Product

Folder

Order

Now

Technical

Documents

Support &

Community

Tools &

Software

UCD90160A

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

UCD90160A 16-Rail Power Supply Sequencer and Monitor With ACPI Support

1 Features

3 Description

•

The UCD90160A is a 16-rail PMBus/I2C addressable

power supply sequencer and monitor. The device

integrates a 12-bit ADC for monitoring up to 16 power

supply voltage inputs. Twenty-six GPIO pins can be

used for power supply enables, power-on reset

signals, external interrupts, cascading, or other

system functions. Twelve of these pins offer PWM

functionality. Using these pins, the UCD90160A offers

support for margining, and general-purpose PWM

functions.

1

•

•

•

•

•

•

•

•

•

•

Monitor and sequence 16 voltage rails

– All rails sampled every 400 μs

– 12-Bit ADC with 2.5-V, 0.5% internal VREF

– Sequence based on time, rail and pin

dependencies

– Four programmable undervoltage and

overvoltage thresholds per monitor

Nonvolatile error and peak-value logging per

monitor (up to 12 fault detail entries)

Closed-loop margining for 10 rails

– Margin output adjusts rail voltage to match

user-defined margin thresholds

Programmable watchdog timer and system reset

Easily cascade multiple power sequencers and

take coordinated fault responses

Pin selected rail states for ACPI support

Flexible digital I/O configuration

Cascading multiple devices

Response and monitor to GPI-triggered fault

Multi-phase PWM clock generator

– Clock frequencies from 15.259 kHz to 125

MHz

– Capability to configure independent clock

outputs for synchronizing switch-mode power

supplies

JTAG and I2C/SMBus/PMBus™ interfaces

2 Applications

•

•

•

•

•

•

•

Wired networking

Wireless infrastructure

Datacom module

Data center and enterprise computing

Factory automation and control

Test and measurement

Medical

Specific power states can be achieved using the PinSelected Rail States feature. This feature allows with

the use of up to 3 GPIs to enable and disable any

rail. This is useful for implementing system low-power

modes and the Advanced Configuration and Power

Interface (ACPI) specification that is used for

hardware devices.

The Fault Pin feature enables easily cascading

multiple devices and coordinates among those

devices to take synchronized fault responses.

The TI Fusion Digital Power™ designer software is

provided for device configuration. This PC-based

graphical user interface (GUI) offers an intuitive

interface for configuring, storing, and monitoring all

system operating parameters.

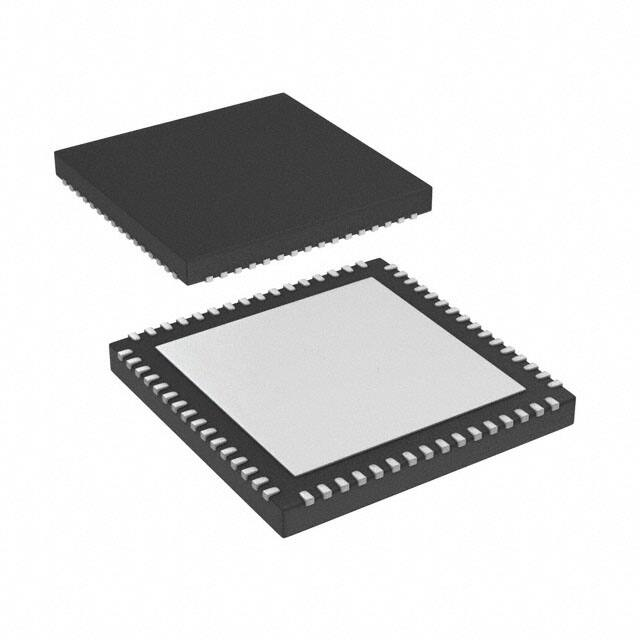

Device Information(1)

PART NUMBER

PACKAGE

UCD90160A

BODY SIZE (NOM)

VQFN (64)

9.00 mm × 9.00 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Simplified Application

12-V OUT

12 V

3.3-V Supply

12-V OUT

V33A

V33D

VMON

VOUT

3.3 V

VMON

VOUT

1.8 V

VMON

VOUT

0.8 V

VMON

GPIO

VOUT

3.3 V

GPIO

EN

VIN

VOUT

DC-DC1

VFB

UCD90160A

VMON

VMON

VMON

VMON

WDI from main

processor

GPIO

VIN

GPIO

EN

VOUT

VOUT

1.8 V

LDO1

WDO

GPIO

POWER_GOOD

GPIO

WARN_OV_ 0.8 V

or WARN_OV_12 V

GPIO

SYSTEM_RESET

GPIO

GPIO

EN

VIN

VOUT

VOUT

0.8 V

DC-DC2

VFB

Other sequencer

done (cascade input)

GPIO

I2C/PMBUS

2 MHz

PWM

JTAG

VMARG

Closed loop

margining

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�UCD90160A

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

6

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6

6

6

6

7

8

9

Absolute Maximum Ratings .....................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Timing Requirements ................................................

Typical Characteristics ..............................................

Detailed Description ............................................ 10

7.1

7.2

7.3

7.4

Overview .................................................................

Functional Block Diagram .......................................

Feature Description.................................................

Device Functional Modes........................................

10

10

10

16

7.5 Programming........................................................... 40

8

Application and Implementation ........................ 45

8.1 Application Information............................................ 45

8.2 Typical Application ................................................. 45

9 Power Supply Recommendations...................... 48

10 Layout................................................................... 48

10.1 Layout Guidelines ................................................. 48

10.2 Layout Example .................................................... 49

11 Device and Documentation Support ................. 51

11.1

11.2

11.3

11.4

11.5

11.6

11.7

Device Support......................................................

Documentation Support ........................................

Receiving Notification of Documentation Updates

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

51

51

51

51

51

51

51

12 Mechanical, Packaging, and Orderable

Information ........................................................... 51

4 Revision History

Changes from Revision B (August 2019) to Revision C

Page

•

Changed Figure 32............................................................................................................................................................... 45

•

Added two more design requirements ................................................................................................................................. 46

Changes from Revision A (February 2018) to Revision B

Page

•

Changed Applications list ...................................................................................................................................................... 1

•

Changed "52" to "53" ............................................................................................................................................................. 5

Changes from Original (September 2016) to Revision A

Page

•

Changed the Timing Requirements table .............................................................................................................................. 8

•

Changed Figure 28 .............................................................................................................................................................. 38

