PRODUCT SPECIFICATION SHEET

Customer

Customer P/N

-

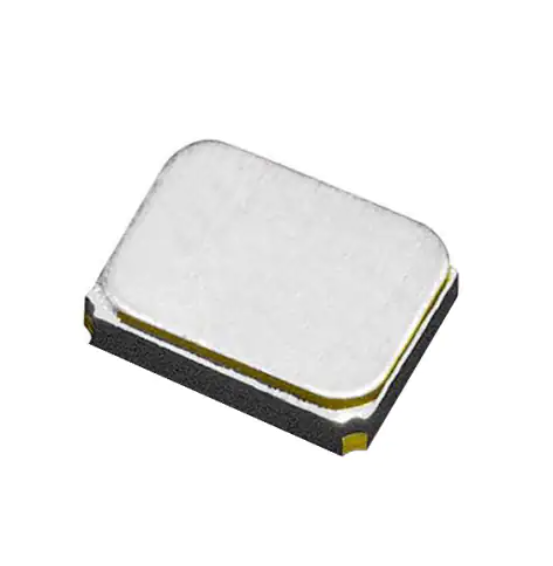

Product Type

Temperature Sensing Crystal

Part Number

1Z38400002

Part Description

Nominal Frequency

Prepared

Li Xiang

Reviewed

Kuro Peng

Approved

Xing Yue

Date

Version

B2

SMD TSX 1.6 x 1.2 (TH + Xtal)

38.4

Customer's Approval & Date:

2022-6-10

廣東惠倫晶體科技股份有限公司

中 国 广 东 省 东 莞 市 黄 江 镇 东 环 路 鸡 啼 岗 段 68 号

68 Donghuan Road, Jitigang Village, Huangjiang,

Dongguan, Guangdong Province, P. R. China

WEB : http://www.dgylec.com/

TEL : +86 ( 0 ) 769 - 38879888

FAX : +86 ( 0 ) 769 - 38879889

EMAIL : yl@dgylec.com

FAITH LONG CRYSTAL Proprietary and Confidential Information

RoHS

COMPLIANT

Pb

Lead-Free

Moisture Sensitivity Level 1

Page 1 of 14

�SMD TSX 1.6 x 1.2 (TH + Xtal)

PN: 1Z38400002

Ver.

B2

CONTENTS

#

Item

1

History of Specification Revision

3

2

Electrical Specifications

4

3

4

5

6

Page

2.1 Specifications for operation condition and electrical characteristics

4

2.2 Specifications for crystal drive level dependency (DLD)

5

2.3 Specifications for GPS quality

6

2.4 NTC thermistor specification table

7

Product Design

8

3.1 Package dimensions and pad functions

8

3.2 Recommended land pattern

8

3.3 Recommended reflow profile

8

3.4 Marking definition

9

3.5 Recommended reflow profile

9

3.6 Structure illustration

10

Reliability Assurance

11

4.1 Mechanical endurance

11

4.2 Environmental endurance

11

Taping and Packing

12

5.1 Tape and reel

12

5.2 Packing standard

13

Specification of the Environment-related Substances

FAITH LONG CRYSTAL Proprietary and Confidential Information

14

Page 2 of 14

�SMD TSX 1.6 x 1.2 (TH + Xtal)

PN:

1Z38400002

Ver.

B2

1. History of Specification Revision

Ver.

Content

Date

Reviser

Remark

A0

Initial released.

2017-5-10

N/A

K. Yasuda

A1

Add revision record sheet.

2018-4-10

P.2

K. Yasuda

A2

#3 Change reference temperature from 30℃

to 29℃.

2018-5-29

P.2

K. Yasuda

A3

Correct Suggested Reflow Profile.

2019-3-8

P.2

Chen XuanRu

A4

P.8 Delete Pressure Cooker Storage; P.10

Change packaging requirement; P.11 Change

Specification of the environment-related

substances.

2020-3-20

P.4 P.5

Chen XuanRu

B0

P.3 Change ESR, change item 20.

2020-7-22

P.3

Chen XuanRu

B1

Update marking

2021-10-13

P.2

May

B2

Add ESD & MSL

2022-6-10

P.2

Li Xiang

FAITH LONG CRYSTAL Proprietary and Confidential Information

Page 3 of 14

�SMD TSX 1.6 x 1.2 (TH + Xtal)

PN: 1Z38400002

Ver.

