System LSIs for Blu-ray Drive

System Motor Driver IC

for Half Height Drive(Sensor less)

BD7763EFV

General Description

BD7763EFV are 9ch system motor driver ICs,

developed for the spindle motor, actuator coil,

stepping motor, SA stepping motor and the loading

motor drive of the Blu-ray drive. Since spindle

driver adopts sensor less drive system and the hall

sensor (3 pieces) of the motor position detection is

not needed, it is suitable for making of flexible

cable conserve wiring and the reductions of

external parts. The actuator, loading driver, the

spindle, stepping, and SA stepping use power

MOSFET to reduce power consumption.

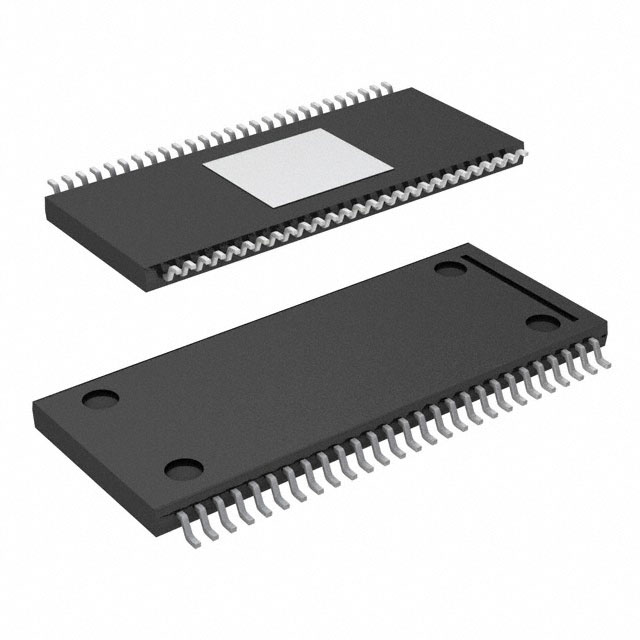

Package(s)

HTSSOP-B54

Applications

For Blu-ray drive

Features

The hall sensor is not needed by 3-phase sensor less

drive system.

The spindle motor driver achieves stability high speed

start by ROHM's own energizing method.

Spindle, stepping and SA stepping achieve high

efficiency drive by PWM control driver. The actuator is

able to reduce power consumption by using PWM

drive system.

The loading adopts forward/reverse-rotation drive

system.

ON/OFF of loading and other channels, brake mode

of spindle driver, and stand-by mode are selectable by

the two control terminals.

Built-in thermal-shut down circuit.

Improved heat radiation efficiency utilizing lm-type

HTSSOP package with good thermal conductivity.

18.5mm x 9.5mm x 1.0mm

R2

R1 DVCC

28

SPLIM

29

MTR_R

30

GND

31

SPVM

32

COM RDET

33

W

34

V

35

U

36

SPGND

10k

37

SADETOUT

38

SLVM

39

SLO2-

SLO2+

40

41

42

SLO1-

12V

SLO1+

43

SL/SAGND

44

SAO2-

SAO2+

12V

45

46

SAO1-

47

SAO1+

10k

48

49

SLDET

50

SAVM

51

SLIN1

52

SLIN2

53

SAIN1

54

SAIN2

5V

SLDETOUT

STM

STM

Typical Application Circuit(s)

SW

BEMF

DETECTER

CURR.

LIMIT

OSC

CURR.

FEED

FF

OSC

FF

Logic

OSC

PRE

Logic

CURR.FEED

CURR.FEED

AMP

OSC

OSC

PRE

Logic

LEVEL

SHIFT

LEVEL

SHIFT

PR E

Logic

AMP

PR E

Logic

SW

DETECTER

CUR R.

LIM IT

FC1

CTL

FC2

CTL

27

C_OUT

C_COM

25

10k FG

26

24

CTL1

23

CTL2

PULL_CTL

STBY

BRAKE

CONTROL

22

21

20

SPIN

19

PULL_BIAS

12V or 5V

LDIN

18

LDVM

17

LDO+

LDO-

16

AGND

14

5V

15

TKO+

13

TKO-

12

PULL

FCO2+

11

FCO2-

FCO1-

10

9

FCO1+

8

FC1IN

FC2IN

7

6

TKIN

5

AVM

VC

4

3

12V

VCC

2

SADET

1

DVCC

PR E

Logic

M

5V

PROTECT

T.S.D

PRE

Logic

LEVEL

SHIFT

PRE

Logic

DETECTER

PRE

Logic

OSC

NF AMP

OSC

NF AMP

OSC

NF AMP

LEVEL

SHIFT

1000pF

3.3V

○Product structure:Silicon monolithic integrated circuit

www.rohm.com

© 2015 ROHM Co., Ltd. All rights reserved.

TSZ22111・14・001

○This product is not designed protection against radioactive rays.

1/15

TSZ02201-0P1P0B800260-1-2

19.NOV.2012 Rev.001

�Datasheet

BD7763EFV

Pin Description(s)

No.

Symbol

1

DVcc

2

SADET

3

Description

No.

