TPS57114C-Q1

SLVSDQ7B – OCTOBER 2016 – REVISED JULY 2021

TPS57114C-Q1 Automotive 2.95-V to 6-V, 4-A 2-MHz Synchronous Buck Converter

1 Features

3 Description

•

•

The TPS57114C-Q1 device is a full-featured 6-V, 4-A,

synchronous step-down current-mode converter with

two integrated MOSFETs.

•

•

•

•

•

•

•

•

•

•

•

Low-voltage, high-density power systems

Point-of-load regulation for high-performance

DSPs, FPGAs, ASICs, and microprocessors

Broadband, networking, and optical

communications infrastructure

TPS57114C-Q1

V(VIN)

VIN

The TPS57114C-Q1 device provides accurate

regulation for a variety of loads with an accurate ±1%

voltage reference (Vref) over temperature.

Efficiency is maximized through the integrated 12-mΩ

MOSFETs and 515-μA typical supply current. Using

the enable pin, shutdown supply current is reduced to

5.5 µA by entering a shutdown mode.

The internal undervoltage lockout setting is 2.45 V,

but programming the threshold with a resistor network

on the enable pin can increase the setting. The slowstart pin controls the output-voltage start-up ramp. An

open-drain power-good signal indicates the output is

within 93% to 107% of the nominal voltage.

Frequency foldback and thermal shutdown protect the

device during an overcurrent condition.

2 Applications

•

•

The TPS57114C-Q1 device enables small designs by

integrating the MOSFETs, implementing current-mode

control to reduce external component count, reducing

inductor size by enabling up to 2-MHz switching

frequency, and minimizing the IC footprint with a small

3-mm × 3-mm thermally enhanced QFN package.

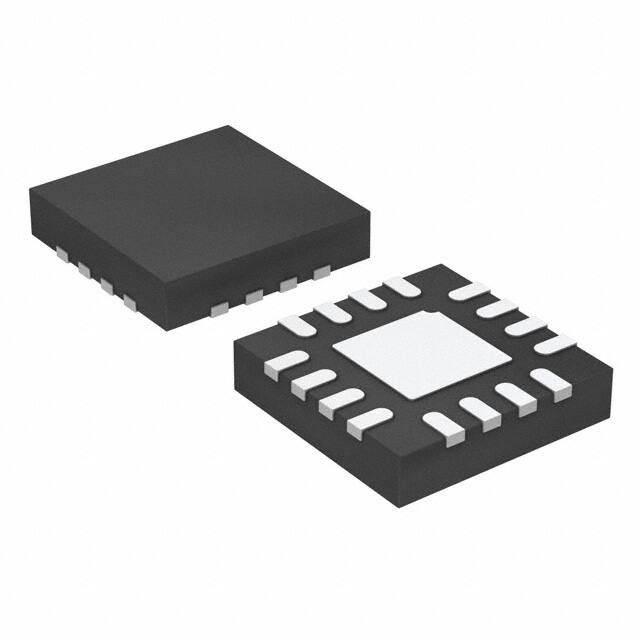

Device Information

PACKAGE(1)

PART NUMBER

TPS57114C-Q1

(1)

WQFN (16)

V(VIN) = 3 V

95

BOOT

V(VIN) = 5 V

90

R4

C(I)

L(O)

EN

85

PH

R5

VO

C(O)

R1

PWRGD

C(SS)

Rt

R3

C1

GND

AGND

Thermal Pad

80

75

70

65

VSENSE

SS/TR

RT/CLK

COMP

BODY SIZE (NOM)

3.00 mm × 3.00 mm

For all available packages, see the orderable addendum at

the end of the data sheet.

100

C(BOOT)

Efficiency (%)

•

Qualified for automotive applications

AEC-Q100 qualified with the following results:

– Device temperature grade 1: –40°C to +125°C

ambient operating temperature range

– Device HBM ESD classification level 2

– Device CDM ESD classification level C4B

Functional Safety-Capable

– Documentation available to aid functional safety

system design

Two 12-mΩ (typical) MOSFETs for high efficiency

at 4-A loads

200-kHz to 2-MHz switching frequency

0.8 V ± 1% voltage reference over temperature

(–40°C to +150°C)

