Input

Gate Drive SET Resistor (RDD)

S

D

CVCC

VDD Filter Capacitor (CVDD)

D

VDD

RDD

CVDD

PCB

1

PWM

4

VDD SET Zener (DZ)

NV6117

VCC

Thermal Vias

(dia = 0.65mm, hole = 0.33mm,

pitch = 0.925mm,

via wall thickness = 1mil)

DZ

S

DZ

(Top View)

PWR GND

(Top View)

With Current Sensing Resistor

Bottom Layer

Thermal Copper Area

(adjust size as necessary)

Place supply filter

capacitor (CVCC)

NV6117

PWM filter capacitor (CPWM)

Drain

Switching

Node

CVCC

PWM filter resistor (RPWM)

VCC Supply

CVCC

1

RPWM

PWM Input

Gate Drive SET Resistor (RDD)

S

D

CPWM

4

CS

1

PWM

RDD

VDD Filter Capacitor (CVDD)

VDD SET Zener (DZ)

Current Sensing Signal

NV6117

VCC

CVDD

D

VDD

DZ

S

DZ

RCS

PCB

Current Sensing

Resistors (RCS)

Thermal Vias

(dia = 0.65mm, hole = 0.33mm,

pitch = 0.925mm,

via wall thickness = 1mil)

(Top View)

PWR GND

(Top View)

Final Datasheet

17

Rev 6-4-2018

�NV6117

11. PCB Layout Guidelines (cont.)

PCB

Via

Top Layer

Paralleling 2 ICs (Boost PFC, BCM Mode only)

Bottom Layer

Component Landing

Pad (Top Layer)

Drain Switching

Node

NV6117

NV6117

D

D

S

S

RDD1

10V to 24V

CVDD1

CVCC2

CVDD2

RDD2

CPWM2

CPWM1

RPWM

DZ

DZ

PWM

VCC

DZ

VDD

PWM

VCC

CVCC1

VDD

1

1

CS

RCS

PWR GND

Drain

Switching Node

PCB

Bottom Layer

Thermal Copper Area

(adjust size as necessary)

NV6117

NV6117

D

D

S

1

S

1

4

CVCC1

DZ

CPWM1

4

CVCC2

CPWM2

RDD1

Thermal Vias

(dia = 0.65mm, hole = 0.33mm,

pitch = 0.925mm,

via wall thickness = 1mil)

RDD2

CVDD1

CVDD2

RPWM

PWM Input

VCC Supply

CS Signal

RCS

PWR GND

Current Sensing

Resistors (RCS)

(Top View)

Final Datasheet

18

Rev 6-4-2018

�NV6117

12. QFN Package Outline

Final Datasheet

19

Rev 6-4-2018

�NV6117

13. Tape and Reel Dimensions

Final Datasheet

20

Rev 6-4-2018

�NV6117

14. Ordering Information

Part Number

Operating Temperature Grade

Storage

Temperature Range

Package

MSL

Rating

Packing

(Tape & Reel)

NV6117

-40 °C to +125 °C TCASE

-55 °C to +150 °C TCASE

5 x 6 mm QFN

3

1,000 : 7” Reel

5,000 : 13” Reel

Additional Information

DISCLAIMER Navitas Semiconductor Inc. (Navitas) reserves the right to modify the products and/or specifications described herein at any time and at Navitas’ sole

discretion. All information in this document, including descriptions of product features and performance, is subject to change without notice. Performance

specifications and the operating parameters of the described products are determined in the independent state and are not guaranteed to perform the same way

when installed in customer products. The information contained herein is provided without representation or warranty of any kind, whether express or implied. This

document is presented only as a guide and does not convey any license under intellectual property rights of Navitas or any third parties.

Navitas’ products are not intended for use in applications involving extreme environmental conditions or in life support systems.

Products supplied under Navitas Terms and Conditions.

Navitas Semiconductor, Navitas, GaNFast and associated logos are registered trademarks of Navitas.

Copyright ©2018 Navitas Semiconductor Inc. All rights reserved

Navitas Semiconductor Inc., 2101 E El Segundo Blvd, Suite 201, El Segundo, California 90245, USA.

Final Datasheet

21

Contact info@navitassemi.com

Rev 6-4-2018

