PTH04040W

www.ti.com

SLTS238C – SEPTEMBER 2005 – REVISED JUNE 2010

60-A, 3.3/5-V INPUT, NONISOLATED WIDE-OUTPUT

ADJUST POWER MODULE

Check for Samples: PTH04040W

FEATURES

APPLICATIONS

•

•

•

•

•

•

•

•

1

2

•

•

•

•

•

•

•

•

60-A Output Current

3.3-V and 5-V Input Voltage

Wide-Output Voltage Adjust (0.8 V to 2.5 V)

Efficiencies up to 93%

On/Off Inhibit

Differential Output Sense

Output Overcurrent Protection

(Nonlatching, Auto-Reset)

Overtemperature Protection

Auto-Track™ Sequencing

Start Up Into Output Prebias

Margin Up/Down Controls

Operating Temperature: –40°C to 85°C

Multi-Phase, Switch-Mode Topology

Programmable Undervoltage Lockout (UVLO)

Safety Agency Approvals:

UL/IEC/CSA-22.2 60950-1

Advanced Computing and Server Applications

NOMINAL SIZE =

2.05 in x 1.05 in

(52 mm x 26,7 mm)

DESCRIPTION

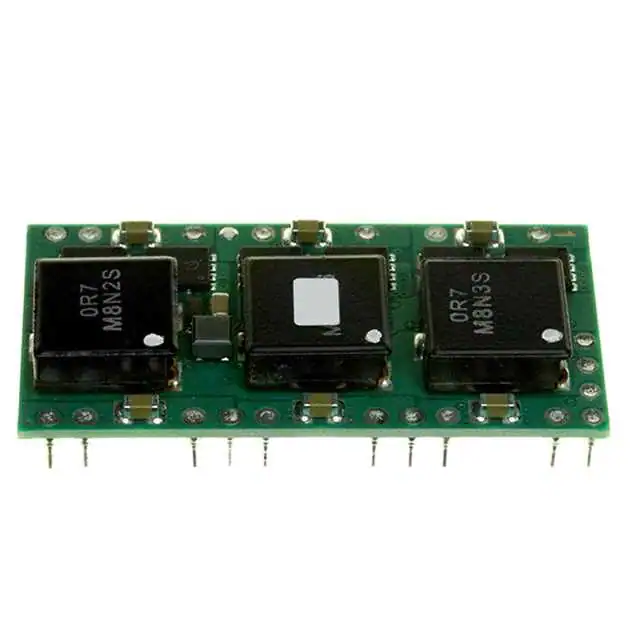

The PTH04040W is a high-performance 60-A rated, nonisolated, power module, which uses the latest

multi-phase switched-mode topology. This provides a small, ready-to-use module, that can power the most

densely populated multiprocessor systems.

The PTH04040W operates over an input voltage range of 2.95 V to 5.5 V, and can be set to any output voltage

over the range, 0.8 V to 2.5 V, using a single external resistor. The combination of a wide input voltage and

wide-output adjust range allows the PTH04040W to be used in many of high-performance applications. These

include advanced computing platforms and servers that utilize either a 3.3-V or 5-V distribution bus.

These modules incorporate a comprehensive list of features. They include an on/off inhibit and margin up/down

controls. A differential remote output voltage sense ensures tight load regulation, and an output overcurrent and

overtemperature shutdown protect against most load faults. A programmable undervoltage lockout allows the

turn-on threshold to be customized.

The PTH04040W incorporates Auto-Track™. Auto-Track is a popular feature of the PTH family that allows the

outputs of multiple modules to track a common voltage during power-up and power-down transitions. This greatly

simplifies the sequencing of voltages for VLSI ICs that operate off multiple power rails.

The double-sided surface mount construction has a low profile and compact footprint. It is available in both

throughhole and surface-mount packages.

1

2

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Auto-Track, POLA, TMS320 are trademarks of Texas Instruments.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2005–2010, Texas Instruments Incorporated

�PTH04040W

SLTS238C – SEPTEMBER 2005 – REVISED JUNE 2010

www.ti.com

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

STANDARD APPLICATION

19

Margin

Up

2

VI

4

20

Margin

Down

8

+Sense

11

9

PTH04040W

Vo

12

VO

15

UVLO

Inhibit

A

Track

VI

6

+

18

CI

1000 µF

(Required)

7

GND

1

3

GND

5

10

13

−Sense

VoAdj

14

+

16 17

RSET B

1%

0.05 W

C

+

CO1

330 µF

C

CO2

330 µF

UDG−05085

A.

For CI, a minimum of 1,000 mF (or 2 × 470 mF) of input capacitance is required for proper operation.

B.

RSET is required to set the desired output voltage from the module higher than the minimum value.

C.

For CO1 and CO2, a minimum of 660 mF (or 2 × 330 mF) of output capacitance is required for load transient

regulation.

ORDERING INFORMATION

For the most current package and ordering information, see the Package Option Addendum at the end of this datasheet, or see

the TI website at www.ti.com.