Synchronizes to external clock

Adjustable slow start and sequencing

UV and OV power-good output

–40°C to +150°C operating junction temperature

range

Thermally enhanced 3-mm × 3-mm 16-pin WQFN

Pin-compatible to the TPS54418

Newer product available: TPS62810-Q1, 6-V stepdown converter in 3-mm × 2-mm VQFN package

with wettable flanks

R2

60

55

50

0

1

2

3

4

Output Current (A)

Efficiency Curve

Simplified Schematic

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�TPS57114C-Q1

www.ti.com

SLVSDQ7B – OCTOBER 2016 – REVISED JULY 2021

Table of Contents

1 Features............................................................................1

2 Applications..................................................................... 1

3 Description.......................................................................1

4 Revision History.............................................................. 2

5 Pin Configuration and Functions...................................3

6 Specifications.................................................................. 4

6.1 Absolute Maximum Ratings........................................ 4

6.2 ESD Ratings............................................................... 4

6.3 Recommended Operating Conditions.........................4

6.4 Thermal Information....................................................5

6.5 Electrical Characteristics.............................................5

6.6 Typical Characteristics................................................ 7

7 Detailed Description...................................................... 11

7.1 Overview................................................................... 11

7.2 Functional Block Diagram......................................... 12

7.3 Feature Description...................................................12

7.4 Device Functional Modes..........................................13

8 Application and Implementation.................................. 22

8.1 Application Information............................................. 22

8.2 Typical Application.................................................... 22

9 Power Supply Recommendations................................31

10 Layout...........................................................................32

10.1 Layout Guidelines................................................... 32

10.2 Layout Example...................................................... 33

11 Device and Documentation Support..........................34

11.1 Device Support........................................................34

11.2 Documentation Support.......................................... 34

11.3 Receiving Notification of Documentation Updates.. 34

11.4 Support Resources................................................. 34

11.5 Trademarks............................................................. 34

11.6 Electrostatic Discharge Caution.............................. 34

11.7 Glossary.................................................................. 34

12 Mechanical, Packaging, and Orderable

Information.................................................................... 34

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision A (July 2021) to Revision B (December 2020)

Page

• Added functional safety bullet to the Features ...................................................................................................1

• Updated the numbering format for tables, figures, and cross-references throughout the document. ................1

• Added TPS62810-Q1 bullet in the Features ......................................................................................................1

Changes from Revision * (October 2016) to Revision A (December 2019)

Page

• First public release..............................................................................................................................................1

2

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS57114C-Q1

�TPS57114C-Q1

www.ti.com

SLVSDQ7B – OCTOBER 2016 – REVISED JULY 2021

PH

12

PH

11

BOOT

PWRGD

EN

VIN

5 Pin Configuration and Functions

13

14

15

16

1

VIN

2

VIN

Exposed Thermal Pad

GND

SS/TR

9

4

GND

7

6

5

AGND

8

VSENSE

3

COMP

10

RT/CLK

PH

Figure 5-1. 16-Pin WQFN With Exposed Thermal Pad RTE Package (Bottom View)

Table 5-1. Pin Functions

PIN

I/O

DESCRIPTION

NAME

NO.

AGND

5

—

Connect analog ground electrically to GND close to the device.

BOOT

13

O

The device requires a bootstrap capacitor between BOOT and PH. Having the voltage on this capacitor

below the minimum required by the BOOT UVLO forces the output to switch off until the capacitor

recharges.

COMP

7

O

Error amplifier output, and input to the output-switch current comparator. Connect frequencycompensation components to this pin.

EN

15

I

Enable pin, internal pullup-current source. Pull below 1.2 V to disable. Float to enable. An alternative use

of this pin can be to set the on-off threshold (adjust UVLO) with two additional resistors.

GND

3

4

—

Power ground. Electrically connect this pin directly to the thermal pad under the device.

O

The source of the internal high-side power MOSFET, and drain of the internal low-side (synchronous)

rectifier MOSFET

10

PH

11

12

PWRGD

14

O

An open-drain output; asserts low if output voltage is low because of thermal shutdown, overcurrent,

overvoltage, undervoltage, or EN shutdown.

RT/CLK

8

I

Resistor-timing or external-clock input pin

SS/TR

9

I

Slow start and tracking. An external capacitor connected to this pin sets the output-voltage rise time.

Another use of this pin is for tracking.