Symbol

Description

Adjustable resistor connection

for spindle driver current limit

PWM block control power supply

28

SPLIM

SA motor detection signal control input

29

MTR_R

Vcc

Pre block power supply

30

GND

4

VC

Reference voltage input

31

SPVM

Spindle driver power supply

5

AVM

Actuator driver block power supply

32

COM

Motor coil center point input

6

TKIN

Tracking driver input

33

W

Spindle driver output W

7

FC2IN

Focus 2 driver input

34

V

Spindle driver output V

8

FC1IN

Focus 1 driver input

35

U

Spindle driver output U

9

FCO1+

Focus 1 driver positive output

36

SPGND

10

FCO1-

Focus 1 driver negative output

37

11

FCO2-

Focus 2 driver negative output

38

SLVM

Sled motor driver power supply

12

FCO2+

Focus 2 driver positive output

39

SLO2-

Sled driver 2 negative output

13

TKO-

Tracking driver negative output

40

SLO2+

Sled driver 2 positive output

14

TKO+

Tracking driver positive output

41

SLO1-

Sled driver 1 negative output

15

AGND

Actuator/Loading driver power ground

42

SLO1+

Sled driver 1 positive output

16

LDO-

Loading driver negative output

43

SL/SAGND

17

LDO+

Loading driver positive output

44

SAO2-

SA driver 2 negative output

18

LDVM

Loading driver block power supply

45

SAO2+

SA driver 2 positive output

19

LDIN

Loading driver input

46

SAO1-

SA driver 1 negative output

20

SPIN

Spindle driver input

47

SAO1+

SA driver 1 positive output

motor start pattern adjustment terminal

Pre block ground

Spindle driver power ground

SADETOUT SA motor detection signal output

Sled/SA driver block

pre and power ground

21

PULL_BIAS Pick-up pull current control terminal

48

SLDETOUT Sled motor detection signal output

22

PULL_CTL Pick-up pull control terminal

49

SLDET

Sled motor detection signal control input

23

CTL2

Driver logic control 2 input

50

SAVM

SA driver power block power supply

24

CTL1

Driver logic control 1 input

51

SLIN1

Sled driver 1 input

25

FG

Frequency generator output

52

SLIN2

Sled driver 2 input

26

C_COM

53

SAIN1

SA driver 1 input

27

C_OUT

54

SAIN2

SA driver 2 input

Smooth capacitor connection terminal

(com side)

Smooth capacitor connection terminal

(output side)

*Positive/negative of the output terminals is determined in reference to those of the input terminals.

www.rohm.com

© 2015 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

2/15

TSZ02201-0P1P0B800260-1-2

19.NOV.2012 Rev.001

�Datasheet

BD7763EFV

Block Diagram(s)

1

SADET

2

DETECTER

VCC

3

LEVEL

SHIFT

VC

4

LEVEL

SHIFT

AVM

5

TKIN

6

FC2IN

7

FC1IN

8

DETECTER

SW

O SC

PRE

Logic

9

FC1

CTL

FCO 1-

NF AMP

AMP

10

O SC

PRE

Logic

FCO 2+

11

FC2

CTL

FCO 2-

12

54

SAIN2

53

SAIN1

52

SLIN2

51

SLIN1

50

SAVM

49

SLDET

48

SLDETO UT

47

SAO1+

46

SAO1-

45

SAO2+

44

SAO2-

43

SL/SAGND

42

SLO 1+

41

SLO 1-

40

SLO 2+

39

SLO 2-

38

SLVM

37

SADETO UT

36

SPG ND

35

U

34

V

33

W

32

CO M

31

SPVM

O SC

AMP

NF AMP

PRE

Logic

FCO 1+

PRE

Logic

DVCC

O SC

LDO -

16

FF

O SC

17

CURR.FEED

SW

18

SPIN

20

PULL_BIAS

21

PULL_CTL

22

LEVEL

SHIFT

CURR.

FEED

T.S.D

Logic

19

BEMF

DETECTER

LDIN

O SC

LEVEL

SHIFT

LDVM

O SC

CURR.

LIMIT

PRE

Logic

15

O SC

FF

AG ND

LDO +

PRE

Logic

14

NF AMP

PRE

Logic

TKO +

13

PULL

TKO -

PRE

Logic

CURR.FEED

PROTECT

23

CTL1

24

FG

25

30

G ND

C_COM

26

29

M TR _R

C_O UT

27

28

SPLIM

www.rohm.com

© 2015 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

CURR.

LIMIT

STBY

BRAKE

CONTROL

CTL2

3/15

TSZ02201-0P1P0B800260-1-2

19.NOV.2012 Rev.001

�Datasheet

BD7763EFV

Absolute Maximum Ratings

Parameter

POWER MOS power supply voltage 1

POWER MOS power supply voltage 2

Pre block power supply voltage

PWM control block power supply voltage

Power dissipation

Operating temperature range

Storage temperature

Junction temperature

Symbol

SPVM、SLVM、LDVM

SAVM、AVM

Vcc

DVcc

Pd

Topr

Tstg

Tjmax

Limits

15

7

15

7

2.00

-20~75

-55~150

150

♯1

♯2

♯3

Unit

V

V

V

V

W

℃

℃

℃

♯1 POWER MOS output terminals (16~17pin, 39~42pin, 33~35pin) are contained.