2

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

�UCD90160A

www.ti.com

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

5 Pin Configuration and Functions

5

MON5

TMS/GPIO22

39

6

MON6

TRST

40

55

MON7

56

MON8

GPIO1

11

57

MON9

GPIO2

12

58

MON10

GPIO3

13

59

MON11

GPIO4

14

NC1

MON14

AVSS1

49

MON16

50

MON7

54

51

MON8

55

NC2

MON9

56

MON15

MON10

57

52

MON11

58

38

PMBUS_ADDR1

TDI/GPIO21

59

MON4

PMBUS_ADDR0

4

60

37

MON12

TDO/GPIO20

61

MON3

MON13

36

3

62

10

TCK/GPIO19

AVSS3

TRCK

MON2

63

MON1

2

64

1

53

RGC Package

64-Pin VQFN

Top View

BPCAP

V33D

V33A

V33DIO1

V33DIO2

7 44 45 46 47

MON1

1

MON2

2

47

BPCap

MON3

3

46

V33A

48

AVSS2

MON4

4

45

V33D

MON5

5

44

V33DIO2

MON6

6

43

DVSS3

V33DIO1

7

42

PWM3/GPI3

DVSS1

8

41

PWM4/GPI4

RESET

9

40

TRST

TRCK

10

39

TMS/GPIO22

GPIO1

11

38

TDI/GPIO21

GPIO2

12

37

TDO/GPIO20

Thermal

Pad

21

FPWM6/GPIO10

22

FPWM7/GPIO11

23

FPWM8/GPIO12

24

RESET

9

PMBUS_ADDR0

60

PMBUS_ADDR1

31

PWM1/GPI1

32

PWM2/GPI2

42

PWM3/GPI3

41

PWM4/GPI4

51

NC1

53

NC2

AVSS3

61

DVSS1

PMBUS_CNTRL

32

20

FPWM5/GPIO9

28

PWM2/GPI2

19

FPWM4/GPIO8

PMBUS_ALERT

31

18

FPWM3/GPIO7

PMBUS_DATA

27

30

17

FPWM2/GPIO6

16

GPIO15

FPWM1/GPIO5

PMBUS_CLK

PWM1/GPI1

35

15

29

34

GPIO18

GPIO14

GPIO17

28

MON16

PMBUS_CNTRL

54

27

33

PMBALERT

GPIO16

26

MON15

DVSS2

GPIO16

52

25

33

GPIO13

16

24

PMBUS_DATA

FPWM8/GPIO12

GPIO17

30

23

34

GPIO15

FPWM7/GPIO11

15

MON14

22

PMBUS_CLK

50

FPWM6/GPIO10

GPIO18

21

35

FPWM5/GPIO9

14

20

GPIO4

FPWM4/GPIO8

29

19

GPIO14

FPWM3/GPIO7

MON13

18

TCK/GPIO19

63

17

36

FPWM2/GPIO6

13

FPWM1/GPIO5

GPIO3

AVSS1

25

AVSS2

GPIO13

DVSS3

MON12

DVSS2

62

8 26 43 48 49 64

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

3

�UCD90160A

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

www.ti.com

Pin Functions (1)

PIN

NAME

NO.

I/O

DESCRIPTION

ANALOG MONITOR INPUTS

MON1

1

I

Analog input (0 to 2.5 V)

MON2

2

I

Analog input (0 to 2.5 V)

MON3

3

I

Analog input (0 to 2.5 V)

MON4

4

I

Analog input (0 to 2.5 V)

MON5

5

I

Analog input (0 to 2.5 V)

MON6

6

I

Analog input (0 to 2.5 V)

MON7

55

I

Analog input (0 to 2.5 V)

MON8

56

I

Analog input (0 to 2.5 V)

MON9

57

I

Analog input (0 to 2.5 V)

MON10

58

I

Analog input (0 to 2.5 V)

MON11

59

I

Analog input (0 to 2.5 V)

MON12

62

I

Analog input (0 to 2.5 V)

MON13

63

I

Analog input (0 to 2.5 V)

MON14

50

I

Analog input (0.2 to 2.5 V)

MON15

52

I

Analog input (0.2 to 2.5 V)

MON16

54

I

Analog input (0.2 to 2.5 V)

GENERAL-PURPOSE INPUT AND OUTPUT

GPIO1

11

I/O

General-purpose discrete I/O

GPIO2

12

I/O

General-purpose discrete I/O

GPIO3

13

I/O

General-purpose discrete I/O

GPIO4

14

I/O

General-purpose discrete I/O

GPIO13

25

I/O

General-purpose discrete I/O

GPIO14

29

I/O

General-purpose discrete I/O

GPIO15

30

I/O

General-purpose discrete I/O

GPIO16

33

I/O

General-purpose discrete I/O

GPIO17

34

I/O

General-purpose discrete I/O

GPIO18

35

I/O

General-purpose discrete I/O

FPWM1/GPIO5

17

I/O/PWM

PWM (15.259 kHz to 125 MHz) or GPIO

FPWM2/GPIO6

18

I/O/PWM

PWM (15.259 kHz to 125 MHz) or GPIO

FPWM3/GPIO7

19

I/O/PWM

PWM (15.259 kHz to 125 MHz) or GPIO

FPWM4/GPIO8

20

I/O/PWM

PWM (15.259 kHz to 125 MHz) or GPIO

FPWM5/GPIO9

21

I/O/PWM

PWM (15.259 kHz to 125 MHz) or GPIO

FPWM6/GPIO10

22

I/O/PWM

PWM (15.259 kHz to 125 MHz) or GPIO

FPWM7/GPIO11

23

I/O/PWM

PWM (15.259 kHz to 125 MHz) or GPIO

FPWM8/GPIO12

24

I/O/PWM

PWM (15.259 kHz to 125 MHz) or GPIO

PWM1/GPI1

31

I/PWM

Fixed 10-kHz PWM output or GPI

PWM2/GPI2

32

I/PWM

Fixed 1-kHz PWM output or GPI

PWM3/GPI3

42

I/PWM

PWM (0.93 Hz to 7.8125 MHz) or GPI

PWM4/GPI4

41

I/PWM

PWM (0.93 Hz to 7.8125 MHz) or GPI

PWM OUTPUTS

(1)

4

The maximum number of configurable rails is 16. The maximum number of configurable GPIs is 8. The maximum number of

configurable Boolean Logic GPOs is 16.

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

�UCD90160A

www.ti.com

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

Pin Functions(1) (continued)

PIN

NAME

NO.

I/O

DESCRIPTION

PMBus COMM INTERFACE

PMBUS_CLK

15

I/O

PMBus clock (must have pullup to 3.3 V)

PMBUS_DATA

16

I/O

PMBus data (must have pullup to 3.3 V)

PMBALERT

27

O

PMBus alert, active-low, open-drain output (must have pullup to 3.3 V)

PMBUS_CNTRL

28

I

PMBus control

PMBUS_ADDR0

61

I

PMBus analog address input. Least-significant address bit

PMBUS_ADDR1

60

I

PMBus analog address input. Most-significant address bit

JTAG

TRCK

10

O

Test return clock

TCK/GPIO19

36

I/O

Test clock or GPIO

TDO/GPIO20

37

I/O

Test data out or GPIO

TDI/GPIO21

38

I/O

Test data in (tie to VDD with 10-kΩ resistor) or GPIO

TMS/GPIO22

39

I/O

Test mode select (tie to VDD with 10-kΩ resistor) or GPIO

TRST

40

I

Test reset. Tie to ground with 10-kΩ resistor

INPUT POWER AND GROUNDS

RESET

9

Active-low device reset input. Hold low for at least 2 μs to reset the device. Refer to the

Device Reset section.

V33A

46

Analog 3.3-V supply. Refer to the Layout Guidelines section.

V33D

45

Digital core 3.3-V supply. Refer to the Layout Guidelines section.

V33DIO1

7

Digital I/O 3.3-V supply. Refer to the Layout Guidelines section.

V33DIO2

44

Digital I/O 3.3-V supply. Refer to the Layout Guidelines section.

BPCap

47

1.8-V bypass capacitor. Refer to the Layout Guidelines section.

AVSS1

49

Analog ground

AVSS2

48

Analog ground

AVSS3

64

Analog ground

DVSS1

8

Digital ground

DVSS2

26

Digital ground

DVSS3

43

Digital ground

NC1

51

No Connect

NC2

53

No Connect

QFP ground pad

NA

Thermal pad – tie to ground plane.

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

5

�UCD90160A

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

www.ti.com

6 Specifications

6.1 Absolute Maximum Ratings (1)

MIN

MAX

UNIT

Voltage applied at V33D to DVSS

–0.3

3.8

V

Voltage applied at V33A to AVSS

–0.3

3.8

V

–0.3

(V33A + 0.3)

V

–55

150

°C

Voltage applied to any other pin

(2)

Storage temperature, Tstg

(1)

(2)

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only and functional operation of the device at these or any other conditions beyond those indicated under Recommended Operating

Conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

All voltages referenced to VSS

6.2 ESD Ratings

VALUE

V(ESD)

(1)

(2)

Electrostatic discharge

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001 (1)

±2500

Charged device model (CDM), per JEDEC specification JESD22C101 (2)

±750

UNIT

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

Supply voltage during operation (V33D, V33DIO, V33A)

Operating free-air temperature range, TA

MIN

NOM

MAX

3

3.3

3.6

V

110

°C

125

°C

–40

Junction temperature, TJ

UNIT

6.4 Thermal Information

UCD90160A

THERMAL METRIC (1)

RGC [VQFN]

UNIT

64 PINS

RθJA

Junction-to-ambient thermal resistance

26.4

°C/W

RθJC(top)

Junction-to-case(top) thermal resistance

21.2

°C/W

RθJB

Junction-to-board thermal resistance

1.7

°C/W

ψJT

Junction-to-top characterization parameter

0.7

°C/W

ψJB

Junction-to-board characterization parameter

8.8

°C/W

RθJC(bot)

