Product

Folder

Order

Now

Technical

Documents

Support &

Community

Tools &

Software

Reference

Design

TL4242-Q1

SLVS732G – JULY 2010 – REVISED APRIL 2017

TL4242-Q1 Adjustable LED Driver

1 Features

3 Description

•

•

The TL4242-Q1 device is an integrated adjustable

constant-current source, driving loads up to 500 mA.

One can adjust the output current level through an

external resistor. The device design is for supplying

high-power LEDs (for example, OSRAM Dragon LA

W57B) under the severe conditions of automotive

applications, resulting in constant brightness and

extended LED lifetime. The device comes in the DRJ

(WSON) and KTT (TO-263) package. Protection

circuits prevent damage to the device in case of

overload, short-circuit, reverse polarity, and overheat.

The device provides the connected LEDs protection

against reverse polarity as well as excess voltages up

to 45 V.

1

•

•

•

•

•

•

•

Qualified for Automotive Applications

AEC-Q100 Test Guidance With the Following

Results:

– Device Temperature Grade 2: –40°C to 105°C

Ambient Operating Temperature Range for

WSON package

– Device Temperature Grade 1: –40°C to 125°C

Ambient Operating Temperature Range for

TO-263 package

– Device HBM ESD Classification Level H1C

– Device CDM ESD Classification Level C3B

Adjustable Constant Current up to 500 mA (±5%)

Wide Input-Voltage Range up to 42 V

Low Dropout Voltage

Open-Load Detection

Overtemperature Protection

Short-Circuit Proof

Reverse-Polarity Proof

2 Applications

The integrated PWM input of the TL4242-Q1 device

permits LED brightness regulation by pulse-width

modulation (PWM). The high-input impedance of the

PWM input allows operating the LED driver as a

protected high-side switch.

Device Information(1)

PART NUMBER

TL4242-Q1

Automotive LED Lighting Applications Including:

•

•

•

•

•

•

Rear Light

Daytime Running Light

Fog Light

Position Light

Interior Light

Stop or Tail Light

PACKAGE

BODY SIZE (NOM)

TO-263 (7)

10.00 mm × 9.25 mm

WSON (8)

4.00 mm × 4.00 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Typical Application Schematic

4.5-42 V Input

PWM

MCU

Status

PWM

I

ST

NC

GND

Q

REF

D

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�TL4242-Q1

SLVS732G – JULY 2010 – REVISED APRIL 2017

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

4

5

6.1

6.2

6.3

6.4

6.5

6.6

5

5

5

6

6

7

Absolute Maximum Ratings ......................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Typical Characteristics .............................................

Detailed Description .............................................. 8

7.1 Overview ................................................................... 8

7.2 Functional Block Diagram ......................................... 8

7.3 Feature Description................................................... 8

7.4 Device Functional Modes.......................................... 9

8

Application and Implementation ........................ 10

8.1 Application Information............................................ 10

8.2 Typical Applications ................................................ 10

9 Power Supply Recommendations...................... 14

10 Layout................................................................... 14

10.1 Layout Guidelines ................................................. 14

10.2 Layout Example .................................................... 14

10.3 Thermal Considerations ........................................ 15

11 Device and Documentation Support ................. 16

11.1

11.2

11.3

11.4

11.5

Receiving Notification of Documentation Updates

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

16

16

16

16

16

12 Mechanical, Packaging, and Orderable

Information ........................................................... 16

4 Revision History

Changes from Revision F (January 2015) to Revision G

Page

•

Changed the pinout drawings................................................................................................................................................. 4

•

Changed all occurrences in the data sheet of QFN and SFM to WSON and TO-263, respectively...................................... 4

•

Changed format of Pin Functions table .................................................................................................................................. 4

•

Changed the condition statement for the Electrical Characteristics table .............................................................................. 6

•

Added layout diagram for the TO-263 package ................................................................................................................... 15

•

Added Receiving Notification of Documentation Updates and Community Resources sections to the data sheet............. 16