♯2 POWER MOS output terminals (9~14pin,44~47pin) are contained.

♯3 PCB mounting (70mmX70mmX1.6mm, occupied copper foil is less than 3%, glass epoxy standard board).

Reduce by 16mW/ over 25

Recommended Operating Rating(s)

Parameter

Symbol

SPVM、SLVM

Vcc

LDVM

SAVM、AVM

DVcc

Iosp

Ioo

Spindle / Sled motor driver power block power supply voltage

Pre block power supply voltage

Loading driver Pre block / power block supply voltage

SA, Actuator driver power block power supply voltage

PWM control block power supply voltage

Spindle driver output current

Actuator, SA, sled, loading motor driver output current

Min.

-

10.8

4.3

4.3

4.3

-

-

Typ.

Vcc♯4

12

5.0

5.0

5.0

1.0

0.5

Max.

-

13.2

Vcc

5.5

5.5

2.5♯5

0.8

Unit

V

V

V

V

V

A

A

♯4 Set the same supply voltage to SPVM, SLVM and Vcc.

♯5 The current is guaranteed 3.5A in case of the Short-circuit braking mode and the current which is turned on/off in

a duty-ratio of less than 1/10 with a maximum on-time of 5msec.

www.rohm.com

© 2015 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

4/15

TSZ02201-0P1P0B800260-1-2

19.NOV.2012 Rev.001

�Datasheet

BD7763EFV

Electrical Characteristic(s)

(Unless otherwise noted, Ta=25℃、Vcc=SPVM=SLVM=12V、DVcc=AVM=SAVM= LDVM=5V、Vc=1.65V、RL=8Ω、RLSP=2Ω、RDET=0.33Ω)

Parameter

Symbol

MIN.

TYP.

MAX.

Unit

Condition

IQ1

IQ2

IQ3

IST1

IST2

-

-

-

-

-

4.3

4.4

14

2.2

1.5

13

13

42

5

4

mA

mA

mA

mA

mA

Vcc(at loading OFF)

Vcc(at loading ON)

DVcc

Vcc

DVcc

VDZSL

gmSL

RONSL

ILIMSL

foscSL

0

0.86

-

0.8

-

30

1.15

2.2

1.1

100

80

1.44

3.3

1.4

-

mV

A/V

Ω

A

kHz

IL=500mA

55

1.15

90

1.44

mV

A/V

Circuit current

Quiescent current 1

Quiescent current 2

Quiescent current 3

Standby-on current 1

Standby-on current 2

Sled driver block

Input dead zone (one side)

Input output gain

Output On resistor (top and bottom)

Output limit current

PWM frequency

Spindle driver block<Torque instruction input / output>

Input output gain

VDZSP

gmSP

Output On resistor (top and bottom)

RONSP

-

1.0

1.7

Ω

Output limit current

ILIMSP

foscSP

0.88

-

1.04

167

1.20

-

A

kHz

2.3

-

3.2

0.15

-

0.3

V

V

Voltage gain

VOFACT

RONACT

GVACT

-50

-

15.7

0

1.5

17.5

50

2.5

19.3

mV

Ω

dB

Relative gain difference (FC1,FC2)

△GVFC

-1.0

0

1.0

dB

PWM frequency

foscACT

200

280

360

KHz

VDZSA

GVSA

RONSA

foscSA

10

15.5

-

200

40

17.5

1.3

300

80

19.5

2.5

400

mV

dB

Ω

kHz

VOFLD+

Input threshold voltage(INVc)

IL=500mA

CTL1、CTL2

Input high voltage

Input middle voltage

Input low voltage

PULL_CTL

Input high voltage

Input low voltage

Others

VC input current

VC drop-muting

VC over voltage muting

Vcc drop-muting

IVC

VMLVC

VMUVC

VMVcc

www.rohm.com

© 2015 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

5

0.4

2.0

3.45

5/15

TSZ02201-0P1P0B800260-1-2

19.NOV.2012 Rev.001

�Datasheet

BD7763EFV

Functional description

1-1. Driver logic control terminal 1and 2 (CTL1,2)

All drivers and spindle-drive braking modes can be switched on/off by inputting combinations of H-level signal

(higher than 2.7V and lower than 3.7V), L-level(open) signal (lower than 0.5V) and M-level signal (higher than

1.4V and lower than 2.0V).

Driver ON/OFF logic table

mode

①

②

③

④

⑤

⑥

⑦

CTL1

CTL2

SP

SL(2ch)

ACT(3ch)

SA(2ch)

LOADIN

G

L

H

M

L、H

M

L、H

M

L

L

L

H

H

M

M

×

×

×

○

○

○

○

×

×

Inner detection

○

○

○

Inner detection

×

×

×

○

○

○

○

×

×

Inner detection

○

Inner detection

×

×

×

○

○

×

×

×

×

○:ON

×:OFF

① Stand-by mode

The IC is brought into stand-by mode, and its power dissipation can be limited.

② Drivers muting

All output channels, except the loading, are muted and their outputs are turned off.