I

Input supply voltage: 2.95 V to 6 V

I

Inverting node of the transconductance (gm) error amplifier

1

VIN

2

16

VSENSE

Thermal pad

6

—

Connect the GND pin to the exposed thermal pad for proper operation. Connect this thermal pad to any

internal PCB ground plane using multiple vias for good thermal performance.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS57114C-Q1

3

�TPS57114C-Q1

www.ti.com

SLVSDQ7B – OCTOBER 2016 – REVISED JULY 2021

6 Specifications

6.1 Absolute Maximum Ratings

Input voltage

Output voltage

MIN(1)

MAX(1)

VIN

–0.3

7

EN

–0.3

7

BOOT

–0.3

PH + 7

VSENSE

–0.3

3

COMP

–0.3

3

PWRGD

–0.3

7

SS/TR

–0.3

3

RT/CLK

–0.3

7

BOOT-PH

–0.3

7

PH

–0.6

7

–2

10

PH 10-ns transient

Source current

Sink current

UNIT

V

V

EN

100

µA

RT/CLK

100

µA

COMP

100

µA

PWRGD

10

mA

100

µA

150

°C

SS/TR

Temperature, TJ

–40

Storage temperature, Tstg

(1)

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress

ratings only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under

Recommended Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device

reliability.

6.2 ESD Ratings

VALUE

Human-body model (HBM), per AEC

V(ESD)

(1)

Electrostatic

discharge

Q100-002(1)

Charged-device model (CDM), per AEC

Q100-011

UNIT

±2000

All pins

±500

Corner pins (1, 16, 4, 5, 8, 9, 12, and 13)

±750

V

AEC Q100-002 indicates that HBM stressing shall be in accordance with the ANSI/ESDA/JEDEC JS-001 specification.

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN

4

NOM

MAX

UNIT

V(VIN)

Input voltage

2.95

6

V

TA

Operating ambient temperature

–40

125

°C

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS57114C-Q1

�TPS57114C-Q1

www.ti.com

SLVSDQ7B – OCTOBER 2016 – REVISED JULY 2021

6.4 Thermal Information

TPS57114C-Q1

THERMAL

METRIC(1)

UNIT

RTE (WQFN)

16 PINS

RθJA

Junction-to-ambient thermal resistance

43.8

°C/W

RθJC(top)

Junction-to-case(top) thermal resistance

46.1

°C/W

RθJB

Junction-to-board thermal resistance

15.5

°C/W

ψJT

Junction-to-top characterization parameter

0.7

°C/W

ψJB

Junction-to-board characterization parameter

15.5

°C/W

3.8

°C/W

RθJC(bottom) Junction-to-case(bottom) thermal resistance

(1)

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report (SPRA953).

6.5 Electrical Characteristics

TJ = –40°C to 150°C, V(VIN) = 2.95 to 6 V (unless otherwise noted)

DESCRIPTION

CONDITIONS

MIN

TYP

MAX

UNIT

VIN UVLO start

2.28

2.5

V

VIN UVLO stop

2.45

2.6

V

SUPPLY VOLTAGE (VIN PIN)

Internal undervoltage-lockout threshold

Shutdown supply current

V(EN) = 0 V, 25°C, 2.95 V ≤ V(VIN) ≤ 6 V

5.5

15

µA

Quiescent current – I(q)

V(VSENSE) = 0.9 V, V(VIN) = 5 V, 25°C, Rt = 400 kΩ

515

750

µA

Rising

1.25

Falling

1.18

Enable threshold + 50 mV

–3.2

Enable threshold – 50 mV

–1.65

ENABLE AND UVLO (EN PIN)

Enable threshold

Input current

V

µA

VOLTAGE REFERENCE (VSENSE PIN)

Voltage reference

2.95 V ≤ V(VIN) ≤ 6 V, –40°C < TJ < 150°C

0.792

0.8

0.808

BOOT-PH = 5 V

12

30

BOOT-PH = 2.95 V

16

30

V(VIN) = 5 V

13

30

V(VIN) = 2.95 V

17

30

V

MOSFET

High-side switch resistance

Low-side switch resistance

mΩ

mΩ

ERROR AMPLIFIER

Input current

2

nA

Error-amplifier transconductance (gm)

