ISO8200BQ

Galvanic isolated octal high-side smart power solid state-relay

Datasheet - production data

Applications

Programmable logic control

Industrial PC peripheral input/output

Numerical control machines

Drivers for all types of loads (resistive,

capacitive, inductive)

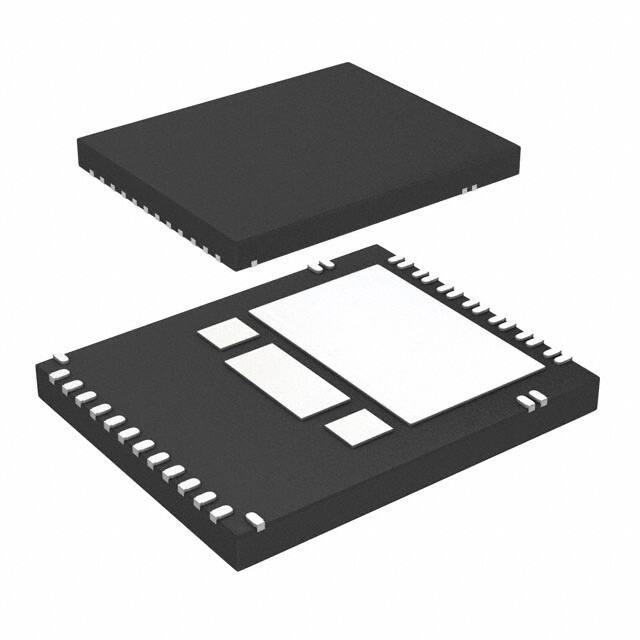

TFQFPN32

Features

Description

Vdemag = VCC - 45 V (per channel)

The ISO8200BQ is a galvanic isolated 8-channel

driver featuring a very low supply current. It

contains 2 independent galvanic isolated voltage

domains (VCC for the power stage and VDD for the

digital stage). Additional embedded functions are:

loss of GND protection, undervoltage shutdown

with hysteresis, and reset function for immediate

power output shutdown.

RDS(on) = 0.12 (per channel)

IOUT = 0.7 A (per channel)

VCC = 45 V

Parallel input interface

Direct and synchronous control mode

High common mode transient immunity

Short-circuit protection

Channel overtemperature protection

Thermal independence of separate channels

Common output disable pin

Case overtemperature protection

Loss of GNDCC and VCC protection

Undervoltage shutdown with auto-restart and

hysteresis

Overvoltage protection (VCC clamping)

Very low supply current

Common fault open-drain output

5 V and 3.3 V TTL/CMOS compatible I/Os

Fast demagnetization of inductive loads

Reset function for IC output disable

ESD protection

IC is intended to drive any kind of load with one

side connected to ground. Active channel current

limitation combined with thermal shutdown,

(independent for each channel), and automatic

restart, protect the device against overload and

short-circuit. In overload conditions, if junction

temperature overtakes threshold, the channel

involved is turned off and on again automatically

after the IC temperature decreases below a reset

threshold. If this condition causes case

temperature to reach TCR limit threshold, the

overloaded channel is turned off and it only

restarts when case and junction temperature

decrease down to the reset thresholds. Nonoverloaded channels continue operating normally.

An internal circuit provides an OR-wired nonlatched common FAULT indicator signaling the

channel OVT. The FAULT pin is an open-drain

active low fault indication pin.

Designed to meet IEC 61000-4-2, IEC 610004-4, IEC 61000-4-5 and IEC 61000-4-8

UL1577 and UL508 certified

Safety Limits as per VDE0884-11

May 2020

This is information on a product in full production.

DS10781 Rev 9

1/40

www.st.com

�Contents

ISO8200BQ

Contents

1

Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2

Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3

Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4

Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5

Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6

Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1

Parallel interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1.1

Input signals (IN1 to IN8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1.2

Load input data (LOAD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1.3

Output synchronization (SYNC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1.4

Watchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1.5

Output enable (OUT_EN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2

Direct control mode (DCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3

Synchronous control mode (SCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.4

Fault indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.4.1

7

Junction overtemperature and case overtemperature . . . . . . . . . . . . . . 23

Power section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.1

Current limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.2

Thermal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8

Reverse polarity protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9

Reverse polarity on VDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10

Demagnetization energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

11

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Supply voltage and power output conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2/40

DS10781 Rev 9

�ISO8200BQ

12

Contents

Thermal information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Thermal impedance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

13

Package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

13.1

14

TFQFPN32 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Packing information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

14.1

TFQFPN32 packing information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

14.1.1

TFQFPN32 packing method concept . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

14.1.2

TFQFPN32 winding direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

14.1.3

TFQFPN32 leader and trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

15

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

16

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

DS10781 Rev 9

3/40

40

�List of tables

ISO8200BQ

List of tables

Table 1.