③ SL/SA inner detection mode

④ Loading OFF mode

⑤ SA inner detection mode

⑥ SA mute mode

⑦ SL inner detection mode

Spindle braking mode table

mode

CTL1

CTL2

⑧

⑨

⑩

M

L

H

M、H

M、H

M、H

SPIN

> VC

SPIN

Forward-rotation mode

< VC

Reverse-rotation braking mode

Short-circuit braking mode

Reverse-rotation braking mode

⑧⑩Reverse-rotation braking mode (spindle)

When SPIN < VC, all outputs are shorted to SPVM in 4500rpm (Typ.) or more. In less than

4500rpm (Typ.), the outputs become reverse-rotation braking mode.

Rotation speed is less than 140rpm when SPIN < VC, all outputs are shorted to SPVM.

(However, the above-mentioned rotational speed is expressed in the case of 12pole motor.)

⑨ Short-circuit braking mode (spindle)

All spindle driver outputs are shorted to SPVM when SPIN < VC.

1-2.Spindle output mode

The spindle output changes as follows by the setting of SPIN.

Rotation speed

0rpm

SPIN>VC

120°energizing

SPIN<VC

120°energizing

www.rohm.com

© 2015 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

400rpm

4500rpm

150°energizing

150°energizing

6/15

Short brake

TSZ02201-0P1P0B800260-1-2

19.NOV.2012 Rev.001

�Datasheet

BD7763EFV

2.Output limit for spindle (SPLIM)

A=3844

ILIMSP =

A

(RSPLIM[Ω ] + 5600)×(RDET)[Ω ]

[A]

3.Torque command (SPIN) (SLIN1,2)

Torque command inputs vs. peak current value Iop of Iosp or Ioo is expressed in the figure below:

The gain is defined by the inclination between two points.

(Please exclude the dead zone from the input voltage when calculating Iop. )

Iop

Forward rotation

Input dead zone +

Input dead zone -

Gain

SPIN

SLIN1,2

VC

4.FG output (FG))

3FG output begins after 900°degrees in electric angle, after the start mode ends and the BEMF detection starts. When

the rotational speed becomes 24rpm (Max.) or less in case of brake, the FG output is fixed to high.

The above-mentioned rotation speed applies to the 12 pole motor.

www.rohm.com

© 2015 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

7/15

TSZ02201-0P1P0B800260-1-2

19.NOV.2012 Rev.001

�Datasheet

BD7763EFV

5.Input/Output timing chart

BEMFU

》

》

BEMFV

》

》

BEMFW

》

》

》

》

》

》

》

》

》

》

SPIN

VC

SOURCE

U

MID

SINK

SOURCE

V

MID

SINK

SOURCE

W

MID

SINK

Ⅰ) Forward-rotation Ⅱ) Reverse-rotation

braking mode

mode

Ⅱ) Short-circuit

braking mode

6.Motor start pattern adjustment terminal (MTR_R)

There are eight pattern setting of MTR_R. The voltage change can be canceled by connecting

the power supply of external resistance R1 and R2 with DVCC. It is as follows of energizing time

and a set voltage of MTR_R. Please decide a set pattern by the adjustment with the spindle motor.

MTR_R

DVCC

R1

Pattern

Energizing time [us]

1

2

3

4

5

6

7

8

14

17

24

34

48

68

92

126

R2

MTR_R

setting voltage[V]

4.24

5

3.75

3.24

2.75

0

2.22

1.76

R1

R2

10kΩ

10kΩ

10kΩ

12kΩ

18kΩ

open

15kΩ

22kΩ

56kΩ

open

30kΩ

22kΩ

22kΩ

10kΩ

12kΩ

12kΩ

The MTR_R setting voltage is a value in DVCC=5V.

7.Pick-up lens pull function

PULL_CTL

Function

L

H

ON

Normal (function:OFF)

FOCUS 1 and the FOCUS2 load are driven by the charge of the electrolytic capacitor connected with VCC (3pin).

The load drive current flows as follows.

FCO1-(10pin)→FCO1+(9pin)

FCO2-(11pin)→FCO2+(12pin)

The load drive current and time can be adjusted according to the voltage of VCC(3pin) and PULL_BIAS(21pin).

After 30 ms(Typ.) when PULL_CTL is made L, the FET Gate voltage is clamped to 1.67V(Typ.).

The above-mentioned clamping function does not work when the DVcc drop-muting operates.

Please turn off this function by PULL_CTL=H when you use the driver usually.

www.rohm.com

© 2015 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

8/15

TSZ02201-0P1P0B800260-1-2

19.NOV.2012 Rev.001

�Datasheet

BD7763EFV

8.Inner detection function

○Sled

BEMF of the motor is monitored according to timing for the sled input signal of micro step drive to pass VC, and

Sled is detected reaching the inner. The judgment voltage of BEMF can be set according to the voltage input to the

SLDET. If BEMF below the judgment voltage is detected twice continuously, it becomes SLDETOUT=L. When the

motor starts, the SLDETOUT might become L because BEMF is unstable. Please take measures such as installing

the time of the mask when it starts for the detection prevention.

