Product

Folder

Order

Now

Support &

Community

Tools &

Software

Technical

Documents

TPS40170

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

TPS40170 4.5 V to 60 V, Wide-Input Synchronous PWM Buck Controller

1 Features

•

•

•

•

•

1

•

•

•

•

•

•

•

•

•

•

•

•

Wide Input Voltage Range from 4.5 V to 60 V

600 mV Reference Voltage with 1% Accuracy

Programmable UVLO and Hysteresis

Voltage Mode Control With Voltage Feed Forward

Programmable Frequency Between 100 kHz and

600 kHz

Bi-directional -Frequency Synchronization With

Master/Slave Option

Low-side FET Sensing Overcurrent Protection and

High-Side FET Sensing Short-Circuit Protection

With Integrated Thermal Compensation

Programmable Closed Loop Soft-Start

Supports Pre-Biased Outputs

Thermal Shutdown at 165°C with Hysteresis

Voltage Tracking

Powergood

ENABLE with 1-µA Low Current Shutdown

8.0-V and 3.3-V LDO Output

Integrated Bootstrap Diode

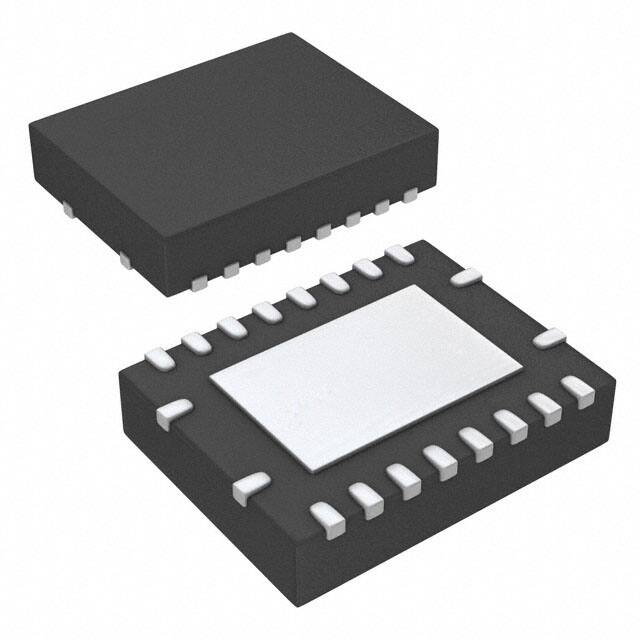

20-Pin 3.5 mm × 4.5 mm VQFN (RGY) Package

Create a Custom Design with WEBENCH Tools

2 Applications

•

•

POL Modules

Wide Input Voltage, High-Power Density DC - DC

Converters for Industrial, Networking and Telecom

Equipment

3 Description

TPS40170 is a full-featured, synchronous PWM buck

controller that operates at an input voltage between

4.5 V and 60 V and is optimized for high-power

density, high-reliability DC-DC converter applications.

The controller implements voltage-mode control with

input voltage feed-forward compensation that enables

instant response to input voltage change. The

switching frequency is programmable from 100 kHz to

600 kHz.

The TPS40170 has a complete set of system

protection and monitoring features such as

programmable

undervoltage

lockout

(UVLO),

programmable overcurrent protection (OCP) by

sensing the low-side FET, selectable short-circuit

protection (SCP) by sensing the high-side FET and

thermal shutdown. The ENABLE pin allows for

system shutdown in a low-current (1 µA typical)

mode. The controller supports pre-biased output,

provides an open-drain PGOOD signal, and has

closed-loop soft-start, output voltage tracking and

adaptive dead-time control.

Device Information(1)

PART NUMBER

PACKAGE

BODY SIZE (NOM)

TPS40170

VQFN (20)

3.50 mm × 4.50 mm

(1) For all available packages, see the orderable addendum at

the end of the datasheet.

Simplified Application

Efficiency vs. Load Current

100

VIN

ENABLE

20

UVLO

2

SYNC

3

M/S

BOOT 18

4

RT

HDRV 17

5

SS

SW 16

6

TRK

7

FB

8

COMP

9

AGND

VIN 19

VOUT

TRK

VDD

10

TPS40170

Efficiency (%)

95

1

ENABLE

90

85

80

VIN = 12 V

VIN = 24 V

VIN = 48 V

75

VBP 15

LDRV 14

70

0

PGND 13

1

2

3

4

Load Current (A)

5

6

GND

ILIM 12

PGOOD

11

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�TPS40170

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

4

6.1

6.2

6.3

6.4

6.5

6.6

4

4

4

5

5

8

Absolute Maximum Ratings ......................................

Handling Ratings ......................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Typical Characteristics ..............................................

Detailed Description ............................................ 11

7.1 Overview ................................................................. 11

7.2 Functional Block Diagram ....................................... 11

7.3 Feature Description................................................. 12

7.4 Device Functional Modes........................................ 27

8

Application and Implementation ........................ 29

8.1 Application Information............................................ 29

8.2 Typical Application ................................................. 30

9 Power Supply Recommendations...................... 37

10 Layout................................................................... 37

10.1 Layout Guidelines ................................................. 37

10.2 Layout Example .................................................... 37

11 Device and Documentation Support ................. 40

11.1

11.2

11.3

11.4

11.5

Custom Design with WEBENCH Tools.................

Device Support......................................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

40

40

40

40

40

12 Mechanical, Packaging, and Orderable

Information ........................................................... 40

4 Revision History

Changes from Revision B (December 2014) to Revision C

Page

Changes from Revision A (November 2013) to Revision B

Page

•

Added Handling Ratings table, Feature Description section, Device Functional Modes, Application and

Implementation section, Power Supply Recommendations section, Layout section, Device and Documentation

Support section, and Mechanical, Packaging, and Orderable Information section................................................................ 3

Changes from Original (March 2011) to Revision A

Page

•

Deleted Ordering Information table. Replaced with Package Option Addenda inserted after the last page of this data

sheet. ..................................................................................................................................................................................... 3

•

Added clarity to Figure 20..................................................................................................................................................... 16

•

Added significant clarity to and corrected typographic errors in DESIGN EXAMPLE ......................................................... 32

2

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

�TPS40170

www.ti.com

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

5 Pin Configuration and Functions

RGY PACKAGE

QFN-20

(Top View)

ENABLE

UVLO

1

20 19

SYNC

2

M/S

3

18

BOOT

RT

4

17

HDRV

SS

5

16

SW

VIN

TPS40170

TRK

6

15

VBP

FB

7

14

LDRV

COMP

8

13

PGND

AGND

9

11 12

10

VDD

ILIM

PGOOD

Pin Functions

PIN

I/O

DESCRIPTION

NAME

NO.

AGND

9

—

Analog signal ground. This pin must be electrically connected to power ground PGND externally.

BOOT

18

O

Boot capacitor node for high-side FET gate driver. The boot capacitor is connected from this pin to SW.

COMP

8

O

Output of the internal error amplifier. The feedback loop compensation network is connected from this pin

to the FB pin.

ENABLE

1

I

This pin must be high for the device to be enabled. If this pin is pulled low, the device is put in a lowpower consumption shutdown mode.

FB

7

I

Negative input to the error amplifier. The output voltage is fed back to this pin through a resistor divider

network.

HDRV

17

O

Gate driver output for the high-side FET.

ILIM

12

I

A resistor from this pin to PGND sets the overcurrent limit. This pin provides source current used for

overcurrent protection threshold setting.

LDRV

14

O

Gate driver output for the low-side FET. Also, a resistor from this pin to PGND sets the multiplier factor to

determine short-circuit current limit. If no resistor is present the multiplier defaults to 7 times the ILIM pin

voltage.

M/S

3

I

Master or slave mode selector pin for frequency synchronization. This pin must be tied to VIN for master

mode. In the slave mode this pin must be tied to AGND or left floating. If the pin is tied to AGND, the

device synchronizes with a 180° phase shift. If the pin is left floating, the device synchronizes with a 0°

phase shift.

PGND

13

—

Power ground. This pin must externally connect to the AGND at a single point.