–2 µA < I(COMP) < 2 µA, V(COMP) = 1 V

245

µS

Error-amplifier transconductance (gm) during

slow start

–2 µA < I(COMP) < 2 µA, V(COMP) = 1 V,

V(VSENSE) = 0.4 V

79

µS

Error-amplifier source and sink

V(COMP) = 1 V, 100-mV overdrive

±20

µA

25

S

COMP to high-side FET current gm

CURRENT LIMIT

Current-limit threshold

V(VIN) = 2.95 V, 25°C

2 ´ DI O

f (SW ) ´ DVO

(26)

where

•

•

•

ΔIO is the change in output current

f(SW) is the regulator switching frequency

ΔVO is the allowable change in the output voltage

C(OUT) >

1

1

´

V

8 ´ f (SW )

O(ripple)

I(ripple)

(27)

where

•

•

•

f(SW) is the switching frequency

VO(ripple) is the maximum allowable output voltage ripple

I(ripple) is the inductor ripple current.

Equation 28 calculates the maximum ESR an output capacitor can have to meet the output-voltage ripple

specification. Equation 28 indicates the ESR should be less than 55 mΩ. In this case, the ESR of the ceramic

capacitor is much less than 55 mΩ.

Factoring in additional capacitance deratings for aging, temperature, and dc bias increases this minimum value.

This example uses two 22-µF, 10-V X5R ceramic capacitors with 3 mΩ of ESR.

Capacitors generally have limits to the amount of ripple current they can handle without failing or producing

excess heat. Select an output capacitor that can support the inductor ripple current. Some capacitor data sheets

specify the root-mean-square (rms) value of the maximum ripple current. Use Equation 29 to calculate the rms

ripple current that the output capacitor must support. For this application, Equation 29 yields 333 mA.

R (ESR) <

I(Co,rms) =

24

VO(ripple)

I(ripple)

(28)

VO ´ (VI(max) - VO )

12 ´ VI(max) ´ L1 ´ f (SW )

(29)

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS57114C-Q1

�TPS57114C-Q1

www.ti.com

SLVSDQ7B – OCTOBER 2016 – REVISED JULY 2021

8.2.2.4 Input Capacitor

The TPS57114C-Q1 device requires a high-quality ceramic, type X5R or X7R, input decoupling capacitor with

at least 4.7 µF of effective capacitance, and in some applications a bulk capacitance. The effective capacitance

includes any dc-bias effects. The voltage rating of the input capacitor must be greater than the maximum input

voltage. The capacitor must also have a ripple-current rating greater than the maximum input-current ripple of

the TPS57114C-Q1 device. Calculate the input ripple current using Equation 30.

The value of a ceramic capacitor varies significantly over temperature and the amount of dc bias applied to

the capacitor. One can minimize the capacitance variations due to temperature by selecting a dielectric material

that is stable over temperature. The dielectrics usually selected for power regulator capacitors are X5R and

X7R ceramic because they have a high capacitance-to-volume ratio and are fairly stable over temperature. Also

select the output capacitor with the dc bias taken into account. The capacitance value of a capacitor decreases

as the dc bias across that capacitor increases.

This example design requires a ceramic capacitor with at least a 10-V voltage rating to support the maximum

input voltage. The selections for this example are one 10-µF and one 0.1-µF 10-V capacitor in parallel. The

input capacitance value determines the input ripple voltage of the regulator. Calculate the input voltage ripple

using Equation 31. Using the design example values, IO(max) = 4 A, C(IN) = 10 µF, and f(SW) = 1 MHz, yields an

input-voltage ripple of 100 mV and an rms input-ripple current of 1.96 A.

I(Ci,rms) = I O ´

DVI =

VO

VI(min)

´

(VI(min) - VO )

VI(min)

(30)

I O(max) ´ 0.25

C(IN) ´ f (SW )

(31)

8.2.2.5 Slow-Start Capacitor

The slow-start capacitor determines the minimum amount of time it takes for the output voltage to reach its

nominal programmed value during power up. Slow start is useful if a load requires a controlled rate of voltage

slew. Another use for slow start is if the output capacitance is large and would require large amounts of current

to charge the capacitor quickly to the output-voltage level. The large currents necessary to charge the capacitor

may make the TPS57114C-Q1 device reach the current limit, or excessive current draw from the input power

supply may cause the input voltage rail to sag. Limiting the output-voltage slew rate solves both of these

problems.

Calculate the slow-start capacitor value using Equation 32. For the example circuit, the slow-start time is not too

critical because the output capacitor value is 44 µF, which does not require much current to charge to 1.8 V. The

example circuit has the slow-start time set to an arbitrary value of 4 ms, which requires a 10-nF capacitor. In the

TPS57114C-Q1 device, I(SS/TR) is 2.2 µA and Vref is 0.8 V.