Judgment voltage Vbemf[V] = 0.62×(SLDET[V] – VC[V]) + 0.66

○SA

BEMF of the motor is monitored according to timing for SA input signal of two aspect excitation drive to pass VC,

and SA is detected reaching the inner. The judgment voltage of BEMF can be set according to the voltage input to

the SADET. If BEMF below the judgment voltage is detected once, it becomes SADETOUT=L. When the motor

starts, the SADETOUT might become L because BEMF is unstable. Please take measures such as installing the

time of the mask when it starts for the detection prevention.

Judgment voltage Vbemf[mV] = 31.6×SADET[V] + 3.4

9.PWM oscillation frequency

The PWM oscillation for driving the spindle and sled is free running.

The sled oscillating frequency is 100kHz (Typ.)

The spindle oscillating frequency is 167kHz (Typ.)

10.Muting functions

a)VC-drop muting

When the VC voltage drops to a value lower than 0.7V (Typ.) or higher than 2.5V(Typ.),

the outputs of all the channels are turned off.

Please set the voltage of the VC from 1.0 to 2.0V.

b)Vcc-drop muting

When the voltage at DVcc terminal and Vcc terminal drop to lower than 3.85V (Typ.),

the outputs of all the channels are turned off.

c)Over voltage protection circuit

When the voltage at SPVM terminal exceed 14.1V (Typ.), only the spindle block output is turned off.

www.rohm.com

© 2015 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

9/15

TSZ02201-0P1P0B800260-1-2

19.NOV.2012 Rev.001

�Datasheet

BD7763EFV

11.Protect system1(Load protection function)

If full drive continues 130ms(Typ.) to protect focus, tracking, and tilt coil, this function protects IC by turning off

actuator output.

※The protection function can be reset by CTL1,2= L(stand-by mode),

when the protection function operates and the output is turned off.

12.Protect system 2 (Connecting to VCC or GND)

This function is to protect output POWER TR when the driver output connects to Vcc or GND.

Spindle,SLED,Actuator,SA

When SINK side POWER TR has been turned on, if the output voltage

(SPVM/2&SLVM/2&AVM/2&SAVM/2 or more) is detected, the channel concerned will be turned off.

When SOURCE side POWER transistor has been turned on, if the output voltage

(SPVM/2&SLVM/2&AVM/2&SAVM/2 or less) is detected, the channel concerned will be turned off

13. Protection system 3(Over voltage input protection function)

When detecting LDIN and SLIN1 input voltage more than DVCC×0.9<TYP>, this function protects motor by turning

off the output.

※If protection function operates and output is turned off, protection function can be reset by CTL1,2 =L(stand by

mode)

14.Thermal-shut down

Thermal-shutdown circuit (over-temperature protection circuit) is built in to prevent the IC from thermal

breakdown. Use the IC according to the thermal loss allowed in the package. In case the IC is left running over

the allowed loss, the junction temperature rises, and the thermal-shutdown circuit works at a junction temperature

of 175℃(Typ.) (the outputs of all the channels are turned off.).

When the junction temperature drops to 150℃ (Typ.), the IC resumes operation.

www.rohm.com

© 2015 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

10/15

TSZ02201-0P1P0B800260-1-2

19.NOV.2012 Rev.001

�Datasheet

BD7763EFV

I/O equivalence circuit

Three-phase motor driver output

BEMF voltage detection input

3pin

31

10k

5k

27

34

33

26

35

5k

32

36

5k

10k

30pin

PWM driver output ( SLED1,2)

PWM driver output ( SA1,2)

PWM driver output ( FC,TK,TL)

5

50

38

25k

25k

245k

39

40

41

42

44

45

46

47

245k

10k

10k

100k

9

10

12

14

11

13

15

43

43

PWM driver output ( LD)

100k

PWM driver input ( FC,TK,TL)

PWM driver input ( SLED1,2)

18

1pin

1pin

150k

6

16

17

150k

51

7

200

52

8

30pin

30pin

15

PWM driver input ( SA1,2)

PWM driver input ( SP)

PWM driver input ( LD)

1pin

53

3pin

1pin

50k

54

400k

19

20

200

30pin

50k

50k

www.rohm.com

© 2015 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

30pin

11/15

200

30pin

TSZ02201-0P1P0B800260-1-2

19.NOV.2012 Rev.001

�Datasheet

BD7763EFV

SADETOUT signal output

FG signal output

38pin

SLDETOUT signal output

3pin

30

1pin

3pin

30

37

SLED inner detection input(SLDET)

30

25

10k

48

49

10k

30pin

43pin

30pin

30pin

Reference voltage input (VC)

Motor start pattern adjustment terminal(MTR-R)

SA inner detection input(SADET)

3pin

1pin

3pin

4

29

50k

30pin

40k

200

10k

10k

2

46k

30pin

×3

×7

30pin

10k

×2

Spindle driver current limit (SPLIM)

Driver logic control 2 input (CTL1,CTL2)

3pin

3pin

23

24

28

5.6k

30pin

50k

175k

235k

42k

100k

20k

20k

50k

30pin

Pick-up pull control terminal(PULL_CTL)

Pick-up pull current control terminal(PULL_BIAS)