Junction-to-case(bottom) thermal resistance

1.7

°C/W

(1)

6

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

�UCD90160A

www.ti.com

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

6.5 Electrical Characteristics

over operating free-air temperature range (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN NOM

MAX

UNIT

SUPPLY CURRENT

IV33A

VV33A = 3.3 V

8

mA

IV33DIO

VV33DIO = 3.3 V

2

mA

VV33D = 3.3 V

40

mA

VV33D = 3.3 V, storing configuration parameters

in flash memory

50

mA

IV33D

Supply current (1)

IV33D

ANALOG INPUTS (MON1–MON16)

VMON

Input voltage range

MON1–MON13

MON14–MON16

0

2.5

0.2

2.5

V

V

INL

ADC integral nonlinearity

–4

4

LSB

DNL

ADC differential nonlinearity

-2

2

LSB

Ilkg

Input leakage current

3 V applied to pin

IOFFSET

Input offset current

1-kΩ source impedance

MON1–MON13, ground reference

RIN

Input impedance

CIN

Input capacitance

tCONVERT

ADC sample period

16 voltages sampled, 3.89 μsec/sample

VREF

ADC 2.5 V, internal reference

accuracy

0°C to 125°C

MON14–MON16, ground reference

100

–5

nA

5

μA

8

0.5

MΩ

1.5

3

MΩ

10

–40°C to 125°C

pF

400

μsec

–0.5%

0.5%

–1%

1%

9

11

ANALOG INPUT (PMBUS_ADDRx)

IBIAS

Bias current for PMBus Addr pins

VADDR_OPEN

Voltage – open pin

PMBUS_ADDR0, PMBUS_ADDR1 open

VADDR_SHORT

Voltage – shorted pin

PMBUS_ADDR0, PMBUS_ADDR1 short to

ground

μA

2.26

V

0.124

V

Dgnd +

0.25

V

DIGITAL INPUTS AND OUTPUTS

VOL

Low-level output voltage

IOL = 6 mA (2), V33DIO = 3 V

VOH

High-level output voltage

IOH = –6 mA (3), V33DIO = 3 V

VIH

High-level input voltage

V33DIO = 3 V

VIL

Low-level input voltage

V33DIO = 3.5 V

V33DIO

– 0.6

V

2.1

3.6

V

1.4

V

MARGINING OUTPUTS

TPWM_FREQ

MARGINING-PWM frequency

FPWM1-8

PWM3-4

DUTYPWM

MARGINING-PWM duty cycle range

15.260

125000

0.001

7800

0%

100%

kHz

SYSTEM PERFORMANCE

VDDSlew

Minimum VDD slew rate

VDD slew rate between 2.3 V and 2.9 V

VRESET

Supply voltage at which device

comes out of reset

For power-on reset (POR)

tRESET

Low-pulse duration needed at

RESET pin

To reset device during normal operation

f(PCLK)

Internal oscillator frequency

TA = 125°C, TA = 25°C

240

tretention

Retention of configuration

parameters

TJ = 25°C

100

Years

Write_Cycles

Number of nonvolatile erase/write

cycles

TJ = 25°C

20

K cycles

(1)

(2)

(3)

0.25

V/ms

2.4

V

2

μS

250

260

MHz

Typical supply current values are based on device programmed but not configured, and no peripherals connected to any pins.

The maximum total current, IOLmax, for all outputs combined, should not exceed 12 mA to hold the maximum voltage drop specified.

The maximum total current, IOHmax, for all outputs combined, should not exceed 48 mA to hold the maximum voltage drop specified.

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

7

�UCD90160A

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

www.ti.com

6.6 Timing Requirements

The timing characteristics and timing diagram for the communications interface that supports I2C/SMBus, and PMBus are

shown in Figure 1 and Figure 2.

PARAMETER

TEST CONDITIONS

MIN

TYP MAX

UNIT

Typical values at TA = 25°C and VCC = 3.3 V (unless otherwise noted)

fSMB

SMBus/PMBus operating frequency

Slave mode, SMBC 50% duty cycle

10

400

kHz

fI2C

I2C operating frequency

Slave mode, SCL 50% duty cycle

10

400

kHz

t(BUF)

Bus free time between start and stop

1.3

μs

t(HD:STA)

Hold time after (repeated) start

0.6

μs

t(SU:STA)

Repeated start setup time

0.6

μs

t(SU:STO)

Stop setup time

0.6

μs

t(HD:DAT)

Data hold time

0

ns

t(SU:DAT)

Data setup time

t(TIMEOUT)

Error signal/detect

t(LOW)

Clock low period

Receive mode

100

See

(1)

1.3

t(HIGH)

Clock high period

See

(2)

t(LOW:SEXT)

Cumulative clock low slave extend time

See

(3)

tf

Clock/data fall time

Fall time tf = 0.9 VDD to (VILmax – 0.15)

tr

Clock/data rise time

Rise time tr = (VILmax – 0.15) to (VIHmin

+ 0.15)

Cb

Total capacitance of one bus line

(1)

(2)

(3)

(4)

ns

35

ms

μs

0.6

μs

25

ms

20 + 0.1 Cb (4)

300

ns

20 + 0.1 Cb (4)

300

ns

400

pF

The device times out when any clock low exceeds t(TIMEOUT).

t(HIGH), Max, is the minimum bus idle time. SMBC = SMBD = 1 for t > 50 ms causes reset of any transaction that is in progress. This

specification is valid when the NC_SMB control bit remains in the default cleared state (CLK[0] = 0).

t(LOW:SEXT) is the cumulative time a slave device is allowed to extend the clock cycles in one message from initial start to the stop.

Cb in picofarads (pF)

Figure 1. I2C/SMBus Timing Diagram

Start

Stop

TLOW:SEXT

TLOW:MEXT

TLOW:MEXT

TLOW:MEXT

PMB_Clk

Clk ACK

Clk ACK

PMB_Data

Figure 2. Bus Timing in Extended Mode

8

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

�UCD90160A

www.ti.com

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

2.500

1.3

2.498

1.0

2.496

0.8

2.494

0.5

DNL High

0.3

DNL Low

DNL (LSB)

ADC Reference Voltage (V)

6.7 Typical Characteristics

2.492

2.490

0.0

2.488

±0.3

2.486

±0.5

2.484

±0.8

2.482

±50

±30

±10

10

30

50

70

90

110

Temperature (Cƒ)

±1.0

130

±50

±30

10

±10

30

50

70

90

110

Temperature (ƒC)

C001

Figure 3. ADC Reference Voltage vs Temperature

130

C002

Figure 4. ADC Differential Nonlinearity vs Temperature

2.5

2.0

INL (LSB)

1.5

1.0

INL High

0.5

INL Low

0.0

±0.5

±1.0

±1.5

±50

±30

±10

10

30

50

70

Temperature (ƒC)

90

110

130

C003

Figure 5. ADC Integral Nonlinearity vs Temperature

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

9

�UCD90160A

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

www.ti.com

7 Detailed Description

7.1 Overview

Electronic systems that include CPU, DSP, microcontroller, FPGA, ASIC, etc. can have multiple voltage rails and

require certain power on/off sequences in order to function correctly. The UCD90160A can control up to 16

voltage rails and ensure correct power sequences during normal condition and fault conditions.

In addition to sequencing, UCD90160A can continuously monitor rail voltages, fault conditions, and report the

system health information to a PMBus host, improving systems’ long term reliability.

Also, UCD90160A can protect electronic systems by responding to power system faults. The fault responses are

conveniently configured with Fusion Digital Power Designer software. Fault events are stored in on-chip

nonvolatile flash memory with time stamp in order to assist failure analysis.

System reliability can be improved through four-corner testing during system verification. During four-corner

testing, each voltage rail is required to operate at the minimum and maximum output voltages, commonly known

as margining. UCD90160A can perform closed-loop margining for up to 10 voltage rails. During normal

operation, UCD90160A can also actively trim DC output voltages using the same margining circuitry.