PGOOD

11

O

Power good indicator. This pin is an open-drain output pin and a 10 kΩ pull-up resistor is recommended

to be connected between this pin and VDD.

RT

4

I

A resistor from this pin to AGND sets the oscillator frequency. Even if operating in slave mode, it is

required to have a resistor at this pin to set the free running switching frequency.

SS

5

I

Soft-start. A capacitor must be connected at this pin to AGND. The capacitor value sets the soft-start

time.

SW

16

I

This pin must connect to the switching node of the synchronous buck converter. The high-side and lowside FET current sensing are also done from this node.

SYNC

2

I/O

Synchronization. This is a bi-directional pin used for frequency synchronization. In the master mode, it is

the SYNC output pin. In the slave mode, it is a SYNC input pin. If unused, this pin can be left open.

TRK

6

I

Tracking. External signal at this pin is used for output voltage tracking. This pin goes directly to the

internal error amplifier as a positive reference. The lesser of the voltages between VTRK and the internal

600 mV reference sets the output voltage. If not used, this pin should be pulled up to VDD.

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

3

�TPS40170

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

www.ti.com

Pin Functions (continued)

PIN

I/O

DESCRIPTION

NAME

NO.

UVLO

20

I

Undervoltage lockout. A resistor divider on this pin from VIN to AGND can be used to set the UVLO

threshold.

VBP

15

O

8 V regulated output for gate driver. A ceramic capacitor with a value from 1 µF to 10 µF must be

connected from this pin to PGND and placed close to this pin.

VDD

10

O

3.3 V regulated output. A ceramic by-pass capacitor with a value from 0.1 µF to 1 µF must be connected

from this pin to AGND and placed close to this pin.

VIN

19

I

Input voltage for the controller which is also the input voltage for the DC/DC converter. A ceramic by-pass

capacitor with a value from 0.1 µF to 1 µF must be connected from this pin to PGND and placed close to

this pin.

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

MIN

Input voltage

MAX

VIN

–0.3

62

M/S

–0.3

VIN

UVLO

–0.3

16

SW

–5

VVIN

SW (for duration less than 200 ns)

–10

VSW +

8.8

HDRV

VSW

BOOT

BOOT-SW, HDRV-SW (differential from BOOT or HDRV to SW)

–0.3

8.8

VBP, LDRV, COMP, RT, ENABLE, PGOOD, SYNC

–0.3

8.8

VDD, FB, TRK, SS, ILIM

–0.3

3.6

AGND-PGND, PGND-AGND

200

200

PowerPAD to AGND (must be electrically connected external to device)

0

Lead Temperature

Operating junction

temperature

V

VVIN

BOOT

Output voltage

UNIT

TJ

–40

V

mV

260

°C

125

°C

6.2 Handling Ratings

Tstg

Storage temperature

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001, all pins

V(ESD)

(1)

(2)

Electrostatic discharge

MIN

MAX

UNIT

–55

150

°C

(1)

2000

Charged device model (CDM), per JEDEC specification JESD22-C101, all

pins (2)

1000

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN

MAX

UNIT

VIN

Input voltage

4.5

60

V

TJ

Operating junction temperature range

-40

125

°C

4

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

�TPS40170

www.ti.com

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

6.4 Thermal Information

TPS40170

THERMAL METRIC (1)

RGY

UNIT

20 PINS

RθJA

Junction-to-ambient thermal resistance

35.0

RθJC(top)

Junction-to-case(top) thermal resistance

36.7

RθJB

Junction-to-board thermal resistance

12.6

ψJT

Junction-to-top characterization parameter

0.4

ψJB

Junction-to-board characterization parameter

12.7

RθJC(bot)

Junction-to-case(bottom) thermal resistance

3.1

(1)

°C/W

For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

6.5 Electrical Characteristics

Unless otherwise stated, these specifications apply for -40ºC ≤ TJ ≤ 125ºC, VVIN=12 V

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

60

V

1

2.5

µA

4.5

mA

INPUT SUPPLY

VVIN

Input voltage range

ISD

Shutdown current

VENABLE < 100 mV

4.5

IQ

Operating current, drivers not switching

VENABLE ≥ 2 V, fSW = 300 kHz

ENABLE

VDIS

ENABLE pin voltage to disable the device

VEN

ENABLE pin voltage to enable the device

IENABLE

ENABLE pin source current

100

600

mV

300

nA

8.0

8.3

V

110

200

mV

3.30

3.42

V

8-V AND 3.3-V REGULATORS

VBP

8 V regulator output voltage

VENABLE ≥ 2 V, 8.2 V < VIN ≤ 60 V,

0 mA < IIN < 20 mA

VDO

8 V regulator dropout voltage,

VIN-BP

4.5 < VIN ≤ 8.2 V, VEN ≥ 2.0 V,

IIN = 10 mA

VVDD

3.3 V regulator output voltage

VENABLE ≥ 2 V, 4.5 V < VIN ≤ 60 V,

0 mA < IIN < 5 mA

7.8

3.22

FIXED AND PROGRAMMABLE UVLO

VUVLO

Programmable UVLO ON voltage (at UVLO pin)

VENABLE ≥ 2 V

878

900

919

mV

IUVLO

Hysteresis current out of UVLO pin

VENABLE ≥ 2 V , UVLO pin > VUVLO

4.06

5.00

6.20

µA

VBP(ON)

VBP turn-on voltage

VBP(OFF)

VBP turn-off voltage

VBP(HYS)

VBP UVLO Hysteresis voltage

VENABLE ≥ 2 V, UVLO pin > VUVLO

3.85

4.40

3.60

4.05

180

400

V

mV

REFERENCE

VREF

Reference voltage (+ input of the error amplifier)

TJ = 25°C, 4.5 V < VIN ≤ 60 V

594

600

606

–40°C ≤ TJ ≤ 125ºC, 4.5 V < VIN ≤ 60 V

591

600

609

Range (typical)

100

mV

OSCILLATOR

fSW

Switching frequency

VVALLEY

Valley voltage

KPWM (1)

PWM Gain (VIN / VRAMP)

600

RRT = 100 kΩ, 4.5 V 0.5 V

11.60

−40 −25 −10

95

Figure 8. UVLO Pin Hysteresis Current vs. Junction

Temperature

4.15

4.08

−40 −25 −10

5

20 35 50 65 80

Junction Temperature (°C)

5

20 35 50 65 80

Junction Temperature (°C)

95

110 125

Figure 11. Soft-Start Source Current vs. Junction

Temperature (VSS > 0.5 V)

VSS < 0.5 V

51.00

−40 −25 −10

5

20 35 50 65 80

Junction Temperature (°C)

95

110 125

Figure 12. Soft-Start Source Current vs. Junction

Temperature (VSS < 0.5 V)

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

9

�TPS40170

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

www.ti.com

11.1

680

10.8

674

Soft−Start Initial Offset Voltage (mV)

ILIM Source Current (µA)

Typical Characteristics (continued)

10.5

10.2

9.9

9.6

9.3

9.0

8.7

8.4

−40 −25 −10

5

20 35 50 65 80

Junction Temperature (°C)

95

110 125

Figure 13. ILIM Source Current vs. Junction Temperature

668

662

656

650

644

638

632

626

620

614

−40 −25 −10

5

20 35 50 65 80

Junction Temperature (°C)

95

110 125

Figure 14. Soft-Start Initial Offset Voltage vs. Junction

Temperature

Power Good Threshold Voltage (mV)

675

650

625

Overvoltage

Undervoltage

600

575

550

525

−40 −25 −10

5

20 35 50 65 80

Junction Temperature (°C)

95

110 125

Figure 15. VOV/VUV Power Good Threshold Voltage

10

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

�TPS40170

www.ti.com

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

7 Detailed Description

7.1 Overview

The TPS40170 is a synchronous PWM buck controller that accepts a wide range of input voltage from 4.5 V to

60 V and features voltage-mode control with input-voltage, feed-forward compensation. The switching frequency

is programmable from 100 kHz to 600 kHz.