Changes from Revision E (July 2013) to Revision F

•

Added Pin Configuration and Functions section, ESD Ratings table, Feature Description section, Device Functional

Modes, Application and Implementation section, Power Supply Recommendations section, Layout section, Device

and Documentation Support section, and Mechanical, Packaging, and Orderable Information section .............................. 1

Changes from Revision D (May 2013) to Revision E

•

Page

Added new graph to Typical Characteristics .......................................................................................................................... 7

Changes from Revision C (October 2012) to Revision D

•

Page

Page

Changed minimum storage temperature to –55ºC ................................................................................................................. 5

Changes from Revision B (September 2012) to Revision C

Page

•

Added Stoplight and Taillight Application section................................................................................................................. 12

•

Added Thermal Considerations section................................................................................................................................ 15

•

Added PCB Design Guideline section .................................................................................................................................. 15

2

Submit Documentation Feedback

Copyright © 2010–2017, Texas Instruments Incorporated

Product Folder Links: TL4242-Q1

�TL4242-Q1

www.ti.com

SLVS732G – JULY 2010 – REVISED APRIL 2017

Changes from Revision A (August, 2012) to Revision B

•

Page

Manually appended mechanical data, thermal pad data, and package option addendum .................................................. 11

Submit Documentation Feedback

Copyright © 2010–2017, Texas Instruments Incorporated

Product Folder Links: TL4242-Q1

3

�TL4242-Q1

SLVS732G – JULY 2010 – REVISED APRIL 2017

www.ti.com

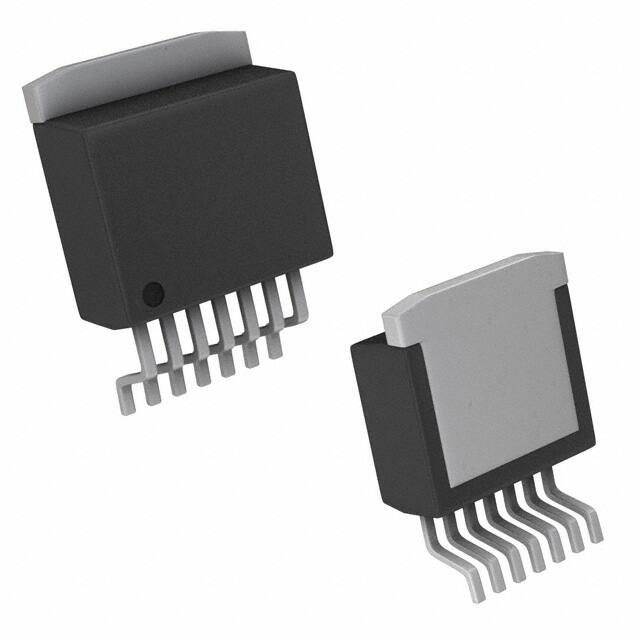

5 Pin Configuration and Functions

DRJ Package

8-Pin WSON With Exposed Thermal Pad

Top View

KTT Package

7-Pin TO-263 With Exposed Thermal Pad

Top View

Not to scale

PWM

1

ST

2

GND

3

REF

4

Thermal

Pad

8

I

7

NC

6

Q

5

D

1

2

3

4

5

6

7

I

PWM

ST

GND

REF

D

Q

Not to scale

Pin Functions

PIN

NAME

4

NO.

I/O

DRJ

KTT

D

5

6

I

GND

3

4

—

I

8

1

I

DESCRIPTION

Status delay. To set status reaction delay, connect to GND with a capacitor. For no

delay, leave open.

Ground

Input. Connect directly to GND as close as possible to the device with a 100-nF ceramic

capacitor.

NC

7

—

—

PWM

1

2

I

No internal connection

Pulse-width modulation input. If not used, connect to the I pin.

Q

6

7

O

Output

REF

4

5

I

Reference input. Connect to a shunt resistor.

ST

2

3

O

Status output. Open-collector output. Connect to an external pullup resistor (RPULLUP ≥

4.7 kΩ).

Thermal pad

—

—

—

Solder the thermal pad directly to the PCB. Connect to ground or leave floating.