UCD90160A supports both PMBus- and pin-based control environments. UCD90160A functions as a PMBus

slave. It can communicate with PMBus host with PMBus commands, and control voltage rails accordingly. Also,

UCD90160A can be controlled by up to 8 GPIO configured GPI pins. One GPI can be used as fault pin which

can shut down rails. The GPIs can be used as Boolean logic input to control up to 16 Logic GPO outputs. Each

Logic GPO has a flexible Boolean logic builder. Input signals of the Boolean logic builder can include GPIs, other

Logic GPO outputs, and selectable system flags such as POWER_GOOD, faults, warnings, etc. A simple state

machine is also available for each Logic GPO pin.

UCD90160A provides additional features such a scascading, pin-selected states, system watchdog, system

reset, runtime clock, peak value log, reset counter, and so on. Pin-selected states feature allows users to use up

to 3 GPIs to define up to 8 rail states. These states can implement system low-power modes as set out in the

Advanced Configuration and Power Interface (ACPI) specification.

7.2 Functional Block Diagram

Comparators

JTAG

Or

GPIO

I2C/PMBus

General Purpose I/O

(GPIO)

Rail Enables (16 max)

6

Digital Outputs (16 max)

Monitor

Inputs

Digital Inputs (8 max)

16

12-bit

200ksps,

ADC

(0.5% Int. Ref)

22

SEQUENCING ENGINE

Multi-phase PWM (8 max)

FLASH Memory

User Data, Fault

and Peak Logging

BOOLEAN

Logic Builder

Margining Outputs (10 max)

64-pin QFN

7.3 Feature Description

7.3.1 Rail Configuration

A rail includes voltage, a power supply enable and a margining output. At least one must be included in a rail

definition. Once the user has defined how the power supply rails should operate in a particular system, analog

input pins and GPIOs can be selected to monitor and enable each supply (Figure 6).

10

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

�UCD90160A

www.ti.com

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

Feature Description (continued)

Figure 6. Fusion Digital Power Designer Software Pin-Assignment Tab

After the pins have been configured, other key monitoring and sequencing criteria are selected for each rail from

the Vout Config tab (Figure 7):

• Nominal operating voltage (VOUT)

• Undervoltage (UV) and overvoltage (OV) warning and fault limits

• Margin-low and margin-high values

• Power-good on and power-good off limits

• PMBus or pin-based sequencing control (On/Off Config)

• Rails, GPOs and GPIs for Sequence On dependencies

• Rails, GPOs and GPIs for Sequence Off dependencies

• Turn-on and turn-off delay timing

• Maximum time allowed for a rail to reach POWER_GOOD_ON or POWER_GOOD_OFF after being enabled

or disabled

• Other rails to turn off in case of a fault on a rail (fault-shutdown slaves)

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

11

�UCD90160A

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

www.ti.com

Feature Description (continued)

Figure 7. Fusion Digital Power Designer Software VOUT-Config Tab

Use the Synchronize margins/limits/PG to Vout checkbox to change the nominal operating voltage of a rail and

also update all of the other limits associated with that rail according to the percentages shown to the right of each

entry.

The plot in the upper left section of Figure 7 shows a simulation of the overall sequence-on and sequence-off

configuration, including the nominal voltage, the turnon and turnoff delay times, the power-good on and powergood off voltages and any timing dependencies between the rails.

After a rail voltage has reached its POWER_GOOD_ON voltage and is considered to be in regulation, it is

compared against two UV and two OV thresholds in order to determine if a warning or fault limit has been

exceeded. If a fault is detected, the UCD90160A responds based on a variety of flexible, user-configured options.

Faults can cause rails to restart, shut down immediately, sequence off using turnoff delay times or shut down a

group of rails and sequence them back on. Different types of faults can result in different responses.

Fault responses, along with a number of other parameters including user-specific manufacturing information and

external scaling and offset values, are selected in the different tabs within the Configure function of the Fusion

Digital Power Designer software. Once the configuration satisfies the user requirements, it can be written to

device SRAM if Fusion Digital Power Designer software is connected to a UCD90160A device using an I2C or

PMBus interface. SRAM contents are stored to data flash memory so that the configuration remains in the device

after a reset or power cycle.

The Fusion Digital Power Designer software Monitor page has a number of options, including a device

dashboard and a system dashboard, for viewing and controlling device and system status.

12

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

�UCD90160A

www.ti.com

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

Feature Description (continued)

Figure 8. Fusion Digital Power Designer Software Monitor Page

The UCD90160A also has rail state for each rail to debug the system.

Table 1. Rail State

RAIL STATE

VALUE

DESCRIPTION

IDLE

1

On condition is not met, or

rail is shut down due to fault, or

rail is waiting for the resequence

SEQ_ON

2

Wait the dependency to be met to assert ENABLE signal

START_DELAY

3

TON_DELAY to assert ENABLE signal

RAMP_UP

4

Enable is asserted and rail is on the way to reach power good threshold. If the

power good threshold is set to 0 V, the rail stays at this state even if the

monitored voltage is bigger than 0 V.

REGULATION

5

Once the monitoring voltage is over POWER_GOOD when enable signal is

asserted, rails stay at this state even if the voltage is below POWER_GOOD

late as long as there is no fault action taken.

SEQ_OFF

6

Wait the dependency to be met to de-assert ENABLE signal

STOP_DELAY

7

TOFF_DELAY to de-assert ENABLE signal

8

Enable signal is de-asserted and rail is ramping down. This state is only

available if TOFF_MAX_WARN_LIMIT is not set to unlimited; or If the turn off

is triggered by a fault action, rail must not be under fault retry to show RAMP

DOWN state. Otherwise, IDLE state is present.

RAMP_DOWN

The UCD90160A also has status registers for each rail and the capability to log faults to flash memory for use in

system troubleshooting. This is helpful in the event of a power supply or system failure. The status registers

(Figure 9) and the fault log (Figure 10) are available in the Fusion Digital Power Designer software. See the

UCD90xxx Sequencer and System Health Controller PMBus Command Reference (SLVU352) and the PMBus

Specification for detailed descriptions of each status register and supported PMBus commands.

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

13

�UCD90160A

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

www.ti.com

Figure 9. Fusion GUI Rail-Status Register

14

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

�UCD90160A

www.ti.com

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

Figure 10. Fusion GUI Flash-Error Log (Logged Faults)

7.3.2 TI Fusion GUI

The Texas Instruments Fusion Digital Power Designer is provided for device configuration. This PC-based

graphical user interface (GUI) offers an intuitive I2C/PMBus interface to the device. It allows the design engineer

to configure the system operating parameters for the application without directly using PMBus commands, store

the configuration to on-chip nonvolatile memory, and observe system status (voltage, etc). Fusion Digital Power

Designer is referenced throughout the data sheet as Fusion Digital Power Designer software and many sections

include screen shots. The Fusion Digital Power Designer software can be downloaded from www.ti.com.

7.3.3 PMBus Interface

The PMBus is a serial interface specifically designed to support power management. It is based on the SMBus

interface that is built on the I2C physical specification. The UCD90160A supports revision 1.1 of the PMBus

standard. Wherever possible, standard PMBus commands are used to support the function of the device. For

unique features of the UCD90160A, MFR_SPECIFIC commands are defined to configure or activate those

features. These commands are defined in the UCD90xxx Sequencer and System Health Controller PMBUS

Command Reference (SLVU352). The most current UCD90xxx PMBus Command Reference can be found within

the TI Fusion Digital Power Designer software via the Help Menu (Help, Documentation & Help Center,

Sequencers tab, Documentation section).

This document makes frequent mention of the PMBus specification. Specifically, this document is PMBus Power

System Management Protocol Specification Part II – Command Language, Revision 1.1, dated 5 February 2007.

The specification is published by the Power Management Bus Implementers Forum and is available from

www.pmbus.org.

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

15

�UCD90160A

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

www.ti.com

The UCD90160A is PMBus compliant, in accordance with the Compliance section of the PMBus specification.

The firmware is also compliant with the SMBus 1.1 specification, including support for the SMBus ALERT

function. The hardware can support either 100-kHz or 400-kHz PMBus operation.