B2

2. Electrical Specifications

2.1 Specifications for operation condition and electrical characteristics

#

Parameter

Min.

Typ.

1

Nominal frequency

38.400000

2

Crystal cut type

AT-cut

3

Mode of vibration

Fundamental

4

ESD

HBM>2000V

5

MSL

Level 1

Load

capacitance

(C

)

6

8.0

L

7

Drive level

10

8

Operating temperature range

-30

9

Storage temperature range

-40

-

Max.

200

+105

+105

Unit

MHz

pF

mW

°C

°C

Remark

JESD22-A114-B

IPC/JEDEC J-STD-033C

Note 1.

10

Initial frequency tolerance

-10

-

+10

ppm

At 25±3°C, drive level

10mW

11

Frequency drift after reflow

-2.0

-

+2.0

ppm

After two times of reflow

12

Frequency tolerance over temperature

-12

-

+12

ppm

Within -30°C to +85°C.

Above +85°C see Note 2.

13

14

15

16

17

18

Frequency aging

Equivalent series resistance (ESR)

Insulation resistance

Quality factor (Q)

Spurious mode series resistance

Pullability

-0.7

500

75,000

1,100

7

-

+0.7

50

16

ppm/yr

Ω

MΩ

Ω

ppm/pF

Note 3.

Note 4.

Within ±1 MHz offset.

Specified at max drive

level.

𝐶2

𝑡 = 𝑡0 −

3𝐶3

19

Inflection point

27.5

-

30.5

°C

20

First-order curve fitting parameter (C1)

-0.4

-

-0.1

ppm/°C

Note 5.

21

Second-order curve fitting parameter

(C2)

-4.5

0

+4.5

x10-4

ppm/°C2

Note 5.

22

Third-order curve fitting parameter (C3)

+8.5

+10.0

+11.5

x10

3

ppm/°C

-5

Note 5.

Note 1

Note 2

Note 3

The load capacitance is measured according to IEC Standard #60444-8.

Above 85°C, the frequency tolerance over temperature is bound by the third order coefficient range.

The ESR max is specified at max drive level minimum Q, drives a smaller ESR; that is, design the crystal to the

minimum Q.

Note 4

Note 5

The minimum Q value calculated from ESR and L is smaller than this specification.

The curve fitting parameter is obtained from the QTI crystal curve fitting algorithm, using the temperature

inflection point t0 = 24.5°C (option A), or t0 = 27.5°C (option B). Refer to Curve Fit Calculation Table

Spreadsheet (80-V9695-23).

FAITH LONG CRYSTAL Proprietary and Confidential Information

Page 4 of 14

�SMD TSX 1.6 x 1.2 (TH + Xtal)

PN: 1Z38400002

Ver.

B2

2. Electrical Specifications (Cont.)

2.2 Specifications for crystal drive level dependency (DLD)

#

Parameter

Min.

1

Drive level measurement condition

0.01

Typ.

Max.

Unit

Remarks

-

250

mW

Drive level from 0.01 μW

to 250 μW to 0.01 μW

2

Number of points

3

DLD Frequency (Maximum - Minimum)

-

-

6

ppm

Define as FDLD.

Note 6.

4

DLD Frequency (Repeatability)

-

-

0.7

ppm

Define as FDLDH.

Note 7.

5

DLD ESR (Maximum)

-

-

20

%

Define as RLD2.

Note 8.

6

DLD ESR (Repeatability)

-

-

10

%

Define as DLDH3.

Note 7 and Note 9.

Note 6

Note 7

Note 8

Note 9

Note 10

Note 11

29

points

15 points up and 15

points down = 29 total

data points.

Maximum - minimum: Difference between the maximum and minimum in a two-way measurement.

Repeatability of the two-way measurement is defined in the above Drive level measurement condition.

Maximum: ESR at 250 μW drive level is 30 Ω.

For DLD ESR (Repeatability), the change rate is defined as (ESR2 - ESR1)/ESR1.

ESR1: This is the first measurement on each drive level.

ESR2: This is the second measurement on each drive level.

FAITH LONG CRYSTAL Proprietary and Confidential Information

Page 5 of 14

�SMD TSX 1.6 x 1.2 (TH + Xtal)

PN: 1Z38400002

Ver.