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

UNIT

Signal input voltages

Track control (pin 18)

TA

Operating temperature range over VI range

Twave

Wave solder

temperature

Surface temperature of module body or pins

(5 seconds)

Treflow

Solder reflow

temperature

Surface temperature of module body or pins

TS

Storage temperature

–40°C to 85°C

2

260°C

(1)

PTH04040WAS

235°C

(1)

PTH04040WAZ

260°C

(1)

–55°C to 125°C

Per Mil-STD-883D, Method 2002.3, 1 msec, ½ Sine, mounted

500 G (2)

Mechanical vibration

Mil-STD-883D, Method 2007.2, 20–2000 Hz

10 G (2)

Flammability

(2)

PTH04040WAH

PTH04040WAD

Mechanical shock

Weight

(1)

–0.3 V to VI + 0.3 V

22.5 grams

Meets UL94V-O

During soldering of package version, do not elevate peak temperature of the module, pins or internal components above the stated

maximum.

Qualification limits

Submit Documentation Feedback

Copyright © 2005–2010, Texas Instruments Incorporated

Product Folder Link(s): PTH04040W

�PTH04040W

www.ti.com

SLTS238C – SEPTEMBER 2005 – REVISED JUNE 2010

ELECTRICAL CHARACTERISTICS

TA = 25°C, VI = 5 V, VO = 2.5 V, CI = 1000 µF, CO = 660 µF, and IO = IOmax (unless otherwise stated)

PARAMETER

TEST CONDITIONS

MIN

MAX

UNIT

0

TYP

60 (1)

A

2.95 (2)

5.5

IO

Output current

60°C, 200 LFM airflow

VI

Input voltage range

Over IO range

VOtol

Set-point voltage tolerance

ΔRegtemp

Temperature variation

–40°C < TA < 85°C

±0.5

%VO

ΔRegline

Line regulation

Over VI range

±5

mV

ΔRegload

Load regulation

Over IO range

±5

ΔRegtot

Total output variation

Includes set-point, line, load, –40°C ≤ TA ≤ 85°C

VO,

Output adjust range

ADJ

±2 (3)

VI = 5 V, IO = 45 A

Efficiency

h

VI = 3.3 V, IO = 45 A

mV

±3 (3)

2.95 ≤ VI ≤ 4.5 V (3)

0.8

-

1.65

4.5 < VI ≤ 5.5 V (3)

0.8

-

2.5

RSET = 2.21 kΩ, VO = 2.5 V

93%

RSET = 5.49 kΩ, VO = 1.8 V

90%

RSET = 8.87 kΩ, VO = 1.5 V

88%

RSET = 17.4 kΩ, VO = 1.2 V

86%

RSET = 6.92 kΩ, VO = 1.65 V

92%

RSET = 8.87 kΩ, VO = 1.5 V

91%

RSET = 36.5 kΩ, VO = 1 V

87%

All voltages

15

V

%VO

%VO

V

VR

VO ripple (peak-to-peak)

20-MHz bandwidth

IOtrip

Overcurrent threshold

Reset, followed by auto-recovery

Transient response

1 A/µs load step, 50 to 100%

IOmax, CO=660µF

Margin up down adjust

From a given set-point voltage

±5%

%

IILmargin

Margin input current

Pin to GND

–8 (4)

µA

IILtrack

Track input current (pin 18)

Pin to GND

dV/dt

Track slew rate capability

|VTRACK – VO | ≤ 50 mV and V(TRACK) < VO(nom)

UVLO

Undervoltage lockout

Pin 8 open

trr

ΔVtr

Inhibit control (pin 7)

Recovery time

VO over/undershoot

mVPP

90

A

100

µS

200

mV

–0.11 (5)

1

On-threshold

2.6 (6)

Hysterisis

0.6 (6)

mA

V/ms

V

Input high voltage (VIH), Referenced to GND

2.5

Open (7)

Input low voltage (VIL), Referenced to GND

–0.2

0.5

V

Input low current (IIL), Pin to GND

0.5

mA

IIinh

Input standby current

Inhibit (pin 7) to GND

60

mA

fs

Switching frequency

Over VI and IO ranges

(1)

(2)

(3)

(4)

(5)

(6)

(7)

675

825

975

kHz

See SOA curves or consult factory for appropriate derating.

The nominal input voltage must be at least 2 × VO. Output voltage regulation is specified with an input voltage within ±10% from nominal

3.3 V or 5 V. For example, for VI = 5 V and VO = 2.5 V, the input can vary between 4.5 V and 5.5 V.

The set-point voltage tolerance is affected by the tolerance of RSET. The stated limit is unconditionally met if RSET has a tolerance of 1%

with 100 ppm/°C or better temperature stability.