7.4 Device Functional Modes

7.4.1 Power Supply Sequencing

The UCD90160A can control the turn-on and turn-off sequencing of up to 16 voltage rails by using a GPIO to set

a power supply enable pin high or low. In PMBus-based designs, the system PMBus master can initiate a

sequence-on event by asserting the PMBUS_CNTRL pin or by sending the OPERATION command over the I2C

serial bus. In pin-based designs, the PMBUS_CNTRL pin can also be used to sequence-on and sequence-off.

The auto-enable setting ignores the OPERATION command and the PMBUS_CNTRL pin. Sequence-on is

started at power up after any dependencies and time delays are met for each rail. A rail is considered to be on or

within regulation when the measured voltage for that rail crosses the power-good on (POWER_GOOD_ON (1))

limit. The rail is still in regulation until the voltage drops below power-good off (POWER_GOOD_OFF). In the

case that there isn't voltage monitoring set for a given rail, that rail is considered ON if it is commanded on (either

by

OPERATION

command,

PMBUS

CNTRL

pin,

or

auto-enable)

and

(TON_DELAY

+

TON_MAX_FAULT_LIMIT) time passes. Also, a rail is considered OFF if that rail is commanded OFF and

(TOFF_DELAY + TOFF_MAX_WARN_LIMIT) time passes

7.4.1.1 Turn-on Sequencing

The following sequence-on options are supported for each rail:

• Monitor only – do not sequence-on

• Fixed delay time (TON_DELAY) after an OPERATION command to turn on

• Fixed delay time after assertion of the PMBUS_CNTRL pin

• Fixed time after one or a group of parent rails achieves regulation (POWER_GOOD_ON)

• Fixed time after a designated GPI has reached a user-specified state

• Fixed time after a designated GPO has reached a user-specified state

• Any combination of the previous options

The maximum TON_DELAY time is 3276 ms.

7.4.1.2 Turn-off Sequencing

The following sequence-off options are supported for each rail:

• Monitor only – do not sequence-off

• Fixed delay time (TOFF_DELAY) after an OPERATION command to turn off

• Fixed delay time after deassertion of the PMBUS_CNTRL pin

• Fixed time after one or a group of parent rails drop below regulation (POWER_GOOD_OFF)

• Fixed delay time in response to an undervoltage, overvoltage, or max turn-on fault on the rail

• Fixed delay time in response to a fault on a different rail when set as a fault shutdown slave to the faulted rail

• Fixed delay time in response to a GPI reaching a user-specified state

• Fixed time after a designated GPO has reached a user-specified state

• Any combination of the previous options

The maximum TOFF_DELAY time is 3276 ms.

(1)

16

In this document, configuration parameters such as Power Good On are referred to using Fusion GUI names. The UCD90xxx

Sequencer and System Health Controller PMBus Command Reference name is shown in parentheses (POWER_GOOD_ON) the first

time the parameter appears.

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

�UCD90160A

www.ti.com

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

Device Functional Modes (continued)

Rail 1 and Rail 2 are both sequenced “ON”

and “OFF” by the PMBUS_CNTRL pin

only

Rail 2 has Rail 1 as an “ON” dependency

Rail 1 has Rail 2 as an “OFF” dependency

PMBUS_CNTRL PIN

RAIL 1 EN

TON_DELAY[1]

TOFF_DELAY[1]

POWER_GOOD_ON[1]

POWER_GOOD_OFF[1]

RAIL 1 VOLTAGE

TOFF_DELAY[2]

TON_DELAY[2]

RAIL 2 EN

RAIL 2 VOLTAGE

TON_MAX_FAULT_LIMIT[2]

TOFF_MAX_WARN_LIMIT[2]

Figure 11. Sequence-on and Sequence-off Timing

7.4.1.3 Sequencing Configuration Options

In addition to the turn-on and turn-off sequencing options, the time between when a rail is enabled and when the

monitored rail voltage must reach its power-good-on setting can be configured using max turn-on

(TON_MAX_FAULT_LIMIT). Max turn-on can be set in 1-ms increments. A value of 0 ms means that there is no

limit and the device can try to turn on the output voltage indefinitely.

Rails can be configured to turn off immediately or to sequence-off according to rail and GPI dependencies, and

user-defined delay times. A sequenced shutdown is configured by selecting the appropriate rail and GPI

dependencies, and turn-off delay (TOFF_DELAY) times for each rail. The turn-off delay times begin when the

PMBUS_CNTRL pin is deasserted, when the PMBus OPERATION command is used to give a soft-stop

command, or when a fault occurs on a rail that has other rails set as fault-shutdown slaves.

Shutdowns on one rail can initiate shutdowns of other rails or controllers. In systems with multiple UCD90160As,

it is possible for each controller to be both a master and a slave to another controller.

7.4.2 Pin-Selected Rail States

This feature allows with the use of up to 3 GPIs to enable and disable any rail. This is useful for implementing

system low-power modes and the Advanced Configuration and Power Interface (ACPI) specification that is used

for operating system directed power management in servers and PCs. In up to 8 system states, the power

system designer can define which rails are on and which rails are off. If a new state is presented on the input

pins, and a rail is required to change state, it does so with regard to its sequence-on or sequence-off

dependencies.

The OPERATION command is modified when this function causes a rail to change its state. This means that the

ON_OFF_CONFIG for a given rail must be set to use the OPERATION command for this function to have any

effect on the rail state. The first three pins configured with the GPI_CONFIG command are used to select 1 of 8

system states. Whenever the device is reset, these pins are sampled and the system state, if enabled, are used

to update each rail state. When selecting a new system state, changes to the status of the GPIs must not take

longer than 1 microsecond. See the UCD90xxx Sequencer and System Health Controller PMBus Command

Reference for complete configuration settings of PIN_SELECTED_RAIL_STATES.

Table 2. GPI Selection of System States

GPI 2 State

GPI 1 State

GPI 0 State

System

State

NOT Asserted

Not Asserted

Not Asserted

0

NOT Asserted

Not Asserted

Asserted

1

NOT Asserted

Asserted

Not Asserted

2

NOT Asserted

Asserted

Asserted

3

Asserted

Not Asserted

Not Asserted

4

Asserted

Not Asserted

Asserted

5

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

17

�UCD90160A

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

www.ti.com

Table 2. GPI Selection of System States (continued)

GPI 2 State

GPI 1 State

GPI 0 State

System

State

Asserted

Asserted

Not Asserted

6

Asserted

Asserted

Asserted

7

7.4.3 Voltage Monitoring

Up to 16 voltages can be monitored using the analog input pins. The input voltage range is 0 to 2.5 V for MON

pins 1-6, 55-59, 62, and 63. Pins 50, 52, and 54 can measure down to 0.2 V.

The ADC operates continuously, requiring 3.89 μs to convert a single analog input. Each rail is sampled by the

sequencing and monitoring algorithm every 400 μs. The maximum source impedance of any sampled voltage

should be less than 4 kΩ. The source impedance limit is particularly important when a resistor-divider network is

used to lower the voltage applied to the analog input pins.

MON1 - MON6 can be configured using digital hardware comparators, which can be used to achieve faster fault

responses. Each hardware comparator has four thresholds (two UV (Fault and Warning) and two OV (Fault and

Warning)). The hardware comparators respond to UV or OV conditions in about 80 μs (faster than 400 µs for the

ADC inputs) and can be used to disable rails or assert GPOs. The only fault response available for the hardware

comparators is to shut down immediately.

An internal 2.5-V reference is used by the ADC. The ADC reference has a tolerance of ±0.5% between 0°C and

125°C and a tolerance of ±1% between –40°C and 125°C. An external voltage divider is required for monitoring

voltages higher than 2.5 V. The nominal rail voltage and the external scale factor can be entered into the Fusion

Digital Power Designer software and are used to report the actual voltage being monitored instead of the ADC

input voltage. The nominal voltage is used to set the range and precision of the reported voltage according to

Table 3.

MON1 – MON6

MON1

MON2

.

.

.

.