C(SS) (nF) =

t (SS) (ms) ´ I(SS/TR) (mA)

Vref (V)

(32)

8.2.2.6 Bootstrap Capacitor Selection

Connect a 0.1-µF ceramic capacitor between the BOOT and PH pins for proper operation. TI recommends using

a ceramic capacitor with X5R or better-grade dielectric. The capacitor should have a 10-V or higher voltage

rating.

8.2.2.7 Output-Voltage And Feedback-Resistor Selection

For the example design, the selection for R6 is 100 kΩ. Using Equation 33, calculate R7 as 80 kΩ. The nearest

standard 1% resistor is 80.5 kΩ.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS57114C-Q1

25

�TPS57114C-Q1

www.ti.com

SLVSDQ7B – OCTOBER 2016 – REVISED JULY 2021

R7 =

Vref

´ R6

VO - Vref

(33)

Due to the internal design of the TPS57114C-Q1 device, there is a minimum output voltage limit for any given

input voltage. The output voltage can never be lower than the internal voltage reference of 0.8 V. Above 0.8 V,

an output voltage limit may exist due to the minimum controllable on-time. In this case, Equation 34 gives the

minimum output voltage

(

)

(

VO(min) = t (ONmin) ´ f(SWmax) ´ VI(max) - I O(min) ´ 2 ´ rDS(on) - I O(min) ´ R (L) + rDS(on)

)

(34)

where

•

•

•

•

•

•

•

VO(min) = minimum achievable output voltage

t(ONmin) = minimum controllable on-time (65 ns, typical; 120 ns, no load)

f(SWmax) = maximum switching frequency, including tolerance

VI(max) = maximum input voltage

IO(min) = minimum load current

rDS(on) = minimum high-side MOSFET on-resistance (15 mΩ–19 mΩ)

R(L) = series resistance of output inductor

There is also a maximum achievable output voltage, which is limited by the minimum off-time. Equation 35 gives

the maximum output voltage.

(

) (

)

(

VO(max) = 1 - t (OFFmax) ´ f (SWmax) ´ VI(min) - I O(max) ´ 2 ´ rDS(on) - I O(max) ´ R (L) + rDS(on)

)

(35)

where

•

•

•

•

•

•

•

VO(max) = maximum achievable output voltage

t(OFFmax) = maximum off-time (60 ns, typical)

f(SWmax) = maximum switching frequency, including tolerance

VI(min) = minimum input voltage

IO(max) = maximum load current

rDS(on) = maximum high-side MOSFET on-resistance (19 mΩ–30 mΩ)

R(L) = series resistance of output inductor

8.2.2.8 Compensation

There are several industry techniques used to compensate dc-dc regulators. The method presented here is easy

to calculate and yields high phase margins. For most conditions, the regulator has a phase margin between 60

and 90 degrees. The method presented here ignores the effects of the slope compensation that is internal to the

TPS57114C-Q1 device. Because of ignoring the slope compensation, the actual crossover frequency is usually

lower than the crossover frequency used in the calculations. Use SwitcherPro software for a more-accurate

design.

To get started, calculate the modulator pole, f(p,mod), and the ESR zero, f(z, mod), using Equation 36 and Equation

37. For C(OUT), derating the capacitor is not necessary, as the 1.8-V output is a small percentage of the 10-V

capacitor rating. If the output is a high percentage of the capacitor rating, use the manufacturer information for

the capacitor to derate the capacitor value. Use Equation 38 and Equation 39 to estimate a starting point for the

crossover frequency, f(c). For the example design, f(p,mod) is 6.03 kHz and f(z,mod) is 1210 kHz. Equation 38 is the

geometric mean of the modulator pole and the ESR zero and Equation 39 is the mean of the modulator pole

and the switching frequency. Equation 38 yields 85.3 kHz and Equation 39 gives 54.9 kHz. Use the lower value

of Equation 38 or Equation 39 as the approximate crossover frequency. For this example, f(c) is 56 kHz. Next,

calculate the compensation components. Use a resistor in series with a capacitor to create a compensating zero.

A capacitor in parallel with these two components forms the compensating pole (if needed).