A small, low-leakage (4500 mA

>5440 mA

10x10.5

10x12.7

2 (2)

2

≤5

≤4

10SP470M

6SVP820M

Panasonic, Poly-Aluminum:

S/SE (SMD)

63 V

180

0.005 Ω

4000 mA

7.3x4.3x4.2

N/R

≤2

EEFSE0J181R

10 V

10 V

470

470

0.045 Ω

0.060 Ω

1723 mA

1826 mA

7.3x5.7x4.1

7.3x5.7x4.1

2 (2)

2 (2)

≤7

≤7

TPSE477M010R0045

TPSV477M010R0060

6.3 V

10 V

6.3 V

470

330

470

0.018 Ω

0.015 Ω

0.012 Ω

>1200 mA

>3800 mA

4200 mA

7.3x4.3x4

7.3x4.3x4

7.3x4.3x4

2 (2)

3

2 (2)

≤6

≤4

≤3

T520X477M006SE018

T530X337M010AS

T530X477M006AS

595D, Tantalum (SMD)

94SA, Os-con (Radial)

10 V

16 V

470

2200

0.100 Ω

0.015 Ω

1440 mA

9740 mA

7.2x6×4.1

16 × 25

2 (2)

1

≤7

≤4

595D477X0010R2T

94SA108X0016HBP

Kemet, Ceramic X5R (SMD)

16 V

6.3 V

10

47

0.002 Ω

0.002 Ω

–

1210 case

3225 mm

1 (3)

1 (3)

≤9

≤8

C1210C106M4PAC

C1210C476K9PAC

Murata, Ceramic X5R (SMD)

6.3 V

6.3 V

16 V

16 V

100

47

22

10

0.002 Ω

–

1210 case

3225 mm

1 (3)

1 (3)

1 (3)

≤4

≤8

≤8

≤9

GRM32ER60J107M

GRM32ER60J476M

GRM32ER61C226K

GRM32DR61C106K

TDK, Ceramic X5R (SMD)

6.3 V

6.3 V

16 V

16 V

100

47

22

10

0.002 Ω

–

1210 case

3225 mm

1 (3)

1 (3)

1 (3)

≤4

≤8

≤8

≤9

C3225X5R0J107MT

C3225X5R0J476MT

C3225X5R1C226MT

C3225X5R1C106MT

Physical

Size (mm)

Input

Bus

Output

Bus

Vendor Part No.

Panasonic

FC (Radial)

FC (Radial)

FK (SMD)

United Chemi-Con

FX, Oscon (Radial)

PXA, (Poly-Aluminum (SMD)

PSA (Poly-Aluminum)

LXZ, Aluminum (Radial)

Nichicon, Aluminum

HD (Radial)

PM (Radial)

Sanyo, Os-Con

AVX, Tantalum, Series III

TPS (SMD)

Kemet, Poly-Tantalum

T520 (SMD)

T530 (SMD)

Vishay-Sprague

(1)

(2)

(3)

10

Capacitor Supplier Verification

1.Please verify availability of capacitors identified in this table. Capacitor suppliers may recommend alternative part numbers because of

limited availability or obsolete products. In some instances, the capacitor product life cycle may be in decline and have short-term

consideration for obsolescence.

RoHS, Lead-free and Material Details

2.Please consult capacitor suppliers regarding material composition, RoHS status, lead-free status, and manufacturing process

requirements. Component designators or part number deviations can occur when material composition or soldering requirements are

updated.

The total capacitance is slightly lower than 1000 mF, but is acceptable based on the combined ripple current rating.

Ceramic capacitors can be used to complement electrolytic types at the input to further reduce high-frequency ripple current.

Submit Documentation Feedback

Copyright © 2005–2010, Texas Instruments Incorporated

Product Folder Link(s): PTH04040W

�PTH04040W

www.ti.com

SLTS238C – SEPTEMBER 2005 – REVISED JUNE 2010

ADJUSTING THE OUTPUT VOLTAGE OF THE PTH04040W

The VO Adjust control (pin 17) sets the output voltage of the PTH04040W to a value higher than 0.8 V. The

adjustment range is from 0.8 V to 2.5 V. For an output voltage other than 0.8 V a single external resistor, RSET 1,

must be connected directly between the VO Adjust (pin 17) and the output GND (pin 16)(2). Table 2 gives the

preferred value of the external resistor for a number of standard voltages, along with the actual output voltage

that this resistance value provides.

For other output voltages, the value of the required resistor is calculated using the following formula, or by

selecting from the range of values given in Table 3. Figure 9 shows the placement of the required resistor.

0.8 V

R set + 10 kW

* 2.49 kW

V out * 0.8 V

(1)

Table 2. Preferred Values of Rset for Standard Output Voltages

VOUT (Standard)

(1)

(1)

RSET (Preferred Value)

VOUT (Actual)

2.5 V

2.21 kΩ

2.502 V

2V

4.12 kΩ

2.010 V

1.8 V

5.49 kΩ

1.803 V

1.5 V

8.87 kΩ

1.504 V

1.2 V

17.4 kΩ

1.202 V

1V

36.5 kΩ

1.005 V

0.8 V

Open

0.8 V

The nominal input voltage must be at least 2 × VO. Output voltage regulation is specified with an input voltage within ±10% from nominal