3pin

3pin

20k

50k

22

220k

21

50k

175k

235k

50k

20k

20k

50k

30pin

30pin

×2

www.rohm.com

© 2015 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

12/15

TSZ02201-0P1P0B800260-1-2

19.NOV.2012 Rev.001

�Datasheet

BD7763EFV

Operational Notes

1.Absolute maximum ratings

We are careful enough for quality control about this IC. So, there is no problem under normal operation, excluding that it exceeds the

absolute maximum ratings. However, this IC might be destroyed when the absolute maximum ratings, such as impressed voltages (Vcc,

VM) or the operating temperature range(Topr), is exceeded, and whether the destruction is short circuit mode or open circuit mode

cannot be specified. Please take into consideration the physical countermeasures for safety, such as fusing, if a particular mode that

exceeds the absolute maximum rating is assumed.

2.Power supply line

Due to switching and EMI noise generated by magnetic components (inductors and motors), using electrolytic and ceramic suppress

filter capacitors(0.1μF) close to the IC power input terminals (Vcc and GND) is recommended. Please note: the electrolytic capacitor

value decreases at lower temperatures.

Current rush might flow momentarily by the order of turning on the power supply and the delay in IC with two or more power supplies.

Note the capacity of the power supply coupling, width and drawing the power supply and the GND pattern wiring.

Please make the power supply lines (where large current flow) wide enough to reduce the resistance of the power supply patterns,

because the resistance of power supply pattern might influence the usual operation (output dynamic range etc…).

3.GND line

The ground line is where the lowest potential and transient voltages are connected to the IC.

4.Thermal design

Do not exceed the power dissipation (Pd) of the package specification rating under actual operation, and please design enough

temperature margins.

5.Short circuit mode between terminals and wrong mounting

Do not mount the IC in the wrong direction and be careful about the reverse-connection of the power connector. Moreover, this IC

might be destroyed when the dust short the terminals between them or GND

6.Radiation

Strong electromagnetic radiation can cause operation failures.

7.ASO(Area of Safety Operation.)

Do not exceed the maximum ASO and the absolute maximum ratings of the output driver.

8.TSD(Thermal shut-down)

The TSD is activated when the junction temperature (Tj) reaches 175℃(with 25℃ hysteresis), and the output terminal is switched to

Hi-z. The TSD circuit aims to intercept IC from high temperature. The guarantee and protection of IC are not purpose. Therefore,

please do not use this IC after TSD circuit operates, nor use it for assumption that operates the TSD circuit.

9.Inspection by the set circuit board

The stress might hang to IC by connecting the capacitor to the terminal with low impedance. Then, please discharge electricity in each

and all process. Moreover, in the inspection process, please turn off the power before mounting the IC, and turn on after mounting the

IC. In addition, please take into consideration the countermeasures for electrostatic damage, such as giving the earth in assembly

process, transportation or preservation.

www.rohm.com

© 2015 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

13/15

TSZ02201-0P1P0B800260-1-2

19.NOV.2012 Rev.001

�Datasheet

BD7763EFV

10.Earth wiring pattern

+

This IC is a monolithic IC, and has P isolation and P substrate for the element separation. Therefore, a parasitic PN junction is firmed

in this P-layer and N-layer of each element. For instance, the resistor or the transistor is connected to the terminal as shown in the

figure below. When the GND voltage potential is greater than the voltage potential at Terminals A or B, the PN junction operates as a

parasitic diode. In addition, the parasitic NPN transistor is formed in said parasitic diode and the N layer of surrounding elements close

to said parasitic diode. These parasitic elements are formed in the IC because of the voltage relation. The parasitic element operating

causes the wrong operation and destruction. Therefore, please be careful so as not to operate the parasitic elements by impressing to

input terminals lower voltage than GND(P substrate). Please do not apply the voltage to the input terminal when the power-supply

voltage is not impressed. Moreover, please impress each input terminal lower than the power-supply voltage or equal to the specified

range in the guaranteed voltage when the power-supply voltage is impressing.

Simplified structure of IC

11.Earth wiring pattern

Use separate ground lines for control signals and high current power driver outputs. Because these high current outputs that flows to

the wire impedance changes the GND voltage for control signal. Therefore, each ground terminal of IC must be connected at the one

point on the set circuit board. As for GND of external parts, it is similar to the above-mentioned.

12.Reverse-rotation braking

In the case of reverse-rotation braking from high speed rotation, pay good attention to reverse electromotive force. Furthermore, fully

check the voltage to be applied to the output terminal and consider the revolutions applied to the reverse-rotation brake.

13.About the capacitor between SPVM and SPGND

The capacitor between SPVM and SPGND absorbs the change in a steep voltage and the current because of the PWM drive, as a

result, there is a role to suppress the disorder of the SPVM voltage. However, the effect falls by the influence of the wiring impedance

etc, if the capacitor becomes far from IC. Please examine the capacitor between SPVM and SPGND to arrange it near IC.

14.About wiring between SPVM and RNF

Please be careful about the wiring resistor for power supply terminal (current detect terminal) of spindle. Detect resistor should be

connected by being shorted to the IC as near as possible.

12V

This area is considered as detect resistor.