MON16

Analog

Inputs

(16)

M

U

X

Fast Digital

Comparators

12-bit

SAR ADC

200ksps

MON1 – MON16

Glitch

Filter

Internal

2.5Vref

0.5%

Figure 12. Voltage Monitoring Block Diagram

Table 3. Voltage Range and Resolution

18

VOLTAGE RANGE

(V)

RESOLUTION

(mV)

0 to 127.99609

3.90625

0 to 63.99805

1.95313

0 to 31.99902

0.97656

0 to 15.99951

0.48824

0 to 7.99976

0.24414

0 to 3.99988

0.12207

0 to 1.99994

0.06104

0 to 0.99997

0.03052

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

�UCD90160A

www.ti.com

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

Although the monitor results can be reported with a resolution of about 15 μV, the real conversion resolution of

610 μV is fixed by the 2.5-V reference and the 12-bit ADC.

7.4.4 Fault Responses and Alert Processing

The UCD90160A monitors whether the rail stays within a window of normal operation. There are two

programmable warning levels (under and over) and two programmable fault levels (under and over). When any

monitored voltage goes outside of the warning or fault window, the PMBALERT# pin is asserted immediately,

and the appropriate bits are set in the PMBus status registers (see Figure 9). Detailed descriptions of the status

registers are provided in the UCD90xxx Sequencer and System Health Controller PMBus Command Reference

and the PMBus Specification.

A programmable glitch filter can be enabled or disabled for each MON input. A glitch filter for an input defined as

a voltage can be set between 0 and 102 ms with 400-μs resolution. The glitch filter only applies to fault

responses; a fault condition that is filtered by the glitch filter will still be recorded in the fault log.

Fault-response decisions are based on results from the 12-bit ADC. The device cycles through the ADC results

and compares them against the programmed limits. The time to respond to an individual event is determined by

when the event occurs within the ADC conversion cycle and the selected fault response.

PMBUS_CNTRL PIN

RAIL 1 EN

TON_DELAY[1]

TOFF_DELAY[1]

TIME BETWEEN

RESTARTS

TIME BETWEEN

RESTARTS

MAX_GLITCH_TIME +

TOFF_DELAY[1]

MAX_GLITCH_TIME +

TOFF_DELAY[1]

TIME BETWEEN

RESTARTS

VOUT_OV_FAULT _LIMIT

VOUT_UV_FAULT _LIMIT

RAIL 1 VOLTAGE

POWER_GOOD_ON[1]

MAX_GLITCH_TIME

TON_DELAY[2]

RAIL 2 EN

TOFF_DELAY[1]

MAX_GLITCH_TIME

MAX_GLITCH_TIME

TOFF_DELAY[2]

RAIL 2 VOLTAGE

Rail 1 and Rail 2 are both sequenced “ON” and

“OFF” by the PMBUS_CNTRL pin only

Rail 2 has Rail 1 as an “ON” dependency

Rail 1 has Rail 2 as a Fault Shutdown Slave

Rail 1 is set to use the glitch filter for UV or OV events

Rail 1 is set to RESTART 3 times after a UV or OV event

Rail 1 is set to shutdown with delay for a OV event

Figure 13. Sequencing and Fault-Response Timing

PMBUS_CNTRL PIN

TON_DELAY[1]

RAIL 1 EN

Rail 1 and Rail 2 are both sequenced

“ON” and “OFF” by the PMBUS_CNTRL

pin only

Time Between Restarts

Rail 2 has Rail 1 as an “ON” dependency

POWER_GOOD_ON[1]

Rail 1 is set to shutdown immediately

and RESTART 1 time in case of a Time

On Max fault

POWER_GOOD_ON[1]

RAIL 1 VOLTAGE

TON_MAX_FAULT_LIMIT[1]

TON_DELAY[2]

TON_MAX_FAULT_LIMIT[1]

RAIL 2 EN

RAIL 2 VOLTAGE

Figure 14. Maximum Turn-on Fault

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

19

�UCD90160A

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

www.ti.com

The configurable fault limits are:

• TON_MAX_FAULT – Flagged if a rail that is enabled does not reach the POWER_GOOD_ON limit within the

configured time

• VOUT_UV_WARN – Flagged if a voltage rail drops below the specified UV warning limit after reaching the

POWER_GOOD_ON setting

• VOUT_UV_FAULT – Flagged if a rail drops below the specified UV fault limit after reaching the

POWER_GOOD_ON setting

• VOUT_OV_WARN – Flagged if a rail exceeds the specified OV warning limit at any time during startup or

operation

• VOUT_OV_FAULT – Flagged if a rail exceeds the specified OV fault limit at any time during startup or

operation

• TOFF_MAX_WARN – Flagged if a rail that is commanded to shut down does not reach 12.5% of the nominal

rail voltage within the configured time

Faults are more serious than warnings. The PMBALERT# pin is always asserted immediately if a warning or fault

occurs. If a warning occurs, the following takes place:

Warning Actions

— Immediately assert the PMBALERT# pin

— Status bit is flagged

— Assert a GPIO pin (optional)

— Warnings are not logged to flash

A number of fault response options can be chosen from:

Fault Responses

— Continue Without Interruption: Flag the fault and take no action

— Shut Down Immediately: Shut down the faulted rail immediately

— Shut Down using TOFF_DELAY: If a fault occurs on a rail, schedule the shutdown of this rail and all

fault-shutdown slaves. All selected rails, including the faulty rail, are sequenced off according to their

sequence-off dependencies and T_OFF_DELAY times.

Restart

— Do Not Restart: Do not attempt to restart a faulted rail after it has been shut down.

— Restart Up To N Times: Attempt to restart a faulted rail up to 14 times after it has been shut down.

The time between restarts is measured between when the rail enable pin is deasserted (after any

glitch filtering and turn-off delay times, if configured to observe them) and then reasserted. It can be

set between 0 and 1275 ms in 5-ms increments. Under voltage faults only have a maximum of 1

restart as an option.

— Restart Continuously: Same as Restart Up To N Times except that the device continues to restart

until the fault goes away, it is commanded off by the specified combination of PMBus OPERATION

command and PMBUS_CNTRL pin status, the device is reset, or power is removed from the device.

This option is not available for under voltage faults.

— Shut Down Rails and Sequence On (Re-sequence): Shut down selected rails immediately or after

continue-operation time is reached and then sequence-on those rails using sequence-on

dependencies and T_ON_DELAY times.

One GPI pin can also trigger faults if the GPI Fault Enable checkbox in Figure 19 is checked and proper

responses are set in Figure 20. Refer to GPI Special Functions for more details.

20

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

�UCD90160A

www.ti.com

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

7.4.5 Shut Down All Rails and Sequence On (Resequence)

In response to a fault, or a RESEQUENCE command, the UCD90160A can be configured to turn off a set of rails

and then sequence them back on. To sequence all rails in the system, then all rails must be selected as faultshutdown slaves of the faulted rail. The rails designated as fault-shutdown slaves initiate soft shutdowns

regardless of whether the faulted rail is set to stop immediately or stop with delay. Shut-down-all-rails and

sequence-on are not performed until retries are exhausted for a given fault.

While waiting for the rails to turn off, an error is reported if any of the rails reaches its TOFF_MAX_WARN_LIMIT.

There is a configurable option to continue with the resequencing operation if this occurs. After the faulted rail and

fault-shutdown slaves sequence-off, the UCD90160A waits for a programmable delay time between 0 and 1275

ms in increments of 5 ms and then sequences-on the faulted rail and fault-shutdown slaves according to the

start-up sequence configuration. This is repeated until the faulted rail and fault-shutdown slaves successfully

achieve regulation or for a user-selected 1, 2, 3, or 4 times. If the resequence operation is successful, the

resequence counter is reset if all of the rails that were resequenced maintain normal operation for one second.

Once shut-down-all-rails and sequence-on begin, any faults on the fault-shutdown slave rails are ignored. If there

are two or more simultaneous faults with different fault-shutdown slaves, the more conservative action is taken.

For example, if a set of rails is already on its second resequence and the device is configured to resequence

three times, and another set of rails enters the resequence state, that second set of rails is only resequenced

once. Another example – if one set of rails is waiting for all of its rails to shut down so that it can resequence,

and another set of rails enters the resequence state, the device now waits for all rails from both sets to shut

down before resequencing.

If any rails at resequence state are caused by a GPI fault response, the whole resequence is suspended until the

GPI fault is clear.