3.3 V or 5 V. For example, for VI = 5 V and VO = 2.5 V, the input can vary between 4.5 V and 5.5 V.

18

Track

+Sense 11

9

VO

PTH04040W

VO

12

15

−Sense 14

GND

10 13

Adjust

16

17

RSET

1%

0.05 W

CO

GND

GND

Figure 9. VO Adjust Resistor Placement

Submit Documentation Feedback

Copyright © 2005–2010, Texas Instruments Incorporated

Product Folder Link(s): PTH04040W

11

�PTH04040W

SLTS238C – SEPTEMBER 2005 – REVISED JUNE 2010

www.ti.com

Table 3. Output Voltage Set-Point Resistor Values

VOUT

RSET

VOUT

RSET

0.8

Open

1.425

10.3 kΩ

0.825

318 kΩ

1.45

9.82 kΩ

0.85

158 kΩ

1.475

9.36 kΩ

0.875

104 kΩ

1.5

8.94 kΩ

0.9

77.5 kΩ

1.55

8.18 kΩ

0.925

61.5 kΩ

1.6

7.51 kΩ

0.95

50.8 kΩ

1.65

6.92 kΩ

0.975

43.2 kΩ

1.7

6.4 kΩ

1

37.5 kΩ

1.75

5.93 kΩ

1.025

33.1 kΩ

1.8

5.51 kΩ

1.05

29.5 kΩ

1.85

5.13 kΩ

1.075

26.6 kΩ

1.9

4.78 kΩ

1.1

24.2 kΩ

1.95

4.47 kΩ

1.125

22.1 kΩ

2

4.18 kΩ

1.15

20.4 kΩ

2.05

3.91kΩ

1.175

18.8 kΩ

2.1

3.66 kΩ

1.2

17.5 kΩ

2.15

3.44 kΩ

1.225

16.3 kΩ

2.2

3.22 kΩ

1.25

15.3 kΩ

2.25

3.03 kΩ

1.275

14.4 kΩ

2.3

2.84 kΩ

1.3

13.5 kΩ

2.35

2.67 kΩ

1.325

12.7 kΩ

2.4

2.51 kΩ

1.35

12.1 kΩ

2.45

2.36 kΩ

1.375

11.4 kΩ

2.5

2.22 kΩ

1.4

10.8 kΩ

NOTES:

1. A 0.05-W rated resistor can be used. The tolerance should be 1%, with temperature stability of 100 ppm/°C

(or better). Place the resistor as close to the regulator as possible. Connect the resistor directly between pins

17 and 16 using dedicated PCB traces.

2. Never connect capacitors from VO Adjust to either GND or VO . Any capacitance added to the VO Adjust pin

affects the stability of the regulator.

12

Submit Documentation Feedback

Copyright © 2005–2010, Texas Instruments Incorporated

Product Folder Link(s): PTH04040W

�PTH04040W

www.ti.com

SLTS238C – SEPTEMBER 2005 – REVISED JUNE 2010

ADJUSTING THE UNDERVOLTAGE LOCKOUT (UVLO) OF THE PTH04040W

The PTH04040W power modules incorporate an input undervoltage lockout (UVLO). The UVLO feature prevents

the operation of the module until there is sufficient input voltage to produce a valid output voltage. This enables

the module to provide a monotonic powerup for the load circuit, and also limits the magnitude of current drawn

from the module’s input source during the power-up sequence.

The UVLO characteristic is defined by the on-threshold (VTHD) and hysterisis (VHYS) voltages. Below the on

threshold, the Inhibit control is overriden, and the module does not produce an output. Hysterisis voltage is the

difference between the on and off threshold voltages. It ensures a clean power-up, even when the input voltage

is rising slowly. The hysterisis prevents start-up oscillations, which can occur if the input voltage droops slightly

when the module begins drawing current from the input source.

UVLO ADJUSTMENT

The UVLO feature of the PTH04040W gives the user the option of adjusting the on-threshold voltage higher than

the default value. This might be desirable if the module is powered from a 5-V input bus. This prevents the

module from operating until the input bus has risen closer to its regulation voltage.

The adjustment method uses the UVLO Prog control (pin 8). If the UVLO Prog pin is left open circuit, the

onthreshold voltage remains at its nominal value of 2.63 V (see electrical specification table). This ensures that

the unadjusted module produces a regulated output when the minimum input voltage is applied. The hysterisis

voltage is approximately 0.62 V, which correlates to an off-threshold voltage of about 2 V. The magnitude of the

hysterisis is automatically set to about 22% of the onthreshold. So if the on-threshold voltage is increased, then

the Hysterisis also increases.

UVLO ADJUSTMENT METHOD

Figure 10 shows the placement of the resistor, RTHD, for adjusting the UVLO on-threshold voltage. It connects

from the UVLO Prog control pin to GND. Equation 2 determines the value of RTHD required to adjust VTHD to a

new value. The default value is 2.63 V, and it can only be adjusted higher. Once the value of RTHD has been set,

Equation 3 is used to determine the new hysterisis voltage.

R THD

12.9

=

kΩ

VTHD − 2.63

VHYS = 2.191

1

R THD

(2)

+ 0.283

V

(3)

2

VI

4

6

8

VI

PTH04040W

UVLO Prog

Inhibit

7

CI

GND

1

3 5

RTHD

1,000 mF

GND

Figure 10. UVLO Program Resistor Placement

Submit Documentation Feedback

Copyright © 2005–2010, Texas Instruments Incorporated

Product Folder Link(s): PTH04040W

13

�PTH04040W

SLTS238C – SEPTEMBER 2005 – REVISED JUNE 2010

www.ti.com

FEATURES OF THE PTH FAMILY OF NONISOLATED WIDE OUTPUT ADJUST POWER

MODULES

POLA™ COMPATIBILITY

The PTH/PTV family of nonisolated, wide-output adjustable power modules are optimized for applications that

require a flexible, high performance module that is small in size. Each of these products are POLA™ compatible.