The TPS40170 has a complete set of system protections such as programmable undervoltage lockout (UVLO),

programmable overcurrent protection (OCP), selectable short-circuit protection (SCP) and thermal shutdown. The

ENABLE pin allows for system shutdown in a low-current (1 µA typical) mode. The controller supports pre-biased

outputs, provides an open-drain PGOOD signal, and has closed loop programmable soft-start, output voltage

tracking and adaptive dead time control.

The TPS40170 provides accurate output voltage regulation via 1% specified accuracy.

Additionally, the controller implements a novel scheme of bidirectional synchronization with one controller acting

as the master other downstream controllers acting as slaves, synchronized to the master in-phase or 180° out-ofphase. Slave controllers can be synchronized to an external clock within ±30% of the internal switching

frequency.

7.2 Functional Block Diagram

ENABLE

VIN

UVLO

1

19

20

TPS40170

8-V

Regulator

VBP

Input and

Regulators OK

Run

3.3-V

Regulator

Gate Drivers

VDD 10

RT

4

SYNC

2

M/S

3

TRK

6

FB

7

COMP

8

AGND

9

18 BOOT

VBP

VIN

17 HDRV

CLK

Oscillator

and

Synchronization

16 SW

PWM Logic

Anti-Cross

Conduction

RAMP

+

15 VBP

PWM

Comparator

Run

+

+

+

SSEAMP

VREF

Error

Amplifier

14 LDRV

Run

13 PGND

Fault

Run

Run

TJ

Over-Temperature

Fault Controller

CLK

VIN

LDRV

CLK

11 PGOOD

FAULT

FAULT

Reset

Soft-Start

and

Fault Logic

Overcurrent

Fault Controller

OC_FAULT

Run

Power Good

Controller

Run

Run

SW

ILIM 12

FB

VREF

T_FAULT

5

SS

SSEAMP

Run

UDG-09218

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

11

�TPS40170

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

www.ti.com

7.3 Feature Description

7.3.1 LDO Linear Regulators and Enable

The TPS40170 has two internal low-drop-out (LDO) linear regulators. One has a nominal output voltage of VVBP

and is present at the VBP pin. This is the voltage that is mainly used for the gate-driver output. The other linear

regulator has an output voltage of VVDD and is present at the VDD pin. This voltage can be used in external lowcurrent logic circuitry. The maximum allowable current drawn from the VDD pin must not exceed 5 mA.

The TPS40170 has a dedicated device enable pin (ENABLE). This simplifies user level interface design because

no multiplexed functions exist. If the ENABLE pin of the TPS40170 is higher than VEN, then the LDO regulators

are enabled. To ensure that the LDO regulators are disabled, the ENABLE pin must be pulled below VDIS. By

pulling the ENABLE pin below VDIS, the device is completely disabled and the current consumption is very low

(nominally, 1 µA). Both LDO regulators are actively discharged when the ENABLE pin is pulled below VDIS. A

functionally equivalent circuit to the enable circuitry on the TPS40170 is shown in Figure 16.

VIN

19

TPS40170

Always Active

ISD= 1 mA

ENABLE

1

+

DISABLE

+

VDIS

AGND

9

UDG-09147

Figure 16. TPS40170 Enable Functional Block

The ENABLE pin must not be allowed to float. If the ENABLE function is not needed for the design, then it is

suggested that the ENABLE pin be pulled up to VIN by a high value resistor ensuring that the current into the

ENABLE pin does not exceed 10 µA. If it is not possible to meet this clamp current requirement, then it is

suggested that a resistor divider from VIN to GND be used to connect to ENABLE pin. The resistor divider should

be such that the ENABLE pin should be higher than VEN and lower than 8 V.

NOTE

To avoid potential erroneous behavior of the enable function, the ENABLE signal applied

must have a minimum slew rate of 20 V/s.

7.3.2 Input Undervoltage Lockout (UVLO)

The TPS40170 has both fixed and programmable input undervoltage lockout (UVLO). In order for the device to

turn ON, all of the following conditions must be met:

• The ENABLE pin voltage must be greater than VEN

• The VBP voltage (at VBP pin) must be greater than VBP(on)

• The UVLO pin must be greater than VUVLO

In order for the device to turn OFF, any one of the following conditions must be met:

• The ENABLE pin voltage must be less than VDIS

• The VBP voltage (at VBP pin) must be less than VBP(off)

• The UVLO pin must be less than VUVLO

12

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

�TPS40170

www.ti.com

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

Feature Description (continued)

Programming the input UVLO can be accomplished using the UVLO pin. A resistor divider from the input voltage

(VIN pin) to GND sets the UVLO level. Once the input voltage reaches a value that meets the VUVLO level at the

UVLO pin, then a small hysteresis current, IUVLO at the UVLO pin is switched in. The programmable UVLO

function is shown in Figure 17.

VIN

TPS40170

IUVLO

R1

UVLO

+

20

R2

VIN_OK

1 nF

+

VUVLO

AGND

9

UDG-09199

Figure 17. UVLO Functional Block Schematic

7.3.2.1 Equations for Programming the Input UVLO:

Components R1 and R2 represent external resistors for programming UVLO and hysteresis and can be

calculated in Equation 1 and Equation 2 respectively.

V - VOFF

R1 = ON

IUVLO

(1)

VUVLO

R2 = R1 ´

(VON - VUVLO )

where

•

•

•

•

VON is the desired turn-on voltage of the converter

VOFF is the desired turn-off voltage for the converter

IUVLO is the hysteresis current generated by the device, 5.0 µA (typ)

VUVLO is the UVLO pin threshold voltage, 0.9 V (typ)

(2)

NOTE

If the UVLO pin is connected to a voltage greater than 0.9 V, the programmable UVLO is

disabled and the device defaults to an internal UVLO (VBP(on) and VBP(off)). For example,

the UVLO pin can be connected to VDD or the VBP pin to disable the programmable

UVLO function.

A 1 nF ceramic by-pass capacitor must be connected between the UVLO pin and GND.

7.3.3 Oscillator and Voltage Feed-Forward

TPS40170 implements an oscillator with input-voltage feed-forward compensation that enables instant response

to input voltage changes. Figure 18 shows the oscillator timing diagram for the TPS40170. The resistor from the

RT pin to GND sets the free running oscillator frequency. The voltage VRT on the RT pin is made proportional to

the input voltage (see Equation 3).

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

13

�TPS40170

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

www.ti.com

Feature Description (continued)

VRT =

VIN

KPWM

where

•

KPWM = 15

(3)

The resistor at the RT pin sets the current in the RT pin. The proportional current charges an internal 100-pF

oscillator capacitor. The ramp voltage on this capacitor is compared with the RT pin voltage, VRT. Once the ramp

voltage reaches VRT, the oscillator capacitor is discharged. The ramp that is generated by the oscillator (which is

proportional to the input voltage) acts as voltage feed-forward ramp to be used in the PWM comparator.

The time between the start of the discharging oscillator capacitor and the start of the next charging cycle is fixed

at 170 ns (typical). During the fixed discharge time, the PWM output is maintained as OFF. This is the minimum

OFF-time of the PWM output.

VIN

Minimum OFF Time

RAMP

VCOMP

VCLK

PWM

t – Time

UDG-09200

Figure 18. Feed-Forward Oscillator Timing Diagram

7.3.3.1 Calculating the Timing Resistance (RRT)

æ 104

RRT = ç

ç fSW

è

ö

÷ - 2 (kW )

÷

ø

where

•

•

fSW is the switching frequency in kHz

RRT is the resistor connected from RT pin to GND in kΩ

(4)

NOTE

The switching frequency can be adjusted between 100 kHz and 600 kHz. The maximum

switching frequency before skipping pulses is determined by the input voltage, output

voltage, FET resistances, DCR of the inductor, and the minimum on time of the

TPS40170. Use Equation 5 to determine the maximum switching frequency. For further

details, please see application note SLYT293.

fSW (max ) =

14

(

)

VOUT(min ) + IOUT(min ) ´ (RDS2 + RLOAD )

(

)

tON(min ) ´ VIN(max ) - IOUT(min ) ´ (RDS1 - RDS2 )

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

�TPS40170

www.ti.com

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

Feature Description (continued)

where

•

•

•

•

•

•

•

fSW(max) is the maximum switching frequency

VOUT(min) is the minimum output voltage

VIN(max) is the maximum input voltage

IOUT(min) is the minimum output current

RDS1 is the high-side FET resistance

RDS2 is the low-side FET resistance

and RLOAD is the inductor series resistance

(5)

7.3.4 Overcurrent Protection and Short-Circuit Protection (OCP and SCP)

The TPS40170 has the capability to set a two-level overcurrent protection. The first level of overcurrent

protection (OCP) is the normal overload setting based on low-side MOSFET voltage sensing. The second level

of protection is the heavy overload setting such as short-circuit based on the high-side MOSFET voltage sensing.