26

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS57114C-Q1

�TPS57114C-Q1

www.ti.com

SLVSDQ7B – OCTOBER 2016 – REVISED JULY 2021

f (p,mod) =

f (z,mod) =

I O(max)

2p ´ VO ´ C(OUT)

(36)

1

2p ´ R (ESR) ´ C(OUT)

f (c) =

f (p,mod) ´ f (z,mod)

f (c) =

f (p,mod) ´

(37)

(38)

f (SW)

2

(39)

The compensation design takes the following steps:

1. Set up the anticipated crossover frequency. Use Equation 40 to calculate the resistor value for the

compensation network. In this example, the anticipated crossover frequency (f(c)) is 56 kHz. The powerstage gain (gm(ps)) is 25 S, and the error-amplifier gain (gm(ea)) is 245 µS.

R3 =

2p ´ f (c) ´ VO ´ C(OUT)

g m(ea) ´ Vref ´ g m(ps)

(40)

2. Place compensation zero at the pole formed by the load resistor and the output capacitor. Calculate the

capacitor for the compensation network using Equation 41.

C3 =

R0 ´ C0

R3

(41)

3. One can include an additional pole to attenuate high-frequency noise. In this application, the extra pole is not

necessary.

From the preceding procedures, the compensation network includes a 7.68-kΩ resistor and a 3300-pF capacitor.

8.2.2.9 Power-Dissipation Estimate

The following formulas show how to estimate the IC power dissipation under continuous-conduction mode

(CCM) operation. The power dissipation of the IC (PT) includes conduction loss (P(con)), dead-time loss (P(d)),

switching loss (P(SW)), gate-drive loss (P(gd)), and supply-current loss (P(q)).

P(con) = I O 2 ´ rDS(on)(Temp)

(42)

P(d) = f (SW ) ´ I O ´ 0.7 ´ 60 ´ 10 -9

(43)

P(SW ) = 1/2 ´ VI ´ I O ´ f (SW ) ´ 8 ´ 10 -9

(44)

P(gd) = 2 ´ VI ´ f (SW ) ´ 2 ´ 10 -9

(45)

P(q) = VI ´ 515 ´ 10 -6

(46)

where:

•

•

IO is the output current (A)

rDS(on)(Temp) is the on-resistance of the high-side MOSFET with given temperature (Ω)

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS57114C-Q1

27

�TPS57114C-Q1

www.ti.com

SLVSDQ7B – OCTOBER 2016 – REVISED JULY 2021

•

•

VI is the input voltage (V)

f(SW) is the switching frequency (Hz)

So

PT = P(con) + P(d) + P(SW ) + P(gd) + P(q)

(47)

For a given TA,

T J = TA + R qJA ´ PT

(48)

For a given TJ(max) = 150°C

T A(max) = TJ(max) - R qJA ´ PT

(49)

where:

•

•

•

•

•

•

PT is the total device power dissipation (W)

TA is the ambient temperature (°C)

TJ is the junction temperature (°C)

RθJA is the thermal resistance of the package (°C/W)

TJ(max) is maximum junction temperature (°C)

TA(max) is maximum ambient temperature (°C)

There are additional power losses in the regulator circuit due to the inductor ac and dc losses and trace

resistance that impact the overall efficiency of the regulator.

28

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS57114C-Q1

�TPS57114C-Q1

www.ti.com

SLVSDQ7B – OCTOBER 2016 – REVISED JULY 2021

8.2.3 Application Curves

100

100

90

90

80

V(VIN) = 5 V

70

70

V(VIN) = 3.3 V

Efficiency (%)

Efficiency (%)

80

60

50

40

60

50

40

30

30

20

20

0

V(VIN) = 3.3 V

V(VIN) = 5 V

10

10

2

1

0

3

0

0.001

4

0.01

Output Current (A)

0.1

Output Current (A)

VO = 1.8 V

100

100

95

95

90

D001

f(SW) = 2 MHz

90

VO = 1.8 V

85

VO = 3.3 V

80

85

Efficiency (%)

Efficiency (%)

10

Figure 8-3. Efficiency vs Load Current

Figure 8-2. Efficiency vs Load Current

VO = 1.05 V

75

70

VO = 1.05 V

75

70

65

60

60

55

VO = 1.8 V

80

65

50

1

55

2

1

0

3

4

50

1

0

V(VIN) = 5 V

f(SW) = 1 MHz

3

2

4

Output Current (A)