POLA-compatible products are produced by a number of manufacturers, and offer customers advanced,

nonisolated modules with the same footprint and form factor. POLA parts are also assured to be interoperable,

thereby providing customers with second-source availability.

Many of the POLA-compatible parts include a feature called Auto-Track™. Auto-Track was specifically designed

to simplify the task of sequencing the supply voltages in a power system. This and other features are described

the following sections.

SOFT-START POWER UP

The Auto-Track feature allows the power-up of multiple PTH modules to be directly controlled from the Track pin.

However in a stand-alone configuration, or when the Auto-Track feature is not being used, the Track pin should

be directly connected to the input voltage, Vin (see Figure 11).

5V

2

VI

Dn

8

5

Track

Sense

VO

PTH05020W

Inhibit

3

3.3 V

6

VO (1 V/Div)

Adjust

GND

1

VI (1 V/Div)

7

4

CI

RSET

1,000 mF

698 W

0.1 W, 1%

+

GND

+

10 9

Up

II (5 A/Div)

CO

330 mF

GND

Figure 11. Power-Up Application Circuit

t - Time = 5 msec/Div

Figure 12. Power-Up Waveforms

When the Track pin is connected to the input voltage the Auto-Track function is permanently disengaged. This

allows the module to power up entirely under the control of its internal soft-start circuitry. When power up is

under soft-start control, the output voltage rises to the set-point at a quicker and more linear rate.

From the moment a valid input voltage is applied, the soft-start control introduces a short time delay (typically

5 ms–10 ms) before allowing the output voltage to rise. The output then progressively rises to the module’s

setpoint voltage. Figure 12 shows the soft-start power-up characteristic of the 22-A output product

(PTH05020W), operating from a 5-V input bus and configured for a 3.3-V output. The waveforms were measured

with a 5-A resistive load and the Auto-Track feature disabled. The initial rise in input current when the input

voltage first starts to rise is the charge current drawn by the input capacitors. Power-up is complete within 15 ms.

14

Submit Documentation Feedback

Copyright © 2005–2010, Texas Instruments Incorporated

Product Folder Link(s): PTH04040W

�PTH04040W

www.ti.com

SLTS238C – SEPTEMBER 2005 – REVISED JUNE 2010

OVERCURRENT PROTECTION

For protection against load faults, all modules incorporate output overcurrent protection. Applying a load that

exceeds the regulator’s overcurrent threshold causes the regulated output to shut down. Following shutdown, a

module periodically attempts to recover by initiating a soft-start powerup. This is described as a hiccup mode of

operation, whereby the module continues in a cycle of successive shutdown and power up until the load fault is

removed. During this period, the average current flowing into the fault is significantly reduced. Once the fault is

removed, the module automatically recovers and returns to normal operation.

OVERTEMPERATURE PROTECTION (OTP)

Products with a high output current capability (>20 A), incorporate overtemperature protection. This feature is

provided by an on-board temperature sensor that protects the module’s internal circuitry against excessively high

temperatures. A rise in the internal temperature may be the result of a drop in airflow, or a high ambient

temperature. If the internal temperature exceeds the OTP threshold, the module’s Inhibit control is automatically

pulled low. This turns the output off. The output voltage drops as the external output capacitors are discharged

by the load circuit. The recovery is automatic, and begins with a soft-start power up. It occurs when the sensed

temperature decreases by about 10°C below the trip point.

Note: The overtemperature protection is a last resort mechanism to prevent thermal stress to the regulator.

Operation at or close to the thermal shutdown temperature is not recommended, and reduces the long-term

reliability of the module. Always operate the regulator within the specified safe operating area (SOA) limits for

the worst-case conditions of ambient temperature and airflow.

OUTPUT ON/OFF INHIBIT

For applications requiring output voltage on/off control, each series of the PTH family incorporates an output

Inhibit control pin. The inhibit feature can be used wherever there is a requirement for the output voltage from the

regulator to be turned off.

The power modules function normally when the Inhibit pin is left open-circuit, providing a regulated output

whenever a valid source voltage is connected to Vin with respect to GND.

Figure 13 shows the typical application of the inhibit function. Note the discrete transistor (Q1). The Inhibit control

has its own internal pull-up to VI potential. The input is not compatible with TTL logic devices. An open-collector

(or open-drain) discrete transistor is recommended for control.

VOSense

VO (2 V/Div)

VI

2

1,000 mF

1 = Inhibit

5

8

6

PTH05020W

3

+

CI

9

1

4

7

RSET

Q1

BSS138

CO

VO

330 mF

GND

II (2 A/Div)

L

O

A

D

+

10

Q1Vds (5 V/Div)

GND

Figure 13. Inhibit Control Circuit

t - Time = 10 msec/Div

Figure 14. Power-Up from Inhibit Control

Turning Q1 on applies a low voltage to the Inhibit control and disables the output of the module. If Q1 is then

turned off, the module executes a soft-start powerup. A regulated output voltage is produced within 20 ms.

