EEPROM Serial 128-Kb I2C

CAT24C128

Description

The CAT24C128 is a EEPROM Serial 128−Kb I2C internally

organized as 16,384 words of 8 bits each.

It features a 64−byte page write buffer and supports both the

Standard (100 kHz), Fast (400 kHz) and Fast−Plus (1 MHz) I2C

protocol.

Write operations can be inhibited by taking the WP pin High (this

protects the entire memory).

On−Chip ECC (Error Correction Code) makes the device suitable

for high reliability applications.*

www.onsemi.com

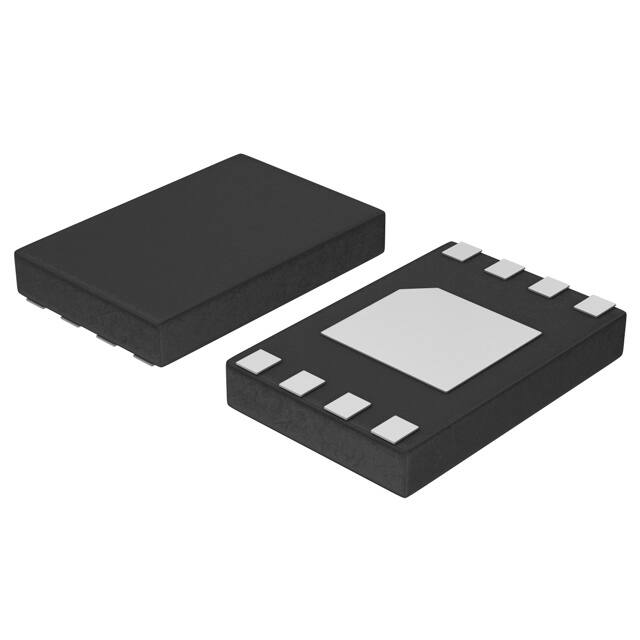

UDFN−8

HU4 SUFFIX

CASE 517AZ

Features

•

•

•

•

•

•

•

•

•

•

Supports Standard, Fast and Fast−Plus I2C Protocol

1.8 V to 5.5 V Supply Voltage Range

64−Byte Page Write Buffer

Hardware Write Protection for Entire Memory

Schmitt Triggers and Noise Suppression Filters on I2C Bus Inputs

(SCL and SDA)

Low Power CMOS Technology

1,000,000 Program/Erase Cycles

100 Year Data Retention

Industrial and Extended Temperature Range

This Device is Pb−Free, Halogen Free/BFR Free and RoHS

Compliant**

TSSOP−8

Y SUFFIX

CASE 948AL

SOIC−8 WIDE

X SUFFIX

CASE 751BE

SOIC−8

W SUFFIX

CASE 751BD

PIN CONFIGURATION

1

VCC

A0

VCC

A1

WP

A2

SCL

VSS

SDA

SOIC (W), TSSOP (Y), UDFN (HU4)

SCL

CAT24C128

A2, A1, A0

For the location of Pin 1, please consult the

corresponding package drawing.

SDA

WP

PIN FUNCTION

Pin

Name†

A0, A1, A2

VSS

Figure 1. Functional Symbol

** For additional information on our Pb−Free strategy and soldering details,

please download the ON Semiconductor Soldering and Mounting Techniques

Reference Manual, SOLDERRM/D.

Function

Device Address Inputs

SDA

Serial Data Input/Output

SCL

Serial Clock Input

WP

Write Protect Input

VCC

Power Supply

VSS

Ground

†The exposed pad for the TDFN/UDFN packages can

be left floating or connected to Ground.

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 10 of this data sheet.

© Semiconductor Components Industries, LLC, 2013

July, 2020 − Rev. 17

1

Publication Order Number:

CAT24C128/D

�CAT24C128

Table 1. ABSOLUTE MAXIMUM RATINGS

Parameter

Rating

Units

Storage Temperature

−65 to +150

°C

Voltage on Any Pin with Respect to Ground (Note 1)

−0.5 to +6.5

V

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. The DC input voltage on any pin should not be lower than −0.5 V or higher than VCC + 0.5 V. During transitions, the voltage on any pin may

undershoot to no less than −1.5 V or overshoot to no more than VCC + 1.5 V, for periods of less than 20 ns.