Submit Documentation Feedback

Copyright © 2010–2017, Texas Instruments Incorporated

Product Folder Links: TL4242-Q1

�TL4242-Q1

www.ti.com

SLVS732G – JULY 2010 – REVISED APRIL 2017

6 Specifications

6.1 Absolute Maximum Ratings

over operating ambient temperature range (unless otherwise noted) (1)

Supply voltage (2), VCC

Input voltage, VI

Output voltage, VO

Output current, IO

MIN

MAX

UNIT

–42

45

V

D

–0.3

7

PWM

–40

40

REF

–1

16

Q

–1

41

ST

–0.3

40

PWM

±1

REF

±2

ST

±5

V

V

mA

Virtual-junction temperature, TJ

–40

150

°C

Storage temperature, Tstg

–55

150

°C

(1)

(2)

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under Recommended Operating

Conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

All voltage values are with respect to the network ground terminal.

6.2 ESD Ratings

VALUE

UNIT

DRJ Package

Human body model (HBM), per AEC Q100-002 (1)

V(ESD)

Electrostatic discharge

Charged device model (CDM), per

AEC Q100-011

±1500

Corner pins (1, 4, 5, and 8)

±1000

Other pins

±1000

Machine model (MM) AEC-Q100 Classification Level M3

±200

Human body model (HBM), per AEC Q100-002 (1)

±1500

V

KTT Package

V(ESD)

Electrostatic discharge

Charged device model (CDM), per

AEC Q100-011

Corner pins (1 and 7)

±1000

Other pins

±1000

Machine model (MM) AEC-Q100 Classification Level M3

(1)

V

±200

AEC Q100-002 indicates HBM stressing is done in accordance with the ANSI/ESDA/JEDEC JS-001 specification.

6.3 Recommended Operating Conditions

MIN

MAX

4.5

42

UNIT

V

16

V

VCC

Supply voltage

VST

Status (ST) output voltage

VPWM

PWM voltage

0

40

V

CD

Status delay (D) capacitance

0

2.2

μF

RREF

Reference (REF) resistor

Ω

TA

Operating ambient temperature

TJ

Operating junction temperature

0

10

WSON

–40

105

TO-263

–40

125

–40

150

Submit Documentation Feedback

Copyright © 2010–2017, Texas Instruments Incorporated

Product Folder Links: TL4242-Q1

°C

°C

5

�TL4242-Q1

SLVS732G – JULY 2010 – REVISED APRIL 2017

www.ti.com

6.4 Thermal Information

TL4242-Q1

THERMAL METRIC

(1)

DRJ (WSON)

KTT (TO263)

8 PINS

7 PINS

UNIT

RθJA

Junction-to-ambient thermal resistance

39

31.6

°C/W

RθJCtop

Junction-to-case (top) thermal resistance

31.5

34.7

°C/W

RθJB

Junction-to-board thermal resistance

15.5

8.2

°C/W

ψJT

Junction-to-top characterization parameter

0.3

0.7

°C/W

ψJB

Junction-to-board characterization parameter

15.6

8.2

°C/W

RθJCbot

Junction-to-case (bottom) thermal resistance

1.8

0.7

°C/W

(1)

For more information about traditional and new thermal metrics, see Semiconductor and IC Package Thermal Metrics

6.5 Electrical Characteristics

over recommended operating ambient temperature range, VI = 13.5 V, RREF = 0.47 Ω, VPWM,H, TJ = –40°C to 150°C, all

voltages with respect to ground (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

OVERALL DEVICE

IqL

Supply current

VQ = 6.6 V

12

22

mA

IqOFF

Supply current, off mode

PWM = L, TJ < 85°C

0.1

2

μA

357

376

395

VQ – VREF = 6.6 V, RREF = 1 Ω

168

177

185

VQ – VREF = 6.6 V, RREF = 0.39 Ω

431

454

476

VQ – VREF = 5.4 V to 7.8 V, VI = 9 V

to 16 V

357

376

395

OUTPUT

VQ – VREF

IQ

Output current

(1)