Output Current (A)

TA = 25°C

Figure 8-4. Efficiency vs Load Current

V(VIN) = 5 V

f(SW) = 1 MHz

TA = 25°C

Figure 8-5. Efficiency vs Load Current

V(VIN) = 2 V/div

V(VIN) = 2 V/div

EN = 1 V/div

EN = 1 V/div

SS/TR = 1 V/div

SS/TR = 1 V/div

VO = 1 V/div

VO = 1 V/div

Time = 5 ms/div

Time = 500 ms/div

Figure 8-6. Power-Up VO, V(VIN)

Figure 8-7. Power-Down VO, V(VIN)

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS57114C-Q1

29

�TPS57114C-Q1

www.ti.com

SLVSDQ7B – OCTOBER 2016 – REVISED JULY 2021

V(VIN) = 5 V/div

VO = 100 mV/div (ac-coupled)

VO = 2 V/div

IO = 1 A/div (0-A to 1.5-A load step)

EN = 2 V/div

PWRGD = 5 V/div

Time = 200 µs/div

Time = 5 ms/div

Figure 8-8. Transient Response, 1.5-A Step

Figure 8-9. Power-Up VO, V(VIN)

V(VIN) = 5 V/div

VO = 20 mV/div (ac-coupled)

VO = 2 V/div

PH = 2 V/div

EN = 2 V/div

PWRGD = 5 V/div

Time = 500 ns/div

Time = 5 ms/div

Figure 8-10. Power-Up VO, V(VIN)

Figure 8-11. Output Ripple, 4 A

150

Gain (dB)

120

Phase

80

Gain (dB)

V(VIN) = 100 mV/div (ac-coupled)

PH = 2 V/div

60

90

40

60

20

30

0

0

-20

-30

-40

-60

-60

-90

-80

-120

-100

100

VO = 1.2 V

IO = 4 A

Time = 400 ns/div

1000

10000

Frequency (Hz)

f(SW) = 2 MHz

100000

Phase (q)

100

-150

500000

D003

V(VIN) = 5 V

Figure 8-13. Closed-Loop Response

Figure 8-12. Input Ripple, 4 A

30

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS57114C-Q1

�TPS57114C-Q1

www.ti.com

SLVSDQ7B – OCTOBER 2016 – REVISED JULY 2021

0.4

0.3

0.3

V(VIN) = 5 V

Output Voltage Deviation (%)

Output Voltage Deviation (%)

0.4

0.2

0.1

V(VIN) = 3.3 V

0

–0.1

–0.2

–0.3

0.2

0.1

0

-0.1

-0.2

-0.3

–0.4

0

1

2

3

4

Output Current (A)

-0.4

3

3.5

Figure 8-14. Load Regulation vs Load Current

VO = 1.8 V

4

4.5

5

Input Voltage (V)

f(SW) = 2 MHz

5.5

6

D002

IO = 4 A

Figure 8-15. Regulation vs Input Voltage

9 Power Supply Recommendations

By design, the TPS57114C-Q1 device works with an analog supply voltage range of 2.95 V to 6 V. Ensure good

regulation for the input supply, and connect the supply to the VIN pins with the appropriate input capacitor as

calculated in Section 8.2.2.4. If the input supply is located more than a few inches from the TPS57114C-Q1

device, the design may require extra capacitance in addition to the recommended value.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS57114C-Q1

31

�TPS57114C-Q1

www.ti.com

SLVSDQ7B – OCTOBER 2016 – REVISED JULY 2021

10 Layout

10.1 Layout Guidelines

Layout is a critical portion of good power-supply design. There are several signal paths which conduct fastchanging currents or voltages that can interact with stray inductance or parasitic capacitance to generate noise

or degrade the power-supply performance. Take care to minimize the loop area formed by the bypass capacitor

connections and the VIN pins. See Figure 10-1 for a PCB layout example. Tie the GND pins and AGND pin

directly to the thermal pad under the IC. Connect the thermal pad to any internal PCB ground planes using

multiple vias directly under the IC. Use additional vias to connect the top-side ground area to the internal planes

near the input and output capacitors. For operation at full-rated load, the top-side ground area along with any

additional internal ground planes must provide adequate heat-dissipating area.

Locate the input bypass capacitor as close to the IC as possible. Route the PH pin to the output inductor.