This protection takes effect immediately. The second level is termed short-circuit protection (SCP).

The OCP level is set by the ILIM pin voltage. A current (IILIM) is sourced into the ILIM pin from which a resistor

RILIM is connected to GND. Resistor RILIM sets the first level of overcurrent limit. The OCP is based on the lowside FET voltage at the switch-node (SW pin) when the LDRV is ON after a blanking time, which is the product of

inductor current and low-side FET turn-on resistance RDS(on). The voltage is inverted and compared to ILIM pin

voltage. If it is greater than the ILIM pin voltage, then a 3-bit counter inside the device increments the fault-count

by 1 at the start of the next switching cycle. Alternatively, if it is less than the ILIM pin voltage, then the counter

inside the device decrements the fault-count by 1. When the fault-count reaches 7, an overcurrent fault

(OC_FAULT) is declared and both the HDRV and LDRV are turned OFF. The resistor RILIM can be calculated by

the following Equation 6.

IOC ´ RDS(on) IOC ´ RDS(on)

RILIM =

=

IILIM

9.0 mA

(6)

The SCP level is set by a multiple of the ILIM pin voltage. The multiplier has three discrete values, 3, 7 or 15

times, which can be selected by respectively choosing a 10-kΩ, open circuit, or 20 kΩ resistor from LDRV pin to

GND. This multiplier AOC information is translated during the tCAL time, which starts after the enable and UVLO

conditions are met.

The SCP is based on sensing the high-side FET voltage drop from VVIN to VSW when the HDRV is ON after a

blanking time, which is product of inductor current and high-side FET turn-on resistance RDS(on). The voltage is

compared to the product of multiplier and the ILIM pin voltage. If it exceeds the product, then the fault-count is

immediately set to 7 and the OC_FAULT is declared. The HDRV is terminated immediately without waiting for

the duty cycle to end. When an OC_FAULT is declared, both the HDRV and LDRV are turned OFF. The

appropriate multiplier (A), can be selected using Equation 7.

ISC ´ RDS(on)HS

A=

IOC ´ RDS(on)LS

(7)

Figure 19 shows the functional block of the two-level overcurrent protection.

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

15

�TPS40170

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

www.ti.com

Feature Description (continued)

A

10

3

OPEN

7

20

15

HDRV On

tBLNK

VIN

(A x VILIM)

3-Bit

State

Machine

+

+

RLDRV (kW)

19

HDRV

R

tBLNK

17

LDRV On

SW

R

Q0

OC_FAULT

+

Q1

Q2

16

+

LDRV

VDD

14

CLK

RLDRV

IILIM

ILIM

12

PGND

RILIM

13

UDG-09198

Figure 19. OCP and SCP Protection Functional Block Diagram

NOTE

Both OCP and SCP are based on low-side and high-side MOSFET voltage sensing at the

SW node. Excessive ringing on the SW node can have negative impact on the accuracy of

OCP and SCP. Adding an RC snubber from the SW node to GND helps minimize the

potential impact.

7.3.5 Soft-Start and Fault-Logic

A capacitor from the SS pin to GND defines the SS time, tSS. The TPS40170 enters into soft-start immediately

after completion of the overcurrent calibration. The SS pin goes through the device's internal level-shifter circuit

before reaching one of the positive inputs of the error amplifier. The SS pin must reach approximately 0.65 V

before the input to the error amplifier begins to rise above 0 V. To charge the SS pin from 0 V to 0.65 V faster, at

the beginning of the soft-start in addition to the normal charging current, (11.6 µA, typ.), an extra charging current

(40.4 µA, typ.) is switched-in to the SS pin. As the SS capacitor reaches 0.5 V, the extra charging current is

turned off and only the normal charging current remains. Figure 20 shows the soft-start function block.

16

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

�TPS40170

www.ti.com

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

Feature Description (continued)

TPS40170

VDD

40.4 µA

11.6 µA

SS

Soft-Start

Charge/Discharge

Control

5

CSS

1.05 µA

VDD

TRK

VOUT

SS_EAmp

R1

VREF

FB

+

+

+

SS Error

Amplifier

COMP

FB

7

R2

UDG-09202

Figure 20. Soft-Start Schematic Block

As the SS pin voltage approaches 0.65 V, the positive input to the error amplifier begins to rise (see Figure 21).

The output of the error amplifier (the COMP pin) starts rising. The rate of rise of the COMP voltage is mainly

limited by the feedback loop compensation network. Once VCOMP reaches the valley of the PWM ramp, the

switching begins. The output is regulated to the error amplifier input through the FB pin in the feedback loop.

Once the FB pin reaches the 600 mV reference voltage, the feedback node is regulated to the reference voltage,

VREF. The SS pin continues to rise and is clamped to VDD.

The SS pin is discharged through an internal switch during the following conditions:

• Input (VIN) undervoltage lock out UVLO pin less than VUVLO

• Overcurrent protection calibration time (tCAL)

• VBP less than threshold voltage (VBP(off))

Because it is discharged through an internal switch, the discharging time is relatively fast compared with the

discharging time during the fault restart which is discussed in the Soft-Start During Overcurrent Fault section.

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

17

�TPS40170

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

www.ti.com

Feature Description (continued)

Internal Logic RUN

Clamped at VDD

SS

tCAL

SS_EAMP

1.1 V

0.5 V

VREF = 0.6 V

0.65 V

VSS

tSS

VVALLEY

VCOMP

(2)

(1)

VOUT

t – Time

UDG-09203

Figure 21. Soft-Start Waveforms

NOTE

Referring to Figure 21

• (1) VREF dominates the positive input of the error amplifier

• (2) SS_EAMP dominates the positive input of the error amplifier

For 0 < VSS_EAMP < VREF

VOUT = VSS(EAMP) ´

(R1 + R2 )

R2

(8)

For VSS_EAMP > VREF

VOUT = VREF ´

(R1 + R2 )

R2

(9)

7.3.5.1 Soft-Start During Overcurrent Fault

The soft-start block also has a role to controls the fault-logic timing. If an overcurrent fault (OC_FAULT) is

declared, the soft-start capacitor is discharged internally through the device by a small current ISS(sink) (1.05 µA,

typ.). Once the SS pin capacitor is discharged to below VSS(flt,low) (300 mV, typ.), the soft-start capacitor begins

charging again. If the fault is persistent, a fault is declared which is determined by the overcurrent protection

state machine. If the soft-start capacitor is below VSS(flt,high) (2.5 V, typ.), then the soft-start capacitor continues to

charge until it reaches VSS(flt,high) before a discharge cycle is initiated. This ensures that the re-start time-interval

is always constant. Figure 22 shows the restart timing.

18

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

�TPS40170

www.ti.com

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

Feature Description (continued)

Persistent FAULT

OC_FAULT

FAULT Reset

FAULT Set

tRS

2.5 V

VSS

300 mV

t – Time

UDG-09204

Figure 22. Overcurrent Fault Restart Timing

NOTE

For the feedback to be regulated to the SS_EAMP voltage, the TRK pin must be pulled up

high directly or through a resistor to VDD.

7.3.5.2 Equations for Soft-Start and Restart Time

The soft-start time (tSS) is defined as the time taken for the internal SS_EAMP node to go from 0 V to the 0.6 V,

VREF voltage. The SS_EAMP starts rising as the SS pin goes beyond 0.65 V. The offset voltage between the SS

and the SS_EAMP starts increasing as the SS pin voltage starts rising. Figure 21, shows that the SS time can be

defined as the time taken for the SS pin voltage to change by 1.05 V (see Equation 10).