Please make wiring thick and short.

Nearest to the IC

31

+

SPVM

RDET

3

Vcc

Status of this document

The Japanese version of this document is formal specification. A customer may use this translation version only for a

reference to help reading the formal version.

If there are any differences in translation version of this document formal version takes priority

www.rohm.com

© 2015 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

14/15

TSZ02201-0P1P0B800260-1-2

19.NOV.2012 Rev.001

�Datasheet

BD7763EFV

Power dissipation : Pd (W)

Power Dissipation

2.0

1.0

0

25

50

75

100

125

150

AMBIENT TEMPERATURE : Ta (℃)

Ordering Information

B

D

7

7

6

E

3

F

V

E2

Package

EFV: HTSSOP-B54

Part Number

Packaging and forming specification

E2: Embossed tape and reel

Physical Dimension Tape and Reel Information

HTSSOP-B54

18.5±0.1

(MAX 18.85 include BURR)

Embossed carrier tape (with dry pack)

Quantiy

1PIN MARK

0.8

(5.0)

0.5±0.15

28

BD7763EFV

7.5±0.1

9.5±0.2

54

1

Tape

+6°

4° −4°

(6.0)

1.0±0.2

Product

No.

Direction

of feed

The direction is the 1pin of product is at the upper left when you hold

reel on the left hand and you pull out the tape on the right hand

27

+0.05

0.17 -0.03

Lot No.

0.08±0.05

1.0MAX

0.85±0.05

S

0.08 S

0.65

+0.05

0.22 -0.04

0.08

1pin

M

(Unit : mm)

www.rohm.com

© 2015 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

Direction of feed

Reel

15/15

TSZ02201-0P1P0B800260-1-2

19.NOV.2012 Rev.001

�Datasheet

Notice

Precaution on using ROHM Products

1.

Our Products are designed and manufactured for application in ordinary electronic equipments (such as AV equipment,

OA equipment, telecommunication equipment, home electronic appliances, amusement equipment, etc.). If you

(Note 1)

, transport

intend to use our Products in devices requiring extremely high reliability (such as medical equipment

equipment, traffic equipment, aircraft/spacecraft, nuclear power controllers, fuel controllers, car equipment including car

accessories, safety devices, etc.) and whose malfunction or failure may cause loss of human life, bodily injury or

serious damage to property (“Specific Applications”), please consult with the ROHM sales representative in advance.

Unless otherwise agreed in writing by ROHM in advance, ROHM shall not be in any way responsible or liable for any

damages, expenses or losses incurred by you or third parties arising from the use of any ROHM’s Products for Specific

Applications.

(Note1) Medical Equipment Classification of the Specific Applications

JAPAN

USA

EU

CHINA

CLASSⅢ

CLASSⅡb

CLASSⅢ

CLASSⅢ

CLASSⅣ

CLASSⅢ

2.

ROHM designs and manufactures its Products subject to strict quality control system. However, semiconductor

products can fail or malfunction at a certain rate. Please be sure to implement, at your own responsibilities, adequate

safety measures including but not limited to fail-safe design against the physical injury, damage to any property, which

a failure or malfunction of our Products may cause. The following are examples of safety measures:

[a] Installation of protection circuits or other protective devices to improve system safety

[b] Installation of redundant circuits to reduce the impact of single or multiple circuit failure

3.

Our Products are designed and manufactured for use under standard conditions and not under any special or

extraordinary environments or conditions, as exemplified below. Accordingly, ROHM shall not be in any way

responsible or liable for any damages, expenses or losses arising from the use of any ROHM’s Products under any

special or extraordinary environments or conditions. If you intend to use our Products under any special or

extraordinary environments or conditions (as exemplified below), your independent verification and confirmation of

product performance, reliability, etc, prior to use, must be necessary:

[a] Use of our Products in any types of liquid, including water, oils, chemicals, and organic solvents

[b] Use of our Products outdoors or in places where the Products are exposed to direct sunlight or dust

[c] Use of our Products in places where the Products are exposed to sea wind or corrosive gases, including Cl2,

H2S, NH3, SO2, and NO2

[d] Use of our Products in places where the Products are exposed to static electricity or electromagnetic waves

[e] Use of our Products in proximity to heat-producing components, plastic cords, or other flammable items

[f] Sealing or coating our Products with resin or other coating materials

[g] Use of our Products without cleaning residue of flux (even if you use no-clean type fluxes, cleaning residue of

flux is recommended); or Washing our Products by using water or water-soluble cleaning agents for cleaning

residue after soldering

[h] Use of the Products in places subject to dew condensation

4.

The Products are not subject to radiation-proof design.

5.

Please verify and confirm characteristics of the final or mounted products in using the Products.

6.

In particular, if a transient load (a large amount of load applied in a short period of time, such as pulse. is applied,

confirmation of performance characteristics after on-board mounting is strongly recommended. Avoid applying power

exceeding normal rated power; exceeding the power rating under steady-state loading condition may negatively affect

product performance and reliability.

7.

De-rate Power Dissipation (Pd) depending on Ambient temperature (Ta). When used in sealed area, confirm the actual

ambient temperature.

8.