= 6.6 V

IQmax

Output current limit

RREF = 0 Ω

600

Vdr

Drop voltage

IQ = 300 mA

0.35

mA

mA

0.7

V

PWM INPUT

VPWM,H

High-level PWM voltage

VPWM,L

Low-level PWM voltage

2.6

IPWM,H

High-level PWM input current

VPWM = 5 V

IPWM,L

Low-level PWM input current

VPWM = 0 V

tPWM,ON

Delay time, turnon

70% of IQnom, see Figure 7

tPWM,OFF

Delay time, turnoff

30% of IQnom, see Figure 7

V

0.7

V

220

500

μA

1

μA

0

15

40

μs

0

15

40

μs

–1

REFERENCE (REF)

VREF

Reference voltage

RREF = 0.39 Ω to 1 Ω

168

177

185

mV

IREF

Reference input current

VREF = 180 mV

–1

0.1

1

μA

15

25

STATUS OUTPUT (ST)

VIQL

Lower status-switching threshold

ST = L

VIQH

Upper status-switching threshold

ST = H

VSTL

Low-level status voltage

IST = 1.5 mA

ISTLK

Leakage current

VST = 5 V

30

mV

40

mV

0.4

V

5

μA

10

14

ms

10

20

μs

STATUS DELAY (D)

tSTHL

Delay time, status reaction

CD = 47 nF, ST H→L

tSTLH

Delay time, status release

CD = 47 nF, ST L→H

(1)

6

6

VQ – VREF equals the forward voltage sum of the connected LEDs (see Typical Application Schematic).

Submit Documentation Feedback

Copyright © 2010–2017, Texas Instruments Incorporated

Product Folder Links: TL4242-Q1

�TL4242-Q1

www.ti.com

SLVS732G – JULY 2010 – REVISED APRIL 2017

6.6 Typical Characteristics

450

700

400

600

350

300

Output Current (mA)

Output Current (mA)

500

400

300

250

200

150

100

200

50

100

0

0

0.00

±50

0.25

0.50

0.75

1.00

1.25

1.50

1.75

2.00

0

2.25

5

10

External Reference (

15

20

25

30

C001

40

C002

Figure 1. Output Current vs External Resistance

Figure 2. Output Current vs Supply Voltage

178.5

60

50

178.0

40

177.5

PWM Current ( A)

Reference Voltage (mV)

35

Supply Voltage (V)

177.0

30

20

176.5

10

176.0

0

175.5

±10

±40

±20

0

20

40

60

80

100

120

140

0

10

Virtual Junction Temperature ( C)

20

30

40

PWM Voltage (V)

C003

C004

Figure 3. Reference Voltage vs Junction Temperature

Figure 4. PWM Pin Input Current vs PWM Voltage

250

ST Pin Voltage (mV)

200

150

100

50

0

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

Pulldown Current (mA)

C005

Figure 5. ST Pin Voltage vs ST Pin Pulldown Current

Submit Documentation Feedback

Copyright © 2010–2017, Texas Instruments Incorporated

Product Folder Links: TL4242-Q1

7

�TL4242-Q1

SLVS732G – JULY 2010 – REVISED APRIL 2017

www.ti.com

7 Detailed Description

7.1 Overview

The TL4242-Q1 device is an integrated adjustable constant-current source, driving loads up to 500 mA. The

current can be set by an external resistor. And the load current can be modulated by a PWM input. The TL4242Q1 device integrates protections such as open load, overtemperature, and reverse polarity.

7.2 Functional Block Diagram

I

PWM

6

8

1

Q

Bias Supply

+

−

Bandgap

Reference

4

REF

Comparator

2

ST

Status

Delay

3

GND

5

D

7.3 Feature Description

The TL4242-Q1 device is an integrated adjustable constant-current source driving loads up to 500 mA. The

TL4242-Q1 device is qualified for automotive applications. The output current level can be adjusted via an

external resistor. Protection circuits prevent damage to the device in case of overload, short-circuit, reverse

polarity, and overtemperature. The connected LEDs are protected against reverse polarity as well as

overvoltages up to 45 V. The integrated PWM input of the TL4242-Q1 device permits LED brightness regulation

by pulse-width modulation. Due to the high input impedance of the PWM input, the LED driver can be operated

as a protected high-side switch.