Because the PH connection is the switching node, locate the output inductor close to the PH pins, and minimize

the area of the PCB conductor to prevent excessive capacitive coupling. Also, locate the boot capacitor close

to the device. Connect the sensitive analog ground connections for the feedback voltage divider, compensation

components, slow-start capacitor, and frequency-set resistor to a separate analog ground trace as shown. The

RT/CLK pin is particularly sensitive to noise, so locate the Rt resistor as close as possible to the IC and connect

it with minimal lengths of trace. Place the additional external components approximately as shown. It may

be possible to obtain acceptable performance with alternative PCB layout. However, this layout, meant as a

guideline, produces good results.

32

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS57114C-Q1

�TPS57114C-Q1

www.ti.com

SLVSDQ7B – OCTOBER 2016 – REVISED JULY 2021

10.2 Layout Example

VIA to

Ground

Plane

UVLO SET

RESISTORS

VIN

INPUT

BYPASS

CAPACITOR

BOOT

PWRGD

EN

VIN

VIN

BOOT

CAPACITOR

VIN

OUTPUT

INDUCTOR

PH

VIN

PH

EXPOSED

POWERPAD

AREA

GND

PH

PH

GND

VOUT

OUTPUT

FILTER

CAPACITOR

SLOW START

CAPACITOR

RT/CLK

COMP

VSENSE

AGND

SS

FEEDBACK

RESISTORS

ANALOG

GROUND

TRACE

FREQUENCY

SET

RESISTOR

TOPSIDE

GROUND

AREA

COMPENSATION

NETWORK

VIA to Ground Plane

Figure 10-1. PCB Layout Example

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS57114C-Q1

33

�TPS57114C-Q1

www.ti.com

SLVSDQ7B – OCTOBER 2016 – REVISED JULY 2021

11 Device and Documentation Support

11.1 Device Support

11.1.1 Third-Party Products Disclaimer

TI'S PUBLICATION OF INFORMATION REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT

CONSTITUTE AN ENDORSEMENT REGARDING THE SUITABILITY OF SUCH PRODUCTS OR SERVICES

OR A WARRANTY, REPRESENTATION OR ENDORSEMENT OF SUCH PRODUCTS OR SERVICES, EITHER

ALONE OR IN COMBINATION WITH ANY TI PRODUCT OR SERVICE.

11.1.2 Development Support

For more SWIFT™ documentation, see the TI Web site at www.ti.com/swift.

11.2 Documentation Support

11.2.1 Related Documentation

For related documentation see the following:

• Enable Functionality and Adjusting Undervoltage Lockout for TPS57112-Q1 (SLVA784)

• Interfacing TPS57xxx-Q1,TPS65320-Q1 Family, and TPS65321-Q1 Devices With Low Impendence External

Clock Drivers (SLVA755)

• TPS57112-Q1 High Frequency (2.35 MHz) Operation (SLVA743)

• TPS57114EVM User's Guide (SLVU963)

11.3 Receiving Notification of Documentation Updates

To receive notification of documentation updates, navigate to the device product folder on ti.com. Click on

Subscribe to updates to register and receive a weekly digest of any product information that has changed. For

change details, review the revision history included in any revised document.

11.4 Support Resources

TI E2E™ support forums are an engineer's go-to source for fast, verified answers and design help — straight

from the experts. Search existing answers or ask your own question to get the quick design help you need.

Linked content is provided "AS IS" by the respective contributors. They do not constitute TI specifications and do

not necessarily reflect TI's views; see TI's Terms of Use.

11.5 Trademarks

SWIFT™ is a trademark of Texas Instruments.

TI E2E™ is a trademark of Texas Instruments.

All trademarks are the property of their respective owners.

11.6 Electrostatic Discharge Caution

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled

with appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may

be more susceptible to damage because very small parametric changes could cause the device not to meet its published

specifications.

11.7 Glossary

TI Glossary

This glossary lists and explains terms, acronyms, and definitions.

12 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

34

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS57114C-Q1

�PACKAGE OPTION ADDENDUM

www.ti.com

10-Dec-2020

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

MSL Peak Temp

Op Temp (°C)

Device Marking

(3)

(4/5)

(6)

TPS57114CQRTERQ1

ACTIVE

WQFN

RTE

16

3000

RoHS & Green

NIPDAU

Level-3-260C-168 HR

-40 to 125

7114Q

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of