Figure 14 shows the typical rise in both the output voltage and input current, following the turn-off of Q1. The turn

off of Q1 corresponds to the rise in the waveform, Q1 Vds. The waveforms were measured with a 5-A constant

current load.

Submit Documentation Feedback

Copyright © 2005–2010, Texas Instruments Incorporated

Product Folder Link(s): PTH04040W

15

�PTH04040W

SLTS238C – SEPTEMBER 2005 – REVISED JUNE 2010

www.ti.com

REMOTE SENSE

The remote sense feature allows the regulator to compensate for limited amounts of voltage drop, that may be

incurred between the converter and load, due to resistance in the PCB traces. Connecting the +Sense and

–Sense pins to the respective VO and GND output nodes improves the load regulation of the regulator output at

those connection points. This is recommended even if the load circuit is located close to the module.

If either the +Sense and –Sense are left open-circuit, an internal low-value resistor (15-Ω or less), connected

from the respective sense pin to either VO or GND, ensures the output voltage remains in regulation.

With the sense pins connected, the difference between the voltage measured across the VO and GND pins of the

regulator, and that measured at +Sense with respect to +Sense, is the amount of IR drop being compensated by

the regulator. This should be limited to a maximum of 0.3 V.

Note: The remote sense feature is not designed to compensate for the forward drop of nonlinear or

frequency dependent components that may be placed in series with the converter output. Examples include

OR-ing diodes, filter inductors, ferrite beads, and fuses. When these components are enclosed by the remote

sense connection they are effectively placed inside the regulation control loop, which can adversely affect the

stability of the regulator.

Auto-Track™ FUNCTION

The Auto-Track function is unique to the PTH/PTV family, and is available with the all POLA-compatible

products. Auto-Track was designed to simplify the amount of circuitry required to make the output voltage from

each module power up and power down in sequence. The sequencing of two or more supply voltages during

power up is a common requirement for complex mixed-signal applications, that use dual-voltage VLSI ICs such

as the TMS320™ DSP family, micro-processors, and ASICs.

HOW Auto-Track WORKS

Auto-Track works by forcing the module’s output voltage to follow a voltage presented at the Track control pin.

This control range is limited to between 0 V and the module’s set-point voltage. Once the Track input is raised

above the set-point voltage, the module’s output remains at its set-point 1. As an example, if the Track pin of a

2.5-V regulator is at 1 V, the regulated output will be 1 V. But, if the voltage at the Track pin rises to 3 V, the

regulated output does not go higher than 2.5 V.

When the Track input is used to connect a number of modules together, it forces the output voltage from each

module to follow a common signal during power-up and power-down. The control signal can be an externally

generated master ramp waveform, or the output voltage from another power supply circuit.(3) For convenience,

each module’s Track input incorporates an internal RC charge circuit. This operates off the module’s input

voltage to provide a suitable rising voltage ramp waveform.

TYPICAL Auto-Track APPLICATION

Connecting the Track inputs of two or more modules forces their Track input to follow the same collective RC

ramp waveform, and allows their power-up sequence to be coordinated from a common Track control signal.

This can be an open-collector (or open drain) device, such as a power-up reset voltage supervisor IC.

To coordinate a power-up sequence the Track control must first pulled to ground potential. This should be done

at or before input power is applied to the modules. The ground signal should be maintained for at least 10 ms

after input power has been applied. This brief period gives the modules time to complete their internal soft-start

initialization, enabling them to produce an output voltage. A low-cost supply voltage supervisor IC, that includes

built-in time delay, is an ideal component for automatically controlling the Track inputs at power up.

Figure 17 shows how the TPS3808G50 supply voltage supervisor IC (U3) can be used to coordinate the

sequenced power-up of two 5-V input Auto-Track modules. The output of the TPS3808 supervisor becomes

active above an input voltage of 0.8 V, enabling it to assert a ground signal to the common Track control well

before the input voltage has reached the module’s undervoltage lockout threshold. The ground signal is

maintained until approximately 27 ms after the input voltage has risen above U3’s voltage threshold, which is

4.65 V. The 27-ms time period is controlled by the capacitor C3. The value of 4700 mF provides sufficient time

delay for the modules to complete their internal soft-start initialization. The output voltage of each module

remains at zero until the Track control voltage is allowed to rise. When U3 removes the ground signal, the Track

control voltage automatically rises to the input voltage. This causes the output voltage of each module to rise

simultaneously with the other modules, until each reaches its respective set-point voltage.

16

Submit Documentation Feedback

Copyright © 2005–2010, Texas Instruments Incorporated

Product Folder Link(s): PTH04040W

�PTH04040W

www.ti.com

SLTS238C – SEPTEMBER 2005 – REVISED JUNE 2010

Figure 15 shows the output voltage waveforms from the circuit of Figure 17 after input voltage is applied to the

circuit. The waveforms, VO1 and VO2, represent the output voltages from the two power modules, U1 (3.3 V) and

U2 (1.8 V), respectively. VTRK, VO1, and VO2 are shown rising together to produce the desired simultaneous

power-up characteristic.