The external shunt resistor in the ground path of the connected LEDs senses the LED current. A regulation loop

holds the voltage drop at the shunt resistor at a constant level of 177 mV (typical). The selection of the shunt

resistance, RREF, sets the constant-current level. Calculate the typical output current using Equation 1:

V

IQ,typ = REF

RREF

(1)

where VREF is the reference voltage (typically 177 mV) (see Electrical Characteristics). The equation applies for

RREF = 0.39 Ω to 10 Ω.

The output current is shown as a function of the reference resistance in Equation 1. With the PWM input, one

can regulate the LED brightness through the duty cycle. Also, PWM = L sets the TL4242-Q1 device in sleep

mode, resulting in a very low current consumption of < 1 μA (typical). The high impedance of the PWM input (see

Figure 4) permits the use of the PWM pin as an enable input.

8

Submit Documentation Feedback

Copyright © 2010–2017, Texas Instruments Incorporated

Product Folder Links: TL4242-Q1

�TL4242-Q1

www.ti.com

SLVS732G – JULY 2010 – REVISED APRIL 2017

7.4 Device Functional Modes

7.4.1 Pulse-Width Modulation (PWM)

In general applications, PWM can be used to control the TL4242-Q1 device as a high-side driver. High level

enables the device. Low level disables the device. In LED lighting, PWM input provides a convenient way to

control the brightness of the LED load. Due to the high input impedance of the PWM input, the LED driver can be

operated as a protected high-side switch.

7.4.2 Status Output (ST)

The ST pin is an open-collector output. Connect the pin to an external pullup resistor (RPULLUP ≥ 4.7 kΩ). This

output provides information of open-load and overtemperature faults.

7.4.3 Reference (REF)

REF is used to set load current. In applications, the load current is sensed by a resistor in series with the load.

The voltage on the REF pin is regulated at 177 mV during normal operation. Therefore, the current of the load is

determined by VREF / RSENSE.

Submit Documentation Feedback

Copyright © 2010–2017, Texas Instruments Incorporated

Product Folder Links: TL4242-Q1

9

�TL4242-Q1

SLVS732G – JULY 2010 – REVISED APRIL 2017

www.ti.com

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

8.1 Application Information

The TL4242-Q1 device is usually used in the automotive lighting applications. A microcontroller is usually used to

generate PWM waveform to dimming the LED.

8.2 Typical Applications

8.2.1 Application Circuit

Figure 6 shows a typical application with the TL4242-Q1 LED driver. A supply current adjusted by the RREF

resistor drives the three LEDs, preventing brightness variations due to forward voltage spread of the LEDs. An

appropriate duty cycle applied to the PWM pin can compensate through software for the luminosity spread

arising from the LED production process. Therefore, it is not necessary to select LEDs for forward voltage or

luminosity classes. The minimum supply voltage should be equal to or greater than the sum of the LED forward

voltages, the TL4242-Q1 drop voltage (maximum 0.7 V at an LED current of 300 mA), and the maximum voltage

drop at the shunt resistor RREF of 185 mV.

VBAT

I

RO

SI

Microcontroller

Q

RADJ

GND

10 µF

D

10 kΩ

100 nF

PWM

ST

I

Q

TL4242-Q1

REF

GND

LED

Dragon

D

47 nF

0.47 Ω

0.25 W

RREF

Figure 6. Application Circuit

8.2.1.1 Design Requirements

10

DESIGN PARAMETER

EXAMPLE VALUE

RREF

0.47 Ω

Submit Documentation Feedback

Copyright © 2010–2017, Texas Instruments Incorporated

Product Folder Links: TL4242-Q1

�TL4242-Q1

www.ti.com

SLVS732G – JULY 2010 – REVISED APRIL 2017

8.2.1.2 Detailed Design Procedure

The status output of the LED driver (ST) detects an open-load condition, enabling supervision of correct LED

operation. A voltage drop at the shunt resistor (RREF) below 25 mV (typical) detects an LED failure. In this case,

the status output pin (ST) goes low after a delay time adjustable by an optional capacitor connected to pin D.