Confirm that operation temperature is within the specified range described in the product specification.

9.

ROHM shall not be in any way responsible or liable for failure induced under deviant condition from what is defined in

this document.

Precaution for Mounting / Circuit board design

1.

When a highly active halogenous (chlorine, bromine, etc.) flux is used, the residue of flux may negatively affect product

performance and reliability.

2.

In principle, the reflow soldering method must be used on a surface-mount products, the flow soldering method must

be used on a through hole mount products. If the flow soldering method is preferred on a surface-mount products,

please consult with the ROHM representative in advance.

For details, please refer to ROHM Mounting specification

Notice-PGA-E

© 2015 ROHM Co., Ltd. All rights reserved.

Rev.001

�Datasheet

Precautions Regarding Application Examples and External Circuits

1.

If change is made to the constant of an external circuit, please allow a sufficient margin considering variations of the

characteristics of the Products and external components, including transient characteristics, as well as static

characteristics.

2.

You agree that application notes, reference designs, and associated data and information contained in this document

are presented only as guidance for Products use. Therefore, in case you use such information, you are solely

responsible for it and you must exercise your own independent verification and judgment in the use of such information

contained in this document. ROHM shall not be in any way responsible or liable for any damages, expenses or losses

incurred by you or third parties arising from the use of such information.

Precaution for Electrostatic

This Product is electrostatic sensitive product, which may be damaged due to electrostatic discharge. Please take proper

caution in your manufacturing process and storage so that voltage exceeding the Products maximum rating will not be

applied to Products. Please take special care under dry condition (e.g. Grounding of human body / equipment / solder iron,

isolation from charged objects, setting of Ionizer, friction prevention and temperature / humidity control).

Precaution for Storage / Transportation

1.

Product performance and soldered connections may deteriorate if the Products are stored in the places where:

[a] the Products are exposed to sea winds or corrosive gases, including Cl2, H2S, NH3, SO2, and NO2

[b] the temperature or humidity exceeds those recommended by ROHM

[c] the Products are exposed to direct sunshine or condensation

[d] the Products are exposed to high Electrostatic

2.

Even under ROHM recommended storage condition, solderability of products out of recommended storage time period

may be degraded. It is strongly recommended to confirm solderability before using Products of which storage time is

exceeding the recommended storage time period.

3.

Store / transport cartons in the correct direction, which is indicated on a carton with a symbol. Otherwise bent leads

may occur due to excessive stress applied when dropping of a carton.

4.

Use Products within the specified time after opening a humidity barrier bag. Baking is required before using Products of

which storage time is exceeding the recommended storage time period.

Precaution for Product Label

QR code printed on ROHM Products label is for ROHM’s internal use only.

Precaution for Disposition

When disposing Products please dispose them properly using an authorized industry waste company.

Precaution for Foreign Exchange and Foreign Trade act

Since concerned goods might be fallen under listed items of export control prescribed by Foreign exchange and Foreign

trade act, please consult with ROHM in case of export.

Precaution Regarding Intellectual Property Rights

1.

All information and data including but not limited to application example contained in this document is for reference

only. ROHM does not warrant that foregoing information or data will not infringe any intellectual property rights or any

other rights of any third party regarding such information or data.

2.

ROHM shall not have any obligations where the claims, actions or demands arising from the combination of the

Products with other articles such as components, circuits, systems or external equipment (including software).

3.

No license, expressly or implied, is granted hereby under any intellectual property rights or other rights of ROHM or any

third parties with respect to the Products or the information contained in this document. Provided, however, that ROHM

will not assert its intellectual property rights or other rights against you or your customers to the extent necessary to

manufacture or sell products containing the Products, subject to the terms and conditions herein.

Other Precaution

1.

This document may not be reprinted or reproduced, in whole or in part, without prior written consent of ROHM.

2.

The Products may not be disassembled, converted, modified, reproduced or otherwise changed without prior written

consent of ROHM.

3.

In no event shall you use in any way whatsoever the Products and the related technical information contained in the

Products or this document for any military purposes, including but not limited to, the development of mass-destruction

weapons.

4.

The proper names of companies or products described in this document are trademarks or registered trademarks of

ROHM, its affiliated companies or third parties.

Notice-PGA-E

© 2015 ROHM Co., Ltd. All rights reserved.

Rev.001

�Datasheet

General Precaution

1. Before you use our Pro ducts, you are requested to care fully read this document and fully understand its contents.

ROHM shall n ot be in an y way responsible or liabl e for fa ilure, malfunction or acci dent arising from the use of a ny

ROHM’s Products against warning, caution or note contained in this document.

2. All information contained in this docume nt is current as of the issuing date and subj ect to change without any prior

notice. Before purchasing or using ROHM’s Products, please confirm the la test information with a ROHM sale s

representative.

3.

The information contained in this doc ument is provi ded on an “as is” basis and ROHM does not warrant that all

information contained in this document is accurate an d/or error-free. ROHM shall not be in an y way responsible or

liable for an y damages, expenses or losses incurred b y you or third parties resulting from inaccur acy or errors of or

concerning such information.

Notice – WE

© 2015 ROHM Co., Ltd. All rights reserved.

Rev.001