Table 2. RELIABILITY CHARACTERISTICS (Note 2)

Symbol

NEND (Notes 3, 4)

TDR

Parameter

Endurance

Data Retention

Min

Units

1,000,000

Program / Erase Cycles

100

Years

2. These parameters are tested initially and after a design or process change that affects the parameter according to appropriate AEC−Q100

and JEDEC test methods.

3. Page Mode, VCC = 5 V, 25°C

4. The new product revision (C) uses ECC (Error Correction Code) logic with 6 ECC bits to correct one bit error in 4 data bytes. Therefore, when

a single byte has to be written, 4 bytes (including the ECC bits) are re−programmed. It is recommended to write by multiple of 4 bytes in order

to benefit from the maximum number of write cycles.

www.onsemi.com

2

�CAT24C128

Table 3. D.C. OPERATING CHARACTERISTICS

(VCC = 1.8 V to 5.5 V, TA = −40°C to +85°C and VCC = 2.5 V to 5.5 V, TA = −40°C to +125°C, unless otherwise specified.)

Symbol

Parameter

ICCR

Read Current

ICCW

Write Current

ISB

IL

Standby Current

Test Conditions

Min

Max

Units

1

mA

3

mA

TA = −40°C to +85°C

2

mA

TA = −40°C to +125°C

5

TA = −40°C to +85°C

1

Read, fSCL = 400 kHz/1 MHz

All I/O Pins at GND or VCC

I/O Pin Leakage

Pin at GND or VCC

VIL1

Input Low Voltage

2.5 V ≤ VCC ≤ 5.5 V

−0.5

0.3 VCC

V

VIL2

Input Low Voltage

1.8 V ≤ VCC < 2.5 V

−0.5

0.25 VCC

V

VIH1

Input High Voltage

2.5 V ≤ VCC ≤ 5.5 V

0.7 VCC

VCC + 0.5

V

VIH2

Input High Voltage

1.8 V ≤ VCC < 2.5 V

0.75 VCC

VCC + 0.5

V

VOL1

Output Low Voltage

VCC ≥ 2.5 V, IOL = 3.0 mA

0.4

V

VOL2

Output Low Voltage

VCC < 2.5 V, IOL = 1.0 mA

0.2

V

TA = −40°C to +125°C

mA

2

Table 4. PIN IMPEDANCE CHARACTERISTICS

(VCC = 1.8 V to 5.5 V, TA = −40°C to +85°C and VCC = 2.5 V to 5.5 V, TA = −40°C to +125°C, unless otherwise specified.)

Symbol

Parameter

Conditions

Max

Units

8

pF

CIN (Note 5)

SDA I/O Pin Capacitance

VIN = 0 V

CIN (Note 5)

Input Capacitance (other pins)

VIN = 0 V

6

pF

WP Input Current, Address Input

Current (A0, A1, A2)

VIN < VIH, VCC = 5.5 V

75

mA

VIN < VIH, VCC = 3.3 V

50

VIN < VIH, VCC = 1.8 V

25

VIN > VIH

2

IWP, IA (Note 6)

5. These parameters are tested initially and after a design or process change that affects the parameter according to appropriate AEC−Q100

and JEDEC test methods.