Table 2.

Table 3.

Table 4.

Table 5.

Table 6.

Table 7.

Table 8.

Table 9.

Table 10.

Table 11.

Table 12.

Table 13.

Table 14.

Table 15.

Table 16.

Table 17.

Table 18.

Table 19.

4/40

Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Thermal data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Digital supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Diagnostic pin and output protection function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Power switching characteristics (VCC = 24 V; -40 °C < TJ < 125 °C) . . . . . . . . . . . . . . . . 11

Logic input and output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Parallel interface timings (VDD = 5 V; VCC = 24 V; -40 °C < TJ < 125 °C) . . . . . . . . . . . . 14

Insulation and safety-related specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Insulation characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Safety limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Interface signal operation (general) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Interface signal operation in direct control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Interface signal operation in synchronous control mode. . . . . . . . . . . . . . . . . . . . . . . . . . . 21

TFQFPN32 package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Tolerance of form and position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Document revision history. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

DS10781 Rev 9

�ISO8200BQ

List of figures

List of figures

Figure 1.

Figure 2.

Figure 3.

Figure 4.

Figure 5.

Figure 6.

Figure 7.

Figure 8.

Figure 9.

Figure 10.

Figure 11.

Figure 12.

Figure 13.

Figure 14.

Figure 15.

Figure 16.

Figure 17.

Figure 18.

Figure 19.

Figure 20.

Figure 21.

Figure 22.

Figure 23.

Figure 24.

Figure 25.

Figure 26.

Figure 27.

Figure 28.

Figure 29.

Figure 30.

Figure 31.

Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pin connection (top through view). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

RDS(on) measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

dV/dT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

td(ON) - td(OFF) synchronous mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

td(ON) - td(OFF) direct control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Watchdog behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Output channel enable timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Direct control mode IC configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Direct control mode time diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Synchronous control mode IC configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Synchronous control mode time diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Multiple device synchronous control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Thermal status update (DCM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Thermal status update (SCM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Current limitation with different load conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Thermal protection flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Thermal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Reverse polarity protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Reverse polarity protection on VDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Maximum demagnetization energy vs. load current, typical values Tamb = 125 °C . . . . . 30

Supply voltage and power output conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Simplified thermal model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

TFQFPN32 package outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TFQFPN32 package detail outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

TFQFPN32 suggested footprint (measured in mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

TFQFPN32 packing method concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

TFQFPN32 carrier tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

TFQFPN32 reel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

TFQFPN32 winding direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

TFQFPN32 leader and trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

DS10781 Rev 9

5/40

40

�Block diagram

1

ISO8200BQ

Block diagram

Figure 1. Block diagram

6/40

DS10781 Rev 9

�ISO8200BQ

2

Pin connection

Pin connection

Figure 2. Pin connection (top through view)

Table 1. Pin description

Pin

Name

1

GNDDD

2

NC

3

GNDCC

4

OUT8

5

OUT8

6

OUT7

7

OUT7

8

OUT6

9

OUT6

10

OUT5

11

OUT5

12

OUT4

13

OUT4

14

OUT3

15

OUT3

16

OUT2

17

OUT2

Description

Input logic ground, negative logic supply

Not connected

Output power ground

Channel 8 power output

Channel 7 power output

Channel 6 power output

Channel 5 power output

Channel 4 power output

Channel 3 power output

Channel 2 power output

DS10781 Rev 9

7/40

40

�Pin connection

ISO8200BQ

Table 1. Pin description (continued)

Pin

Name

18

OUT1

19

OUT1

20

VDD

21

8/40

Description

Channel 1 power output

Positive logic supply

OUT_EN Output enable

22

SYNC

Input-to-output synchronization signal. Active low, see Section 6.3:

Synchronous control mode (SCM) on page 21.

23

LOAD

Load input data signal. Active low, see Section 6.3

24

IN1

Channel 1 input

25

IN2

Channel 2 input

26

IN3

Channel 3 input

27

IN4

Channel 4 input

28

IN5

Channel 5 input

29

IN6

Channel 6 input

30

IN7

Channel 7 input

31

IN8

Channel 8 input

32

FAULT

TAB(VCC)

VCC

TAB(GNDCC)

GNDCC

Common fault indication, active low

Exposed tab internally connected to VCC, positive power supply voltage

Exposed tab internally connected to GNDCC

DS10781 Rev 9

�ISO8200BQ

3

Absolute maximum ratings

Absolute maximum ratings

Table 2. Absolute maximum ratings

Symbol

Parameter

Min.