The same circuit also provides a power-down sequence. When the input voltage falls below U3's voltage

threshold, the ground signal is re-applied to the common Track control. This pulls the Track inputs to zero volts,

forcing the output of each module to follow, as shown in Figure 16. In order for a simultaneous power-down to

occur, the Track inputs must be pulled low before the input voltage has fallen below the modules' undervoltage

lockout. This is an important constraint. Once the modules recognize that a valid input voltage is no longer

present, their outputs can no longer follow the voltage applied at their Track input. During a power-down

sequence, the fall in the output voltage from the modules is limited by the maximum output capacitance and the

Auto-Track slew rate.

NOTES ON USE OF Auto-Track

1. The Track pin voltage must be allowed to rise above the module’s set-point voltage before the module can

regulate at its adjusted set-point voltage.

2. The Auto-Track function tracks almost any voltage ramp during power up, and is compatible with ramp

speeds of up to 1 V/ms.

3. The absolute maximum voltage that may be applied to the Track pin is VI.

4. The module does not follow a voltage at its Track input until it has completed its soft-start initialization. This

takes at least 10 ms from the time that the module has sensed that a valid voltage is present. During this

period, the Track input should be held at ground potential.

5. The module is capable of both sinking and sourcing current when following a voltage at its Track input.

Therefore startup into an output prebias is not supported when the module is under Auto-Track control.

Prebias hold off is not necessary when all supply voltages simultaneously under the control of Auto-Track.

6. The Auto-Track function can be disabled by connecting the Track pin to the input voltage (VI). With

Auto-Track disabled, the output voltage rises at a quicker and more linear rate after input power is applied.

VTRK (1 V/div)

VTRK (1 V/div)

V01 (1 V/div)

V01 (1 V/div)

V02 (1 V/div)

V02 (1 V/div)

t − Time − 20 ms/div

t − Time − 200 µs/div

Figure 15. Auto-Track Simultaneous Power Up

Waveforms

Figure 16. Auto-Track Simultaneous Power Down

Waveforms

Submit Documentation Feedback

Copyright © 2005–2010, Texas Instruments Incorporated

Product Folder Link(s): PTH04040W

17

�PTH04040W

SLTS238C – SEPTEMBER 2005 – REVISED JUNE 2010

www.ti.com

14

U1

13

Track

TT

+Sense

+5 V

2, 6

VI

VO

PTH05T210W

10

5, 9

VO1 = 3.3 V

1

−Sense

INH/UVLO

11

VOAdj

GND GND

3, 4

7, 8

+

12

CO1

+

CI1

RSET1

1.62 kΩ

U3

6

VCC

5

3

MR SENSE

C4

0.1 µF

RESET

4 TPS3808G50

CT

GND

C3

4700 pF

1

RTRK#

50 Ω

U2

2

19

20

18

Margin Margin Track

Up Down

+Sense

VI

2

4

6

8

RTRK# = 100 Ω/N

N = Number of track pins connected together

11

9

VI

VO

PTH04040W

−Sense

UVLO Prog

Inhibit

7

GND

1

3

GND

5

12

15

VOAdj

10 13 16

VO2 = 1.8 V

14

17

+

+

CO2

CI2

RSET2

5.49 kΩ

Figure 17. Sequenced Power Up and Power Down using Auto-Track

18

Submit Documentation Feedback

Copyright © 2005–2010, Texas Instruments Incorporated

Product Folder Link(s): PTH04040W

�PTH04040W

www.ti.com

SLTS238C – SEPTEMBER 2005 – REVISED JUNE 2010

MARGIN UP/DOWN CONTROLS

The PTHxx060, PTHxx010, PTHxx020, and PTHxx030 products incorporate Margin Up and Margin Down control

inputs. These controls allow the output voltage to be momentarily adjusted(1), either up or down, by a nominal

5%. This provides a convenient method for dynamically testing the operation of the load circuit over its supply

margin or range. It can also be used to verify the function of supply voltage supervisors. The ±5% change is

applied to the adjusted output voltage, as set by the external resistor, Rset at the Vo Adjust pin.

The 5% adjustment is made by pulling the appropriate margin control input directly to the GND terminal 2. A

low-leakage open-drain device, such as an n-channel MOSFET or p-channel JFET is recommended for this

purpose(3). Adjustments of less than 5% can also be accommodated by adding series resistors to the control

inputs. The value of the resistor can be selected from Table 4, or calculated using the following formula.

UP/DOWN ADJUST RESISTANCE CALCULATION

RU or RD =

499

- 99.8 kW

D%

(4)

Where Δ% = The desired amount of margin adjusted in percent.

NOTES

1. The Margin Up and Margin Down controls were not intended to be activated simultaneously. If they are

activated simultaneously, the effects on the output voltage may not completely cancel, resulting in the

possibility of a higher error in the output voltage set point.

2. The ground reference should be a direct connection to the module GND at pin 7 (pin 1 for the PTHxx050).

This produces a more accurate adjustment at the load circuit terminals. The transistors Q1 and Q2 should be

located close to the regulator.

3. The Margin Up and Margin Down control inputs are not compatible with devices that source voltage. This

includes TTL logic. These are analog inputs and should only be controlled with a true open-drain device

(preferably discrete MOSFET transistor). The device selected should have low off-state leakage current.

Each input sources 8 µA when grounded, and has an open-circuit voltage of 0.8 V.

