DATA SHEET

www.onsemi.com

Industrial Inductive

Load Driver

3

1

This micro−integrated part provides a single component solution to

switch inductive loads such as relays, solenoids, and small DC motors

without the need of a free−wheeling diode. It accepts logic level

inputs, thus allowing it to be driven by a large variety of devices

including logic gates, inverters, and microcontrollers.

MARKING DIAGRAMS

JW8 = Specific Device Code

M

= Date Code

G

= Pb−Free Package

(Note: Microdot may be in either location)

• Provides Robust Interface between D.C. Relay Coils and Sensitive

Logic

• Capable of Driving Relay Coils Rated up to 150 mA at 12 V, 24 V

or 48 V

Replaces 3 or 4 Discrete Components for Lower Cost

Internal Zener Eliminates Need for Free−Wheeling Diode

Meets Load Dump and other Automotive Specs

SZ Prefix for Automotive and Other Applications Requiring Unique

Site and Control Change Requirements; AEC−Q101 Qualified and

PPAP Capable

These Devices are Pb−Free, Halogen Free/BFR Free and are RoHS

Compliant

Typical Applications

• Automotive and Industrial Environment

• Drives Window, Latch, Door, and Antenna Relays

JW8 = Specific Device Code

M

= Date Code

G

= Pb−Free Package

(Note: Microdot may be in either location)

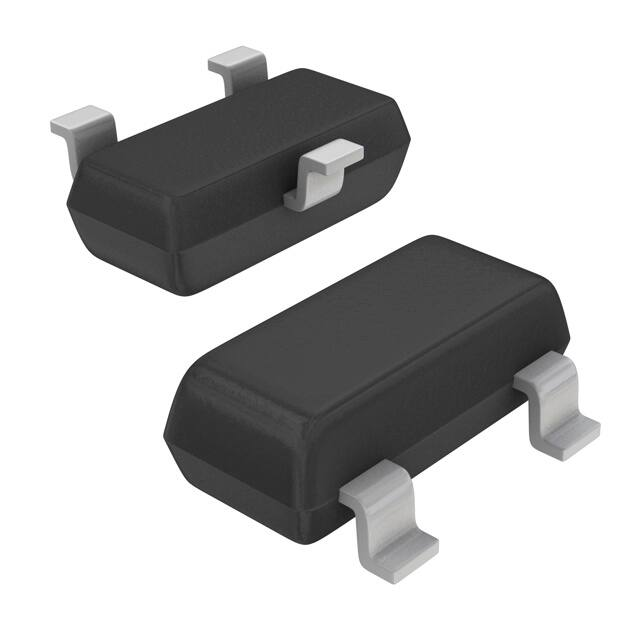

ORDERING INFORMATION

Package

Shipping†

NUD3160LT1G

SOT−23

(Pb−Free)

3000 / Tape &

Reel

SZNUD3160LT1G

SOT−23

(Pb−Free)

3000 / Tape &

Reel

NUD3160DMT1G

SC−74

(Pb−Free)

3000 / Tape &

Reel

SZNUD3160DMT1G

SC−74

(Pb−Free)

3000 / Tape &

Reel

Device

Benefits

•

•

•

•

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specifications

Brochure, BRD8011/D.

Reduced PCB Space

Standardized Driver for Wide Range of Relays

Simplifies Circuit Design and PCB Layout

Compliance with Automotive Specifications

Drain (3)

Gate (1)

100 k

10 k

10 k

CASE 318

© Semiconductor Components Industries, LLC, 2003

Gate (5)

100 k

100 k

Source (2)

October, 2022 − Rev. 9

Drain (3)

Drain (6)

Gate (2)

10 k

JW8 MG

G

JW8 MG

G

Features

•

1

SC−74

CASE 318F

STYLE 7

SOT−23

CASE 318

STYLE 21

NUD3160, SZNUD3160

•

•

•

•

6

2

Source (4)

Source (1)

CASE 318F

Figure 1. Internal Circuit Diagrams

1

Publication Order Number:

NUD3160/D

�NUD3160, SZNUD3160

MAXIMUM RATINGS (TJ = 25°C unless otherwise specified)

Rating

Symbol

Value

Unit

VDSS

Drain−to−Source Voltage – Continuous (TJ = 125°C)

60

V

VGSS

Gate−to−Source Voltage – Continuous (TJ = 125°C)

12

V

ID

Drain Current – Continuous (TJ = 125°C)

Minimum copper, double sided board, TA = 80°C

SOT−23

SC74 Single device driven

SC74 Both devices driven

1 in2 copper, double sided board, TA = 25°C

SOT−23

SC74 Single device driven

SC74 Both devices driven

mA

158

157

132 ea

272

263

230 ea

EZ

Single Pulse Drain−to−Source Avalanche Energy

(For Relay’s Coils/Inductive Loads of 80 W or Higher) (TJ Initial = 85°C)

200

mJ

PPK

Peak Power Dissipation, Drain−to−Source (Notes 1 and 2)

(TJ Initial = 85°C)

20

W

ELD1

Load Dump Pulse, Drain−to−Source (Note 3)

RSOURCE = 0.5 W, T = 300 ms)

(For Relay’s Coils/Inductive Loads of 80 W or Higher) (TJ Initial = 85°C)

60

V

ELD2

Inductive Switching Transient 1, Drain−to−Source

(Waveform: RSOURCE = 10 W, T = 2.0 ms)

(For Relay’s Coils/Inductive Loads of 80 W or Higher) (TJ Initial = 85°C)

100

V

ELD3

Inductive Switching Transient 2, Drain−to−Source

(Waveform: RSOURCE = 4.0 W, T = 50 ms)

(For Relay’s Coils/Inductive Loads of 80 W or Higher) (TJ Initial = 85°C)

300

V

Rev−Bat

Reverse Battery, 10 Minutes (Drain−to−Source)

(For Relay’s Coils/Inductive Loads of 80 W or more)

−14

V

Dual−Volt

Dual Voltage Jump Start, 10 Minutes (Drain−to−Source)

28

V

2000

V

ESD

Human Body Model (HBM)

According to EIA/JESD22/A114 Specification

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

THERMAL CHARACTERISTICS

Symbol

Value

Unit

TA

Operating Ambient Temperature

−40 to 125

°C

TJ

Maximum Junction Temperature

150

°C

−65 to 150

°C

TSTG

Rating

Storage Temperature Range

PD

Total Power Dissipation (Note 4)

Derating above 25°C

SOT−23

225

1.8

mW

mW/°C

PD

Total Power Dissipation (Note 4)

Derating above 25°C

SC−74

380

3.0

mW

mW/°C

SOT−23

SC−74 One Device Powered

SC−74 Both Devices Equally Powered

556

556

398

SOT−23

SC−74 One Device Powered

SC−74 Both Devices Equally Powered

395

420

270

RqJA

Thermal Resistance, Junction–to–Ambient

Minimum Copper

300 mm2 Copper

1.

2.

3.

4.

Nonrepetitive current square pulse 1.0 ms duration.

For different square pulse durations, see Figure 12.

Nonrepetitive load dump pulse per Figure 3.

Mounted onto minimum pad board.

www.onsemi.com

2

°C/W

�NUD3160, SZNUD3160

ELECTRICAL CHARACTERISTICS (TJ = 25°C unless otherwise specified)

Symbol

Min

Typ

Max

Unit

VBRDSS

61

66

70

V

−

−

−

−

−

−

−

−

0.5

1.0

50

80

−

−

−

−

−

−

−

−

60

80

90

110

1.3

1.3

1.8

−

2.0

2.0

−

−

−

−

−

−

−

−

2.4

3.7

1.8

2.9

150

100

200

−

−

−

gFS

−

400

−

mmho

Input Capacitance

(VDS = 12 V, VGS = 0 V, f = 10 kHz)

Ciss

−

30

−

pf

Output Capacitance

(VDS = 12 V, VGS = 0 V, f = 10 kHz)

Coss

−

14

−

pf

Transfer Capacitance

(VDS = 12 V, VGS = 0 V, f = 10 kHz)

Crss

−

6.0

−

pf

tPHL

tPLH

−

−

918

798

−

−

tPHL

tPLH

−

−

331

1160

−

−

tf

tr

−

−

2290

618

−

−

tf

tr

−

−

622

600

−

−

Characteristic

OFF CHARACTERISTICS

Drain to Source Sustaining Voltage

(ID = 10 mA)

Drain to Source Leakage Current

(VDS = 12 V, VGS = 0 V)

(VDS = 12 V, VGS = 0 V, TJ = 125°C)

(VDS = 60 V, VGS = 0 V)

(VDS = 60 V, VGS = 0 V, TJ = 125°C)

IDSS

Gate Body Leakage Current

(VGS = 3.0 V, VDS = 0 V)

(VGS = 3.0 V, VDS = 0 V, TJ = 125°C)

(VGS = 5.0 V, VDS = 0 V)

(VGS = 5.0 V, VDS = 0 V, TJ = 125°C)

IGSS

mA

mA

ON CHARACTERISTICS

Gate Threshold Voltage

(VGS = VDS, ID = 1.0 mA)

(VGS = VDS, ID = 1.0 mA, TJ = 125°C)

VGS(th)

Drain to Source On−Resistance

(ID = 150 mA, VGS = 3.0 V)

(ID = 150 mA, VGS = 3.0 V, TJ = 125°C)

(ID = 150 mA, VGS = 5.0 V)

(ID = 150 mA, VGS = 5.0 V, TJ = 125°C)

RDS(on)

Output Continuous Current

(VDS = 0.3 V, VGS = 5.0 V)

(VDS = 0.3 V, VGS = 5.0 V, TJ = 125°C)

IDS(on)

Forward Transconductance

(VDS = 12 V, ID = 150 mA)

V

W

mA

DYNAMIC CHARACTERISTICS

SWITCHING CHARACTERISTICS

Propagation Delay Times:

High to Low Propagation Delay; Figure 2, (VDS = 12 V, VGS = 3.0 V)

Low to High Propagation Delay; Figure 2, (VDS = 12 V, VGS = 3.0 V)

High to Low Propagation Delay; Figure 2, (VDS = 12 V, VGS = 5.0 V)

Low to High Propagation Delay; Figure 2, (VDS = 12 V, VGS = 5.0 V)

Transition Times:

Fall Time; Figure 2, (VDS = 12 V, VGS = 3.0 V)

Rise Time; Figure 2, (VDS = 12 V, VGS = 3.0 V)

Fall Time; Figure 2, (VDS = 12 V, VGS = 5.0 V)

Rise Time; Figure 2, (VDS = 12 V, VGS = 5.0 V)

ns

ns

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

www.onsemi.com

3

�NUD3160, SZNUD3160

TYPICAL WAVEFORMS

(TJ = 25°C unless otherwise specified)

VIH

Vin

50%

0V

tPHL

tPLH

VOH

90%

Vout

50%

10%

VOL

tr

tf

Figure 2. Switching Waveforms

tr

Load Dump Pulse Not Suppressed:

Vr = 13.5 V Nominal ±10%

VS = 60 V Nominal ±10%

T = 300 ms Nominal ±10%

tr = 1 − 10 ms ±10%

90%

10% of Peak;

Reference = Vr, Ir

10%

Vr, Ir

Figure 3. Load Dump Waveform Definition

www.onsemi.com

4

VS

T

�NUD3160, SZNUD3160

TYPICAL PERFORMANCE CURVES

(TJ = 25°C unless otherwise specified)

80

VDS = 60 V

70

IGSS GATE LEAKAGE (mA)

IDSS, DRAIN LEAKAGE (mA)

80

60

50

40

30

20

10

0

−50

−25

0

25

50

100

75

70

60

40

VGS = 3 V

30

20

−50

125

VGS = 5 V

50

−25

TJ, JUNCTION TEMPERATURE (°C)

1E+03

66.2

ID DRAIN CURRENT (mA)

BVDSS BREAKDOWN VOLTAGE (V)

66.4

66.0

ID = 10 mA

65.6

65.4

65.2

65.0

64.8

−50

−25

0

25

75

50

100

0.01

0.001

125 °C

1E−05

1E−07

1.0

25 °C

1.2

1.4

−40 °C

1.6

1.8

2.0

2.2

VGS = 2.5 V

VGS = 3 V

VGS = 2 V

1E+00

1E−01

VGS = 1.5 V

1E−02

1E−03

0.0

125

VGS = 5 V

1E+01

2.4

VGS, GATE−TO−SOURCE VOLTAGE (V)

RDS(ON), DRAIN−TO−SOURCE RESISTANCE (mW)

ID DRAIN CURRENT (A)

VDS = 0.8 V

85 °C

125

0.2

0.1

0.3

0.4

0.5

0.6

0.7

0.8

Figure 7. Output Characteristics

1

1E−06

100

75

VDS, DRAIN−TO−SOURCE VOLTAGE (V)

Figure 6. Breakdown Voltage vs.

Junction Temperature

1E−04

50

1E+02

TJ, JUNCTION TEMPERATURE (°C)

0.1

25

Figure 5. Gate−to−Source Leakage vs.

Junction Temperature

Figure 4. Drain−to−Source Leakage vs.

Junction Temperature

65.8

0

TJ, JUNCTION TEMPERATURE (°C)

2.6

3200

ID = 0.15 A

2800

2400

VGS = 3.0 V

2000

1600

VGS = 5.0 V

1200

800

−50

Figure 8. Transfer Function

−25

0

25

50

75

TJ, JUNCTION TEMPERATURE (°C)

Figure 9. On Resistance Variation vs

Junction Temperature

www.onsemi.com

5

100

125

�NUD3160, SZNUD3160

TYPICAL PERFORMANCE CURVES

(TJ = 25°C unless otherwise specified)

90

ID = 250 mA

125 °C

VZ ZENER CLAMP VOLTAGE (V)

RDS(ON), DRAIN−TO−SOURCE

RESISTANCE (mW)

100

80

70

60

85 °C

50

25 °C

40

30

−40 °C

20

10

0

1.0

1.2

1.4

1.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

68.0

67.5

67.0

66.5

−40 °C

66.0

65.5

25 °C

85 °C

65.0

64.5

64.0

63.5

63.0

62.5

62.0

0.1

125 °C

1.0

VGS, GATE−TO−SOURCE VOLTAGE (V)

10

100

1000

IZ, ZENER CURRENT (mA)

Figure 11. Zener Clamp Voltage vs. Zener

Current

Figure 10. On Resistance Variation vs.

Gate−to−Source Voltage

100

600

SC74−1 (One Device Powered)

qJA (°C/W)

POWER (WATTS)

SC74−2 (Both Devices Powered Equally)

500

10

SC74−1

400

SOT23

300

1

0.1

1.0

10

200

100

SC74−2

1 oz. Copper, Single−sided Board

0

100

200

300

400

500

600

PW, PULSE WIDTH (ms)

COPPER AREA (mm2)

Figure 12. Maximum Non−repetitive Surge

Power vs. Pulse Width

Figure 13. Thermal Performance vs. Board

Copper Area

www.onsemi.com

6

700

�NUD3160, SZNUD3160

APPLICATIONS INFORMATION

12 V Battery

−

+

NC

NO

Relay, Vibrator,

or

Inductive Load

Drain (3)

Gate (1)

Micro

Processor

Signal

for

Relay

10 k

100 K

NUD3160

Source (2)

Figure 14. Applications Diagram

www.onsemi.com

7

�MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SOT−23 (TO−236)

CASE 318−08

ISSUE AS

DATE 30 JAN 2018

SCALE 4:1

D

0.25

3

E

1

2

T

HE

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. MAXIMUM LEAD THICKNESS INCLUDES LEAD FINISH.

MINIMUM LEAD THICKNESS IS THE MINIMUM THICKNESS OF

THE BASE MATERIAL.

4. DIMENSIONS D AND E DO NOT INCLUDE MOLD FLASH,

PROTRUSIONS, OR GATE BURRS.

DIM

A

A1

b

c

D

E

e

L

L1

HE

T

L

3X b

L1

VIEW C

e

TOP VIEW

A

A1

SIDE VIEW

SEE VIEW C

c

MIN

0.89

0.01

0.37

0.08

2.80

1.20

1.78

0.30

0.35

2.10

0°

MILLIMETERS

NOM

MAX

1.00

1.11

0.06

0.10

0.44

0.50

0.14

0.20

2.90

3.04

1.30

1.40

1.90

2.04

0.43

0.55

0.54

0.69

2.40

2.64

−−−

10 °

MIN

0.035

0.000

0.015

0.003

0.110

0.047

0.070

0.012

0.014

0.083

0°

INCHES

NOM

0.039

0.002

0.017

0.006

0.114

0.051

0.075

0.017

0.021

0.094

−−−

MAX

0.044

0.004

0.020

0.008

0.120

0.055

0.080

0.022

0.027

0.104

10°

GENERIC

MARKING DIAGRAM*

END VIEW

RECOMMENDED

SOLDERING FOOTPRINT

XXXMG

G

1

3X

2.90

3X

XXX = Specific Device Code

M = Date Code

G

= Pb−Free Package

0.90

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

0.95

PITCH

0.80

DIMENSIONS: MILLIMETERS

STYLE 1 THRU 5:

CANCELLED

STYLE 6:

PIN 1. BASE

2. EMITTER

3. COLLECTOR

STYLE 7:

PIN 1. EMITTER

2. BASE

3. COLLECTOR

STYLE 9:

PIN 1. ANODE

2. ANODE

3. CATHODE

STYLE 10:

PIN 1. DRAIN

2. SOURCE

3. GATE

STYLE 11:

STYLE 12:

PIN 1. ANODE

PIN 1. CATHODE

2. CATHODE

2. CATHODE

3. CATHODE−ANODE

3. ANODE

STYLE 15:

PIN 1. GATE

2. CATHODE

3. ANODE

STYLE 16:

PIN 1. ANODE

2. CATHODE

3. CATHODE

STYLE 17:

PIN 1. NO CONNECTION

2. ANODE

3. CATHODE

STYLE 18:

STYLE 19:

STYLE 20:

PIN 1. NO CONNECTION PIN 1. CATHODE

PIN 1. CATHODE

2. CATHODE

2. ANODE

2. ANODE

3. GATE

3. ANODE

3. CATHODE−ANODE

STYLE 21:

PIN 1. GATE

2. SOURCE

3. DRAIN

STYLE 22:

PIN 1. RETURN

2. OUTPUT

3. INPUT

STYLE 23:

PIN 1. ANODE

2. ANODE

3. CATHODE

STYLE 24:

PIN 1. GATE

2. DRAIN

3. SOURCE

STYLE 27:

PIN 1. CATHODE

2. CATHODE

3. CATHODE

STYLE 28:

PIN 1. ANODE

2. ANODE

3. ANODE

DOCUMENT NUMBER:

DESCRIPTION:

98ASB42226B

SOT−23 (TO−236)

STYLE 8:

PIN 1. ANODE

2. NO CONNECTION

3. CATHODE

STYLE 13:

PIN 1. SOURCE

2. DRAIN

3. GATE

STYLE 25:

PIN 1. ANODE

2. CATHODE

3. GATE

STYLE 14:

PIN 1. CATHODE

2. GATE

3. ANODE

STYLE 26:

PIN 1. CATHODE

2. ANODE

3. NO CONNECTION

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

ON Semiconductor and

are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

www.onsemi.com

�MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SC−74

CASE 318F

ISSUE P

6

1

SCALE 2:1

DATE 07 OCT 2021

GENERIC

MARKING DIAGRAM*

XXX MG

G

XXX

M

G

= Specific Device Code

= Date Code

= Pb−Free Package

(Note: Microdot may be in either location)

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “G”, may

or may not be present. Some products may

not follow the Generic Marking.

STYLE 1:

PIN 1. CATHODE

2. ANODE

3. CATHODE

4. CATHODE

5. ANODE

6. CATHODE

STYLE 2:

PIN 1. NO CONNECTION

2. COLLECTOR

3. EMITTER

4. NO CONNECTION

5. COLLECTOR

6. BASE

STYLE 3:

PIN 1. EMITTER 1

2. BASE 1

3. COLLECTOR 2

4. EMITTER 2

5. BASE 2

6. COLLECTOR 1

STYLE 4:

PIN 1. COLLECTOR 2

2. EMITTER 1/EMITTER 2

3. COLLECTOR 1

4. EMITTER 3

5. BASE 1/BASE 2/COLLECTOR 3

6. BASE 3

STYLE 5:

PIN 1. CHANNEL 1

2. ANODE

3. CHANNEL 2

4. CHANNEL 3

5. CATHODE

6. CHANNEL 4

STYLE 7:

PIN 1. SOURCE 1

2. GATE 1

3. DRAIN 2

4. SOURCE 2

5. GATE 2

6. DRAIN 1

STYLE 8:

PIN 1. EMITTER 1

2. BASE 2

3. COLLECTOR 2

4. EMITTER 2

5. BASE 1

6. COLLECTOR 1

STYLE 9:

PIN 1. EMITTER 2

2. BASE 2

3. COLLECTOR 1

4. EMITTER 1

5. BASE 1

6. COLLECTOR 2

STYLE 10:

PIN 1. ANODE/CATHODE

2. BASE

3. EMITTER

4. COLLECTOR

5. ANODE

6. CATHODE

STYLE 11:

PIN 1. EMITTER

2. BASE

3. ANODE/CATHODE

4. ANODE

5. CATHODE

6. COLLECTOR

DOCUMENT NUMBER:

DESCRIPTION:

98ASB42973B

SC−74

STYLE 6:

PIN 1. CATHODE

2. ANODE

3. CATHODE

4. CATHODE

5. CATHODE

6. CATHODE

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

onsemi and

are trademarks of Semiconductor Components Industries, LLC dba onsemi or its subsidiaries in the United States and/or other countries. onsemi reserves

the right to make changes without further notice to any products herein. onsemi makes no warranty, representation or guarantee regarding the suitability of its products for any particular

purpose, nor does onsemi assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation

special, consequential or incidental damages. onsemi does not convey any license under its patent rights nor the rights of others.

© Semiconductor Components Industries, LLC, 2019

www.onsemi.com

�onsemi,

, and other names, marks, and brands are registered and/or common law trademarks of Semiconductor Components Industries, LLC dba “onsemi” or its affiliates

and/or subsidiaries in the United States and/or other countries. onsemi owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property.

A listing of onsemi’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. onsemi reserves the right to make changes at any time to any

products or information herein, without notice. The information herein is provided “as−is” and onsemi makes no warranty, representation or guarantee regarding the accuracy of the

information, product features, availability, functionality, or suitability of its products for any particular purpose, nor does onsemi assume any liability arising out of the application or use

of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages. Buyer is responsible for its products

and applications using onsemi products, including compliance with all laws, regulations and safety requirements or standards, regardless of any support or applications information

provided by onsemi. “Typical” parameters which may be provided in onsemi data sheets and/or specifications can and do vary in different applications and actual performance may

vary over time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. onsemi does not convey any license

under any of its intellectual property rights nor the rights of others. onsemi products are not designed, intended, or authorized for use as a critical component in life support systems

or any FDA Class 3 medical devices or medical devices with a same or similar classification in a foreign jurisdiction or any devices intended for implantation in the human body. Should

Buyer purchase or use onsemi products for any such unintended or unauthorized application, Buyer shall indemnify and hold onsemi and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that onsemi was negligent regarding the design or manufacture of the part. onsemi is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

onsemi Website: www.onsemi.com

◊

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