Max.

Unit

VCC

Power supply voltage

-0.3

45

V

VDD

Digital supply voltage

-0.3

6.5

V

VIN

DC input pin voltage (INx, OUT_EN, LOAD, SYNC)

-0.3

+6.5

V

VFAULT

Fault pin voltage

-0.3

+6.5

V

IGNDDD

DC digital ground reverse current

-

-25

mA

Channel output current (continuous)

-

Internally limited

A

IGNDcc

DC power ground reverse current

-

-250

mA

-IOUT

Reverse output current (single channel)

-

-5

A

DC input pin current (INx, OUT_EN, LOAD, SYNC)

-10

+ 10

mA

IFAULT

Fault pin current

-10

+ 10

mA

VESD

Electrostatic discharge with human body model

(R = 1.5 k; C = 100 pF)

-

2000

V

Single pulse avalanche energy per channel not

simultaneously at Tamb= 125 °C, IOUT = 0.5 A

-

1.8

Single pulse avalanche energy per channel, all channels

driven simultaneously at Tamb = 125 °C, IOUT = 0.5 A

-

0.35

PTOT

Power dissipation at Tc = 25 °C

-

Internally limited(1)

W

TJ

Junction operating temperature

-

Internally limited(1)

°C

Storage temperature

-

-55 to 150

°C

IOUT

IIN

EAS

TSTG

J

1. Protection functions are intended to avoid IC damage in fault conditions and are not intended for

continuous operation. Continuous or repetitive operations of protection functions may reduce the IC

lifetime.

4

Thermal data

Table 3. Thermal data

Symbol

Rthj-case

Rthj-amb

Parameter

Thermal resistance, junction-case((1)

Thermal resistance,

junction-ambient(2)

Max. value

Unit

2

°C/W

15

°C/W

1. For each channel.

2. TFQFPN32 mounted on the product evaluation board (FR4, 4 layers, 8 cm2 for each layer, copper

thickness 35 mm).

DS10781 Rev 9

9/40

40

�Electrical characteristics

5

ISO8200BQ

Electrical characteristics

(10.5 V < VCC < 36 V; -40 °C < TJ < 125 °C, unless otherwise specified)

Table 4. Power section

Symbol

Parameter

Test conditions

Min. Typ. Max. Unit

VCC(THON)

VCC undervoltage turn-ON

threshold

-

-

9.5

10.5

V

VCC(THOFF)

VCC undervoltage turn-OFF

threshold

-

8

9

-

V

VCC(hys)

VCC undervoltage hysteresis

-

0.25

0.5

-

V

VCCclamp

Clamp on VCC pin

Iclamp = 20 mA

45

50

52

V

On-state resistance(1)

IOUT = 0.5 A, TJ = 25 °C

IOUT = 0.5 A TJ = 125 °C

RDS(on)

Rpd

Output pull-down resistor

ICC

Power supply current

Ground disconnection output

current

ILGND

VOUT(OFF) Off-state output voltage

IOUT(OFF)

Off-state output current

-

0.12

0.24

-

210

-

k

All channels in OFF-state

All channels in ON-state

-

5

9

-

mA

VCC = VGND = 0 V

VOUT = -24 V

-

-

500

μA

Channel OFF and IOUT = 0 A

-

-

1

V

Channel OFF and VOUT = 0 V

-

-

5

μA

1. See Figure 3: RDS(on) measurement.

Table 5. Digital supply voltage

Symbol

VDD

Test conditions

Min. Typ. Max. Unit

Operating voltage

-

2.75

-

5.5

V

VDD(THON)

VDD undervoltage turn-ON

threshold

-

2.55

-

2.75

V

VDD(THOFF)

VDD undervoltage turn-OFF

threshold

-

2.45

-

2.65

V

VDD undervoltage hysteresis -

0.04

0.1

-

V

-

4.5

6

mA

-

4.4

5.9

mA

VDD(hys)

IDD

10/40

Parameter

IDD supply current

VDD = 5 V and input channel

with a steady logic level

VDD = 3.3 V and input channel

with a steady logic level

DS10781 Rev 9

�ISO8200BQ

Electrical characteristics

Table 6. Diagnostic pin and output protection function

Symbol

Parameter

Test conditions

Min.

Typ.

Max.