B2

2. Electrical Specifications (Cont.)

2.3 Specifications for GPS quality

#

Parameter

1

Min.

Drive level measurement condition

Typ.

Max.

250

Unit

Remarks

mW

All measurements in GPS

quality are taken at 250 μ

W drive level.

2

Residual frequency stability slope 1

-100

-

+100

ppb/°C

Within -30°C to -15°C.

Note 13 and Note 14

(Condition 1A).

3

Residual frequency stability slope 2

-50

-

+50

ppb/°C

Within -15°C to +70°C.

Note 13 and Note 14

(Condition 1A).

4

Residual frequency stability slope 3

-100

-

+100

ppb/°C

Within +70°C to +85°C.

Note 13 and Note 14

(Condition 1A).

5

5°C small orbit hysteresis 1-1

-100

-

+100

ppb/°C

Within -30°C to -15°C.

Note 15 (Condition 1B).

6

5°C small orbit hysteresis 1-2

-50

-

+50

ppb/°C

Within -15°C to +70°C.

Note 15 (Condition 1B).

7

5°C small orbit hysteresis 1-3

-100

-

+100

ppb/°C

Within +70°C to +85°C.

Note 15 (Condition 1B).

8

5°C small orbit hysteresis 2

100 (magnitude)

ppb pk-pk

Note 16.

Note 13

Note 14

Residual = difference from fifth-order curve fit. Must meet below 1A (Note 14) and 1B (Note 15) conditions:

Condition 1A – Test condition (continuous temperature rate change of ~1.0°C/min.):

Measure F/T points every 1°C, heating up from -30 to +85°C, subtract a fifth-order polynomial best fit

and then calculate the slope of the residual.

Note 15

Condition 1B – Hysteresis 1 test condition (continuous temperature rate change of ~1.0°C/minute):

Measure F/T points every 0.5°C while cycling temperature over a 5°C small temperature orbit; an

example 5°C small orbit temperature cycle is +30°C to +35°C to +30°C.

During every individual heating/cooling cycle, there should be 11 points. Discard the first point of each

heating and cooling cycle. This leaves 10 points for each heating and cooling cycle. Subtract the fifthorder polynomial best fit from 1A for each of the 10 points, and then calculate the slope of the residual

for each of these heating and cooling 10 point curves.

Note 16

Hysteresis 2 test condition (continuous temperature rate change of ~1.0°C/min.):

Measure F/T points every 0.5°C while cycling temperature over a 5°C small temperature orbit; an

example 5°C small orbit temperature cycle is +30°C to +35°C to +30°C.

During every individual heating/cooling cycle there should be 11 points; discard the first and last point

of each heating and cooling cycle, which results in 9 temperature points. Calculate the average

measured peak-to-peak frequency difference for these 9 temperature points.

The average difference is the magnitude of the small orbit hysteresis 2.

FAITH LONG CRYSTAL Proprietary and Confidential Information

Page 6 of 14

�SMD TSX 1.6 x 1.2 (TH + Xtal)

PN: 1Z38400002

Ver.

B2

2. Electrical Specifications (Cont.)

2.4 NTC thermistor specification table

#

Parameter

1

Operating temperature range

2

Storage temperature range

3

Resistance

4

B-constant

5

Tolerance

Min.

-30

-40

-

FAITH LONG CRYSTAL Proprietary and Confidential Information

Typ.

100

4,250

-

Max.

+105

+105

1

Unit

°C

°C

kΩ

K

%

Remarks

At 25°C

At 25°C - 50°C

Page 7 of 14

�PN: 1Z38400002

SMD TSX 1.6 x 1.2 (TH + Xtal)

Ver.

B2

3. Product Design

3.1 Package dimensions and pad functions

Top view

(Unit : mm)

3.2 Pad connection diagram and function

Bottom view

1.6± 0.1

0.1

1.6±

#3

#1

#2

#1

#2

#4

#3

1.2± 0.1

#4

0.22

0.65 Max.

Lateral view

Bottom view

Pad

1

2

3

4

Function

Xtal in

Thermistor out, connecting to ground

Xtal out

Thermistor in

#1

#2

#4

#3

0.3

0.1

0.15

1.01

3.3 Recommended land pattern

(Unit : mm)

FAITH LONG CRYSTAL Proprietary and Confidential Information

Page 8 of 14

�PN: 1Z38400002

SMD TSX 1.6 x 1.2 (TH + Xtal)

Ver.