7.4.6 GPIOs

The UCD90160A has 22 GPIO pins that can function as either inputs or outputs. Each GPIO has configurable

output mode options including open-drain or push-pull outputs that can be actively driven to 3.3 V or ground.

There are an additional four pins that can be used as either inputs or PWM outputs but not as GPOs. Table 4

lists possible uses for the GPIO pins and the maximum number of each type for each use. GPIO pins can be

dependents in sequencing and alarm processing. They can also be used for system-level functions such as

external interrupts, power-goods, resets, or for the cascading of multiple devices. GPOs can be sequenced up or

down by configuring a rail without a MON pin but with a GPIO set as an enable.

Table 4. GPIO Pin Configuration Options

PIN NAME

PIN

RAIL EN

(16 MAX)

GPI

(8 MAX)

GPO

(16 MAX)

PWM OUT

(12 MAX)

MARGIN PWM

(10 MAX)

FPWM1/GPIO5

17

X

X

X

X

X

FPWM2/GPIO6

18

X

X

X

X

X

FPWM3/GPIO7

19

X

X

X

X

X

FPWM4/GPIO8

20

X

X

X

X

X

FPWM5/GPIO9

21

X

X

X

X

X

FPWM6/GPIO10

22

X

X

X

X

X

FPWM7/GPIO11

23

X

X

X

X

X

FPWM8/GPIO12

24

X

X

X

X

X

GPI1/PWM1

31

X

X

GPI2/PWM2

32

X

X

GPI3/PWM3

42

X

X

X

GPI4/PWM4

41

X

X

X

GPIO1

11

X

X

X

GPIO2

12

X

X

X

GPIO3

13

X

X

X

GPIO4

14

X

X

X

GPIO13

25

X

X

X

GPIO14

29

X

X

X

GPIO15

30

X

X

X

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

21

�UCD90160A

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

www.ti.com

Table 4. GPIO Pin Configuration Options (continued)

PIN NAME

PIN

RAIL EN

(16 MAX)

GPI

(8 MAX)

GPO

(16 MAX)

GPIO16

33

X

X

X

GPIO17

34

X

X

X

GPIO18

35

X

X

X

TCK/GPIO19

36

X

X

X

TDO/GPIO20

37

X

X

X

TDI/GPIO21

38

X

X

X

TMS/GPIO22

39

X

X

X

PWM OUT

(12 MAX)

MARGIN PWM

(10 MAX)

7.4.7 GPO Control

The GPIOs when configured as outputs can be controlled by PMBus commands or through logic defined in

internal Boolean function blocks. Controlling GPOs by PMBus commands (GPIO_SELECT and GPIO_CONFIG)

can be used to have control over LEDs, enable switches, etc. with the use of an I2C interface. See the

UCD90xxx Sequencer and System Health Controller PMBus Command Reference for details on controlling a

GPO using PMBus commands.

7.4.8 GPO Dependencies

GPIOs can be configured as outputs that are based on Boolean combinations of up to two ANDs, all ORed

together (Figure 15). Inputs to the logic blocks can include the first 8 defined GPOs, GPIs and rail-status flags.

One rail status type is selectable as an input for each AND gate in a Boolean block. For a selected rail status, the

status flags of all active rails can be included as inputs to the AND gate. _LATCH rail-status types stay asserted

until cleared by a MFR PMBus command or by a specially configured GPI pin. The different rail-status types are

shown in Table 5. See the UCD90xxx Sequencer and System Health Controller PMBus Command Reference for

complete definitions of rail-status types. The GPO response can be configured to have a delayed assertion or

deassertion. The first 8 GPOs can be chosen as Rail Sequence on/off Dependency. The logic state of the GPO

instead of actual pin output is used as dependency condition.

Sub block repeated for each of GPI(1:7)

GPI_INVERSE(0)

GPI_POLARITY(0)

GPI_ENABLE(0)

1

AND_INVERSE(0)

_GPI(0)

GPI(0)

_GPI(1:7)

_STATUS(0:14)

_STATUS(15)

_GPO(1:7)

There is one STATUS_TYPE_SELECT for each of the two AND

gates in a boolean block

STATUS_TYPE_SELECT

STATUS(0)

OR_INVERSE(x)

Status Type 1

STATUS(1)

Sub block repeated for each of STATUS(0:14)

GPOx

STATUS_INVERSE(15)

Status Type 33

STATUS_ENABLE(15)

STATUS(15)

ASSERT_DELAY(x)

1

AND_INVERSE(1)

DE-ASSERT_DELAY(x)

_GPI(0:7)

_STATUS(0:15)

_GPO(0:7)

Sub block repeated for each of GPO(1:7)

GPO_INVERSE(0)

GPO_ENABLE(0)

1

GPO(0)

_GPO(0)

Figure 15. Boolean Logic Combinations

22

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

�UCD90160A

www.ti.com

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

Figure 16. Fusion Boolean Logic Builder

Table 5. Rail-Status Types for Boolean Logic

Rail-Status Types

POWER_GOOD

TON_MAX_FAULT

VOUT_UV_WARN_LATCH

MARGIN_EN

TOFF_MAX_WARN

VOUT_UV_FAULT_LATCH

MRG_LOW_nHIGH

SEQ_ON_TIMEOUT

TON_MAX_FAULT_LATCH

VOUT_OV_FAULT

SEQ_OFF_TIMEOUT

TOFF_MAX_WARN_LATCH

VOUT_OV_WARN

SYSTEM_WATCHDOG_TIMEOUT

SEQ_ON_TIMEOUT_LATCH

VOUT_UV_WARN

VOUT_OV_FAULT_LATCH

SEQ_OFF_TIMEOUT_LATCH

VOUT_UV_FAULT

VOUT_OV_WARN_LATCH

SYSTEM_WATCHDOG_TIMEOUT_LATCH

When GPO is set to POWER_GOOD, this POWER_GOOD state is based on the actual voltage measurement on

the monitor pins assigned to those rails. For a rail that does not have a monitor pin, or have a monitor pin but

without voltage monitoring, its POWER_GOOD state is used by sequencing purpose only, and is not be used by

the GPO logic evaluation.

7.4.8.1 GPO Delays

The GPOs can be configured so that they manifest a change in logic with a delay on assertion, deassertion, both

or none. GPO behavior using delays have different effects depending if the logic change occurs at a faster rate

than the delay. On a normal delay configuration, if the logic for a GPO changes to a state and reverts back to

previous state within the time of a delay then the GPO does not manifest the change of state on the pin. In

Figure 17 the GPO is set so that it follows the GPI with a 3-ms delay at assertion and also at de-assertion. When

the GPI first changes to high logic state, the state is maintained for a time longer than the delay allowing the

GPO to follow with appropriate logic state. The same goes for when the GPI returns to its previous low logic

state. The second time that the GPI changes to a high logic state it returns to low logic state before the delay

time expires. In this case the GPO does not change state. A delay configured in this manner serves as a glitch

filter for the GPO.

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

23

�UCD90160A

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

3ms

www.ti.com

3ms

GPI

GPO

1ms

Figure 17. GPO Behavior When Not Ignoring Inputs During Delay

The Ignore Input During Delay bit allows to output a change in GPO even if it occurs for a time shorter than the

delay. This configuration setting has the GPO ignore any activity from the triggering event until the delay expires.

Figure 18 represents the two cases for when ignoring the inputs during a delay. In the case in which the logic

changes occur with more time than the delay, the GPO signal looks the same as if the input was not ignored.

Then on a GPI pulse shorter than the delay the GPO still changes state. Any pulse that occurs on the GPO when

having the Ignore Input During Delay bit set has a width of at least the time delay.

3ms

3ms

3ms

3ms

GPI

GPO

1ms

Figure 18. GPO Behavior When Ignoring Inputs During Delay

7.4.8.2 State Machine Mode Enable

When this bit within the GPO_CONFIG command is set, only one of the AND path will be used at a given time.

When the GPO logic result is currently TRUE, AND path 0 will be used until the result becomes FALSE. When

the GPO logic result is currently FALSE, AND path 1 will be used until the result becomes TRUE. This provides a

very simple state machine and allows for more complex logical combinations.

24

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

�UCD90160A

www.ti.com

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

7.4.9 GPI Special Functions

Special input functions for which GPIs can be used. There can be no more than one pin assigned to each of

these functions.