Unit

VFAULT

FAULT pin open-drain voltage

output low

IFAULT = 10 mA

-

-

0.4

V

ILFAULT

FAULT output leakage current

VFAULT = 5 V

-

-

1

μA

IPEAK

Maximum DC output current

before limitation

VCC = 24 V

RLOAD = 0

-

1.6

-

A

ILIM

Short-circuit current limitation

-

0.7

1.3

1.9

A

Hyst

ILIM tracking limits

-

-

0.3

-

A

TJSD

Junction shutdown temperature

-

150

170

-

°C

TJR

Junction reset temperature

-

-

150

-

°C

THIST

Junction thermal hysteresis

-

-

20

-

°C

TCSD

Case shutdown temperature

-

115

130

145

°C

TCR

Case reset temperature

-

-

110

-

°C

TCHYST

Case thermal hysteresis

-

-

20

-

°C

Vdemag

Output voltage at turn-OFF

IOUT = 0.5 A

ILOAD > = 1 mH

VCC -45

VCC -50

VCC -52

V

Table 7. Power switching characteristics (VCC = 24 V; -40 °C < TJ < 125 °C)

Symbol

dV/dt(ON)

Parameter

Test conditions

Turn-ON voltage slope

dV/dt(OFF) Turn-OFF voltage slope

td(ON)

Turn-ON delay time(1)

td(OFF)

Turn-OFF delay

tf

time(1)

tr

Fall

(1)

Rise time

time(1)

Min. Typ. Max. Unit

IOUT = 0.5 A, resistive load 48

-

5.6

-

V/μs

IOUT = 0.5 A, resistive load 48

-

2.81

-

V/μs

IOUT = 0.5 A, resistive load 48

-

17

22

μs

IOUT = 0.5 A, resistive load 48

-

22

40

μs

IOUT = 0.5 A, resistive load 48

-

5

-

μs

IOUT = 0.5 A, resistive load 48

-

5

-

μs

1. See Figure 3: RDS(on) measurement , Figure 4: dV/dT and Figure 6: td(ON) - td(OFF) direct control mode.

DS10781 Rev 9

11/40

40

�Electrical characteristics

ISO8200BQ

Figure 3. RDS(on) measurement

Figure 4. dV/dT

12/40

DS10781 Rev 9

�ISO8200BQ

Electrical characteristics

Figure 5. td(ON) - td(OFF) synchronous mode

Figure 6. td(ON) - td(OFF) direct control mode

DS10781 Rev 9

13/40

40

�Electrical characteristics

ISO8200BQ

Table 8. Logic input and output

Symbol

Parameter

Test conditions

VIL

Logic input pin low level voltage (INx, OUT_EN,

LOAD, SYNC)

VIH

Logic input pin high level voltage (INx, OUT_EN,

LOAD, SYNC)

Min.

Max.

Unit

-0.3

0.3 x VDD

V

0.7 x VDD

VDD + 0.3

V

-

Typ.

VI(HYST)

Logic input hysteresis voltage (INx, OUT_EN,

LOAD, SYNC)

VDD = 5 V

-

100

-

mV

IIN

Logic input pin current (INx, OUT_EN, LOAD,

SYNC)

VIN = 5 V

10

-

-

μA

Power side watchdog time

-

272

320

400

μs

tWM

Table 9. Parallel interface timings (VDD = 5 V; VCC = 24 V; -40 °C < TJ < 125 °C)

Symbol

Parameter

tdis(SYNC) SYNC disable time

Test conditions

Min.

Typ.

Max.

Unit

Sync. control mode

10

-

-

μs

tdis(DCM)

SYNC, LOAD disable time

Direct control mode

80

-

-

ns

tw(SYNC)

SYNC negative pulse width

Sync. control mode

20

-

195

μs

tsu(LOAD)

LOAD setup time

Sync. control mode

80

-

-

ns

th(LOAD)

LOAD hold time

Sync. control mode

400

-

-

ns

tw(LOAD)

LOAD pulse width

Sync. control mode

240

-

-

ns

tsu(IN)

Input setup time

-

80

-

-

ns

th(IN)

Input hold time

-

10

-

-

ns

tw(IN)

Input pulse width

Sync. control mode

160

-

-

ns

Direct control mode

20

-

-

μs

tINLD

IN to LOAD time

Direct control mode

From IN variation to LOAD falling edge

80

-

-

ns

tLDIN

LOAD to IN time

Direct control mode

From LOAD falling edge to IN variation

400

-

-

ns

-

150

-

-

ns

tp(OUT_EN) OUT_EN propagation delay -

-

22

40

μs

tjitter(SCM)

tw(OUT_EN) OUT_EN pulse width

tjitter(DCM)

frefresh

14/40

Jitter on single channel

Sync. mode

Direct mode

-

-

6

20

μs

Refresh delay

-

-

15

-

kHz

DS10781 Rev 9

�ISO8200BQ

Electrical characteristics

Table 10. Insulation and safety-related specifications

Symbol

Parameter

Test conditions

Value Unit

CLR

Clearance (minimum

external air gap)