Table 4. Margin Up/Down Resistor Values

% ADJUST

5%

4%

3%

2%

1%

RU / RD

0 kΩ

24.9 kΩ

66.5 kΩ

150.0 kΩ

397.0 kΩ

1

9

10

8

7

+VO

0V

PTH05010W

(Top View)

VI

2

3

CI

+

RD

RU

+VO

6

4

5

RSET

0.1 W, 1%

+

CO

L

O

A

D

Q1

Margin Down

Q2

Margin Up

GND

GND

Figure 18. Margin Up/Down Application Schematic

Submit Documentation Feedback

Copyright © 2005–2010, Texas Instruments Incorporated

Product Folder Link(s): PTH04040W

19

�PTH04040W

SLTS238C – SEPTEMBER 2005 – REVISED JUNE 2010

www.ti.com

PREBIAS STARTUP CAPABILITY

A prebias startup condition occurs as a result of an external voltage being present at the output of a power

module prior to its output becoming active. This often occurs in complex digital systems when current from

another power source is backfed through a dual-supply logic component, such as an FPGA or ASIC. Another

path might be via clamp diodes as part of a dual-supply power-up sequencing arrangement. A prebias can cause

problems with power modules that incorporate synchronous rectifiers. This is because under most operating

conditions, these types of modules can sink as well as source output current.

The PTH/PTV family of power modules incorporate synchronous rectifiers, but does not sink current during

startup(1), or whenever the Inhibit pin is held low. However, to ensure satisfactory operation of this function,

certain conditions must be maintained(2). Figure 19 shows an application demonstrating the prebias startup

capability. The start-up waveforms are shown in Figure 20. Note that the output current from the PTH03010W (Io)

shows negligible current until its output voltage rises above that backfed through diodes D1 and D2.

Note: The prebias start-up feature is not compatible with Auto-Track. When the module is under Auto-Track

control, it sinks current if the output voltage is below that of a back-feeding source. To ensure a prebias

hold-off, one of two approaches must be followed when input power is applied to the module. The Auto-Track

function must be disabled(3), or the module’s output held off (for at least 50 ms) using the Inhibit pin. Either

approach ensures that the Track pin voltage is above the set-point voltage at start up.

NOTES

1. Startup includes the short delay (approximately 10 ms) prior to the output voltage rising, followed by the rise

of the output voltage under the module’s internal soft-start control. Startup is complete when the output

voltage has risen to either the set-point voltage or the voltage at the Track pin, whichever is lowest.

2. To ensure that the regulator does not sink current when power is first applied (even with a ground signal

applied to the Inhibit control pin), the input voltage must always be greater than the output voltage throughout

the powerup and power-down sequence.

3. The Auto-Track function can be disabled at power up by immediately applying a voltage to the module’s

Track pin that is greater than its set-point voltage. This can be easily accomplished by connecting the Track

pin to Vin.

VI = 3.3 V

10

5

8

9

Sense

Track

2

VI

PTH03010W

Inhibit

3

+C

I

330 mF

VO = 2.5 V

6

+

VAdj

GND

1

VO

7

Io

4

R2

2k21

VCORE

+C

VCCIO

O

330 mF

ASIC

Figure 19. Application Circuit Demonstrating Prebias Startup

20

Submit Documentation Feedback

Copyright © 2005–2010, Texas Instruments Incorporated

Product Folder Link(s): PTH04040W

�PTH04040W

www.ti.com

SLTS238C – SEPTEMBER 2005 – REVISED JUNE 2010

VI (1 V/Div)

VO (1 V/Div)

IO (5 A/Div)

t - Time = 5 msec/Div

Figure 20. Pre-Bias Startup Waveforms

Submit Documentation Feedback

Copyright © 2005–2010, Texas Instruments Incorporated

Product Folder Link(s): PTH04040W

21

�PTH04040W

SLTS238C – SEPTEMBER 2005 – REVISED JUNE 2010

www.ti.com

REVISION HISTORY

Changes from Revision B (JULY 2009) to Revision C

•

22

Page

Changed from: "input" to: "output" ........................................................................................................................................ 2

Submit Documentation Feedback

Copyright © 2005–2010, Texas Instruments Incorporated

Product Folder Link(s): PTH04040W

�PACKAGE OPTION ADDENDUM

www.ti.com

10-Mar-2022

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

MSL Peak Temp

Op Temp (°C)

(3)

Device Marking

(4/5)

(6)

PTH04040WAD

ACTIVE

ThroughHole Module

EVF

20

12

RoHS Exempt

& Green

SN

N / A for Pkg Type

-40 to 85

PTH04040WAH

ACTIVE

ThroughHole Module

EVF

20

12

RoHS Exempt

& Green

SN

Level-1-235C-UNLIM

-40 to 85

PTH04040WAS

ACTIVE

Surface

Mount Module

EVG

20

12

Non-RoHS

& Green

SNPB

Level-1-235C-UNLIM/

Level-3-260C-168HRS

-40 to 85

PTH04040WAZ

ACTIVE

Surface

Mount Module

EVG

20

12

RoHS (In

Work) & Green

SNAGCU

Level-3-260C-168 HR

-40 to 85

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of