• GPI Fault Enable - When set, the de-assertion of the GPI is treated as a fault.

• Latched Statuses Clear Source - When a GPO uses a latched status type (_LATCH), a correctly configured

GPI clears the latched status.

• Input Source for Margin Enable - When this pin is asserted, all rails with margining enabled will be put in a

margined state (low or high).

• Input Source for Margin Low/Not-High - When this pin is asserted all margined rails will be set to Margin

Low as long as the Margin Enable is asserted. When this pin is de-asserted the rails will be set to Margin

High.

• Fault Shutdown Rails - See Fault Shutdown Rails.

• Configured as Sequencing Debug Pin - See Configured as Sequencing Debug Pin.

• Configured as Fault Pin - See Configured as Sequencing Debug Pin.

• Enable Cold Boot Mode - See Cold Boot Mode Enable.

The polarity of GPI pins can be configured to be either Active Low or Active High. The first 3 GPIs that are

defined regardless of their main purpose will be used for the PIN_SELECTED_RAIL_STATES command.

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

25

�UCD90160A

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

www.ti.com

Figure 19. GPI Configurations

26

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

�UCD90160A

www.ti.com

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

7.4.9.1 Fault Shutdown Rails

GPI Fault Enable must be set to enable this feature. When set, the de-assert of the assigned GPI trigger a

number of fault response options (see Figure 20). Retry action is not supported.

Figure 20. GPI Fault Response

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

27

�UCD90160A

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

www.ti.com

7.4.9.2 Configured as Sequencing Debug Pin

When the pin is asserted, device does not alert PMBUS_Alert pin, not response for faults, log faults defined in

the Table 6. The rail sequence on/off dependency conditions are ignored, as soon as the sequence on/off

timeout is expired, the rails will be sequenced on or off accordingly regardless of the timeout action, if the

sequence on/off timeout value is set to 0, the rails is sequenced on or off immediately. The fault pins do not pull

the fault bus low. The LGPOs affected by these events should be back to it original states.

Table 6. List of Events Affected by Debug Mode

EVENTS

DESCRIPTION

VOUT_OV_FAULT

Voltage Rail is over OV fault threshold

VOUT_OV_WARNING

Voltage Rail is over OV warning threshold

VOUT_UV_FAULT

Voltage Rail is under UV fault threshold

VOUT_UV_WARNING

Voltage Rail is under UV warning threshold

TON_MAX

Voltage Rail fails to reach power good threshold in predefined period

TOFF_MAX Warning

Voltage rail fails to reach power not good threshold in predefined period

All GPI deasserted

No logging, no fault responses, but the function of the GPI is not ignored.

SYSTEM_WATCHDOG_TIMEOUT

System watch timeout

RESEQUENCE_ERROR

Rail fails to resequence

SEQ_ON_TIMEOUT

Rail fails to meeting sequence on dependency in predefined period

SEQ_OFF_TIMEOUT

Rail fails to meeting sequence on dependency in predefined period

SLAVE_FAULT

Rail is shut down due to that its master has fault

7.4.9.3 Configured as Fault Pin

GPI Fault Enable must be set to enable this feature. When set, if there is no fault on a Fault Bus, the Fault Pin is

digital input pin and listen to the Fault Bus. When one or multiple UCD90160A devices detect a rail fault (see

Table 7), the corresponding Fault Pin is turned into active driven low state, pulling down the Fault Bus and

informing all other UCD90160A devices of the corresponding fault. This way, a coordinated action can be taken

across multiple devices. After the fault is cleared, the state of the Fault Pin is turned back to an input pin.

Table 7. Events Affecting Fault Pin

EVENTS

DESCRIPTION

RESEQUENCE_ERROR

Rail fails to resequence

SEQ_ON_TIMEOUT

Rail fails to meeting sequence on dependency in predefined period

SEQ_OFF_TIMEOUT

Rail fails to meeting sequence on dependency in predefined period

VOUT_UV_FAULT

Voltage rail is under UV threshold

VOUT_OV_FAULT

Voltage rail is over OV threshold

TON_MAX_FAULT

Voltage rail fails to reach power good threshold in predefined period.

28

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

�UCD90160A

www.ti.com

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

7.4.9.4 Cold Boot Mode Enable

Cold boot mode is used to heat-up a system by turning on cold boot rails for certain amounts of time when it is

under an extreme code temperature. UCD device is communicated with the system via particular GPI (thermal

state GPI) which is output from a thermal device. Cold boot mode is only entering once per UCD reset. There is

no system watch dog Reset during the cold boot mode.

Device reads the thermal state GPI to determine whether it should start cold boot or not when it is out of reset.

When the input of thermal state GPI is DE-ASSERTED, device enters cold boot mode and log the GPI fault if the

GPI fault log enable bit is set, otherwise device enters normal mode. The following changes on the thermal state

GPI do not introduce any logging. Only one GPI can be assigned for this function and one it is assigned, it

cannot be used for any other GPI functions.

The rails used in the cold boot mode are configurable. For those rails with Sequence On Dependency on the

thermal state GPI, they (non-cold boot rails) are not powered-up during the cold boot because the dependency is

not met. But non-cold boot rails will be power-on under normal mode because thermal state GPI is treated as

ASSERTED when cold boot mode is over. For those rails without sequence on dependency on the thermal state

GPI, they (cold boot rails) are power-on under both cold boot and normal mode. It is application’s responsibility to

set the proper ON_OFF_CONFIG for those cold boot rails. Cold boot rails are not power-on if their

ON_OFF_CONFIG settings are not met under cold boot mode. Cold boot mode timeout is used to tell how long

the device shall stay at the cold boot before it stops monitoring the thermal state GPI and shutdown all cold boot

rails with EN control. Normal Boot Start Delay is used to tell how long device should wait to ramp up the powers

after all cold boot rails with EN are below POWER_GOOD_OFF.

spacer

- If system temperature is < threshold degree C (Thermal State GPI)

o

Yes(DE_ASSERTED):

§ Log GPI fault

§ Start Cold Boot Timeout

§ No System Watchdog output

§ Ramp up the power supplies based on ON_OFF_CONFIG

§ Wait for thermal state GPI ASSERTED OR “Cold Boot Mode Timeout expired”

§ Disable the thermostat input listening mode

§ Force to shutdown down all cold boot rails with EN control immediately

§ Wait all cold boot rails with EN control below POWER_GOOD_OFF

§ Start and Wait “Normal boot Start Delay expired”

- Disable the thermostat input listening mode

- Treated Thermal State GPI as ASSERTED

- Ramp up power supplies based on ON_OFF_CONFIG

Submit Documentation Feedback

Copyright © 2016–2020, Texas Instruments Incorporated

Product Folder Links: UCD90160A

29

�UCD90160A

SLVSDD4C – SEPTEMBER 2016 – REVISED MARCH 2020

www.ti.com

7.4.10 Power Supply Enables

Each GPIO can be configured as a rail-enable pin with either active-low or active-high polarity. Output mode

options include open-drain or push-pull outputs that can be actively driven to 3.3 V or ground. During reset, the

GPIO pins are high-impedance except for FPWM/GPIO pins 17 to 24, which are driven low. External pulldown or

pullup resistors can be tied to the enable pins to hold the power supplies off during reset. The UCD90160A can

support a maximum of 16 enable pins.

NOTE

GPIO pins that have FPWM capability (pins 17 to 24) should only be used as power

supply enable signals if the signal is active high.

7.4.11 Cascading Multiple Devices

A GPIO pin can be used to coordinate multiple controllers by using it as a power good-output from one device

and connecting it to the PMBUS_CNTRL input pin of another. This imposes a master/slave relationship among

multiple devices. During startup, the slave controllers initiate their start sequences after the master has

completed its start sequence and all rails have reached regulation voltages. During shutdown, as soon as the

master starts to sequence-off, it sends the shut-down signal to its slaves.

A shutdown on one or more of the master rails can initiate shutdowns of the slave devices. The master

shutdowns can be initiated intentionally or by a fault condition. This method works to coordinate multiple

controllers, but it does not enforce interdependency between rails within a single controller.