6. When not driven, the WP, A0, A1, A2 pins are pulled down to GND internally. For improved noise immunity, the internal pull−down is relatively

strong; therefore the external driver must be able to supply the pull−down current when attempting to drive the input HIGH. To conserve power,

as the input level exceeds the trip point of the CMOS input buffer (~ 0.5 x VCC), the strong pull−down reverts to a weak current source.

www.onsemi.com

3

�CAT24C128

Table 5. A.C. CHARACTERISTICS

(VCC = 1.8 V to 5.5 V, TA = −40°C to +85°C and VCC = 2.5 V to 5.5 V, TA = −40°C to +125°C) (Note 7)

Standard

VCC = 1.8 V − 5.5 V

Parameter

Symbol

FSCL

tHD:STA

Min

Max

Clock Frequency

Fast

VCC = 1.8 V − 5.5 V

Min

100

START Condition Hold Time

Max

Fast−Plus (Note 10)

VCC = 2.5 V − 5.5 V

TA = −405C to +855C

Min

400

Max

Units

1,000

kHz

4

0.6

0.25

ms

tLOW

Low Period of SCL Clock

4.7

1.3

0.45

ms

tHIGH

High Period of SCL Clock

4

0.6

0.40

ms

4.7

0.6

0.25

ms

tSU:STA

START Condition Setup Time

tHD:DAT

Data In Hold Time

0

0

0

ms

tSU:DAT

Data In Setup Time

250

100

50

ns

tR (Note 8)

SDA and SCL Rise Time

1,000

300

100

ns

tF (Note 8)

SDA and SCL Fall Time

300

300

100

ns

tSU:STO

STOP Condition Setup Time

tBUF

Bus Free Time Between

STOP and START

tAA

SCL Low to Data Out Valid

tDH

Data Out Hold Time

Ti (Note 8)

4

0.6

0.25

ms

4.7

1.3

0.5

ms

3.5

100

0.9

100

Noise Pulse Filtered at SCL

and SDA Inputs

100

0.40

50

100

ms

ns

50

ns

tSU:WP

WP Setup Time

0

0

0

ms

tHD:WP

WP Hold Time

2.5

2.5

1

ms

tWR

tPU

(Notes 8, 9)

Write Cycle Time

5

5

Power-up to Ready Mode

1

1

0.1

5

ms

1

ms

7. Test conditions according to “A.C. Test Conditions” table.

8. Tested initially and after a design or process change that affects this parameter.

9. tPU is the delay between the time VCC is stable and the device is ready to accept commands.

10. Fast−Plus (1 MHz) speed class available for new product revision “C”. The die revision “C” is identified by letter “C” or a dedicated marking

code on top of the package.

Table 6. A.C. TEST CONDITIONS

Input Levels

0.2 x VCC to 0.8 x VCC

Input Rise and Fall Times

v 50 ns

Input Reference Levels

0.3 x VCC, 0.7 x VCC

Output Reference Levels

0.5 x VCC

Output Load

Current Source: IOL = 3 mA (VCC ≥ 2.5 V); IOL = 1 mA (VCC < 2.5 V); CL = 100 pF

www.onsemi.com

4

�CAT24C128

Power−On Reset (POR)

The CAT24C128 incorporates Power−On Reset (POR)

circuitry which protects the device against powering up in

the wrong state.

The CAT24C128 will power up into Standby mode after

VCC exceeds the POR trigger level and will power down into

Reset mode when VCC drops below the POR trigger level.

This bi−directional POR feature protects the device against

‘brown−out’ failure following a temporary loss of power.

resistors. Master and Slave devices connect to the 2−wire

bus via their respective SCL and SDA pins. The transmitting

device pulls down the SDA line to ‘transmit’ a ‘0’ and

releases it to ‘transmit’ a ‘1’.

Data transfer may be initiated only when the bus is not

busy (see A.C. Characteristics).

During data transfer, the SDA line must remain stable

while the SCL line is HIGH. An SDA transition while SCL

is HIGH will be interpreted as a START or STOP condition

(Figure 2). The START condition precedes all commands. It

consists of a HIGH to LOW transition on SDA while SCL

is HIGH. The START acts as a ‘wake−up’ call to all

receivers. Absent a START, a Slave will not respond to

commands. The STOP condition completes all commands.

It consists of a LOW to HIGH transition on SDA while SCL

is HIGH.

Pin Description

SCL: The Serial Clock input pin accepts the Serial Clock

generated by the Master.