The restart time (tRS) is defined in Equation 11 as the time taken for the soft-start capacitor (CSS) to discharge

from 2.5 V to 0.3 V and to then recharge up to 2.5 V.

t

CSS = SS

0.09

(10)

tRS » 2.28 ´ CSS

where

•

•

•

CSS is the soft-start capacitance in nF

tSS is the soft-start time in ms

tRS is the re-start time in ms

(11)

NOTE

During soft-start (VSS < 2.5 V), the overcurrent protection limit is 1.5 times normal

overcurrent protection limit. This allows higher output capacitance to fully charge without

activating overcurrent protection.

7.3.6 Over-Temperature Fault

Figure 23 shows the over-temperature protection scheme. If the junction temperature of the device reaches the

thermal shutdown limit of tSD(set) (165°C, typ) and SS charging is completed, an over-temperature FAULT is

declared. The soft-start capacitor begins to be discharged. During soft-start discharging period, the PWM

switching is terminated; therefore both HDRV and LDRV are driven low, turning off both MOSFETs.

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

19

�TPS40170

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

www.ti.com

Feature Description (continued)

The soft-start capacitor begins to charge and over-temperature fault is reset whenever the soft-start capacitor is

discharged below VSS(flt,low) (300 mV, typ.). During each restart cycle, PWM switching is turned on. When SS is

fully charged, PWM switching is terminated. These restarts repeat until the temperature of the device has fallen

below the thermal reset level, tSD(reset) (135°C typ). PWM switching continues and system returns to normal

regulation.

Persistent FAULT

TS_FAULT

FAULT Reset

FAULT Set

tRS

2.5 V

300 mV

VSS

t – Time

UDG-09205

Figure 23. Over-Temperature Fault Restart Timing

The soft-start timing during over-temperature fault is the same as the soft-start timing during overcurrent fault.

See the Equations for Soft-Start and Restart Time section.

7.3.7 Tracking

The TRK pin is used for output voltage tracking. The output voltage is regulated so that the FB pin equals the

lowest of the internal reference voltage (VREF) or the level-shifted SS pin voltage (SSEAMP) or the TRK pin

voltage. Once the TRK pin goes above the reference voltage, then the output voltage is no longer governed by

the TRK pin, but it is governed by the reference voltage.

If the voltage tracking function is used, then it should be noted that the SS pin capacitor must remain connected

as the SS pin and is also used for FAULT timing. For proper tracking using the TRK pin, the tracking voltage

should be allowed to rise only after SSEAMP has exceeded VREF, so that there is no possibility of the TRK pin

voltage being higher than the SSEAMP voltage. From Figure 21, for SSEAMP = 0.6 V, the SS pin voltage is typically

1.7 V.

The maximum slew rate on the TRK pin should be determined by the output capacitance and feedback loop

bandwidth. A higher slew rate can possibly trip overcurrent protection.

Figure 24 shows the tracking functional block. For SSEAMP voltages greater than TRK pin voltage, the VOUT is

given by Equation 12 and Equation 13.

20

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

�TPS40170

www.ti.com

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

Feature Description (continued)

.

For 0 V < VTRK < VREF

TPS40170

TRK

TRK

.

TRK IN

VOUT = VTRK ´

(R1 + R2 )

R2

(12)

6

VOUT

SSEAMP

.

For VTRK > VREF

R1

.

VOUT = VREF ´

(R1 + R2 )

R2

+

+

+

FB

COMP

VREF

7

FB

(13)

R2

UDG-09208

Figure 24. Tracking Functional Block

There are three potential applications for the tracking function.

• simultaneous voltage tracking

• ratiometric voltage tracking

• sequential startup mode

The tracking function configurations and waveforms are shown in Figure 25, Figure 27, and Figure 29

respectively.

In simultaneous voltage tracking shown in Figure 25, tracking signals, VTRK1 and VTRK2, of two modules, POL1

and POL2, start up at the same time and their output voltages VOUT1 initial and VOUT2 initial are approximately the

same during initial startup. Since VTRK1 and VTRK2 are less than VREF (0.6 V, typ), Equation 12 is used. As a

result, components selection should meet Equation 14.

æ (R3 + R 4 ) ö

æ (R1 + R2 ) ö

R

÷ ´ VTRK2 Þ 5

ç

÷ ´ VTRK1 = ç

ç

÷

ç

÷

R1

R3

R6

è

ø

è

ø

ææ

ö

ö

R1

çç

÷

÷

ç çè (R1 + R2 ) ÷ø

÷

=ç

- 1÷

ö ÷

R3

çæ

ç çç (R + R ) ÷÷ ÷

4 ø

èè 3

ø

(14)

After the lower output voltage setting reaches output voltage VOUT1 set point, where VTRK1 increases above VREF,

the output voltage of the other one (VOUT2) continues increasing until it reaches its own set point, where VTRK2

increases above VREF. At that time, Equation 13 is used. As a result, the resistor settings should meet

Equation 15 and Equation 16.

æ (R1 + R2 ) ö

VOUT1 = ç

÷ ´ VREF

ç

÷

R1

è

ø

VOUT2

(15)

æ (R3 + R 4 ) ö

=ç

÷ ´ VREF

ç

÷

R3

è

ø

(16)

Equation 14 can be simplified into Equation 17 by replacing with Equation 15 and Equation 16

æ R5 ö æ æ VOUT2 ö ö

ç

÷ = çç ç

÷ - 1÷÷

è R6 ø è è VOUT1 ø ø

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

(17)

21

�TPS40170

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

www.ti.com

Feature Description (continued)

If 5 V = VOUT2 and 2.5 V = VOUT1 are required, according to Equation 15, Equation 16 and Equation 17, the

selected components can be as following:

• R5 = R6 = R4 = R2 = 10 kΩ

• R1 = 3.16 kΩ

• R3 = 1.37 kΩ

VIN

External

Tracking

Input

VTRK1

VOUT1

VTRK1

POL1

R2

VTRK2

0.6

Voltage

R1

R5

VIN

VOUT2

VOUT2

VTRK2

POL2

VOUT1

R4

R6

R3

0

t – Time

UDG-09210

UDG-09209

Figure 25. Simultaneous Voltage Tracking

Schematic

22

Figure 26. Simultaneous Voltage Tracking

Waveform

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

�TPS40170

www.ti.com

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

Feature Description (continued)

In ratiometric voltage tracking shown in Figure 27, the two tracking voltages, VTRK1 and VTRK2, for two modules,

POL1 and POL2, are the same. Their output voltage, VOUT1 and VOUT2, are different with different voltage divider

R2/R1 and R4/R3. VOUT1 and VOUT2 increase proportionally and reach their output voltage set points at about the

same time.

VIN

VTRK2

VOUT1

VTRK1

VTRK1

POL1

External

Tracking

Input

0.6

R2

Voltage

R1

VIN

VOUT2

VOUT2

VTRK2

POL2

VOUT1

R4

R3

0

t – Time

UDG-09212

UDG-09211

Figure 27. Ratiometric Voltage Tracking Schematic

Figure 28. Ratiometric Voltage Tracking Waveform

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

23

�TPS40170

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

www.ti.com

Feature Description (continued)

Sequential startup is shown in Figure 29. During start-up of the first module, POL1, its PGOOD1 is pulled to low.

Since PGOOD1 is connected to soft-start SS2 of the second module, POL2, is not able to charge its soft-start

capacitor. After output voltage VOUT1 of POL1 reaches its setting point, PGOOD1 is released. POL2 starts

charging its soft-start capacitor. Finally, output voltage VOUT2 of POL2 reaches its setting point.

VIN

VOUT1

VOUT1

VSS2, VPGOOD1

PGOOD1

POL1

R2

Voltage

R1

VIN

VOUT2

VOUT2

SS2

POL2

VPGOOD2

R4

CSS

R3

0

t – Time

UDG-09214

UDG-09213

Figure 29. Sequential Start-Up Schematic

Figure 30. Sequential Start-Up Waveform

NOTE

The TRK pin has high impedance, so it is a noise sensitive terminal. If the tracking

function is used, a small RC filter is recommended at the TRK pin to filter out highfrequency noise.

