No. 68 Huangjiang Donghuan Road, Huangjiang Town, Dongguan City, Guangdong Province, China

TEL :+86(0)769-38879888 Fax :+86(0)769-38879889 E-mail : yl@dgylec.com

PRODUCT SPECIFICATION SHEET

CUSTOMER

:

PRODUCT TYPE

:

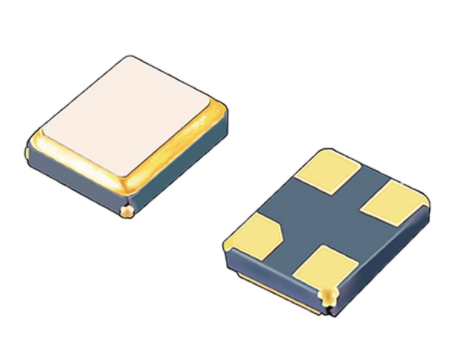

SMD TSX 2.52.0

NOMINAL FREQ.

:

19.200000 MHz

FL P/N

:

2Z19200001-Q

REVISION

:

S1

CUSTOMER P/N

:

CUSTOMER'S APPROVAL & DATE

FL CORPORATION

APPROVED

CHECKED

DESIGNED

Jay Lee

Kuro Peng

Chen XuanRu

MSL 1

RoHS Compliant

�FL P/N

REV.

CONTENTS

2Z19200001-Q

S1

PAGE

PAGE

‧ SPECIFICATION REVISION RECORD SHEET

2

‧ ELECTRICAL SPECIFICATIONS

3 to 4

‧ CONNECTION DIAGRAM, DIMENSIONS & MARKING

5

‧ MARKING

6

‧ SUGGESTED REFLOW PROFILE

6

‧ STRUCTURE ILLUSTRATION

7

‧ RELIABILITY TEST SPECIFICATIONS

8

‧ PACKING

9 to 10

‧ SPECIFICATION OF THE ENVIRONMENT-RELATED SUBSTANCES

11

ATTACHMENT (optional)

‧ ELECTRICAL CHARACTERISTICS TEST

A

YES

NO

‧ TEMPERATURE CHARACTERISTICS TEST

B

YES

NO

1/11

�FL P/N

REV.

2Z19200001-Q

S1

PAGE

2/11

SPECIFICATION REVISION RECORD SHEET

Rev.

Revise Page

S0

N/A

S1

P.6

Revise Contents

Date

Ref. No.

Reviser

Initial released.

1-Jul-20

N/A

Chen XuanRu

Change MARKING

1-Dec-21

N/A

May Zhang

�FL P/N

REV.

2Z19200001-Q

S1

PAGE

PRODUCT DESCRIPION

Standard atmospheric conditions

Unless otherwise specified, the standard range of atmospheric conditions for making measurement and tests are as

follow:

30±10°C

Ambient temperature :

40% to 70%

Relative humidity :

If there is no doubt the results, measurement shall be made within the following limits:

30±3℃

Ambient temperature :

40% to 70%

Relative humidity :

Measure equipment

Electrical characteristics are measured by S&A250B or equivalent.

Crystal cutting type

The crystal is using AT CUT (thickness shear mode).

ELECTRICAL SPECIFICATIONS

#

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Parameters

Nominal frequency

Oscillation mode

Load capacitance

Frequency tolerance

Tolerance over temperature

(reference 30°C)

Aging

Frequency drift after reflow

Operating temperature

Storage temperature

Equivalent series resistance

Quality factor

Spurious mode series

resistance

Insulation resistance

Drive level

Shunt Capaitance

Motional Capacitance

First-order curve fitting

parameter

Symbol

FL

CL

-

Electrical Spec.

19.200000

AT-cut Fundamental

7

-10

+10

Units

MHz

NA

pF

ppm

(Note 1)

At 30±3°C

-

-12

-

+12

ppm

at -30~+85℃(Note 2)

ESR

Q

-0.7

-2

-30

-40

75000

-

+0.7

+2

+105

+105

70

-

ppm/year

ppm

°C

°C

W

-

1100

-

-

W

IR

DL

C0

C1

500

10

0.3

1.8

-

100

1.3

3.1

MW

mW

pF

fF

-

-0.4

-

-0.1

ppm/°C

18

Second-order curve fitting

parameter

-

-4.5

0

+4.5

19

Third-order curve fitting

parameter

-

8.5

10

11.5

10-4

ppm/°C2

10-5

ppm/°C3

Notes

after two reflows

(Note 3)

±1MHz

At DC 100V

(Note 4)

(Note 4)

(Note 4)

3/11

�FL P/N

REV.

2Z19200001-Q

S1

PAGE

4/11

ELECTRICAL SPECIFICATIONS (CONT.)

#

20

21

22

23

24

25

26

Parameters

Residual frequency stability

slope

5°C small orbit hysteresis 1

5°C small orbit hysteresis 2

DLD Freq. (Max-Min)

DLD Freq. (Repeatability)

DLD ESR (Max-Min)

DLD ESR (Repeatability)

Symbol

Electrical Spec.

Units

-

ppb/℃

(Note 5)

ppb/℃

ppb pk-pk

ppm

ppm

%

%

(Note 6)

(Note 7)

(Note 8)

(Note 8)

(Note 8)

(Note 8)

-

-50

+50

-

-50

+50

100 (magnitude)

3.0

0.7

20

10

Notes

Note 1

Note 2

Note 3

Note 4

The load capacitance is measured according to IEC Standard #60444-7.

Above 85°C tolerance over temperature bound by third-order coefficient range.

Minimum Q value calculated from ESR and L is smaller than this specification.

The curve fitting parameter is obtained from the Qualcomm crystal curve fitting algorithm, t0=30 °C

(Refer to Curve Fitting Calculation Table: 80-V9690-23)

Note 5 Condition 1A – Test condition (continuous temperature rate change of ~1.0°C/min):

- Measure FT points every 1°C, heating up from -30 to +85°C, subtract a fifth-order polynomial best fit and

then calculate the slope of the residual.

- The residual slope should be within ±50 ppb/°C.

Note 6 Condition 1B – Hysteresis 1 test condition (continuous temperature rate change of ~1.0°C/min):

- Measure FT points every 0.5°C while cycling temperature over a 5°C small temperature orbit;an example

5°C small orbit temperature cycle is +30°C to +35°C to +30°C.

- During every individual heating/cooling cycle there should be 11 points; discard the first point of each

heating and cooling cycle; this leaves 10 points for the fifth-order polynomial best fit from 1A for each of

the 10 points, and then calculate the slope each heating and cooling cycle. Subtract of the residual for

each of these heating and cooling 10 point curves.

Note 7 Hysteresis 2 test condition (continuous temperature rate change of ~1.0°C/min):

- Measure FT points every 0.5°C while cycling temperature over a 5°C small temperature orbit; an

example 5°C small orbit temperature cycle is +30°C to +35°C to +30°C.

- During every individual heating/cooling cycle there should be 11 points; discard the first and last point

of each heating and cooling cycle, which results in 9 temperature points. Calculate the average measured

peak-to-peak frequency difference for these 9 temperature points.

- The average difference is the magnitude of the small orbit hysteresis 2.

Note 8 0.01 uW to 100 uW to 0.01 uW, number of points: 15 points up and 15 points down = 29 total data points.

Note 9 This crystal specification complies to Qualcomm Mini-Specification 80-V9690-24 Rev. D.

NTC THERMISTOR SPECIFICATIONS TABLE

#

1

2

3

4

5

Parameters

Operating Temperature

Storage Temperature

Resistance

B-constant

Tolerance

Symbol

-

Electrical Spec.

-30

+105

-40

+105

100

4250

1

Units

°C

°C

kW

K

%

Notes

At 25°C

At 25°C - 50°C

�FL P/N

REV.

2Z19200001-Q

S1

CONNECTION DIAGRAM

DIMENSIONS

(Unit : mm)

Unit : mm

Pad

#1

#2

#3

#4

Function

Xtal terminal (Input)

Thermistor + GND terminal

Xtal terminal (Output)

Thermistor terminal

SUGGESTED LAYOUT

PAGE

5/11

�FL P/N

REV.

2Z19200001-Q

S1

MARKING

Frequency

EX: 19.200MHz = 192

YL

lot (2 digits)

year month

Administrative Symbo

2017

2018

2019

2020

2021

2022

2023

2024

SUGGESTED REFLOW PROFILE

Total time : 360 sec. Max.

Solder melting point :225 oC

Temp. (℃)

10 sec. Max.

260 5

220

60 sec. Max.

180

150

120 sec. Max.

Time (sec.)

PAGE

6/11

�FL P/N

REV.

2Z19200001-Q

S1

PAGE

7/11

STRUCTURE ILLUSTRATION

#

COMPONENTS

MATERIALS

QTY

1

Cap (Lid)

Kovar (Fe+Co+Ni)

1

2

Base (Package)

Alumina Ceramics (Al2O3)

+ Kovar (Fe+Co+Ni)

1

3

Pad (Package)

Ni + Au

4

4

Crystal Blank

SiO2

1

5

Electrode

Cr + Nobel material

2

6

Conductive Adhesive

Ag

2

7

Thermistor

Alumina Ceramics (Al2O3),

Ni + Ag+ Sn

1

8

Solder

Sn + Ag + Cu

2

FINISH/SPECIFICATIONS

Ni plating

Silicone resin

�FL P/N

REV.

2Z19200001-Q

S1

PAGE

8/11

RELIABILITY SPECIFICATIONS

1. MECHANICAL ENDURANCE

Test Item

No.

1 Drop test

2 Shock test

3 Mechanical shock

4 Vibration

5 Gross leak

6 Fine leak

7 Solderability

8

Resistance to soldering

heat

Test Methods

150 cm height, fall freely onto stainless plate 3 times.

150g/150cm height, 3times in the direction of ±x, ±y, ±z on concrete

floor.

Device are shocked to half sine wave (1000 G) three mutually

perpendicular axes each 3 times. 1.0ms duration time.

Frequency range

Amplitude

Perpendicular axes each test time

10 to 55 Hz

1.52 mm

2 hours (x, y, z axis)

Total test time 6 hours

Standard sample for automatic gross leak detector. Test pressure

2kg/cm2.

Helium bombing 4.5kgf/cm2 for 2 hours.

Temperature

215°C ± 5°C

Immersing depth

0.5 mm minimum

Immersion time

10 ± 0.5 seconds

Flux

Rosin resin methyl alcohol

solvent ( 1 : 4 )

Pre-heat temperature

125°C

Pre-heat time

60 to 120 sec.

Test temperature

260 ± 5°C

Test time

5 ± 1 sec.

JIS C6701

IEC-68-02-27

MIL-STD-202F

MIL-STD-883E

MIL-STD-883E

MIL-STD-883E

MIL-STD-883E

MIL-STD-202F

2. ENVIRONMENTAL ENDURANCE

Test Item

No.

High

Temp.

storage

9

10 Low Temp. storage

Test Methods

+ 125°C ± 3°C for 500 ± 12 hours

- 40°C ± 3°C for 500 ± 12 hours

Total 100 cycles of the following temperature cycle

MIL-STD-883E

1 cycle

11 Thermal shock

125+/- 3 oC

MIL-STD-883E

25 oC

-55+/- 3

o

C

30 min.

30 min.

10 min. max.

12 High Temp. & humidity

85°C±3℃, RH 85%, 500 hours

JIS C5023

�FL P/N

REV.

2Z19200001-Q

S1

PAGE

9/11

PACKING : (EIA-481-2)

Direction of feed

Index Mark

Direction of products

Dimension

PKG Type

A0

B0

2.25±0.1

2.70±0.1

2520 TSX (8mm)

P1

P2

4±0.1

2±0.1

Standard Reel Quantity is 3,000 pcs per reel.

THE INSPECTION FOR TAPE TENSION

REMARK : NA

K0

1.45±0.10

D1

1±0.1

Unit : mm

T

0.25±0.05

D0

1.55±0.05

W

8±0.3

P0

4±0.1

E

1.75±0.1

F

3.50±0.1

�FL P/N

2Z19200001-Q

REV.

S1

PAGE

10/11

SMD PRODUCT PACKING STANDARD

Out-going packing instruction

Reel Packing

Inner Packing

Name:Reel

Name:Bubble Wrap

Standard:Diameter 18cm

Standard:430×330+20mm

Material:Plastics

Name: Material:HDPE (15 reels enter)

Anti-Static Shielding Bag Standard:205

×250mm

Material:APET/CPP

Carton

Name:Carton

Standard:400×400×280mm

Material:AB corrugated paper (4 bags

enter)

L1

L2

The label instruction

Label Drawing

Mark Name of Article

Spec.

1.Part No.

L1

条码标签

Bar Code Label 2.Lot No.

(Chintz Paper)

3.Q'ty

4.Freq

L2

条码标签

Bar Code Label

(Chintz Paper)

1.Part No.

2.Date Code

3.Q'ty

4.Freq

Size

70x50mm

Printing

White

70x50mm

White

Remark

Specifications on the label is for the use of templates with different product specifications may vary.

If customer specified requirements for labels packaging, please provide the operation procedure.

�FL P/N

REV.

2Z19200001-Q

S1

PAGE

11/11

SPECIFICATION OF THE ENVIRONMENT-RELATED SUBSTANCES

Range

#

Banned Substances

Products

Maximum concentration

ppm (mg/kg)

Packing Material

Maximum concentration

ppm (mg/kg)

1

镉及镉化合物

Cadmium and cadmium compounds

100

100

2

铅及铅化合物

Lead and lead compounds

1000

100

3

汞及汞化合物

Mercury and mercury compounds

1000

100

1000

100

1000

N/A

4

5

六价铬化合物

Hexavalent-Chromium VI (Cr+6)

聚溴联苯 PBB

Polybrominated biphenyls

6

聚溴二苯醚 PBDE

Polybrominated diphenyl ethers

1000

N/A

7

邻苯二甲酸二(2-乙基己基)酯

DEHP

Di (2-ethylhexyl) phthalate

1000

N/A

8

邻苯二甲酸丁苄酯 BBP

Butyl Benzyl Phthalate

1000

N/A

9

邻苯二甲酸二丁酯 DBP

Dibutyl Phthalate

1000

N/A

10

邻苯二甲酸二异丁酯 DIBP

Diisobutyl Phthalate

1000

N/A

11

氟(F)、氯(Cl)、溴(Br)、碘(I)

Fluorine、Chlorine、 Bromine、

Iodine

900、900、900、900

注:Br+Cl<1000

N/A

12

包装材料中重金属(汞、镉、六价

铬、铅、PBB、PBDE)之总量

Heavy metals (mercury, cadmium,

lead, Cr+6,PBB and PBDE) in packing

materials

N/A

100

铅(Pb) + 镉(Cd) + 汞(Hg) + 六价铬

(Cr+6)

很抱歉,暂时无法提供与“2Z19200001-Q”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格

- 1+0.78210

- 100+0.73260

- 300+0.68310

- 500+0.63360

- 2000+0.60885

- 5000+0.59400