Measured from input terminals to output

terminals, the shortest distance through air

3.3

mm

CPG

Creepage (minimum

external tracking)

Measured from input terminals to output

terminals, the shortest distance path along body

3.3

mm

600

V

I

-

CTI

Comparative tracking

DIN IEC 112/VDE 0303 part 1

index (tracking resistance)

Isolation group

Material group (DIN VDE 0110, 1/89, Table 1)

Table 11. Insulation characteristics

Symbol

Parameter

Test conditions

Value

Unit

-

937

VPEAK

Method a, type test,

VPR = VIORM x 1.6, tm = 10s

partial discharge < 5 pC

1500

VPEAK

Method b, 100% production test,

VPR = VIORM x 1.875, tm = 1s

partial discharge < 5 pC

1758

VPEAK

IEC 60747-5-5

VIORM

VPR

Maximum working isolation

Input to output test voltage

VIOTM

Transient overvoltage

Type test

tini = 60 s

4245

VPEAK

VIOSM

Maximum surge insulation

voltage

Type test

4245

VPEAK

Insulation resistance

VIO = 500 V at ts

>109

Insulation withstand voltage

1 min. type test

2500/3536 Vrms/VPEAK

1 s 100% production

3000/4245 Vrms/VPEAK

RIO

UL1577

VISO

VISO test Insulation withstand test

DS10781 Rev 9

15/40

40

�Electrical characteristics

ISO8200BQ

Table 12. Safety limits

Parameter

Description

Test Condition

Limit value

Unit

-

150

o

0.9

W

150

o

4.5

W

Input safety, Logic side

Tsi

Psi

Safety temperature of Logic side

Safety power of Logic side

VDD ≤ 6.5V,

VLOGIC(x) ≤ 6.5V,

ILOGIC(x) ≤ 10mA,

TJ ≤ Tsi

C

Output safety, Process side

Note:

Tso

Safety temperature of Process side

Pso

Safety power of Process side

VCC ≤ 36V,

IOUT(x) ≤ 1.5A,

TJ ≤ Tso

The above limits are measured according to VDE 0884-11. Respecting above limits

prevents potential damage potential damage to the isolation barrier upon failure on logic or

process side circuitry. User can use these values to protect the IC and consequently

guarantee the safety of the embedded isolation barrier.

LOGIC(X) stands for "any pin of logic side".

OUT(X) stands for "any of the 8 output pins of process side".

16/40

C

DS10781 Rev 9

�ISO8200BQ

Functional description

6

Functional description

6.1

Parallel interface

Smart parallel interface built-in ISO8200BQ offers three interfacing signals easily managed

by a microcontroller.

The LOAD signal enables the input buffer storing the value of the channel inputs.

The SYNC signal copies the input buffer value into the transmission buffer and manages the

synchronization between low voltage side and the channel outputs on the isolated side. The

OUT_EN signal enables the channel outputs.

An internal refresh signal updates the configuration of the channel outputs with a frefresh

frequency. This signal can be disabled forcing low the SYNC input when LOAD is high.

SYNC and LOAD pins can be in direct control mode (DCM) or synchronous control mode

(SCM).

The operation of these two signals is described as follows:

Table 13. Interface signal operation (general)

LOAD

SYNC

Don't care Don't care

OUT_EN

Low(1)

Device behavior

The outputs are disabled (turned off)

High

High

High

The outputs are left unchanged

Low

High

High

The input buffer is enabled

The outputs are left unchanged

High

Low

High

The internal refresh signal is disabled

The transmission buffer is updated

The outputs are left unchanged

Low

Low

High

The device operates in direct control mode as described in

Section 6.2: Direct control mode (DCM)

1. The outputs are turned off on OUT_EN falling edge and they are kept disabled as long as it is low.

6.1.1

Input signals (IN1 to IN8)

Inputs from IN1 to IN8 are the driving signals of the corresponding OUT1 to OUT8 outputs.

Data are direct loaded on related outputs if SYNC and LOAD inputs are low (DCM

operation) or stored into input buffer when LOAD is low and SYNC is high.

6.1.2

Load input data (LOAD)

The input is active low; it stores the data from IN1 to IN8 into the input buffer.

6.1.3

Output synchronization (SYNC)

The input is active low; it enables the ISO8200BQ transmission buffer loading input buffer

data and manages the transmission between the two isolated sides of the device.

DS10781 Rev 9

17/40

40

�Functional description

6.1.4

ISO8200BQ

Watchdog

The isolated side of the device provides a watchdog function in order to guarantee a safe

condition when VDD supply voltage is missing.