SDA: The Serial Data I/O pin receives input data and

transmits data stored in EEPROM. In transmit mode, this pin

is open drain. Data is acquired on the positive edge, and is

delivered on the negative edge of SCL.

A0, A1 and A2: The Address pins accept the device address.

When not driven, these pins are pulled LOW internally.

WP: The Write Protect input pin inhibits all write

operations, when pulled HIGH. When not driven, this pin is

pulled LOW internally.

Device Addressing

The Master initiates data transfer by creating a START

condition on the bus. The Master then broadcasts an 8−bit

serial Slave address. The first 4 bits of the Slave address are

set to 1010, for normal Read/Write operations (Figure 3).

The next 3 bits, A2, A1 and A0, select one of 8 possible Slave

devices and must match the state of the external address pins.

The last bit, R/W, specifies whether a Read (1) or Write (0)

operation is to be performed.

Functional Description

The CAT24C128 supports the Inter−Integrated Circuit

(I2C) Bus data transmission protocol, which defines a device

that sends data to the bus as a transmitter and a device

receiving data as a receiver. Data flow is controlled by a

Master device, which generates the serial clock and all

START and STOP conditions. The CAT24C128 acts as a

Slave device. Master and Slave alternate as either

transmitter or receiver. Up to 8 devices may be connected to

the bus as determined by the device address inputs A0, A1,

and A2.

Acknowledge

After processing the Slave address, the Slave responds

with an acknowledge (ACK) by pulling down the SDA line

during the 9th clock cycle (Figure 4). The Slave will also

acknowledge all address bytes and every data byte presented

in Write mode. In Read mode the Slave shifts out a data byte,

and then releases the SDA line during the 9th clock cycle. As

long as the Master acknowledges the data, the Slave will

continue transmitting. The Master terminates the session by

not acknowledging the last data byte (NoACK) and by

issuing a STOP condition. Bus timing is illustrated in

Figure 5.

I2C Bus Protocol

The I2C bus consists of two ‘wires’, SCL and SDA. The

two wires are connected to the VCC supply via pull−up

www.onsemi.com

5

�CAT24C128

SCL

SDA

START

CONDITION

STOP

CONDITION

Figure 2. START/STOP Conditions

DEVICE ADDRESS

1

0

1

A2

0

A1

A0

R/W

Figure 3. Slave Address Bits

BUS RELEASE DELAY (TRANSMITTER)

SCL FROM

MASTER

1

BUS RELEASE DELAY (RECEIVER)

8

9

DATA OUTPUT

FROM TRANSMITTER

DATA OUTPUT

FROM RECEIVER

START

ACK SETUP (≥ tSU:DAT)

ACK DELAY (≤ tAA)

Figure 4. Acknowledge Timing

tF

tHIGH

tLOW

tR

tLOW

SCL

tSU:STA

tHD:DAT

tHD:STA

tSU:DAT

tSU:STO

SDA IN

tAA

tDH

SDA OUT

Figure 5. Bus Timing

www.onsemi.com

6

tBUF

�CAT24C128

Write Operations

latched and the address count automatically increments to

and then wraps−around at the page boundary. Previously

loaded data can thus be overwritten by new data. What is

eventually written to memory reflects the latest Page Write

Buffer contents. Only data loaded within the most recent

Page Write sequence will be written to memory.

Byte Write

Upon receiving a Slave address with the R/W bit set to ‘0’,

the CAT24C128 will interpret the next two bytes as address

bytes. These bytes are used to initialize the internal address

counter; the 2 most significant bits are ‘don’t care’, the next

8 point to one of 256 available pages and the last 6 point to

a location within a 64 byte page. A byte following the

address bytes will be interpreted as data. The data will be

loaded into the Page Write Buffer and will eventually be

written to memory at the address specified by the 14 active

address bits provided earlier. The CAT24C128 will

acknowledge the Slave address, address bytes and data byte.

The Master then starts the internal Write cycle by issuing a

STOP condition (Figure 6). During the internal Write cycle

(tWR), the SDA output will be tri−stated and additional Read

or Write requests will be ignored (Figure 7).

Acknowledge Polling

The ready/busy status of the CAT24C128 can be

ascertained by sending Read or Write requests immediately

following the STOP condition that initiated the internal

Write cycle. As long as internal Write is in progress, the

CAT24C128 will not acknowledge the Slave address.

Hardware Write Protection

With the WP pin held HIGH, the entire memory is

protected against Write operations. If the WP pin is left

floating or is grounded, it has no impact on the operation of

the CAT24C128. The state of the WP pin is strobed on the

last falling edge of SCL immediately preceding the first data

byte (Figure 9). If the WP pin is HIGH during the strobe

interval, the CAT24C128 will not acknowledge the data byte

and the Write request will be rejected.

Page Write

By continuing to load data into the Page Write Buffer after

the 1st data byte and before issuing the STOP condition, up

to 64 bytes can be written simultaneously during one

internal Write cycle (Figure 8). If more data bytes are loaded

than locations available to the end of page, then loading will

continue from the beginning of page, i.e. the page address is

BUS ACTIVITY:

MASTER

S

T

A

R

T

Delivery State

The CAT24C128 is shipped erased, i.e., all bytes are FFh.

ADDRESS

BYTE

a7−a0

ADDRESS

BYTE

a13−a8

SLAVE

ADDRESS

S

S

T

O

P

DATA

BYTE

P

* *

A

C

K

SLAVE

A

C

K

A

C

K

A

C

K

* = Don’t Care Bit

Figure 6. Byte Write Sequence

SCL

SDA

8th Bit

ACK

Byte n

tWR

STOP

CONDITION

Figure 7. Write Cycle Timing

www.onsemi.com

7

START

CONDITION

ADDRESS

�CAT24C128

BUS ACTIVITY: S

T

A

MASTER R

T

ADDRESS

BYTE

a13−a8

SLAVE

ADDRESS

S

DATA

BYTE

n

ADDRESS

BYTE

a7−a0

DATA

BYTE

n+1

DATA

BYTE

n+P

S

T

O

P

P

* *

A

C

K

SLAVE

* = Don’t Care Bit

P v 63

A

C

K

A

C

K

A

C

K

A

C

K

A

C

K

A

C

K

Figure 8. Page Write Sequence

ADDRESS

BYTE

DATA

BYTE

1

8

9

a7

a0

1

8

d7

d0

SCL

SDA

tSU:WP

WP

tHD:WP

Figure 9. WP Timing

Read Operations

with data, the Master instead follows up with an Immediate

Read sequence, then the CAT24C128 will use the 14 active

address bits to initialize the internal address counter and will

shift out data residing at the corresponding location. If the

Master does not acknowledge the data (NoACK) and then

follows up with a STOP condition (Figure 11), the

CAT24C128 returns to Standby mode.

Immediate Read

Upon receiving a Slave address with the R/W bit set to ‘1’,

the CAT24C128 will interpret this as a request for data

residing at the current byte address in memory. The

CAT24C128 will acknowledge the Slave address, will

immediately shift out the data residing at the current address,

and will then wait for the Master to respond. If the Master

does not acknowledge the data (NoACK) and then follows

up with a STOP condition (Figure 10), the CAT24C128

returns to Standby mode.

Sequential Read

If during a Read session the Master acknowledges the 1st

data byte, then the CAT24C128 will continue transmitting

data residing at subsequent locations until the Master

responds with a NoACK, followed by a STOP (Figure 12).

In contrast to Page Write, during Sequential Read the

address count will automatically increment to and then

wrap−around at end of memory (rather than end of page).

Selective Read

To read data residing at a specific location, the internal

address counter must first be initialized as described under

Byte Write. If rather than following up the two address bytes

www.onsemi.com

8

�CAT24C128

BUS ACTIVITY:

MASTER

S

T

A

R

T

N

O

A

C

K

SLAVE

ADDRESS

P

S

A

C

K

SLAVE

SCL

DATA

BYTE

8

SDA

S

T

O

P

9

8th Bit

DATA OUT

NO ACK

STOP

Figure 10. Immediate Read Sequence and Timing

BUS ACTIVITY:

MASTER

S

T

A

R

T

ADDRESS

BYTE

a13−a8

SLAVE

ADDRESS

S

S

T

A

R

T

ADDRESS

BYTE

a7−a0

S

* *

A

C

K

SLAVE

N

O

A

C

K

SLAVE

ADDRESS

A

C

K

S

T

O

P

P

A

C

K

A

C

K

DATA

BYTE

* = Don’t Care Bit

Figure 11. Selective Read Sequence

N

O

A

C

K

BUS ACTIVITY:

MASTER

SLAVE

ADDRESS

S

T

O

P

P

SLAVE

A

C

K

DATA

BYTE

n

A

C

K

DATA

BYTE

n+1

A

C

K

DATA

BYTE

n+2

Figure 12. Sequential Read Sequence

www.onsemi.com

9

A

C

K

DATA

BYTE

n+x

�CAT24C128

ORDERING INFORMATION (Notes 11 thru 14)

Device Order Number

Specific

Device

Marking*

CAT24C128WI−GT3

Package

Type

Temperature Range

Lead Finish

Shipping†

24128C

SOIC−8,

JEDEC

I = Industrial

(−40°C to +85°C)

NiPdAu

Tape & Reel,

3,000 Units / Reel

CAT24C128YI−GT3

C28C

TSSOP−8

I = Industrial

(−40°C to +85°C)

NiPdAu

Tape & Reel,

3,000 Units / Reel

CAT24C128HU4IGT3

C7U

UDFN−8

I = Industrial

(−40°C to +85°C)

NiPdAu

Tape & Reel,

3,000 Units / Reel

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

11. All packages are RoHS−compliant (Lead−free, Halogen−free).

12. The standard lead finish is NiPdAu.

13. For additional package and temperature options, please contact your nearest ON Semiconductor Sales office.

14. For detailed information and a breakdown of device nomenclature and numbering systems, please see the ON Semiconductor Device

Nomenclature document, TND310/D, available at www.onsemi.com

ON Semiconductor is licensed by the Philips Corporation to carry the I2C bus protocol.

www.onsemi.com

10

�MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

UDFN8, 2x3 EXTENDED PAD

CASE 517AZ

ISSUE A

1

SCALE 2:1

PIN ONE

REFERENCE

0.10 C

B

A

D

L1

ÇÇ

ÇÇ

ÇÇ

DETAIL A

ALTERNATE

CONSTRUCTIONS

E

EXPOSED Cu

DETAIL B

A

0.10 C

0.08 C

1

D2

ÉÉ

ÉÉ

ÇÇ

C

MOLD CMPD

ÉÉÉ

ÉÉÉ

ÇÇÇ

A3

A1

ALTERNATE

CONSTRUCTIONS

1

L

4

5

8X

e

XXXXX

A

WL

Y

W

G

BOTTOM VIEW

b

0.10

M

C A B

0.05

M

C

MILLIMETERS

MIN

MAX

0.45

0.55

0.00

0.05

0.13 REF

0.20

0.30

2.00 BSC

1.35

1.45

3.00 BSC

1.25

1.35

0.50 BSC

0.25

0.35

−−−

0.15

GENERIC

MARKING DIAGRAM*

SEATING

PLANE

E2

8

DIM

A

A1

A3

b

D

D2

E

E2

e

L

L1

DETAIL B

A3

A1

SIDE VIEW

DETAIL A

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b APPLIES TO PLATED

TERMINAL AND IS MEASURED BETWEEN

0.15 AND 0.25MM FROM THE TERMINAL TIP.

4. COPLANARITY APPLIES TO THE EXPOSED

PAD AS WELL AS THE TERMINALS.

L

L

0.10 C TOP VIEW

NOTE 4

DATE 23 MAR 2015

XXXXX

AWLYWG

= Specific Device Code

= Assembly Location

= Wafer Lot

= Year

= Work Week

= Pb−Free Package

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

NOTE 3

RECOMMENDED

SOLDERING FOOTPRINT*

1.56

8X

0.68

1.45 3.40

1

8X

0.30

0.50

PITCH

DIMENSIONS: MILLIMETERS

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

DOCUMENT NUMBER:

DESCRIPTION:

98AON42552E

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

UDFN8, 2X3 EXTENDED PAD

PAGE 1 OF 1

ON Semiconductor and

are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

www.onsemi.com

�MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SOIC 8, 150 mils

CASE 751BD−01

ISSUE O

E1

DATE 19 DEC 2008

E

SYMBOL

MIN

A

1.35

1.75

A1

0.10

0.25

b

0.33

0.51

c

0.19

0.25

D

4.80

5.00

E

5.80

6.20

E1

3.80

4.00

MAX

1.27 BSC

e

PIN # 1

IDENTIFICATION

NOM

h

0.25

0.50

L

0.40

1.27

θ

0º

8º

TOP VIEW

D

h

A1

A

θ

c

e

b

SIDE VIEW

L

END VIEW

Notes:

(1) All dimensions are in millimeters. Angles in degrees.

(2) Complies with JEDEC MS-012.

DOCUMENT NUMBER:

DESCRIPTION:

98AON34272E

SOIC 8, 150 MILS

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

ON Semiconductor and

are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

www.onsemi.com

�MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

TSSOP8, 4.4x3.0, 0.65P

CASE 948AL

ISSUE A

DATE 20 MAY 2022

q

q

GENERIC

MARKING DIAGRAM*

XXX

YWW

AG

XXX

Y

WW

A

G

= Specific Device Code

= Year

= Work Week

= Assembly Location

= Pb−Free Package

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “G”, may

or may not be present. Some products may

not follow the Generic Marking.

DOCUMENT NUMBER:

DESCRIPTION:

98AON34428E

TSSOP8, 4.4X3.0, 0.65P

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

onsemi and

are trademarks of Semiconductor Components Industries, LLC dba onsemi or its subsidiaries in the United States and/or other countries. onsemi reserves

the right to make changes without further notice to any products herein. onsemi makes no warranty, representation or guarantee regarding the suitability of its products for any particular

purpose, nor does onsemi assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation

special, consequential or incidental damages. onsemi does not convey any license under its patent rights nor the rights of others.

© Semiconductor Components Industries, LLC, 2019

www.onsemi.com

�onsemi,

, and other names, marks, and brands are registered and/or common law trademarks of Semiconductor Components Industries, LLC dba “onsemi” or its affiliates

and/or subsidiaries in the United States and/or other countries. onsemi owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property.

A listing of onsemi’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. onsemi reserves the right to make changes at any time to any

products or information herein, without notice. The information herein is provided “as−is” and onsemi makes no warranty, representation or guarantee regarding the accuracy of the

information, product features, availability, functionality, or suitability of its products for any particular purpose, nor does onsemi assume any liability arising out of the application or use

of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages. Buyer is responsible for its products

and applications using onsemi products, including compliance with all laws, regulations and safety requirements or standards, regardless of any support or applications information

provided by onsemi. “Typical” parameters which may be provided in onsemi data sheets and/or specifications can and do vary in different applications and actual performance may

vary over time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. onsemi does not convey any license

under any of its intellectual property rights nor the rights of others. onsemi products are not designed, intended, or authorized for use as a critical component in life support systems

or any FDA Class 3 medical devices or medical devices with a same or similar classification in a foreign jurisdiction or any devices intended for implantation in the human body. Should

Buyer purchase or use onsemi products for any such unintended or unauthorized application, Buyer shall indemnify and hold onsemi and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that onsemi was negligent regarding the design or manufacture of the part. onsemi is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

onsemi Website: www.onsemi.com

◊

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