Figure 7 shows the functionality and timing of ST and PWM. One can adjust the status delay through the

capacitor connected to pin D. Delay time scales linearly with the capacitance, CD:

CD

t STHL,typ +

10 ms

47 nF

(2)

CD

t STLH,typ +

10 ms

47 nF

(3)

Open

Load

VPWM

Open

Load

VPWM,H

VPWM,L

IQ

t

tPWM,ON

tPWM,OFF

IQ,nom

70%

30%

t

VD

tSTHL

VLD

t

VST

t

Figure 7. Function and Timing Diagram

Submit Documentation Feedback

Copyright © 2010–2017, Texas Instruments Incorporated

Product Folder Links: TL4242-Q1

11

�TL4242-Q1

SLVS732G – JULY 2010 – REVISED APRIL 2017

www.ti.com

8.2.1.3 Application Curves

Figure 8. Start-Up Waveform

Figure 9. 50% Duty Cycle Waveform

8.2.2 Stoplight and Taillight Application

For many automobiles, the same set of LEDs illuminates both taillights and stop lights. Thus, the LEDs must

operate at two different brightness levels, full brightness for the stoplight and 10% to 25% brightness for the

taillight. The easiest way to achieve the different brightness is dimming by pulse-width modulation (PWM), which

holds the color spectrum of the LED over its whole brightness range. The maximum current that passes through

the LED is programmable by sense resistor RREF.

TL4242-Q1

Q

STOP

PWM

REF

Vin

TAIL

LED

Dragon

TLC555-Q1

VDD

OUT

RREF

Figure 10. Stoplight and Taillight Application Circuit

8.2.2.1 Design Requirements

DESIGN PARAMETER

EXAMPLE VALUE

RREF

1Ω

8.2.2.2 Detailed Design Procedure

Obtain the maximum current, IQmax, that passes through the LEDs by Equation 4:

VREF

I Qmax =

R REF

(4)

For example, if RREF equals 1 Ω, as VREF is a fixed value range from 168 mV to 185 mV, IQmax should be 168 mA

to 185 mA.

Figure 10 shows the application circuit of the stoplight and taillight including an automotive-qualified timer,

TLC555-Q1, the duty cycle of which is programmable by two external resistors. One can see that driving the

STOP signal high pulls the PWM pin constantly high, creating 100% duty cycle. Thus the LEDs operate at full

brightness. When the TAIL signal is high, the LEDs operate at 25% brightness because the TLC555-Q1 timer is

programmed at a fixed duty cycle of 25%.

12

Submit Documentation Feedback

Copyright © 2010–2017, Texas Instruments Incorporated

Product Folder Links: TL4242-Q1

�TL4242-Q1

www.ti.com

SLVS732G – JULY 2010 – REVISED APRIL 2017

8.2.2.3 Application Curves

Figure 11. Stoplight Waveform

Figure 12. Taillight Waveform

Submit Documentation Feedback

Copyright © 2010–2017, Texas Instruments Incorporated

Product Folder Links: TL4242-Q1

13

�TL4242-Q1

SLVS732G – JULY 2010 – REVISED APRIL 2017

www.ti.com

9 Power Supply Recommendations

It is recommended to put a 4.7-µF ceramic capacitor on the input pin. Also a 0.1-µF bypass capacitor can be put

at input pin for noise filtering. Input voltage should be between 4.5 V and 42 V.

10 Layout

10.1 Layout Guidelines

In order to prevent thermal shutdown, TJ must be less than 150ºC. If the input voltage is very high, the power

dissipation might be large. Currently there is the KTT (TO-263) package which has good thermal impedance, but

at the same time, the PCB layout is also very important. Good PCB design can optimize heat transfer, which is

absolutely essential for the long-term reliability of the device.