B2

3. Product Design (Cont.)

3.4 Marking definition

Frequency

EX: 38.400MHz = 384

YL

lot (2 digits)

year month code

Administrative Symbo

Table of Year and Month code

Month

JAN FEB

Year

2021

2022

2023

2024

2025

2026

2027

2028

A

N

a

n

B

P

b

p

MAR

APR

MAY

JUN

JUL

AUG

SEP

OCT

NOV

DEC

C

Q

c

q

D

R

d

r

E

S

e

s

F

T

f

t

G

U

g

u

H

V

h

v

J

W

j

w

K

X

k

x

L

Y

l

y

M

Z

m

z

3.5 Recommended reflow profile

10 sec. Max.

Temp.

(1) Total time : 360 sec. Max.

(2) Solder melting point : 225℃

260 5

220

60 sec. Max.

180

150

120 sec. Max.

Time (sec.)

FAITH LONG CRYSTAL Proprietary and Confidential Information

Page 9 of 14

�SMD TSX 1.6 x 1.2 (TH + Xtal)

PN: 1Z38400002

Ver.

B2

3. Product Design (Cont.)

3.6 Structure illustration

#

1

Components

Cap (Lid)

2

Base (Package)

3

4

5

6

Pad (Package)

Crystal blank

Electrode

Conductive adhesive

7

Thermistor

8

Solder

Materials

Kovar (Fe + Co + Ni)

Ceramic (AI2O3) +

Kovar (Fe + Co + Ni)

Ni + Au

SiO2

Cr + Nobel material

Ag

Alumina Ceramics

(Al2O3), Ni + Ag+ Sn

QTY

1

Finish/Specifications

Ni plating

1

Alumina ceramics

4

1

2

2

Tungsten metalization + Ni plating + Au plating

-

1

-

Sn + Ag + Cu

2

-

FAITH LONG CRYSTAL Proprietary and Confidential Information

Silicone resin

Page 10 of 14

�SMD TSX 1.6 x 1.2 (TH + Xtal)

PN: 1Z38400002

Ver.

B2

4. Reliability Assurance

4.1 Mechanical endurance

#

Item

Test Condition

Reference

1

Drop test

150 cm height, fall freely onto stainless plate, 3 times.

JIS C6701

2

Shock test

150 g weight, 150 cm height onto concrete floor.

Each direction (±x, ±y, ±z) for 3 cycles.

IEC-68-02-27

3

Mechanical shock

Half sine wave 1000 G. Three mutually perpendicular

axes, each axis for 3 times. Duration time 1.0ms.

MIL-STD-202F

4

Vibration

10 to 55 Hz 0.75mm, 55 to 2000Hz 20G, 4 hours to each

three axis (x, y, z). Total test time 6 hours.

MIL-STD-883E

5

Gross Leak

Standard sample for automatic gross leak detector.

Test pressure: 2kg /cm2.

MIL-STD-883E

6

Fine Leak

Helium bombing 4.5 kgf/cm for 2 hours.

Solderability

Temperature : 260°C ± 5°C

Immersing depth : 0.5 mm minimum

Immersion time : 5 ± 1 seconds

Flux : Rosin resin methyl alcohol solvent (1:4)

7

*Storage conditions :18 months

4.2 Environmental endurance

#

Item

2

MIL-STD-883E

GB/T 2424.17-2008

/ IEC 60068-244:1995;GB/T

2423.28-2005 / IEC

60068-2-20:1979

*Constant humidity :40~70%

Test Condition

Reference

1

High temperature storage

Temperature : +125°C ± 3°C

Duration : 500 ± 12 hours

MIL-STD-883E

2

Low temperature storage

Temperature : -40°C ± 3°C

Duration : 500 ± 12 hours

MIL-STD-883E

Total 100 cycles of the following temperature cycle

1 cycle

3

Thermal shock

(Air to Air)

125 ± 3 oC

MIL-STD-883E

25 oC

-40 ± 3 oC

10 min.

10 min.

10 min. max.

4

High temperature &

humidity

Temperature : 85°C ± 3°C

Humidity : RH 85%

Duration : 500 hours

FAITH LONG CRYSTAL Proprietary and Confidential Information

JIS C5023

Page 11 of 14

�SMD TSX 1.6 x 1.2 (TH + Xtal)

PN: 1Z38400002

Ver.

B2

5. Taping and Packing

5.1 Tape and reel (EIA-481-2)

Direction of feed

Index mark

Direction of products

Carrier tape

Reel

Cover tape

Reel label (Model, Qty, Lot, ...)

Package Type

Dimension (Unit : mm)

A0

B0

1.45±0.1

1.85±0.1

1612 TSX (8mm)

P1

P2

4.00±0.1

2.00±0.1

Standard Reel Quantity is 3000 pcs per reel.

The inspection standard of tape tension

Item

K0

0.8±0.10

D1

1.20±0.1

T

0.25±0.05

D0

1.55±0.05

W

8.00±0.3

P0

4.00±0.1

E

1.75±0.1

Defect

Method

F

3.50±0.1

Appearance

All

1. The tape is not coincidence

2. The bubble

Visual inspection

Tape tension

1612 - 8mm

Overstep 34±6g (28 to 40g)

Pull test

FAITH LONG CRYSTAL Proprietary and Confidential Information

Page 12 of 14

�SMD TSX 1.6 x 1.2 (TH + Xtal)

PN: 1Z38400002

Ver.

B2

5. Taping and Packing (Cont.)

5.2 Packing standard

Out-going packing instruction

Reel packing

Name:Reel

Standard:Diameter 18cm

Material:Plastics

Name:Anti-static shielding bag

Standard:205250mm

Material:APET/CPP

Inner packing

Name:Bubble wrap

Standard:430330(t)20mm

Material:HDPE

Quantity : Max.15 reels

Carton

Name:Carton

Standard:400400(H)280mm

Material:AB corrugated paper

Quantity:4 bags

L1

L2

The label information

Label

Label Drawing

Name of Article

Spec.

L1

条码标签

Bar Code Label

(Chintz Paper)

1. Part No.

2. Lot No.

3. Q'ty

4. Freq.

7050mm

White

L2

条码标签

Bar Code Label

(Chintz Paper)

1. Part No.

2. Date Code

3. Q'ty

4. Freq.

7050mm

White

Remark:

Label size

Printing

Specifications on the label is for default templates purpose and may change with different product.

If any specified requirements for labels packaging is needed, please provide the instruction information.

FAITH LONG CRYSTAL Proprietary and Confidential Information

Page 13 of 14

�SMD TSX 1.6 x 1.2 (TH + Xtal)

PN: 1Z38400002

Ver.

B2

6. Specification of the Environment-related Substances

#

Range

Banned Substances

Max. concentration (ppm; mg/kg)

Product

Packing

1

镉及镉化合物

Cadmium and cadmium compounds

100

100

2

铅及铅化合物

Lead and lead compounds

1000

100

3

汞及汞化合物

Mercury and mercury compounds

1000

100

4

六价铬化合物

+6

Hexavalent-Chromium VI (Cr )

1000

100

5

聚溴联苯 PBB

Polybrominated biphenyls

1000

N/A

6

聚溴二苯醚 PBDE

Polybrominated diphenyl ethers

1000

N/A

7

邻苯二甲酸二(2-乙基己基)酯 DEHP

Di (2-ethylhexyl) phthalate

1000

N/A

8

邻苯二甲酸丁苄酯 BBP

Butyl Benzyl Phthalate

1000

N/A

9

邻苯二甲酸二丁酯 DBP

Dibutyl Phthalate

1000

N/A

10

邻苯二甲酸二异丁酯 DIBP

Diisobutyl Phthalate

1000

N/A

11

氟(F)、氯(Cl)、溴(Br)、碘(I)

Fluorine, Chlorine, Bromine, Iodine

900、900、900、900

注:Br + Cl<1000

N/A

12

包装材料中重金属(汞、镉、六价铬、

铅、PBB、PBDE)之总量

Heavy metals (mercury, cadmium, lead,

Cr+6,PBB and PBDE) in packing materials

N/A

100

铅(Pb) + 镉(Cd) + 汞(Hg) + 六价

铬(Cr+6)

很抱歉,暂时无法提供与“1Z38400002”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格

- 1+1.33200

- 30+1.28700

- 100+1.24200

- 500+1.15200

- 1000+1.10700

- 2000+1.08000