If the tracking function is not used, the TRK pin must be pulled up directly or through a

resistor (with a value between 10 kΩ and 100 kΩ) to VDD.

7.3.8 Adaptive Drivers

The drivers for the external high-side and low-side MOSFETs are capable of driving a gate-to-source voltage,

VBP. The LDRV driver for the low-side MOSFET switches between VBP and PGND, while the HDRV driver for

the high-side MOSFET is referenced to SW and switches between BOOT and SW. The drivers have nonoverlapping timing that is governed by an adaptive delay circuit to minimize body diode conduction in the

synchronous rectifier.

7.3.9 Start-Up into Pre-Biased Output

The TPS40170 contains a circuit to prevent current from being pulled out of the output during startup in case the

output is pre-biased. When the soft-start commands a voltage higher than the pre-bias level (internal soft-start

becomes greater than feedback voltage [VFB]), the controller slowly activates synchronous rectification by starting

the first LDRV pulses with a narrow on-time (see Figure 31), where:

• VIN = 5 V

• VOUT = 3.3 V

• VPRE = 1.4 V

24

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

�TPS40170

www.ti.com

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

Feature Description (continued)

•

•

fSW = 300 kHz

L = 0.6 µH

It then increments the on-time on a cycle-by-cycle basis until it coincides with the time dictated by (1-D), where D

is the duty cycle of the converter. This scheme prevents the initial sinking of the pre-bias output, and ensures

that the output voltage (VOUT) starts and ramps up smoothly into regulation and the control loop is given time to

transition from pre-biased startup to normal mode operation with minimal disturbance to the output voltage. The

time from the start of switching until the low-side MOSFET is turned on for the full (1-D) interval is between

approximately 20 and 40 clock cycles.

Figure 31. Start-Up Switching Waveform during Pre-Biased Condition

If the output is pre-biased to a voltage higher than the voltage commanded by the reference, then the PWM

switching does not start.

NOTE

When output is pre-biased at VPRE-BIAS, that voltage also applies to the SW node during

start-up. When the pre-bias circuitry commands the first few high-side pulses before the

first low-side pulse is initiated, the gate voltage for the high-side MOSFET is as described

in Equation 18. Alternatively, If pre-bias level is high, it is possible that SCP can be tripped

due to high turn-on resistance of the high-side MOSFET with low gate voltage. Once

tripped, the device resets and then attempts to re-start. The device may not be able to

start up until output is discharged to a lower voltage level by either an active load or

through feedback resistors.

In the case of a high pre-bias level, a low gate-threshold voltage rated device is

recommended for the high-side MOSFET and increasing the SCP level also helps

alleviate the problem.

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

25

�TPS40170

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

www.ti.com

Feature Description (continued)

VGATE(hs ) =

(VBP -

VDFWD - VPRE-BIAS )

where

•

•

•

VGATE(hs) is the gate voltage for the high-side MOSFET

VBP is the BP regulator output

VDFWD is bootstrap diode forward voltage

(18)

7.3.10 Powergood (PGOOD)

The TPS40170 provides an indication that the output voltage of the converter is within the specified limits of the

regulation as measured at the FB pin. The PGOOD pin is an open-drain signal and pulls low when any condition

exists that would indicate that the output of the supply might be out of regulation. These conditions include:

• VFB is not within the PGOOD threshold limits.

• Soft-start is active, i.e., SS pin voltage is below VSS,FLT,HIGH limit.

• An undervoltage condition exists for the device.

• An overcurrent or short-circuit fault is detected.

• An over-temperature fault is detected.

Figure 32 shows a situation where no fault is detected during the startup, (the normal PGOOD situation). It

shows that PGOOD goes high tPGD (20 µs, typ.) after all the conditions (listed above) are met.

VDD

Track

VSS, steady-state

VSS, FLT, HI

VSS

VOV

VUV

VFB

tPGD

VPGOOD

t – Time

UDG-09215

Figure 32. PGOOD Signal

When there is no power to the device, PGOOD is not able to pull close to GND if an auxiliary supply is used for

the power good indication. In this case, a built-in resistor connected from drain to gate on the PGOOD pull-down

device allows the PGOOD pin to operate like as a diode to GND.

7.3.11 PGND and AGND

TPS40170 provides separate signal ground (AGND) and power ground (PGND) pins. PGND is primarily used for

gate driver ground return. AGND is an internal logic signal ground return. These two ground signals are internally

loosely connected by two anti-parallel diodes. PGND and AGND must be electrically connected externally.

26

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

�TPS40170

www.ti.com

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

7.4 Device Functional Modes

7.4.1 Frequency Synchronization

The TPS40170 has three modes.

• Master mode: In this mode the master/slave selector pin, (M/S) is connected to VIN. The SYNC pin emits a

stream of pulses at the same frequency as the PWM switching frequency. The pulse stream at the SYNC pin

is at 50% duty cycle and the same amplitude as VVBP. Also, the falling edge of the voltage on SYNC pin is

synchronized with the rising edge of the HDRV.

• Slave-180° mode: In this mode the M/S pin is connected to GND. The SYNC pin of the TPS40170 accepts a

synchronization clock signal, and the HDRV is synchronized with the rising edge of the incoming

synchronization clock.

• Slave-0° mode: In this mode, the M/S pin is left open. The SYNC pin of the TPS40170 accepts a

synchronization clock signal, and the HDRV is synchronized with the falling edge of the incoming

synchronization clock.

The two slave modes can be synchronized to an external clock through the SYNC pin. They are shown in

Figure 33. The synchronization frequency should be within ±30% of its programmed free running frequency.

Master Mode (SYNC as an output pin)

VHDRV

VSYNC

t – Time

Slave 180 Mode (SYNC as an input pin)

VSYNC

VHDRV

t – Time

Slave 0 Mode (SYNC as an input pin)

VSYNC

VHDRV

t – Time

UDG-09206

Figure 33. Frequency Synchronization Waveforms In Different Modes

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

27

�TPS40170

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

www.ti.com

Device Functional Modes (continued)

TPS40170 provides a smooth transition for the SYNC clock signal loss at slave mode. In slave mode, a

synchronization clock signal is provided externally through the SYNC pin to the device. The switching frequency

is synchronized to the external SYNC clock signal. If for some reason the external clock signal is missing, the

device switching frequency is automatically overridden by a transition frequency which is 0.7 times its

programmed free running frequency. This transition time is approximately 20 μs. After that, the device switching

frequency is changed to its programmed free running frequency. Figure 34 shows this process.

SYNC clock pulse missing

VSYNC

VHDRV

Synchronized duration

fS = SYNC clock frequency

20-ms transition duration

Free running duration .

fS = 0.7 x running frequency

fS = free running frequency

UDG-09207

Figure 34. Transition for Sync Clock Signal Missing (For Slave-180 Mode)

NOTE

When the device is operating in the master mode with duty ratio around 50%, PWM

jittering may occur. Always configure the device into the slave mode by either connecting

the M/S pin to GND or leaving it floating if master mode is not used.

When an external SYNC clock signal is used for synchronization, limit maximum slew rate

of the clock signal to 10 V/µs to avoid potential PWM jittering and connect the SYNC pin

to the external clock signal via a 5-kΩ resistor.

7.4.2 Operation Near Minimum VIN (VVIN ≤ 4.5 V)

The TPS40170 is designed to operate with input voltages above 4.5 V. With voltages below 4.5 V if the EN pin is

above its 600 mV turn on threshold the VDD and VBP internal regulators are active. These regulators will

operate in drop out and output the highest voltage possible for the given VIN. The EN pin voltage must be below

100 mV to disable the VDD and VBP regulators. Switching is disabled while the VBP output voltage is below the

VBP turn-on voltage of 4.4 V maximum. When there is sufficient VIN voltage to regulate the VBP voltage above

4.4 V the final condition for switching to begin is the UVLO pin voltage must be above its 900 mV typical

threshold. Once all three conditions are met the TPS40170 will begin switching and the soft-start sequence is

initiated. The device starts at the soft-start time determined by the external capacitance at the SS/TR pin. If a

design requires operation near the minimum VIN voltage, due to lower VBP voltage when operating in dropout,

lower gate threshold MOSFETs are recommended

28

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

�TPS40170

www.ti.com

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

8.1 Application Information

The wide input TPS40170 controller can function in a very wide range of applications. The WEBENCH software

uses an iterative design procedure and accesses a comprehensive database of components when generating a

design. This section presents a simplified discussion of the design process.