• Maximize the copper coverage on the PCB to increase the thermal conductivity of the board, because the

major heat-flow path from the package to the ambient is through the copper on the PCB. Maximum copper is

extremely important when there are not any heat sinks attached to the PCB on the other side of the package.

• Add as many thermal vias as possible directly under the package ground pad to optimize the thermal

conductivity of the board.

• All thermal vias should be either plated shut or plugged and capped on both sides of the board to prevent

solder voids. To ensure reliability and performance, the solder coverage should be at least 85 percent.

10.2 Layout Example

PWM

I

ST

NC

GND

Q

REF

D

Figure 13. TL4242-Q1 WSON Board Layout Diagram

14

Submit Documentation Feedback

Copyright © 2010–2017, Texas Instruments Incorporated

Product Folder Links: TL4242-Q1

�TL4242-Q1

www.ti.com

SLVS732G – JULY 2010 – REVISED APRIL 2017

Layout Example (continued)

Copyright © 2017, Texas Instruments Incorporated

Figure 14. TL4242-Q1 TO-263 Board Layout Diagram

10.3 Thermal Considerations

This device operates a thermal shutdown (TSD) circuit as a protection from overheating. For continuous normal

operation, the junction temperature should not exceed the thermal-shutdown trip point. If the junction temperature

exceeds the thermal-shutdown threshold, the output turns off. When the junction temperature falls below the

thermal-shutdown threshold, the output turns on again.

Calculate the power dissipated by the device according to Equation 5:

P = (VI - VO ) ´ I O + VI ´ I Q

(5)

In the formula, VI represents the input voltage of the device, VO stands for the output voltage, IO means the

output current of the LEDs, and IQ is the quiescent current dissipated by the device. The very small value of IQ

sometimes allows one to neglect it.

After determining the power dissipated by the device, calculate the junction temperature from the ambient

temperature and the device thermal impedance.

TJ = TA + RqJA ´ P

(6)

Submit Documentation Feedback

Copyright © 2010–2017, Texas Instruments Incorporated

Product Folder Links: TL4242-Q1

15

�TL4242-Q1

SLVS732G – JULY 2010 – REVISED APRIL 2017

www.ti.com

11 Device and Documentation Support

11.1 Receiving Notification of Documentation Updates

To receive notification of documentation updates, navigate to the device product folder on ti.com. In the upper

right corner, click on Alert me to register and receive a weekly digest of any product information that has

changed. For change details, review the revision history included in any revised document.

11.2 Community Resources

The following links connect to TI community resources. Linked contents are provided "AS IS" by the respective

contributors. They do not constitute TI specifications and do not necessarily reflect TI's views; see TI's Terms of

Use.

TI E2E™ Online Community TI's Engineer-to-Engineer (E2E) Community. Created to foster collaboration

among engineers. At e2e.ti.com, you can ask questions, share knowledge, explore ideas and help

solve problems with fellow engineers.

Design Support TI's Design Support Quickly find helpful E2E forums along with design support tools and

contact information for technical support.

11.3 Trademarks

E2E is a trademark of Texas Instruments.

All other trademarks are the property of their respective owners.

11.4 Electrostatic Discharge Caution

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

11.5 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

12 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the mostcurrent data available for the designated devices. This data is subject to change without notice and without

revision of this document. For browser-based versions of this data sheet, see the left-hand navigation pane.

16

Submit Documentation Feedback

Copyright © 2010–2017, Texas Instruments Incorporated

Product Folder Links: TL4242-Q1

�PACKAGE OPTION ADDENDUM

www.ti.com

10-Dec-2020

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

MSL Peak Temp

Op Temp (°C)

Device Marking

(3)

(4/5)

(6)

TL4242QKTTRQ1

ACTIVE

DDPAK/

TO-263

KTT

7

500

RoHS & Green

SN

Level-3-245C-168 HR

-40 to 125

TL4242Q

TL4242TDRJRQ1

ACTIVE

SON

DRJ

8

3000

RoHS & Green

NIPDAU

Level-3-260C-168 HR

-40 to 105

4242T

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of