If the logic side does not update the output status within tWD, all outputs are disabled until a

new update request is received.

The refresh signal is also considered a valid update signal, so the isolated side watchdog

does not protect the system from a failure of the host controller (MCU freezing).

Figure 7. Watchdog behavior

18/40

DS10781 Rev 9

�ISO8200BQ

6.1.5

Functional description

Output enable (OUT_EN)

This pin provides a fast way to disable all outputs simultaneously. When the OUT_EN pin is

driven low the outputs are disabled. To enable the output stage, the OUT_EN pin has to be

raised. This timing execution is compatible with an external reset push, safety requirement,

and allows, in a PLC system, the microcontroller polling to obtain all internal information

during a reset procedure.

Figure 8. Output channel enable timing

6.2

Direct control mode (DCM)

When SYNC and LOAD inputs are driven by the same signal, the device operates in direct

control mode (DCM).

In DCM the SYNC / LOAD signal operates as an active low input enable:

When the signal is high, the current output configuration is kept regardless the input

values

When the signal is low, each channel input directly drives the respective output

This operation mode can also be set shorting both signals to the digital ground; in this case

the channel outputs are always directly driven by the inputs except when OUT_EN is low

(outputs disabled).

Table 14. Interface signal operation in direct control mode

SYNC / LOAD

Don't care

OUT_EN

Low

(1)

Device behavior

The outputs are disabled (turned off)

High

High

The outputs are left unchanged

Low

High

The channel inputs drive the outputs

1. The outputs are turned off on OUT_EN falling edge and they are kept disabled as long as it is low.

DS10781 Rev 9

19/40

40

�Functional description

ISO8200BQ

Figure 9. Direct control mode IC configuration

Figure 10. Direct control mode time diagram

20/40

DS10781 Rev 9

�ISO8200BQ

6.3

Functional description

Synchronous control mode (SCM)

When SYNC and LOAD inputs are independently driven, the device can operate in

synchronous control mode (SCM). The SCM is used to reduce the jittering of the outputs

and to drive all outputs of different devices at the same time.

In SCM the LOAD signal is forced low to update the input buffer while the SYNC signal is

high. The LOAD signal is raised and the SYNC one is forced low for at least tSYNC(SCM).

During this period, the internal refresh is disabled and any pending transmission between

the low voltage and the isolated side is completed. When the SYNC signal is raised the

channel output configuration is changed according to the one stored in the input.

If the tSYNC(SCM) limit is met, the maximum jitter of the channel outputs is tjitter(SCM).

If more devices share the same SYNC signal, all device outputs change simultaneously with

a maximum jitter related to maximum delay and maximum jitter for single device.

Table 15. Interface signal operation in synchronous control mode

LOAD

SYNC

OUT_EN

Device behavior

Don't care

Don't care

Low(1)

High

High

High

The outputs are left unchanged

Low

High

High

The input buffer is enabled. The outputs are left unchanged.

High

Low

High

The internal refresh signal is disabled. The transmission buffer

is updated. The outputs are left unchanged.

High

Rising

edge

High

The outputs are updated according to the current transmission

buffer value

Low

Low

High

Should be avoided (DCM operation only)

The outputs are disabled (turned off)

1. The outputs are turned off on OUT_EN falling edge and they are kept disabled as long as it is low.

Figure 11. Synchronous control mode IC configuration

DS10781 Rev 9

21/40

40

�Functional description

ISO8200BQ

Figure 12. Synchronous control mode time diagram

Figure 13. Multiple device synchronous control mode

22/40

DS10781 Rev 9

�ISO8200BQ

6.4

Functional description

Fault indication

The FAULT pin is an active low open-drain output indicating fault conditions. This pin is

active when at least one of the following conditions occurs:

Junction overtemperature of one or more channels (TJ >TTJSD)

Communication error

The communication error is intended as an internal data corruption event in the data transfer

through isolation. In case of communication error the outputs are initially kept in the previous

status and then reset (turned off) at the first communication error during data transfer of the

refresh signal.

6.4.1

Junction overtemperature and case overtemperature

The thermal status of the device is updated during each transmission sequence between

the two isolated sides.

In SCM operation, when the LOAD signal is high and the SYNC one is low, the

communication is disabled. In this case the thermal status of the device cannot be updated

and the FAULT indication can be different from the current status.

In any case, the thermal protection of the channel outputs is always operative.

Figure 14. Thermal status update (DCM)

DS10781 Rev 9

23/40

40

�Functional description

ISO8200BQ

Figure 15. Thermal status update (SCM)

24/40

DS10781 Rev 9

�ISO8200BQ

Power section

7

Power section

7.1

Current limitation

The current limitation process is active when the current sense connected on the output

stage measures a current value, which is higher than a fixed threshold.

When this condition is verified the gate voltage is modulated to avoid the increase of the

output current over the limitation value.

Figure 16 shows typical output current waveforms with different load conditions.

Figure 16. Current limitation with different load conditions

DS10781 Rev 9

25/40

40

�Power section

7.2

ISO8200BQ

Thermal protection

The device is protected against overheating in case of overload conditions. During the

driving period, if the output is overloaded, the device suffers two different thermal stresses,

the former related to the junction, and the latter related to the case.

The two faults have different trigger thresholds: the junction protection threshold is higher

than the case protection one; generally the first protection, that is active in thermal stress

conditions, is the junction thermal shutdown. The output is turned off when the temperature

is higher than the related threshold and turned back on when it goes below the reset

threshold. This behavior continues until the fault on the output is present.

If the thermal protection is active and the temperature of the package increases over the

fixed case protection threshold, the case protection is activated and the output is switched

off and back on when the junction temperature of each channel in fault and case

temperature is below the respective reset thresholds.

Figure 17 shows the thermal protection behavior, while Figure 18 reports typical

temperature trends and output vs. input state.

Figure 17. Thermal protection flowchart

26/40

DS10781 Rev 9

�ISO8200BQ

Power section

Figure 18. Thermal protection

DS10781 Rev 9

27/40

40

�Reverse polarity protection

8

ISO8200BQ

Reverse polarity protection

Reverse polarity protection can be implemented on board using two different solutions:

1. Placing a resistor (RGND) between IC GND pin and load GND

2. Placing a diode in parallel to a resistor between IC GND pin and load GND

If option 1 is selected, the minimum resistance value has to be selected according to

Equation 1:

Equation 1

RGND VCC/IGNDcc

where IGNDcc is the DC reverse ground pin current and can be found in Section 3: Absolute

maximum ratings on page 9.

Power dissipated by RGND during reverse polarity situations is:

Equation 2

PD = (VCC)2/RGND

If option 2 is selected, the diode has to be chosen by taking into account VRRM > |VCC| and

its power dissipation capability:

Equation 3

PD IS * VF

Note:

In normal operation (no reverse polarity), there is a voltage drop (ΔV) between GND of

the device and GND of the system. Using option 1, ΔV = Rgnd * Icc. Using option 2,

ΔV = VF@(IF).

Figure 19. Reverse polarity protection

This schematic can be used with any type of load.

28/40

DS10781 Rev 9

�ISO8200BQ

9

Reverse polarity on VDD

Reverse polarity on VDD

The reverse polarity on VDD can be implemented on board by placing a diode between

GNDDD pin and GND digital ground.

The diode has to be chosen by taking into account VRRM > |VDD| and its power dissipation

capability:

Equation 4

PD IDD * VF

Note:

In normal operation (no reverse polarity), there is a voltage drop (ΔV = VF@(Idd))

between GNDDD of the device and digital ground of the system.

In order to guarantee to proper triggering of the input signal, ΔV(max.) must result lower

than VIH(MIN).

Figure 20. Reverse polarity protection on VDD

DS10781 Rev 9

29/40

40

�Demagnetization energy

10

ISO8200BQ

Demagnetization energy

Figure 21. Maximum demagnetization energy vs. load current, typical values

Tamb = 125 °C

11

Conventions

Supply voltage and power output conventions

Figure 22 shows the convention used in this paper for voltage and current usage.

Figure 22. Supply voltage and power output conventions

30/40

DS10781 Rev 9

�ISO8200BQ

12

Thermal information

Thermal information

Thermal impedance

Figure 23. Simplified thermal model

DS10781 Rev 9

31/40

40

�Package information

13

ISO8200BQ

Package information

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK® packages, depending on their level of environmental compliance. ECOPACK®

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK® is an ST trademark.

13.1

TFQFPN32 package information

Figure 24. TFQFPN32 package outline

32/40

DS10781 Rev 9

�ISO8200BQ

Package information

Figure 25. TFQFPN32 package detail outline

Figure 26. TFQFPN32 suggested footprint (measured in mm)

0.3

0

0.3

0

0.7

0

0.3

0

0.9

0

0.2

0

0.2

0

0.9

0

DS10781 Rev 9

33/40

40

�Package information

ISO8200BQ

Table 16. TFQFPN32 package mechanical data

Dimensions (mm]

Symbol

Min.

Typ.

Max.

A

0.95

1.00

1.05

A1

0

-

0.05

A2

-

0.20 REF

-

b(1)

0.20

0.25

0.30

0.25

0.30

0.35

D

10.90

11.0

11.10

E(1)

8.90

9.00

9.10

D2

4.30

4.40

4.50

E2

6.70

6.80

6.90

D3

1.40

1.50

1.60

E3

3.20

3.30

3.40

D4

1.13

1.23

1.33

E4

1.00

1.10

1.20

e

-

0.65

-

e2

-

0.40

-

e3

-

1.05

-

e4

-

3.15

-

e5

-

4.85

-

k

0

0.30

-

z1

-

0.80

-

z2

-

4.07

-

z3

-

3.80

-

z4

-

1.10

-

z5

-

1.15

-

z6

-

2.85

-

0.45

0.50

0.55

b1

(1)

(1)

L

1. Dimensions “b” and “L” are measured on terminal plating surface.

34/40

DS10781 Rev 9

�ISO8200BQ

Package information

Table 17. Tolerance of form and position

Symbol

Tolerance of form

and position

aaa

0.15

The bilateral profile tolerance that controls the position

of the plastic body sides. The centers of the profile

zones are defined by the basic dimensions D and E.

bbb

0.10

The tolerance that controls the position of the entire

terminal pattern with respect to datum's A and B. The

center of the tolerance zone for each terminal is defined

by the basic dimension "e" as related to datum's A and

B.

ccc

0.10

The tolerance located parallel to the seating plane in

which the top surface of the package must be located.

0.08

The tolerance that controls the position of the terminals

to each other. The centers of the profile zones are

defined by basic dimension "e".

0.08

This tolerance is

The unilateral tolerance located above the seating plane

commonly known as

where in the bottom surface of all terminals must be

the “coplanarity” of the

located.

package terminals.

fff

0.10

The tolerance that controls the position of the exposed

metal heat feature. The center of the tolerance zone will

be datum's defined by the centerlines of the package

body.

REF

-

-

ddd

eee

Definition

DS10781 Rev 9

Notes

This tolerance is

normally compounded

with tolerance zone

defined by bbb.

No tolerance for A2

35/40

40

�Packing information

ISO8200BQ

14

Packing information

14.1

TFQFPN32 packing information

14.1.1

TFQFPN32 packing method concept

Figure 27. TFQFPN32 packing method concept

36/40

DS10781 Rev 9

�ISO8200BQ

Packing information

Figure 28. TFQFPN32 carrier tape

Reel – 330 mm diameter x 101 mm hub x 24 mm width

Figure 29. TFQFPN32 reel

DS10781 Rev 9

37/40

40

�Packing information

14.1.2

ISO8200BQ

TFQFPN32 winding direction

Figure 30. TFQFPN32 winding direction

14.1.3

TFQFPN32 leader and trailer

Figure 31. TFQFPN32 leader and trailer

Note:

38/40

Leader and trailer length as per EAI-481specification.

DS10781 Rev 9

�ISO8200BQ

15

Ordering information

Ordering information

Table 18. Ordering information

16

Order code

Package

Packing

ISO8200BQ

TFQFPN32

Tube

ISO8200BQTR

TFQFPN32

Tape and reel

Revision history

Table 19. Document revision history

Date

Revision

17-Nov-2016

3

Datasheet promoted from preliminary to production data. Updated

Table 6: Diagnostic pin and output protection function.

21-Apr-2017

4

Updated Table 10: “Insulation and safety-related specifications”.

Minor text changes.

05-Oct-2017

5

Updated Table 11: “IEC 60747-5-2 insulation characteristics”.

6

Updated Section : Features on page 1.

Replaced Vdd by VDD in whole document.

Updated titles of Table 7 on page 11 and Table 9 on page 14 .

Updated titles of Figure 3 on page 12, Figure 5 on page 13, Figure 6

on page 13, Figure 20 on page 29 and Figure 21 on page 30 .

Added cross-reference to Section 6.2 in Table 13 on page 17.

Updated Figure 9 on page 20 and Figure 11 on page 21 (replaced

ISO8200B by ISO8200BQ).

Added Section on page 34.

Minor modifications throughout document.

24-Apr-2019

7

Added Table 12: Safety limits on page 15,

Updated Table 2: Absolute maximum ratings on page 9

Updated Section : Features on page 1.

Minor text changes.

18-Oct-2019

8

Updated Section : Features on page 1.

08-May-2020

9

Table 4, 11 and 16 updated. Figure 24 replaced. Table 17 added.

18-May-2018

Changes

DS10781 Rev 9

39/40

40

�ISO8200BQ

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and

improvements to ST products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on

ST products before placing orders. ST products are sold pursuant to ST’s terms and conditions of sale in place at the time of order

acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or

the design of Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. All other product or service names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2020 STMicroelectronics – All rights reserved

40/40

DS10781 Rev 9