8.1.1 Bootstrap Resistor

A small resistor in series with the bootstrap capacitor reduces the turn-on speed of the high-side MOSFET,

thereby reducing the rising edge ringing of the SW node and reduces short through induced by dv/dt. A bootstrap

resistor value that is too large delays the turn-on time of the high-side switch and may trigger an apparent SCP

fault.

8.1.2 SW Node Snubber Capacitor

Observable voltage ringing at the SW node is caused by fast switching edges and parasitic inductance and

capacitance. If the ringing results in excessive voltage on the SW node, or erratic operation of the converter, an

RC snubber may be used to dampen the ringing and ensure proper operation over the full load range. See

design example.

8.1.3 Input Resistor

The TPS40170 has a wide input voltage range which allows for the device input to share power source with

power stage input. Power stage switching noise may pollute the device power source if the layout is not

adequate in minimizing noise. It may trigger short-circuit fault. If so, adding a small resistor between the device

input and power stage input is recommended. This resistor composites an RC filter with the device input

capacitor and filter out the switching noise from power stage. See R1 in the design example.

8.1.4 LDRV Gate Capacitor

Power device selection is important for proper switching operation. If the low-side MOSFET has low gate

capacitance CGS (if CGS 2 x VOUT, use overshoot to calculate minimum output capacitance. If VIN(min) < 2 x VOUT, use

undershoot to calculate minimum output capacitance.

2

COUT(min )

ITRAN(max) ) ´ L (3 )2 ´ 8.2 mH

(

=

=

= 59 mF

VOUT ´ VOVER

5 ´ 250mV

(23)

With a minimum capacitance, the maximum allowable ESR is determined by the maximum ripple voltage and is

approximated Equation 24.

æ

ö

IRIPPLE

æ

ö

1.86 A

VRIPPLE(tot) - ç

÷ 100mV - ç

÷

VRIPPLE(tot) - VRIPPLE(cap)

è 8 ´ COUT ´ fSW ø =

è 8 ´ 59 mF ´ 300kHz ø = 47mW

ESRMAX =

=

IRIPPLE

IRIPPLE

1.86 A

(24)

Two 1210, 22 µF, 16 V X7R ceramic capacitors plus two 0805 10 µF, 16 V X7R ceramic capacitors are selected

to provide more than 59 µF of minimum capacitance (including tolerance and DC bias derating) and less than

47 mΩ of ESR (parallel ESR of approximately 4 mΩ).

8.2.2.6 Peak Current Rating of Inductor

With output capacitance, it is possible to calculate the charge current during start-up and determine the minimum

saturation current rating for the inductor. The start-up charging current is approximated in Equation 25.

´ COUT 5 V ´ (2 ´ 22 mF + 2 ´ 10 mF )

V

=

= 0.08 A

ICHARGE = OUT

tSS

4ms

(25)

IL(peak ) = IOUT(max) + (12 ´ IRIPPLE )+ ICHARGE = 6 A +

(26)

1

2 ´ 1.86 A + 0.08 A = 7.01A

An IHLP5050FDER8R2M01 8.2 µH is selected. This 10-A, 16-mΩ inductor exceeds the minimum inductor ratings

in a 13 mm × 13 mm package.

32

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

�TPS40170

www.ti.com

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

8.2.2.7 Input Capacitor Selection (C1, C6)

The input voltage ripple is divided between capacitance and ESR. For this design VRIPPLE(cap) = 400 mV and

VRIPPLE(ESR) = 100 mV. The minimum capacitance and maximum ESR are estimated by:

ILOAD ´ VOUT

6A´5V

=

= 25 mF

CIN(min) =

VRIPPLE(cap) ´ VIN ´ fSW

400mV ´ 10 V ´ 300kHz

(27)

VRIPPLE(esr)

ESRMAX =

ILOAD +

=

1 ´I

2 RIPPLE

100mV

= 14.4mW

6.93A

(28)

The RMS current in the input capacitors is estimated in Equation 29.

IRMS(cin ) = ILOAD ´ D ´ (1 - D ) = 6 A ´ 0.5 ´ (1 - 0.5) = 3.0 A

(29)

To achieve these values, four 1210, 2.2 µF, 100 V, X7R ceramic capacitors plus a 120 µF electrolytic capacitor

are combined at the input. This provides a smaller size and overall cost than 10 ceramic input capacitors or an

electrolytic capacitor with the ESR required.

Table 3. Inductor Summary

PARAMETER

VALUE

UNIT

L

Inductance

8.2

µH

IL(rms)

RMS current (thermal rating)

6.02

A

IL(peak)

Peak current (saturation rating)

7.01

A

8.2.2.8 MOSFET Switch Selection (Q1, Q2)

Using the J/K method for MOSFET optimization, apply Equation 30 through Equation 33.

High-side gate (Q1):

ö

Q

-9 æ V ´ I

J = (10 ) ´ ç IN OUT + G ´ VDRIVE ÷ ´ fSW

QSW

è IDRIVE

ø

-3

K = (10 )

((I

OUT

)2 + 112 ´ (IP-P )2

(W nC)

(30)

)´ æçè VV ö÷ø (W mW)

(31)

)´ æçè1- VV ö÷ø (W mW)

(32)

OUT

IN

Low-side gate (Q2):

-3

K = (10 )

((I

OUT

)2 + 112 ´ (IP-P )2

OUT

IN

æ V ´I

ö

Q

J = 10-9 ç FD OUT + G ´ VDRIVE ÷ ´ fSW W

nC

QSW

è IDRIVE

ø

(

)

(33)

Optimizing for 300 kHz, 24 V input, 5 V output at 6 A, calculate ratios of 5.9 mΩ/nC and 0.5 mΩ/nC for the highside and low-side FETS respectively. BSC110N06NS2 (Ratio 1.2) and BSC076N06NS3 (Ratio 0.69) MOSFETS

are selected.

8.2.2.9 Timing Resistor (R7)

The switching frequency is programmed by the current through RRT to GND. The RRT value is calculated using

Equation 34.

RRT =

(10 )4

fSW

- 2kW =

(10 )4

300kHz

- 2 = 31.3kW » 31.6kW

(34)

8.2.2.10 UVLO Programming Resistors (R2, R6)

The UVLO hysteresis level is programmed by R2 using Equation 35.

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

33

�TPS40170

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

RUVLO(hys ) =

VUVLO(on ) - VUVLO(off )

IUVLO

=

www.ti.com

9V -8V

= 200kW

5.0 mA

(35)

VUVLO(max)

0.919 V

RUVLO(set ) > RUVLO(hys )

= 200kW

= 22.7kW » 22.1kW

(9.0 V - 0.919 V )

VUVLO _ ON(min) - VUVLO(max)

(

)

(36)

8.2.2.11 Boot-Strap Capacitor (C7)

A bootstrap capacitor with a value between 0.1 µF and 0.22 µF must be placed between the BOOT pin and the

SW pin. It should be 10 times higher than MOSFET gate capacitance. To ensure proper charging of the highside FET gate, limit the ripple voltage on the boost capacitor to less than 250 mV.

QG1

25nC

=

= 100nF

CBOOST =

VBOOT(ripple ) 250mV

(37)

8.2.2.12 VIN Bypass Capacitor (C18)

Place a capacitor with a value of 1.0 µF. Select a capacitor with a value from 0.1 µF to 1.0 µF, X5R or better

ceramic bypass capacitor for VIN as specified in Recommended Operating Conditions. For this design a 1.0-µF,

100-V, X7R capacitor has been selected.

8.2.2.13 VBP Bypass Capacitor (C19)

Select a capacitor with a value from 1.0 µF to 10 µF, X5R or better ceramic bypass capacitor for VBP as

specified in Recommended Operating Conditions. It should be at least 10 times higher than the bootstrap

capacitance. For this design a 4.7-µF, 16-V capacitor has been selected.

8.2.2.14 VDD Bypass Capacitor (C16)

Select a capacitor with a value between 0.1 µF and 1 µF, X5R or better ceramic bypass capacitor for VDD as

specified in Recommended Operating Conditions. For this design a 1-µF, 16-V capacitor has been selected.

8.2.2.15 SS Timing Capacitor (C15)

The soft-start capacitor provides smooth ramp of the error amplifier reference voltage for controlled start-up. The

soft-start capacitor is selected by using Equation 38.

t

4ms

CSS = SS =

= 44nF » 47nF

0.09 0.09

(38)

8.2.2.16 ILIM Resistor (R9, C17)

The TPS40170 use the negative drop across the low-side FET at the end of the "OFF" time to measure the

inductor current. Allowing for 30% over the minimum current limit for transient recovery and 20% rise in RDS(on)Q2

for self-heating of the MOSFET, the voltage drop across the low-side FET at current limit is given by

Equation 39.

((

) (

VOC = 1.3 ´ IOCP(min) + 21 ´ IRIPPLE

))´ 1.25 ´ RDS(on)G2 = (1.3 ´ 8 A + 21 ´ 1.86 A) ´ 1.25 ´ 7.6mW = 107.6mV

(39)

The internal current limit temperature coefficient helps compensate for the MOSFET RDS(on) temperature

coefficient, so the current limit programming resistor is selected by Equation 40.

VOC

107.6mV

=

= 12.0kW » 12.1kW

RILIM =

IOCSET(min )

9.0 mA

(40)

A 1000 pF capacitor is placed in parallel to improve noise immunity of the current limit set-point.

8.2.2.17 SCP Multiplier Selection (R5)

The TPS40170 controller uses a multiplier (AOC) to translate the low-side over-current protection into a high-side

RDS(on) pulse-by-pulse short circuit protection. Ensure that Equation 41 is true.

34

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

�TPS40170

www.ti.com

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

A OC >

(21 ´ IRIPPLE )´ RDS(on)Q1 = 8 A + 21 ´ 1.86 A ´ 11 mW = 1.45

IOCP(min) + (21 ´ IRIPPLE ) RDS(on )Q2 8 A + 21 ´ 1.86 A 7.6 mW

IOCP(min) +

(41)

AOC = 3 is selected as the next greater AOC. The value of R5 is set to 10 kΩ.

8.2.2.18 Feedback Divider (R10, R11)

The TPS40170 controller uses a full operational amplifier with an internally fixed 0.6 V reference. The value of

R11 is selected between 10 kΩ and 50 kΩ for a balance of feedback current and noise immunity. With the value

of R11 set to 20 kΩ, the output voltage is programmed with a resistor divider given by Equation 42.

VFB ´ R11

0.600 V ´ 20.0kW

R10 =

=

= 2.73kW » 2.74kW

(VOUT - VFB ) (5.0 V - 0.600 V )

(42)

8.2.2.19 Compensation: (R4, R13, C13, C14, C21)

Using the TPS40k Loop Stability Tool for a 60 kHz bandwidth and a 50° phase margin with an R11 value of

20.0 kΩ, the following values are obtained. The tool is available from the TI website, SLUC263.

• C21 = C1 = 1500 pF

• C13 = C2 = 8200 pF

• C14 = C3 = 220 pF

• R13 = R2 = 511 Ω

• R4 = R3 = 3.83 kΩ

8.2.3 Application Curves

Figure 36 shows an input from 10 V to 60 V for an output of 5.0 V at 6 A, efficiency graph for this design.

Figure 37 shows an input of 24 V for an output of 5.0 V at 6 A, loop response where VIN = 24V and IOUT = 6A,

yielding 58 kHz bandwidth, 51° phase margin. Figure 38 shows the output ripple 20 mV/div, 2 µs/div, 20 MHz

bandwidth.

100

100

225

80

180

60

135

40

90

20

45

0

0

85

VIN = 10 V

VIN = 12 V

VIN = 24 V

VIN = 36 V

VIN = 48 V

VIN = 60 V

80

75

70

0

1

2

3

4

Load Current (A)

5

−20

−40

−60

0.1

6

Figure 36. Efficiency vs. Load Current

−45

−90

Gain

Phase

1

10

Frequency (kHz)

100

−135

1000

Figure 37. Loop Response

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

Phase (°)

90

Gain (dB)

Efficiency (%)

95

35

�TPS40170

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

www.ti.com

Figure 38. Output Ripple Waveform

36

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

�TPS40170

www.ti.com

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

9 Power Supply Recommendations

The TPS40170 is designed for operation from an input voltage supply range between 4.5 V and 60 V. Good

regulation of this input supply is essential. If the input supply is more distant than a few inches from the

TPS40170 and the buck power stage, the circuit may require additional bulk capacitance in addition to ceramic

bypass capacitors. An electrolytic capacitor with a value of 120 µF is a typical choice.

10 Layout

10.1 Layout Guidelines

Figure 39 illustrates an example layout. For the controller, it is important to carefully connect noise sensitive

signals such as RT, SS, FB, and comp as close to the IC as possible and connect to AGND as shown. The

PowerPad should be connected to any internal PCB ground planes using multiple vias directly under the IC. The

AGND and PGND should be connected at a single point.

When using high-performance FETs such as NexFET™ from Texas Instruments, careful attention to the layout is

required. Minimize the distance between positive node of the input ceramic capacitor and the drain pin of the

control (high-side) FET. Minimize the distance between the negative node of the input ceramic capacitor and the

source pin of the syncronization (low-side) FET. Becasue of the large gate drive, smaller gate charge, and faster

turn-on times of the high-performance FETs, it is recommended to use a minimum of 4, 10 µF ceramic input

capacitors such as TDK #C3216X5R1A106M. Ensure the layout allows a continuous flow of the power planes.

The layout of the HPA578 EVM is shown in Figure 39 through Figure 42 for reference.

10.2 Layout Example

Figure 39. Top Copper, Viewed From Top

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

37

�TPS40170

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

www.ti.com

Layout Example (continued)

Figure 40. Bottom Copper, Viewed From Bottom

Figure 41. Internal Layer 1, Viewed from Top

38

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

�TPS40170

www.ti.com

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

Layout Example (continued)

Figure 42. Internal Layer 2, Viewed from Top

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

39

�TPS40170

SLUS970B – NOVEMBER 2013 – REVISED DECEMBER 2014

www.ti.com

11 Device and Documentation Support

11.1 Custom Design with WEBENCH Tools

Create a Custom Design with WEBENCH Tools

11.2 Device Support

11.2.1 Third-Party Products Disclaimer

TI'S PUBLICATION OF INFORMATION REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT

CONSTITUTE AN ENDORSEMENT REGARDING THE SUITABILITY OF SUCH PRODUCTS OR SERVICES

OR A WARRANTY, REPRESENTATION OR ENDORSEMENT OF SUCH PRODUCTS OR SERVICES, EITHER

ALONE OR IN COMBINATION WITH ANY TI PRODUCT OR SERVICE.

11.2.2 Related Devices

The following device has characteristics similar to the TPS40170 and may be of interest.

DEVICE

TPS40057

DESCRIPTION

Wide Input Synchronous Buck Controller

11.3 Trademarks

WEBENCH is a registered trademark of Texas Instruments.

11.4 Electrostatic Discharge Caution

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

11.5 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

12 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

40

Submit Documentation Feedback

Copyright © 2013–2014, Texas Instruments Incorporated

Product Folder Links: TPS40170

�PACKAGE OPTION ADDENDUM

www.ti.com

10-Dec-2020

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

MSL Peak Temp

Op Temp (°C)

Device Marking

(3)

(4/5)

(6)

TPS40170RGYR

ACTIVE

VQFN

RGY

20

3000

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

40170

TPS40170RGYT

ACTIVE

VQFN

RGY

20

250

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

40170

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance